Vertical mill dehydration and separation equipment

UBE Vertical Mill UBE Machinery Corporation, Ltd

2024年1月31日 UBE Vertical Mill is used for grinding of cement raw materials, coal, cement clinker, blast furnace slag and other material Restoring your equipment to its original performance Maximizing your equipment 2016年12月28日 With the combined capability of grinding, drying and separation the vertical mills are clearly seen as the preferred solution compared to other grinding processes The OK OK Mill: The 3: Mechanical optimized and 31: Grinding 4 天之前 Dehydration and solidliquid separation are usually carried out by dewatering screens, hydrocyclones, thickeners, filter presses and other equipment After the tailings are dewatered and dried, it become solid and dry Tailings Processing Plant Equipment JXSC 2024年11月25日 Hydrocyclone is a kind of equipment for classifying the ore pulp by use of centrifugal force It has no motion and dynamic parts,and needs to be matched with Classification EquipmentSBM Industrial Technology Group

Attrition Mills Technology and Experience Roytec Global

The vertical mill has a reducer drive system, Replaceable WearResistent Spiral Agitator and an online monitoring control system It usually uses high chromium steel balls as grinding 17 小时之前 The pilot plant contains dedicated dairy and bakery areas as well thermal processing, dehydration and separation equiptment We also have a range of additional processing equipment so please contact us to discuss your Pilot Plant Equipment University of Reading2024年10月11日 The LM Vertical Grinding Mill, launched by ZENITH, integrates five functions of crushing, grinding, powder selection, drying and material conveying It is characterized by Vertical Mill Shanghai Zenith CompanyThe MPS mill also grinds, dries, calcines, and classifies gypsum without any problem, all in a single machine, for any fineness requested and considering individual requirements The MPS vertical roller mill built to last, reliable and Coal mill, gypsum mill, clay mill, etc Pfeiffer

SEPARATION EFFICIENT SLUDGE THICKENING AND

We put all our energy into delivering the best separation equipment so that you never have to waste energy in your decanter centrifuge KEY ENERGYSAVING FEATURES2022年5月31日 The vertical roller mill (VRM), including powder separation and crushing subsystems, is used extensively for intermediate crushing of minerals in several industries such Analysis of vertical roller mill performance with changes in 2020年8月12日 Vertical Coal Mill (VCM) is equipment for grinding and pulverizing coal into micron size Rotary kilns then use the powders as fuel burners The VCM has a housing section equipped with a lining An investigation of performance characteristics 2016年9月1日 Cement production is one of the most energyintensive manufacturing industries, and the milling circuit of cement plants consumes around 4% of a year's global electrical energy productionOperational parameters affecting the vertical roller mill

Operation parameters multiobjective optimization method

2023年6月1日 This study aims to improve the output and production efficiency of a large vertical mill by optimizing its operational parameters This paper takes a large vertical mill in LGM as the object, a numerical calculation method of particle–fluid coupling system in large vertical mill based on CFDDPM theory, and a multiobjective optimization method of operating parameters of 2024年11月26日 The structure of the hydrocyclone is relatively simple Its upper end is a cylindrical part, and its lower part is a conical container The slurry is fed into the cyclone at a certain speed (generally 5 to 12 meters per second) along the tangential direction, and obtains a rotary motion, thus generating a large centrifugal force (usually tens of times or even hundreds Hydrocyclone JXSC Machinery2023年7月25日 In addition, a VRM offer a greater versatility than a traditional ball mill: the space is reduced, having grinding and separation units gathered in the same machinery, gas flow is higher, allowing the use of material with higher humidity content Nevertheless, vertical mills also present certain disadvantages, if compared to traditional grindingImprovement of cement performances through the use Centrifuges Separation Equipment Since 1893, GEA has been building centrifuges which combine high separating efficiencies, clarifying efficiencies and throughput capacities with maximum savings in terms of energy, water and disposal costs With the Crude Oil Treatment System, GEA has designed a flexible but easytointegrate solution for Centrifuges Separation Equipment

A review of gasliquid separation technologies: Separation

2024年1月1日 The literature contains several reviews of gasliquid separation technology For example, Kouba and Shoham (1996) presented the status of the development prospects of a gasliquid cylindrical cyclone (GLCC), the stateoftheart with respect to modeling the GLCC, and discussed installations and potential applications Saieed et al (2016) reviewed the effect of 17 小时之前 The pilot plant contains dedicated dairy and bakery areas as well thermal processing, dehydration and separation equiptment We also have a range of additional processing equipment so please contact us to discuss your requirements Dairy Equipment covering dairy processing including cheese and cultured milk products:Pilot Plant Equipment University of Reading2023年12月4日 A vertical roller mill (VRM) is a grinding equipment used for the size reduction of minerals, cement, and ceramics In processing plants, size reduction of raw materials is an energyintensive operation A vertical roller mill is a grinding equipment for many industries such as minerals, cement, and ceramics It is also used to grind slag Numerical Investigation of Vertical Roller Mill Operation We provide complete separation, dehydration, and desalting solutions for crude oil MYNOV is a single signon solution Access multiple NOV applications and services with one login We provide advice and technologies based on deep product expertise and handson field experience and provide equipment at a reasonable price that will work as Oil Separation and Stabilization NOV

OIL AND GAS SEPARATION DESIGN MANUAL

2023年4月28日 found on inlets to dehydration units, gas sweetening units, et cetera At some of these locations separators are referred to as knockouts, free liquid knockouts, and traps Sometimes these vessels are called scrubbers Caution should be used when referring to a vessel required for gas/liquid separation as a scrubber5 天之前 Zircon ore, also known as zircon sand (ZrO2) or zircon stone (ZrSiO4), is a mineral mainly composed of zirconium, silicon and oxygen crystallized from magma when igneous rocks are formed Zircon also occurs in dikes and Zircon Sand Separation Solution And Related 2023年3月1日 01 Introduction of quartz sand production line equipment Generally, quartz sand production line equipment is based on the mineral processing process, such as a Xinhai quartz sand mineral processing project, Equipment and Quotation for Quartz Sand 2021年5月20日 What Are Types of Cyclone Separators? Date: From: Longding Author: admin Cyclones separator can be mainly divided into grading cyclones, dehydration cyclones, desliming cyclones, slag removal cyclones, concentration cyclones, and cyclone group, according to the function The hydro cyclone is mainly used for the classification and solid What Are Types of Cyclone Separators? LDHB

.jpg)

Cement grinding Vertical roller mills versus ball mills

2016年1月23日 The grinding process in ball mills and vertical roller mills differ fundamentally In a ball mill the comminution takes place by impact and attrition The comminution in the vertical roller mill takes place by exposing a bed of material to a pressure sufficiently high to cause fracture of the individual particles in the bed, although the 2024年11月26日 Leadzinc ore usually exists in the form of sulfide ores, such as sphalerite and galena Flotation is the most commonly used method The leadzinc ore processing solution is adjusted and used in combination according to ore characteristics, metal grade and other factors, such as gravityflotation, magneticflotation, and gravitymagneticflotation, in order to achieve Lead Zinc Processing Solution JXSC MachineryThe BoneDry™ Dehy system’s revolutionary Patented Technology changes the perceived limits of glycol dehydration by meeting all dehydration specs using TEG Until now, mole sieve has been the only option for cryogenic spec dehydration With the BoneDry Dehy™, glycol performance is extended to meet any dehydration specGlycol Dehydrator Gas Dehydration Systems OTSO Energy2024年11月24日 Textile Mill SolidLiquid Separation Compression Dehydration Equipment, Find Details and Price about Sludge Dewatering Screw Press Sludge Dewatering Machine from Textile Mill SolidLiquid Separation Compression Dehydration Equipment Top Textile Mill SolidLiquid Separation Compression Dehydration Equipment

Industrial Vertical Grinding Mill

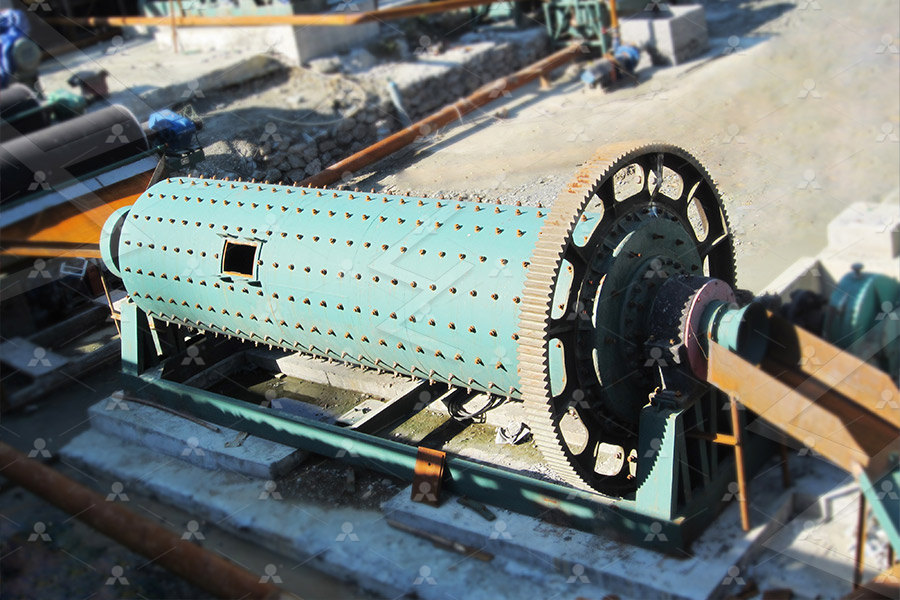

bull; The energy consumption efficiency of the ball mill is low, and there is a tendency to be replaced by vertical grinding mills, roller presses and other equipment However, the ball mill has the unique advantage of "the particle shape is approximately spherical, which is beneficial to the calcination of raw materials and the hydration and In addition to our innovative equipment offering, we also supply: spare parts, including wear segments, and we provide all aftersales services to help you get the most out of your vertical roller mill throughout its lifetime As vertical roller mills are 30 to 50 percent more efficient than other grinding solutions, they give cement plant Vertical roller mills FLSmidth Cement2024年11月8日 We offer quality based separation equipments at a reasonable rate The prominent characteristics of our highly efficient Separation Equipment include: High quality equipment; Installation Services, Automation and Instrumentation service Spare parts and consumables parts support Absolute separation of mechanical unit from the process areaSeparation machine Separation Equipment India2024年9月29日 Gravity Separation We use this process for the separation of a mixture having components of different densities The powdered mixture undergoes with a stream of running water The lighter components wash away Methods of Separation of Mixtures with

Weifang Guote Mining Equipment Co, Ltd

Weifang Guote Mining Equipment Co, Ltd is located in weifang city, shandong province qingzhou economic development zone, covers an area of 50000 square meters, registered capital of 6338 million yuan, is a hightech enterprises in 2021年3月4日 Bioethanol produced from biological resources is considered as an alternative, renewable, and sustainable energy source in the context of the circular economy Moreover, bioethanol is a biofuel that has similar energy content to gasoline, but emits less toxic pollutants compared to fossil fuels Yet bioethanol must be anhydrous to be mixed with regular gasoline Processes and separation technologies for the production of 2017年8月1日 This article examines the use of molecular sieve units for natural gas dehydration, as they are critical components in the operation of an LNG or gas processing plant (typically combined with NGL extraction by cryogenic separation), and any limitation or loss in capacity of this unit can have a significant effect on overall plant economics 1,2Optimal design and operation of molecular sieve gas dehydration 2023年2月23日 Computational fluid dynamics (CFD) is adopted to calculate and analyze the performance and separation mechanism of a steamwater separation equipment for a pressurized water reactor (PWR) steam (PDF) Study on Performance and Operation Mechanism of a Separation

SEPARATION EFFICIENT SLUDGE THICKENING AND

Compared to filtration equipment, centrifugal sedimentation equipment can often achieve the same capacity at We put all our energy into delivering the best separation equipment so that you never have to waste energy in your decanter centrifuge KEY ENERGYSAVING FEATURES • The High Hydraulic Pressure (HHP) design of the rotating assembly 2024年11月25日 Copper shredder, cable recycling, wire granulator, cables peelers, PCB, WEEE, RAEE recycling, electric motor recycling hammer mill Singleshaft twin shaft four Recycling machinery and plants STOKKERMILL2024年3月12日 Dehydration was carried out by distillation with an inert gas As a result, samples of dry scale, oil, and distilled water were obtained and analyzed Laboratory equipment for the separation of oily scale into components through the extraction of dehydrated scale was prepared MY Grishchenko, MV Separation of Oily Mill Scale Into Separation of Oily Mill Scale Into Components Metallurgist1 天前 Elgin Separation Solutions turnkey systems have been improving operations in multiple industries for over 100 years Dependable, rugged, long lasting are terms operators have come to know when using Elgin systems for mining, trenchless, rendering, pulp paper, wood processing, oil gas, and industrial wastewater to name a fewHome Page Elgin Separation Solutions

.jpg)

An investigation of performance characteristics

2020年8月12日 Vertical Coal Mill (VCM) is equipment for grinding and pulverizing coal into micron size Rotary kilns then use the powders as fuel burners The VCM has a housing section equipped with a lining 2016年9月1日 Cement production is one of the most energyintensive manufacturing industries, and the milling circuit of cement plants consumes around 4% of a year's global electrical energy productionOperational parameters affecting the vertical roller mill 2023年6月1日 This study aims to improve the output and production efficiency of a large vertical mill by optimizing its operational parameters This paper takes a large vertical mill in LGM as the object, a numerical calculation method of particle–fluid coupling system in large vertical mill based on CFDDPM theory, and a multiobjective optimization method of operating parameters of Operation parameters multiobjective optimization method 2024年11月26日 The structure of the hydrocyclone is relatively simple Its upper end is a cylindrical part, and its lower part is a conical container The slurry is fed into the cyclone at a certain speed (generally 5 to 12 meters per second) along the tangential direction, and obtains a rotary motion, thus generating a large centrifugal force (usually tens of times or even hundreds Hydrocyclone JXSC Machinery

.jpg)

Improvement of cement performances through the use

2023年7月25日 In addition, a VRM offer a greater versatility than a traditional ball mill: the space is reduced, having grinding and separation units gathered in the same machinery, gas flow is higher, allowing the use of material with higher humidity content Nevertheless, vertical mills also present certain disadvantages, if compared to traditional grindingCentrifuges Separation Equipment Since 1893, GEA has been building centrifuges which combine high separating efficiencies, clarifying efficiencies and throughput capacities with maximum savings in terms of energy, water and disposal costs With the Crude Oil Treatment System, GEA has designed a flexible but easytointegrate solution for Centrifuges Separation Equipment2024年1月1日 The literature contains several reviews of gasliquid separation technology For example, Kouba and Shoham (1996) presented the status of the development prospects of a gasliquid cylindrical cyclone (GLCC), the stateoftheart with respect to modeling the GLCC, and discussed installations and potential applications Saieed et al (2016) reviewed the effect of A review of gasliquid separation technologies: Separation 17 小时之前 The pilot plant contains dedicated dairy and bakery areas as well thermal processing, dehydration and separation equiptment We also have a range of additional processing equipment so please contact us to discuss your requirements Dairy Equipment covering dairy processing including cheese and cultured milk products:Pilot Plant Equipment University of Reading

.jpg)

Numerical Investigation of Vertical Roller Mill Operation

2023年12月4日 A vertical roller mill (VRM) is a grinding equipment used for the size reduction of minerals, cement, and ceramics In processing plants, size reduction of raw materials is an energyintensive operation A vertical roller mill is a grinding equipment for many industries such as minerals, cement, and ceramics It is also used to grind slag We provide complete separation, dehydration, and desalting solutions for crude oil MYNOV is a single signon solution Access multiple NOV applications and services with one login We provide advice and technologies based on deep product expertise and handson field experience and provide equipment at a reasonable price that will work as Oil Separation and Stabilization NOV