Raymond mill roller bottom big screw

.jpg)

Raymond®辊磨——风扫式立式环辊磨机

Raymond®辊磨是一种风扫式立式环辊磨机,具有集成的选粉系统,可同时干燥、粉磨和分选石灰石、粘土、矿物等多种不同类型的产品。 这款辊磨采用尺寸约1050mm/½2英寸以上的进料,即可生产约R2000微米10%10目(10%R2000微 The Raymond® Roller Mill is an airswept vertical ringroll mill with an integral classification system that simultaneously dries, pulverizes and classifies a number of different types of products including limestone, clay, minerals and othersRaymond® Roller Mills CoperionEach mill is °Ffered with rebuilt and new components, six oil journal assemblies with nre grinding rolls, new grinding ring, mill bottom, spider and plow support assembly5057 Raymond High Side Roller Mill Wabash 2019年10月1日 Raymond grinders are an invaluable tool, but one has to know where and how to source Raymond Roller Mill parts Components of the Raymond Roller Mill include: The Raymond Pulverizer comprises of a main Raymond Roller Mill Parts Industrial Mining

.jpg)

Raymond Roller Mill airswept vertical ringroll

The Raymond Roller Mill is an airswept vertical ringroll mill with an integral classification system that simultaneously dries, pulverizes and classifies limestone, clay, minerals and manufactured materialsWe provide modification and upgrade packages for control systems, vertical shaft and roller mill journals Advantages of Raymond OEM replacement parts For parts and service please contact us at 630 3931000 Partnership for us Raymond OEM Replacement Parts and Service2024年7月25日 The Raymond® Fine Grinding Roller Mill (US Patent Nos and ) is specially designed for achieving product size distribution with d50 measurements Raymond Fine Grinding Roller Mill For new or for The Raymond® Roller Mill is an airswept vertical ringroll mill with an integral classification system that simultaneously dries, pulverizes and classifies a number of different types of products including limestone, clay, minerals and others Raymond® Roller Mills Coperion

.jpg)

Raymond® Bowl Mill Coperion

The Raymond® Bowl Mill is considered the finest vertical roller mill available for pulverizing coal Each bowl mill system is designed to achieve the best solution for the processing application The mill, feeder, classifier, fan, cyclone, dust 2015年1月20日 In recent years, more and more customers buy Raymond mill to process material, such as talc, barite, calcite, limestone, manganese ore, chrome ore, quartz, gypsum, bentonite and the like In the course will inevitably encounter this or that problem, such as the roller does not rotate, grinding ring loose, uneven feed and feed and less, which is why?Raymond Mill Operation Specification (a)2024年11月24日 【Raymond Mill Plant】 The Raymond mill plant usually contains a cyclone collector, pipe fittings, dust collector, storage hopper, elevator, crusher, electric control cabinet, feeder, main plant, blower, separator, etc, Structural Features The whole mill is of spatial structure, less premise and systemic strong The whole system from roughing, transportation, Raymond Grinding Mill JXSC Machine2023年2月15日 Main parts of Raymond roller mill Main parts of Raymond mill include grinding roller, grinding ring, powder collector, classifier, air blower, reducer, base plate, shovel, Raymond mill pendulum, star stack, etc Main materials of the parts: manganese(16Mn, 65Mn), High manganese steel, high chromium(Cr13、Cr23、Cr26)Raymond Roller Mill PartsUltimate Guide Fote Machinery

.jpg)

Raymond Grinding Mill: The Ultimate Guide From SMAT

2023年9月18日 The capacity of the Raymond roller mill varies depending on the application and is dependent on the type of roller used Typically, numbers in coneshaped rollers provide greater capacities than in flatbottom rollers Lowpressure designs with single large diameter rolls can deliver up to 40 mph while highcapacity systems utilizing multiple 2020年11月11日 The roller mill requires less energy than other attrition milling methods that rely on multiple highspeed impacts, Roller mill demand grows with Growing markets for uniformly reduced particles M arket demand for the uniform particles produced by roller mills is growing as bulk solids processors strive to improve product characteristics,Roller mills: Precisely reducing particle size with greater Raymond 5057 High Side Roller Mill, with all internal grinding components Equip yourself with the gold standard 16045345313 [ protected] Mill bottom with oil reservoir and oil wicking; Mill base with air housing; Mill side; Gear housing with Raymond 5057 High Side Roller Mill Nelson MachineryRaymond Roller Mills are available with grinding ring diameters ranging from 30120 in / 7603050mm These sizes are capable of producing a wide range of product fineness from a wide variety of material Typical material processed Clay, Fire Clay, Bentonite, Kaolin, Barytes, Gypsum, Limestone, Phosphate Rock, Talc, Coal, Hydrated Lime Raymond Roller Mill airswept vertical ringroll Qlar

Raymond Mill TAYMACHINERY

2024年11月26日 The Raymond mill is a versatile and reliable grinding machine, suitable for producing fine powders for a wide range of industrial applications Its efficiency, ease of maintenance, and ability to handle various materials make it a valuable asset in many industries [Introduction]: Raymond Mill has a strong performance of becoming a complete set with a 2015年1月4日 It is very important to control Raymond mill feeding system, which is related to efficiency and particle size Our company engineersummarizes the control and automatic feeding tuning method After installation, the How to Control Raymond Mill Feeding System2021年8月17日 Maxing Feeding Size: 40 mm Ouput Size: 06130033 micron (40400 mesh) Capacity: 125 t/h D97 325 mesh 2μm 10% Raymond Roller Grinding Mill Machine also named Raymond Mill, Raymond Roller Mill, Raymond Roller Grinding Mill Machine1 (One) Reconditioned #5057 CE Raymond High Side Roller Mill “V” Belt driven by a 100HP 3/60/440V motor Unit is equipped with all internal related grinding components; rebuilt gear housing with gear; horizontal shaft with opinion; mill 5057 Raymond High Side Roller Mill Wabash

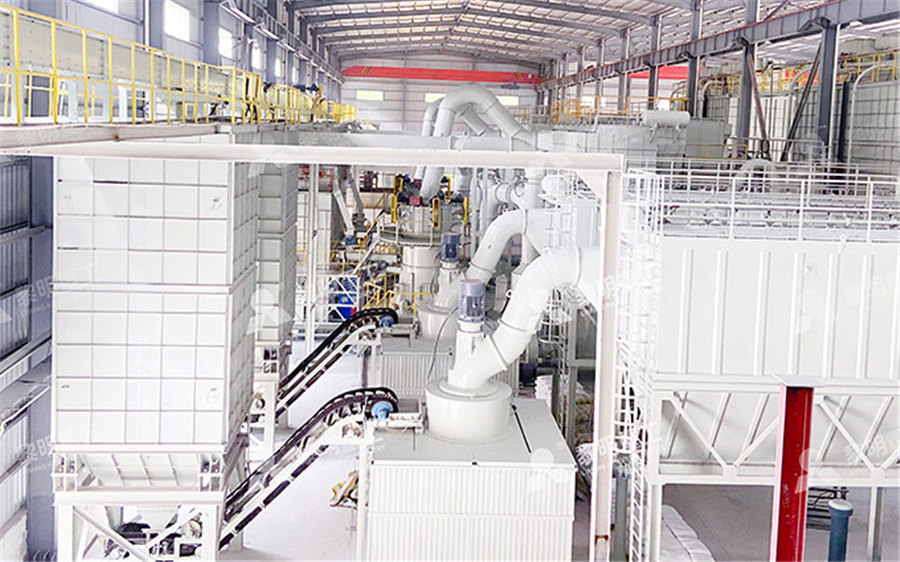

HC Large Grinding Mill, Raymond Mill, Large Pendulum Mill

Technical revolution in the pendulum mill industry, the reinforced product of traditional Raymond mill HC series large grinding mill is a new type of highefficiency grinding equipment independently developed and innovated by Guilin Hongcheng Raymond Bowl Mills L Technical Report I C E N S E D M A T E R A L WARNING: Please read the License Agreement on the back cover before removing the Wrapping Material EPRI Project Manager A Grunsky EPRI • 3412 Hillview Avenue, Palo Alto, California 94304 • PO Box 10412, Palo Alto, California 94303 • USAPulverizer Maintenance Guide, Volume 1 Raymond Bowl 2019年7月25日 Low powder yield rate of Raymond roller mill will directly influence the output Powder yield itself will influence the profits of customers’, longterm low efficiency may possibly lead to bankrupt belt and screw feeder The desulfurized gypsum is predried in a tube bundle dryer with waste heat from the power plant as the heat source How to Increase the Output and Efficiency of Raymond Roller Mill Raymond mill parts The Raymond mill is mainly composed of the main machine, an analyzer, a fan, a finished cyclone separator, a fine powder cyclone separator, and a duct Among them, the main body is composed of a frame, an inlet volute, a blade, a grinding roller, a grinding ring, and a cover Raymond mill working principleRaymond Mill, Raymond Mill For Sale For Cement and Lime

Raymond Fine Grinding Roller Mill For new or for

2024年7月25日 The Raymond® Fine Grinding Roller Mill (US Patent Nos and ) is specially designed for achieving product size distribution with d50 measurements less than 10 microns Available on new Raymond® Roller Mills or as a retrofit to your existing mill Features include: Mill side baffles Optimized plow configuration to enhance mill2024年2月14日 Raymond Roller Mill Brochure Free download as PDF File (pdf), Text File (txt) or read online for free The document discusses Raymond roller mills which are used to grind materials Key details include that Raymond has over 125 years of experience building these mills, they can grind a wide variety of materials from 1050mm in size down to fine particles, Raymond Roller Mill Brochure PDF Mill (Grinding) Gear2024年11月21日 The Raymond mill, also called Raymond roller mill, combines grinding, classifying, and if necessary, drying, in one machine to produce precisely sized powders to meet exact production specificationsIt is an efficient fine grinding machine for largescale powder production Applied materials: various nonflammable and explosive minerals such as gypsum, Raymond Mill epicpowder2024年9月4日 Advantages of Using Raymond Mill Raymond Mill is a versatile industrial equipment known for its numerous advantages in material processing Below, we’ll explore the detailed advantages of using Raymond Mill: Efficient What is Raymond Mill? How Does It Work?

.jpg)

Raymond Mill : The Ultimate FAQ Guide Dry Mortar Plant

2021年12月29日 The Raymond mill operates by rotating a central shaft, which drives a set of rollers or grinding plates to crush the material The crushed material then passes through a classifier, separating the desired particle size Raymond mills are widely used in building materials, chemical industries, metallurgy, mining, etc2024年11月26日 Raymond mill or raymond grinder, raymond grinding mill adopts advanced grinding technology to crush and finely grind raw materials into required powder products It is a powder grinding machine widely used in Raymond Mill JXSC MachineryWhat Is Raymond Mill Raymond mill is also called Raymond roller mill It is a new type of highfineness grinding mill with high efficiency and closed circulation, which can completely replace the cement ball millThis kind of machine is commonly used in cement plants for raw materials fine grinding, such as limestone, coal, gypsum, etc Under normal conditions, these materials’ Raymond Mills Raymond Roller Mill Grinding Mill AGICO 2024年7月25日 The Raymond® Fine Grinding Roller Mill (US Patent Nos and ) is specially designed for achieving product size distribution with d50 measurements less than 10 microns Available on new Raymond® Roller Mills or as a retrofit to your existing mill Features include: Mill side baffles Optimized plow configuration to enhance millRaymond Fine Grinding Roller Mill For new or for

CNU A kind of Activated Carbon Production Raymond mill

The utility model is a kind of Activated Carbon Production Raymond mill, including headstock and main body, power motor is equipped in headstock, power motor is connected with rotary shaft, revolving spindle enters in main body, several grinding roller bars are installed on the plum blossom frame of rotary shaft, grinding roller bar bottom is equipped with grinding roller, main 5 天之前 The Raymond mill is a versatile and reliable grinding machine, suitable for producing fine powders for a wide range of industrial applications Its efficiency, ease of maintenance, and ability to handle various materials make it a valuable asset in many industries [Introduction]: Raymond Mill has a strong performance of becoming a complete set with a production system Raymond Mill TAYMACHINERY2023年5月13日 레이몬드 밀(Raymond Mill = Vertical Roller Mills) Vertical Roller Mill을 Raymond Mill이라고 부르기도 합니다 완전히 새롭고 혁신적인 디자인의 CEMTEC의 Vertical Roller Mills은 연질 및 중간 경도 제품의 보다 효율적인 분쇄를 위한 추가로 개발한 것입니다Raymond Mill 레이몬드 밀 : 네이버 블로그Ball Mill Supplier, Raymond Mill, Ultrafine Mill Manufacturers/ Suppliers Shanghai Mountain River Machinery Co, Ltd LSX Screw Sand Washer XSD Wheel Sand Washer Grinding Machine Grinding Mill 4 Rollers Limestone Powder Grinding Mill with Large Capacity FOB Price: US $5,000300,000 / PieceBall Mill Manufacturer, Raymond Mill, Ultrafine Mill Supplier

.jpg)

Raymond® Roller Mills Coperion

The Raymond® Roller Mill is an airswept vertical ringroll mill with an integral classification system that simultaneously dries, pulverizes and classifies a number of different types of products including limestone, clay, minerals and others The Raymond® Bowl Mill is considered the finest vertical roller mill available for pulverizing coal Each bowl mill system is designed to achieve the best solution for the processing application The mill, feeder, classifier, fan, cyclone, dust Raymond® Bowl Mill Coperion2015年1月20日 In recent years, more and more customers buy Raymond mill to process material, such as talc, barite, calcite, limestone, manganese ore, chrome ore, quartz, gypsum, bentonite and the like In the course will inevitably encounter this or that problem, such as the roller does not rotate, grinding ring loose, uneven feed and feed and less, which is why?Raymond Mill Operation Specification (a)2024年11月24日 【Raymond Mill Plant】 The Raymond mill plant usually contains a cyclone collector, pipe fittings, dust collector, storage hopper, elevator, crusher, electric control cabinet, feeder, main plant, blower, separator, etc, Structural Features The whole mill is of spatial structure, less premise and systemic strong The whole system from roughing, transportation, Raymond Grinding Mill JXSC Machine

.jpg)

Raymond Roller Mill PartsUltimate Guide Fote Machinery

2023年2月15日 Main parts of Raymond roller mill Main parts of Raymond mill include grinding roller, grinding ring, powder collector, classifier, air blower, reducer, base plate, shovel, Raymond mill pendulum, star stack, etc Main materials of the parts: manganese(16Mn, 65Mn), High manganese steel, high chromium(Cr13、Cr23、Cr26)2023年9月18日 The capacity of the Raymond roller mill varies depending on the application and is dependent on the type of roller used Typically, numbers in coneshaped rollers provide greater capacities than in flatbottom rollers Lowpressure designs with single large diameter rolls can deliver up to 40 mph while highcapacity systems utilizing multiple Raymond Grinding Mill: The Ultimate Guide From SMAT 2020年11月11日 The roller mill requires less energy than other attrition milling methods that rely on multiple highspeed impacts, Roller mill demand grows with Growing markets for uniformly reduced particles M arket demand for the uniform particles produced by roller mills is growing as bulk solids processors strive to improve product characteristics,Roller mills: Precisely reducing particle size with greater Raymond 5057 High Side Roller Mill, with all internal grinding components Equip yourself with the gold standard 16045345313 [ protected] Mill bottom with oil reservoir and oil wicking; Mill base with air housing; Mill side; Gear housing with Raymond 5057 High Side Roller Mill Nelson Machinery

Raymond Roller Mill airswept vertical ringroll Qlar

Raymond Roller Mills are available with grinding ring diameters ranging from 30120 in / 7603050mm These sizes are capable of producing a wide range of product fineness from a wide variety of material Typical material processed Clay, Fire Clay, Bentonite, Kaolin, Barytes, Gypsum, Limestone, Phosphate Rock, Talc, Coal, Hydrated Lime 2024年11月26日 The Raymond mill is a versatile and reliable grinding machine, suitable for producing fine powders for a wide range of industrial applications Its efficiency, ease of maintenance, and ability to handle various materials make it a valuable asset in many industries [Introduction]: Raymond Mill has a strong performance of becoming a complete set with a Raymond Mill TAYMACHINERY