HOME→Specialized production of quicklime limestone deep processing equipment spiral quicklimestone crusher

Specialized production of quicklime limestone deep processing equipment spiral quicklimestone crusher

Production of Quicklime Lime and Limestone Wiley Online Library

1998年5月14日 Production of Hydraulic Limes References F Schwarzkopf , “ Lime Burning Technology – a Manual for Lime Plant Operators ”, 3rd ed , Svedala Industries, Kennedy Van Limestone can be directly processed into stone using crushing equipment and fired into quicklime Quicklime absorbs moisture or adds water to become hydrated lime The main component of Limestone Crushing Process JXSC MineralIt is produced by hydrating quicklime, essentially calcium oxide, using a specific apparatus There are a number of variables that can influence the rate of hydration of lime, including the Developing a modular lime plant CimprogettiThere are various processing methods to make lime suitable for practical use We plan and manufacture both complete processing plants and individual machines for you We help you Competence in lime

Impact of Limestone Surface Impurities on Quicklime Product

2024年2月27日 The present study investigated asreceived and manually washed limestone product samples from two operational quarries using elemental compositions and a developed 2007年12月1日 The key to this success lies in the fact that the fuel pulverized coal, fuel oil or gas is introduced in the limestone bed either singly or in combinations by specially designed Production of Quicklime ResearchGate1998年5月14日 Summary This chapter contains sections titled: Processing Production of Ground Quicklime Storage, Handling and Transport ReferencesProcessing Storage and Transport of Quicklime Lime and 2024年6月13日 In the laboratoryproduced quicklime, the surface impurities reacted with calcium forming Larnite, Gehlenite, Åkermanite and Merwinite, reducing the quicklime quality The Characterization of Limestone Surface Impurities and Resulting

.jpg)

Lime SpringerLink

2021年3月3日 In the manufacturing process of hydraulic lime, heating of argillaceous limestones is carried out to produce quicklime with the aim to promote a chemical reaction between the 1998年5月14日 Summary This chapter contains sections titled: Introduction Principles of Lime Burning Development of Lime Kilns Modern Kilns Selection of Lime Kilns Kiln Control Mass Production of Quicklime Lime and Limestone Wiley Online Library2023年6月30日 Over the last few decades, the demand for energyefficient mineralprocessing methods has continued The necessity to develop energyefficient technologies for the mineral industry will increase Modeling and Improving the Efficiency of Crushing The production of quicklime is one of the oldest chemical processes developed by mankind But there is often a lot of confusion between terms like lime and quicklime Are you wondering what quicklime is, and what it is made of? Then you've come to the right page! ScienceStruck gives you a lot of information about quicklime, and explains how it is industrially madeWhat is Quicklime and How is it Made? Science Struck

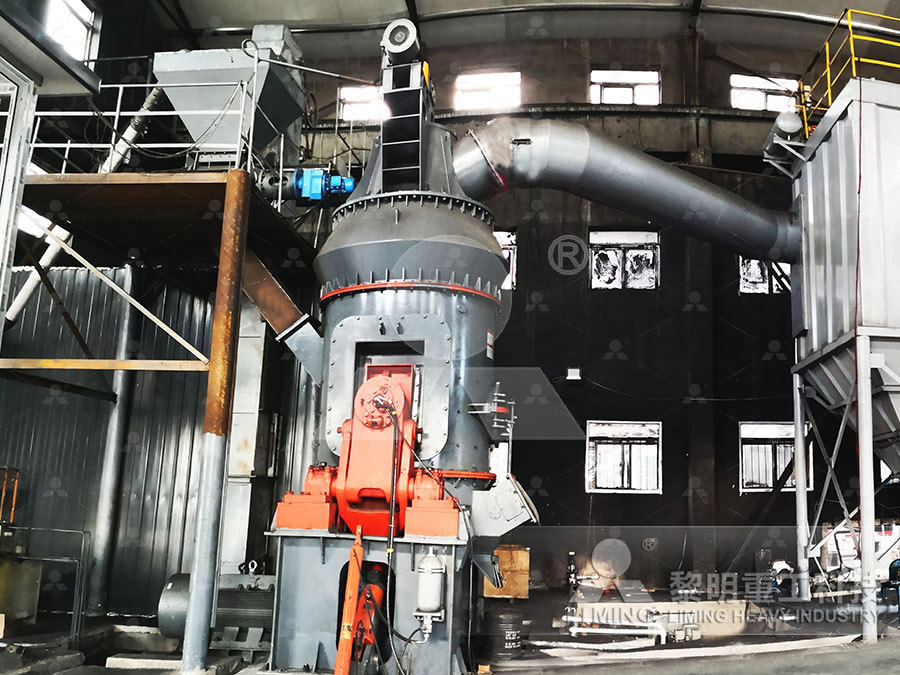

Vertical mill: The preferred equipment for quicklime production

The vertical mill stands out as the preferred equipment for quicklime production due to its high efficiency, energy savings, environmental protection, and ease of maintenance Its advanced grinding technology and compact design make it an ideal choice for lime producers looking to enhance their operational capabilities and product quality1 Crushing Processing Limestone crushing generally requires only simple ore washing Limestone generally adopts dry crushing technology For metallurgical and road limestone, the ore can be crushed and screened 2 Grinding Processing (1) Feeding system: Limestone enters the bucket elevator And then it is sent to the raw material warehouse Limestone Zenith Crusher2024年2月27日 Quicklime is produced through the thermal processing of limestone in industrial kilns During quarry operations, fine particulate quarry dust adheres to limestone lump surfaces, increasing the Impact of Limestone Surface Impurities on Quicklime Product 2020年11月8日 Horizontal Shaft Impactors The Prisec™ crusher range can be configured to operate in application areas such as quarrying and recycling, in either primary or secondary crushing mode Sandvik’s patented design gives you amazing adaptability, ensuring you keep pace with everchanging production requirements Mobile Impact CrusherCrusher; Crushing; and Classification Equipment PPT SlideShare

.jpg)

Limestone crushing and screening production line introduction

2024年1月23日 To transform limestone into various raw materials, a series of processing steps are required Today, we will focus on the limestone crushing and screening process: Initially, the raw limestone blocks are uniformly conveyed to a jaw crusher through a vibrating feederLime Slaker Detention Lime Slaker Specification Feeding Particle Size: 30 Processing Capacity : 120t/h Motor Power : 15105kw Application Areas : Lime plants, steel plants, desulfurization systems, sewage treatment, fine chemical preparation processeLime Processing Plant for Quicklime and Hydrated Lime Production2001年4月1日 This study has examined the effects of limestone characteristics (microstructure and texture) and calcination temperature on the reactivity of the produced quicklime Two types of limestone have (PDF) The Effects of Limestone Characteristics and Calcination Equipment: Vibrating Feeder GZD1500×6000, PE Series Jaw Crusher PE1200×1500, European Type Impact Crusher PFW1318Ⅲ, Vibrating Screen 4YZS2460 CA SE 120TPH Limestone processing in MexicLimestone Crusher LIMING (Shanghai)

.jpg)

Types of Crushers Explained: Everything You Need to

2024年4月19日 Crushers are key equipment in mining, construction and aggregate industries They break large rocks, ore, or other materials into smaller, more usable pieces This equipment reduces the material by means of 2023年2月13日 This article states types of limestone crushing equipment and compares them in production efficiency and other pespectives to help you selecting the best limestone crushing equipment Skip to content Call Us Now: +86 An Essential Equipment for Material Processing; Types of Impact Crusher In Different industry;What Is The Best Limestone Crusher Limestone Crushing AGICOVerticle Shaft Kiln Introduction In factory of lime calcination, where precision and efficiency are paramount, vertical shaft kilns (VSKs) stand as stalwart contributors to the chemical transformation of limestone into quicklime As an engineer Vertical Shaft Kilns in Optimizing Lime Calcination2022年2月3日 Procuring the right equipment is one of the most critical steps in getting a new lime plant up and running Here are the top ten types of equipment every lime plant needs to compete 1 Limestone Bin Limestone bins are typically square or rectangular in shape and smaller in volume than hoppers or silos10 Types of Equipment Every Industrial Lime Plant Needs

.jpg)

Equiment List For Lime Processing Plant Lime Kiln, Crusher,

2023年8月14日 Grinding Equipment Lime grinding equipment is an important machine that determines the fineness of lime powder For producing 200 mesh and 325 mesh commonly used lime powder, one of the main machine configurations for the grinding process is either the vertical lime grinding mill or the Raymond mill (pendulum grinding mill) The Raymond mill has lower 200tph Limestone Crusher Plant Stone Production Line, Find Details and Price about Limestone Crusher Plant Mineral Processing Equipment from 200tph Limestone Crusher Plant Stone Production Line Shibang Industry Technology Group Co, Ltd200tph Limestone Crusher Plant Stone Production Line800 Mesh FoodGrade Hydrated Lime Production Plant AGICO supplies 800 mesh foodgrade hydrated lime production plantThe complete set can produce foodgrade hydrated lime powder from 325 mesh to 2 microns (about 6000 mesh)The foodgrade hydrated lime production plant includes 3 parts:Quicklime Grinding Equipment,Hydrated Lime Slaking System and FoodGrade Hydrated Lime Production Plant Solution2024年1月11日 3 Hammer Crusher The hammer crusher is a crushing processing equipment for limestone This equipment can replace the rough crushing process of the stone crusher, directly crushing limestone into particles below 25mm The hammer crusher adopts a dual motor operation, consisting of a plate hammer and a rotor to form a crushing powerLimestone Crushing And SandMaking Plant Eastman Rock Crusher

Crusher, stone crusher, aggregate processing equipment for

Boost your quarry plant revenue with ZENITH's highquality stone crushers, mobile crusher, grinding mills, and customized solutions Crusher, stone crusher, aggregate processing equipment for sand, quarry, mining and construction• Upstream production of energy and fuels Equipment and ancillary materials (eg drill bits, maintenance items) are listed in Tables 5 and 6 but have not been included in this inventory 4 332 Limestone Processing Operations The LCI for limestone processing operations includes the inputs and outputs for each of the processesLimestone Quarrying and Processing: A LifeCycle Inventory1998年5月14日 Production of Hydraulic Limes References F Schwarzkopf , “ Lime Burning Technology – a Manual for Lime Plant Operators ”, 3rd ed , Svedala Industries, Kennedy Van Saun, 1994 Production of Quicklime Lime and Limestone Wiley Online 2023年10月27日 Quicklime is an alkaline substance produced from heating limestone in specialized kilns Humans have used quicklime since antiquity for construction, agriculture and metalwork applications It is still used in all of Quicklime: A Primer

.jpg)

Limestone Crusher for Efficient Limestone Crushing

Limestone Crusher for Efficient Limestone Crushing Plant Limestone is a versatile nonmetallic mineral with widespread applications in construction, agriculture, environmental protection and more As the primary raw material 2022年2月1日 Decomposing limestone (CaCO 3) into quicklime (burnt limestone; CaO) releases significant CO 2 emissions, both from the combustion of fuel needed to heat the kiln to temperatures over 1,000°C, and by the release of CO 2 from the reaction itself (CaCO 3 → CaO + CO 2)Because quicklime is a key ingredient in the production of cement, as well as being Reducing the carbon footprint of quicklime productionThe limestone crusher is equipment that can crush large limestone gravels about 6001800mm into materials about 25mm or smaller It provides limestone crushed products in the construction industry because limestone is a key ingredient in the production of cement, concrete and other building materialsThe size and type of crushers may vary according to the specific What is Limestone Crusher? AIMIX GROUP2021年11月30日 quicklime produced was measured The procedure was carried out at temperatures of 800, 850, 900, 9500 and 1000 0 CEffects of calcination variables on quicklime yield of Nkalagu limestone

PROCESSING • CHARACTERISTICS • PRODUCTION • KILNS • SOLUTIONS

Using Rotary Kilns in Lime Production Rotary kilns account for 90% of lime production in the United States A rotary kiln consists of a long, cylindrical, slightly inclined, refractorylined furnace The limestone and combustion gases pass through the kiln in a countercurrent flow As the limestone moves down the kiln, the limestone2023年2月15日 The limestone material discharged from a hammer crusher will be further screened to get qualified material for the next step Best crushing and equipment of Fote Manufacturer PE jaw crusher : It weighs 15t, and is driven by a 20horsepower electric motor and powered by a 30kilowatt generatorLime Production Process and Required Equipment2024年6月13日 This was performed by sampling and analyzing limestone, quarry clay, laboratoryproduced quicklime, and industrially produced quicklime with XRF, SEM/EDX, and XRD; interpretations were supported Characterization of Limestone Surface Impurities and Resulting 2023年12月17日 Technologies for multistage processing in the agrotechnical industry are actively developing today, allowing us to offer a highquality product to the end consumer In Russia, such areas are still being formed, but there are already certain successes One of the most promising segments of agricultural production is the deep processing of grain with a Deep processing of grain: technologies, equipment and prospects

Modeling and Improving the Efficiency of Crushing

2023年6月30日 Over the last few decades, the demand for energyefficient mineralprocessing methods has continued The necessity to develop energyefficient technologies for the mineral industry will increase The production of quicklime is one of the oldest chemical processes developed by mankind But there is often a lot of confusion between terms like lime and quicklime Are you wondering what quicklime is, and what it is made of? Then you've come to the right page! ScienceStruck gives you a lot of information about quicklime, and explains how it is industrially madeWhat is Quicklime and How is it Made? Science StruckThe vertical mill stands out as the preferred equipment for quicklime production due to its high efficiency, energy savings, environmental protection, and ease of maintenance Its advanced grinding technology and compact design make it an ideal choice for lime producers looking to enhance their operational capabilities and product qualityVertical mill: The preferred equipment for quicklime production1 Crushing Processing Limestone crushing generally requires only simple ore washing Limestone generally adopts dry crushing technology For metallurgical and road limestone, the ore can be crushed and screened 2 Grinding Processing (1) Feeding system: Limestone enters the bucket elevator And then it is sent to the raw material warehouse Limestone Zenith Crusher

Impact of Limestone Surface Impurities on Quicklime Product

2024年2月27日 Quicklime is produced through the thermal processing of limestone in industrial kilns During quarry operations, fine particulate quarry dust adheres to limestone lump surfaces, increasing the 2020年11月8日 Horizontal Shaft Impactors The Prisec™ crusher range can be configured to operate in application areas such as quarrying and recycling, in either primary or secondary crushing mode Sandvik’s patented design gives you amazing adaptability, ensuring you keep pace with everchanging production requirements Mobile Impact CrusherCrusher; Crushing; and Classification Equipment PPT SlideShare2024年1月23日 To transform limestone into various raw materials, a series of processing steps are required Today, we will focus on the limestone crushing and screening process: Initially, the raw limestone blocks are uniformly conveyed to a jaw crusher through a vibrating feederLimestone crushing and screening production line introductionLime Slaker Detention Lime Slaker Specification Feeding Particle Size: 30 Processing Capacity : 120t/h Motor Power : 15105kw Application Areas : Lime plants, steel plants, desulfurization systems, sewage treatment, fine chemical preparation processeLime Processing Plant for Quicklime and Hydrated Lime Production

.jpg)

(PDF) The Effects of Limestone Characteristics and Calcination

2001年4月1日 This study has examined the effects of limestone characteristics (microstructure and texture) and calcination temperature on the reactivity of the produced quicklime Two types of limestone have Equipment: Vibrating Feeder GZD1500×6000, PE Series Jaw Crusher PE1200×1500, European Type Impact Crusher PFW1318Ⅲ, Vibrating Screen 4YZS2460 CA SE 120TPH Limestone processing in MexicLimestone Crusher LIMING (Shanghai)