Equipment for processing concrete

.jpg)

Cement processing equipment Qlar

With our marketleading MULTICOR cement processing solutions, we help you meet the defining challenges in today’s marketplace, by dramatically reducing your CO2 emissions in line with new regulations – and ensuring the quality Comprehensive range of mobile and static concrete batching plants and concrete mixers Innovative, High quality solutions for the production, recycling and application of hot and cold asphalt materials Innovative offtheshelf and BES: Equipment for Concrete, Asphalt, China Concrete Equipment wholesale Select 2024 high quality Concrete Equipment products in best price from certified Chinese Hardware Equipment manufacturers, Lifting Equipment China Concrete Equipment, Concrete Equipment Madein Concrete Batching Plants are used for manufacturing of highquality in a variety of construction applications, like buildings, roads, bridges, airports and many others MEKA offers a wide range of Ready Mix plants along with MEKA MixersConcrete Batching Plants MEKA Global

Concrete Products ERMC

Offering complete concrete processing, transporting and testing equipment combined with trusted, experienced service make ERMC the choice for concrete professionals Whether you’re Columbia Machine is one of the world’s leading manufacturers of concrete products equipment, serving customers for over 85 years, in over 100 countries From mixing and batching to automatic cubing and splitting, Columbia builds a Concrete Product Machines and SolutionsCentral to this industry are robust and specialized machinery that ensure both quality and efficiency in concrete production From the concrete mixer, which combines cement, sand, and water into a homogenous mixture, to the Concrete equipment for sale Machinery PartnerThe use of vacuum processing of concrete is especially advantageous at low ambient temperatures (down to −5 °C) since the removal of excessive water and air bubbles to a large Construction Machinery SpringerLink

Concrete Processing Concrete Specialists Boels

Everything for sawing or grinding in concrete, asphalt and metal Cutoff saw, manual wall saw, wall saw, angle grinder, stone and mortar saw, router and more We have a wide range of 2024年1月11日 Concrete equipment encompasses a range of tools and machinery used to mix, transport, and finish concrete efficiently and effectively in construction projects Initially, concrete was mixed and laid by hand—a Concrete Equipment that Every Contractor Must 2019年9月27日 Cement mill is another necessary cement equipment of the cement plant After raw material crushing, cement mill plays vital role in the further cement manufacturing process Cement ball mill, vertical cement mill, Cement Euipment Overview Cement Making New equipment for processing Concrete Browse a wide range of equipment perfect for recycling waste concrete; impact and jaw crushers, screeners, excavators, conveyors and more Talk to an Expert about Concrete Best Concrete equipment for sale Machinery Partner

.jpg)

Cement Plant: The Manufacturing Process 4 5 World

2019年10月23日 Cement Plant: The Manufacturing Process worldcementassociation 1 Limestone (CaCO3) is taken from a quarry 2 4 3 The limestone is fed into a crusher and then stored until needed The clinker is mixed with additives, such as gypsum, and then ground in a cement mill, which creates cement The cement is then packed and distributed to consumersCement rotary kiln is the core equipment of cement plant, mainly responsible for clinker calcination, which can be used both in dry process cement production line and wet process cement production line It is usually placed horizontally and at an angle to the ground, forming a state of one end high and one end low The kiln body rotates slowly Cement Manufacturing Machine Cement Making Machine Cement 2020年1月28日 This concrete recycling machine is mainly used for processing materials that often have to be moved It integrates feeding, crushing, screening and conveying into one, which can eliminate the limitation of the operation site and make the recycling flexible This "crushitall" equipment recycles waste concrete with a high proficiency The 5 Concrete Recycling Machines You Have to Know FTMThe MixMaster Pro twocomponent resin injection gun is manufactured specifically for lifting concrete slabs, and designed to handle backpressure As the essential piece of foam jacking equipment for Alchatek’s expanding polyurethane foams, the resin injection gun provides highlyefficient concrete leveling Key Features: Stainless steel gun Concrete Leveling Tools: Pumps, Guns, and Slab Lifting Tools

.jpg)

Cement Making Process: Equipment Manufacturing

Cement manufacturing equipment needs to withstand the heat and the abrasive material from which cement is made Making cement involves combining raw materials including limestone, clay, and shale, which are milled into a very fine powder after being mined These materials are then mixed with other ingredients according to their enduse This mixture is then fired in a kiln 2023年12月7日 Finally, they bake the fiber cement boards in highpressure ovens called autoclaves that harden and cure the cement From making cement to mixing and disposing of concrete, the right equipment can make the process faster and easier Find equipment rentals for your project todayHow Is Cement Made? StepbyStep Guide BigRentzCement Manufacturing Process by TIZITA MOGES , SELAMU ABULE DEREJE ENDALAMAW De dusting system is used to prevent the dust from escaping into the environment, most of the cement plant machinery and equipment is working under negative pressure, which requires the ventilation and cleaning of large volume of air gases respectively Cement Manufacturing Process INFINITY FOR CEMENT EQUIPMENT1 天前 The diagram illustrates the steps and the use of equipment in cement making process, and the way cement is used to produce concrete for construction purposes Overall, cement is produced by crushing limestone with clay which IELTS Diagram: Model Answer Band Score 9 with

.jpg)

Crushing and Screening Equipment for Concrete

2023年3月14日 The equipment should be compact but have high output Systems that have conveyors, jaws, and impacts can provide complete processing of the concrete, from demolition to usable material Vibrating 2022年4月27日 The new generation equipment range covers numerous applications starting with the small, versatile concrete pump and ending with the concrete pump that has the highest reach and best manoeuvrability By Types of Concrete Equipment for different CGS Equipment– providing quality mixing pumping solutions for all things concrete grout and screed We service the mining, mineral processing, civil, construction, and infrastructure industries We are the exclusive distributor for high quality CGS Equipment Mixing Pumping Equipment SupplierThe cement plant produced by AGICO is available for various cement types, such as Portland cement, fastsetting cement, rapid hardening cement, white cement, refractory cement, expansive cement, etc We will provide customers with customized services of cement plant design, and select the most suitable cement equipment according to the Cement Plant For Sale Cement Factory For Sale Cement

.jpg)

Comprehensive Guide to Cement Kilns: Processes, Types,

Overview of Cement Kilns Definition and importance in the cement manufacturing process Historical development and technological advancements Word count: 500; Section 1: Cement Manufacturing Process Raw Material Extraction and Preparation Types of raw materials used (limestone, clay, etc) Extraction and transportation methods Word count As a cement equipment supplier and cement plant manufacturer, AGICO offers quality cement kiln, cement vertical mill cement ball mill, hammer crusher, etc Besides, we provide cement production line, stone crushing plant, etc Cement Production Process Cement is the most widely used material in the construction industry It is a crucial Cement Equipment In Cement Plant AGICO Cement Plant AGICO Cement has large manufacture workshops and professional processing equipment to ensure the fast and highquality production of related equipment in this fly ash processing plant In addition, we have more than 20 years of production and sales experience, the products are exported to all over the world, therefore, we can ensure the timely Fly Ash Processing Plant Cement Equipment Manufacturing 3 天之前 Jaypee® India Ltd is the largest construction equipment manufacturer of Concrete Rebar Processing Equipment from India with over 40 years of expertise, We understand the challenges in the manufacturing process and the opportunities to improve Productivity We have achieved great success by empowering every user in the enterprise with the India's Top Construction Equipment Manufacturer Jaypee

Concrete Crushers: Turning Waste Concrete into Valuable

2024年1月6日 Types of Concrete Crushers Jaw Crushers: These robust crushers utilize powerful jaws to exert pressure, effectively breaking down concrete into smaller chunksThey excel in both primary and secondary crushing, making them versatile for various applications Jaw crushers are commonly used in the initial stages of concrete processing due to their efficiency Concrete Batching Plants are used for manufacturing of highquality concrete for a variety of construction applications more than 110+ countries We are proud to announce Berkshire Engineering as the dealer for the UK Ireland for both Concrete Batching Plants MEKA GlobalConcrete processing equipment Home » Rental » Other equipment » Concrete processing equipment UPRENT Ltd August 12, 2020 0 Comment Filters Sort results Reset Apply Picture Title Lenght Diameter Engine power Weight Engine Concrete vibrator ENAR Dingo ER 105 15 / 3 / 4 mm 25 / 38 / 48 mmConcrete processing equipment For rent UPRENT4 天之前 Explore our diverse material processing equipment range, from complete bespoke processing plants to modular crushers, screens, and more The Kumbee Hammermill, made by us in NZ, is a versatile crusher that Sanland Equipment 100% NZ Owned and

Cement Equipment, Cement Plant Equipment Cement Plant

Before you send inquiry Please provide us with project information as much as possible: For a complete project: the material availability, the required output capacity, the process technology, your budgetary and financing status, the estimated starting time, etc For singular machinery: the model, the capacity, your budgetary information, other requirements, etc2023年5月26日 This blog post will provide valuable information and insights for those looking to purchase or sell equipment Aggregate and Concrete Production Equipment Concrete is widely utilized in the construction industry It relies on specialized equipment to ensure efficiency, capabilities, and quality during productionThe Essential Guide to Aggregate Equipment in Construction2023年11月1日 The burning system of a cement rotary kiln is a fundamental component of the cement manufacturing process, where raw materials are heated to extreme temperatures to produce clinker Its efficiency, temperature control, and environmental considerations are central to the overall performance of a cement plant AGICO CEMENT supplies EPC 8 Tips For Cement Plant Design Cement Manufacturing ProcessPrestressing equipment for bundle stressing and single stressing in precast hollow core slab production For more details, please visit elematic Skip navigation hollow piles and other prestressed precast concrete products The Stresser E9 allows simultaneous prestressing of up to 200 tons and 20 or more strands with one pull Prestressing equipment for precast Elematic precast

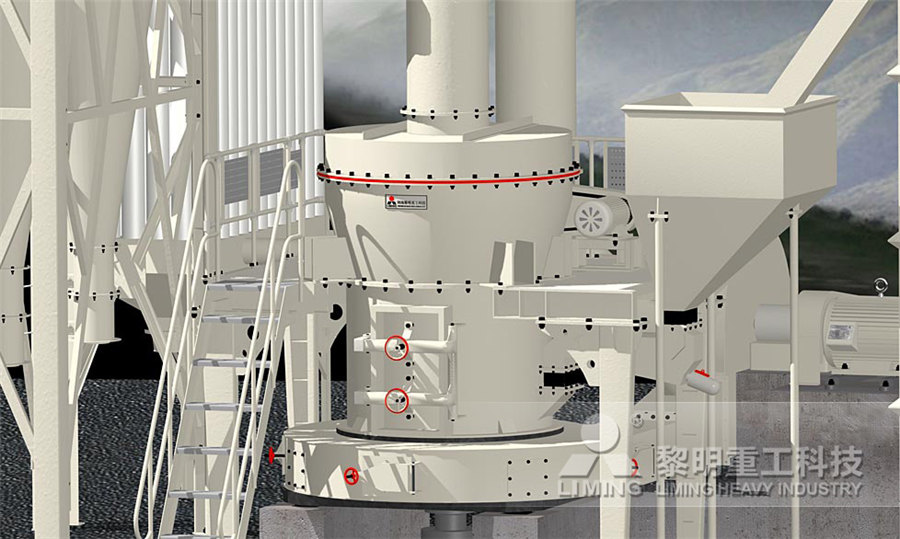

制粉-10.25公众号.jpg)

Common Types of Concreting Equipment Used in Construction

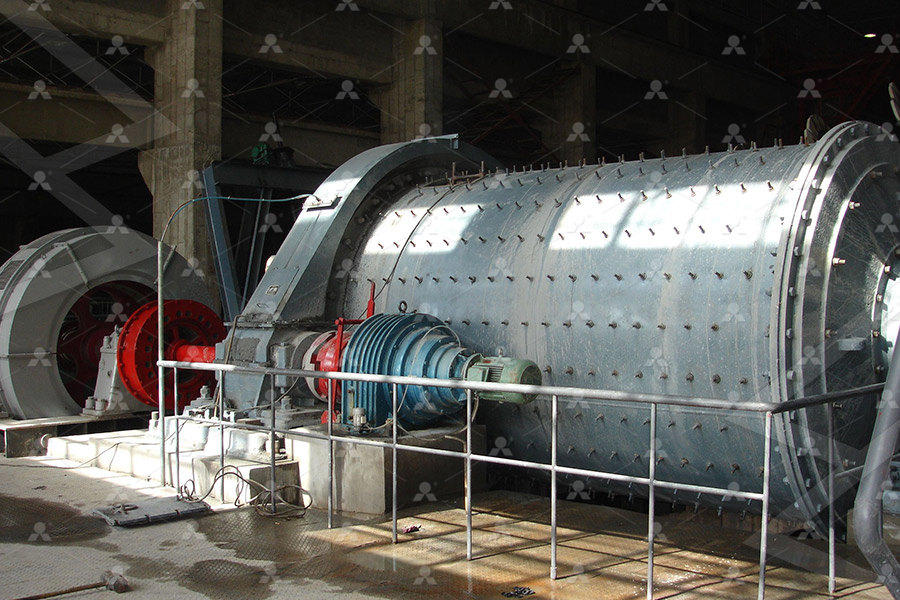

2021年5月5日 From mixing to pouring the concrete onto slabs, many workers have to work together to ensure the process goes well But for bigticket projects, this can be impractical This type of conveyor is usually cheaper and may reduce the need for cranes and other such equipment Concrete conveyors are ideal for large projects like dams and power The cyclone preheater is one of the core equipment for dry process cement production, which consists of a series of vertical cyclones locate on several stages Inside the cyclones, raw meal meats with the exhaust gas emitting from the rotary kiln and performs suspension heat exchange with it The suspension preheating process helps cement How Is Cement Produced in Cement Plants Cement Making Process2024年5月22日 The cement production process 1 The Quarry: The cement production process begins with the extraction of limestone and clay from the quarry 2 Crusher and PreBlending: The material is then crushed to reduce particle sizes and blended to reduce variability in composition 3 Raw Mill and Kiln: Raw materials and additives areA practical guide to improving cement manufacturing 2019年9月27日 Cement mill is another necessary cement equipment of the cement plant After raw material crushing, cement mill plays vital role in the further cement manufacturing process Cement ball mill, vertical cement mill, Cement Euipment Overview Cement Making

.jpg)

Concrete equipment for sale Machinery Partner

New equipment for processing Concrete Browse a wide range of equipment perfect for recycling waste concrete; impact and jaw crushers, screeners, excavators, conveyors and more Talk to an Expert about Concrete Best 2019年10月23日 Cement Plant: The Manufacturing Process worldcementassociation 1 Limestone (CaCO3) is taken from a quarry 2 4 3 The limestone is fed into a crusher and then stored until needed The clinker is mixed with additives, such as gypsum, and then ground in a cement mill, which creates cement The cement is then packed and distributed to consumersCement Plant: The Manufacturing Process 4 5 World Cement rotary kiln is the core equipment of cement plant, mainly responsible for clinker calcination, which can be used both in dry process cement production line and wet process cement production line It is usually placed horizontally and at an angle to the ground, forming a state of one end high and one end low The kiln body rotates slowly Cement Manufacturing Machine Cement Making Machine Cement 2020年1月28日 This concrete recycling machine is mainly used for processing materials that often have to be moved It integrates feeding, crushing, screening and conveying into one, which can eliminate the limitation of the operation site and make the recycling flexible This "crushitall" equipment recycles waste concrete with a high proficiency The 5 Concrete Recycling Machines You Have to Know FTM

Concrete Leveling Tools: Pumps, Guns, and Slab Lifting Tools

The MixMaster Pro twocomponent resin injection gun is manufactured specifically for lifting concrete slabs, and designed to handle backpressure As the essential piece of foam jacking equipment for Alchatek’s expanding polyurethane foams, the resin injection gun provides highlyefficient concrete leveling Key Features: Stainless steel gun Cement manufacturing equipment needs to withstand the heat and the abrasive material from which cement is made Making cement involves combining raw materials including limestone, clay, and shale, which are milled into a very fine powder after being mined These materials are then mixed with other ingredients according to their enduse This mixture is then fired in a kiln Cement Making Process: Equipment Manufacturing2023年12月7日 Finally, they bake the fiber cement boards in highpressure ovens called autoclaves that harden and cure the cement From making cement to mixing and disposing of concrete, the right equipment can make the process faster and easier Find equipment rentals for your project todayHow Is Cement Made? StepbyStep Guide BigRentzCement Manufacturing Process by TIZITA MOGES , SELAMU ABULE DEREJE ENDALAMAW De dusting system is used to prevent the dust from escaping into the environment, most of the cement plant machinery and equipment is working under negative pressure, which requires the ventilation and cleaning of large volume of air gases respectively Cement Manufacturing Process INFINITY FOR CEMENT EQUIPMENT