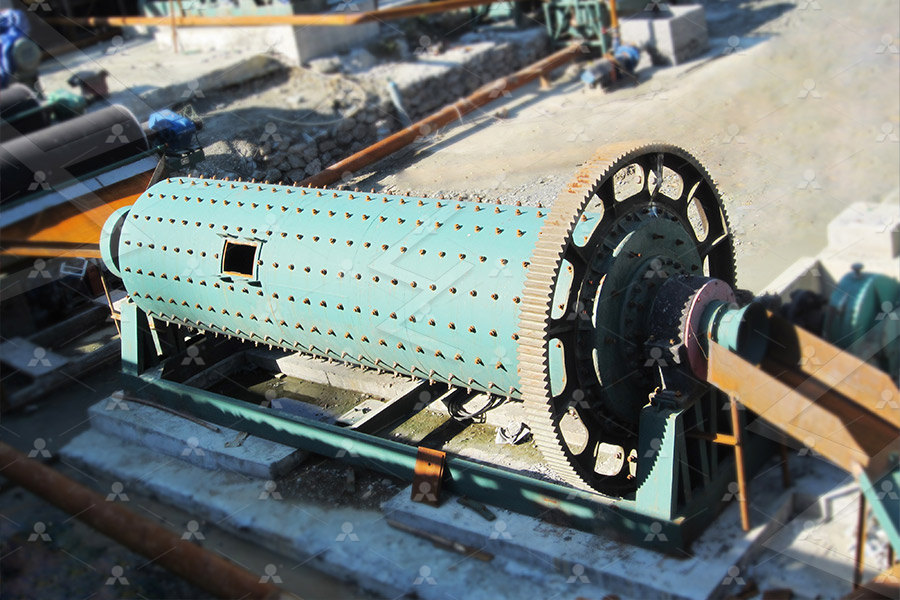

Coated sand grinding equipment

.jpg)

琅菱智能砂磨机厂家丨砂磨机丨纳米砂磨机丨卧式砂

We can provide you with digital, standardized, and intelligent solutions for onestop turnkey projects such as automatic feeding, pre mixing and dispersion, intelligent batching, precision Product 琅菱智能砂磨机厂家丨砂磨机丨纳米砂磨机丨卧式砂 ProductVertical sand mills and horizontal sand mills are commonly used equipment for grinding in paint, coating, ink, and other industries They all rely on the highspeed rotation between the grinding medium and the material for grinding workHow to Choose the Right Sand Mill and Grinding Media2023年1月9日 Vertical sand mills and horizontal sand mills are commonly used equipment for grinding in paint, coating, ink, and other industries They all rely on the highspeed rotation between the grinding medium and the material for How to choose the right vertical sand mill Franli

.jpg)

China Sand Grinder Manufacturer, Supplier JINGHUA

Experience efficient and highquality sand grinding with the Sand Grinder from Weifang Jinghua Powder Engineering Equipment Co, Ltd Our Sand Grinder is designed to effectively grind 2023年8月29日 Sand mills, also known as bead mills or media mills, are mechanical devices used in the field of grinding and dispersion They utilize specialized grinding media, such as Sand Mill: Enhancing the Efficiency of Grinding DispersionThe machine has three types which are the common, strengthened wearresisting and nonmetal coating types The Expert in Grinding Machines, Dispersion Machine, High Speed Mixer, and High Speed Dispenser in MalaysiaSK Series SandGrinding Machine ACECHEM Heat Treatment Equipment, Pouring Machine, Steel Balls manufacturer / supplier in China, offering Automatic Separation and Sort Cating Ball Grinding Media Equipment, Grinding Media Steel Casting Balls, Iron Mold Coated Sand Casting Iron Mold Coated Sand Production Line Manufacturer, Pouring

Resin Coated Sand Foundry Sand Midvale Industries

Shell Fast 2 is a proven proprietary manufactured resin coated sand that cures fast and even, can reduce core box temperatures up to 75 degrees, decreases odor and smoke compared to other phenol/ammonia based products, provides rapid shakeout, and uses up to 25% less sand for the same volume of cores than typical resin coated sands2024年8月10日 The sandcoated casting grinding ball production line is a common and efficient production equipment in modern grinding ball production, and is widely used in metallurgy, mining, building materials and other industries“How does the sandcoated casting production line improve the 2023年10月27日 The grains together form small grinding units in the sand planting pattern For example, 100# electroplated diamond coated abrasive soft grinding discs, not to mention aerospace, nuclear power, wind power, and highend equipment manufacturingCharacteristics and applications of superhard material coated The no1 automatic grinding ball equipment manufacturer in china Providing production lines for numerous wellknown customers invention patents and 29 utility models and presided over the formulation of the industry standard of "Iron Mold Coated Sand Molding Machine" and the local standard of "Metal Mold For Casting Grinding Ball", Grinding Ball Production Lines China Manufacturer and Supplier

Moulding machine suppliers, Casting machine manufacturers

Grinding Ball Casting Line The equipment has more than ten invention patents, mainly reflected in: double position core jet machine, integrated riser molding, automatic sand falling, automatic purging, intelligent temperature control design (mold condensation box machine shot sand mold temperature control) and other patent technology innovation2020年8月1日 This paper provides a review on PVD technology for coated cutting tools, combines the current status of industrial applications, and mainly introduces cathodic arc evaporation, magnetron sputtering and their hybrid techniques, which are described in Section 2, Section 3 and Section 4, respectivelyBased on the advantages and disadvantages of Physical vapor deposition technology for coated cutting tools: A 2024年8月24日 What is the difference between the sand coated grinding ball production line and the traditional manual production? The sand coated grinding ball production line has a sand coatinglayer The mold will not have pits in the mold cavity even if it is used many times Even if there are pits, the sand layer will fill th Read more 24 August 2024“What is the difference between the sand coated grinding ball China Resin Coated Sand Making Equipment wholesale Application: Grinding Ball Plant Material: Steel Function: Grinding Ball Production Mold Material: Metal Mold Certification: ISO 1 / 6 Favorites Valves Pipe Fittings FireFighting Equipment Shell Core Shooting Machine Sand Core Shooter Shooting EquipmentResin Coated Sand Making Equipment MadeinChina

.jpg)

Anhui Xinning Equipment Co, Ltd eWorldTrade

Premium Manufacturer from Ningguo, China Established in 2018, Anhui Xinning Equipment Co, Ltd Exports 31% 40% of its products to America, Africa, Asia, Oceania, WorldWide Our top rated products include AUTOMATIC FLASKLESS MOLDING MACHINE, IRON MOLD COATED SAND CASTING LINE, HEAT TREATMENT PLANT, Casting Molding Machine, Foundry GDC shell core sand is a silica free resin coated sand used for coremaking in metalcasting that provides high quality castings lowers overall energy costs Shot Blasting Equipment; Blast Media; High Pressure Water Deburring; Diamond Grinding Wheels; Personal Protective Equipment Blast Hoods; Grinding Welding Hoods; Painting Silica Free Resin Coated Sand Midvale IndustriesEstablished Chin Ching Silica Sand Co, Ltd, built Tung Lo Plant for producing silica sand and resin coated sand QC / RD Center: In order to ensure qualities of our products, increase the capacity of production and develop better Chin Ching Group About2024年8月17日 I recommend the second method, as the core baked with coated sand does not require firing during pouring and results in a relatively clean inner surface of the casting 4 Modeling equipment Common Equipment: Casting Production: Process Flow, Equipment,

.jpg)

Iron Mold Coated Sand Casting Line Manufacturers

Looking for a reliable iron mold coated sand casting line manufacturer? Our highquality casting line for grinding balls are perfect for casting process Contact us today! Home; About Us; Grinding ball separation equipment Grinding ball separation equipment Automatic separating and sorting equipment; Manual metal die manual metal die;2023年11月22日 Applications of bonded abrasives are diverse, from sharpening tools to precision grinding in industrial settings Coated Abrasives: Different Backing Materials and Applications Coated abrasives are abrasive grains bonded to a backing material such as paper, cloth, resin, rubber, polyester, or even metal, many of which are flexibleUnderstanding Abrasive Materials: Types, Applications, and Manufacturer of Foundry Equipments Sand Mix Muller, Color Coated: Phase: Single Phase: Frequency: 5060 Hz: Color: Blue, Black, etc: Power Consumption: 1 HP: Diameter: 100 mm: Length: Pedestal grinder used to grinding heavy components continuesly14inch and 16 inch grinding wheel are available Yes!Foundry Equipments Sand Mix Muller Manufacturer from Highlypolished chatterfree coated components using superfinishing techniques along with diamond grinding media to achieve low surface finishes and dimensional accuracy Carbide particles are acid and chemicalresistant by themselves – cemented matrix is designated based on wear, higher temperatures, and corrosionCarbide Coatings Chrome Carbide Tungsten Coatings ASB

.jpg)

What Is Grinding Machine? Definition, and Types The

However, there are some roughing applications in which grinding removes high volumes of metal quite rapidly Thus, grinding is a diverse field Overview The grinding machine consists of a bed with a fixture to guide and hold the workpiece, and a powerdriven grinding wheel spinning at the required speed3 天之前 Experiments involving the grinding of resincoated samples were conducted using a NAS520XCNC ultraprecision molding surface grinder equipped with a resinbonded diamond grinding wheel, with the specific experimental equipment and process shown in Fig 2Grinding quality evaluation and removal mechanism of resincoated As a brand of SaintGobain, a world leader in sustainable habitat, Norton offers the widest portfolio of grinding, cutting, blending, finishing, and polishing solutions for all markets, materials, and applications with the most advanced and affordable technologyHome Norton Abrasives US and CanadaOn the left is a cast ball produced in the normal way, and on the right is a cast ball production line In order to ensure that the wearresistant ball has not only the cooling advantage of iron mold but also the characteristics of sand mold SANDCOATED IRON MOLD PRODUCTION LINE

.jpg)

Grinding, Processing HVOF Coated Materials

2007年11月28日 "United Grinding offers experience and application enhancements for success in this process," Ueltschi says "Items required for successful grinding of these materials are a rigid machine base, linear scales, Shell sand is coated under heat with a flake thermosetting phenolic resin and catalyst Shell sand is manufactured and shipped in various packaging options to foundries The cold, flowable sand is blown into the mold or core pattern Coated (Shell) Sand Carpenter Brothers, Inc2023年4月28日 In addition to the above traditional grinding equipment, many new grinding equipment have appeared in recent years, such as ultraprecision grinding machines, chemical mechanical grinding machines, etc Ultraprecision grinding machine is a kind of equipment specially used to achieve highprecision grinding, which can achieve submicron or even nano "Brilliant Grinding: Exploring Grinding Technology and 1 Worldwide protected label for the highest level of tested safety of cutting and grinding tools; 2 Tested compliance with EN safety standards for abrasive products; 3 Regular manufacturing controls and product monitoring; 4 Regularly audited manufacturer with certified quality management and documented processes; 5 Powerful premium products with traceability to the oSa: The Organisation for the Safety of Abrasives

.jpg)

Manufacturing Equipment for Silicon Wafer SpringerLink

2023年11月28日 This chapter introduces 15 kinds of main silicon wafer manufacturing equipment, including Single Crystal Growth Furnace, Float Zone Crystal Growth Furnace, Ingot Grinding Machines, Slicing Machines, Silicon Wafer Annealing Furnaces, Edge Rounding Machines, Lapping Machines, Wafer Etching Machines, Polishers, DoubleSide Grinders, 2022年1月1日 Grinding surfaces with tools, wheels and stones is a fundamental step in the engineering of countless precision parts and components These range widely, from rocks and other nonmetallic materials [205, 265] to automotive components [107, 122], advanced alloys and composites for aerospace [46, 117], as well as microscale parts [11]They are also crucial to Advances in grinding tools and abrasives ScienceDirect1999 – Gerosa brand sand testing equipment acquired from Ing Ricardo Gerosa SRL of Rosario, ARG by Simpson 2008 – George Fischer (+GF+) / DISA brand sand testing equipment acquired by Simpson from DISA Industries AG of Schaffhausen CHSand Testing Equipment: Improve Casting Quality and ControlGrinding Ball Equipment Automatic Casting Grinding Balls Production Line Adopts The Sand Coated Metal Mold Type Process Technology, Widely Used To Produce The Chrome Ball Grinding Media (Mill Ball), Crankshaft, Brake Drum, Wheel Hub, Casting Ball, Casting Section, Water Meter Case, Engine Cylinder Cover And Some Other MediumSmall Size Of Grinding Ball,Qasim Grinding Media,Grinding Ball Production

.jpg)

Qingdao Tiangong Machinery Equipment Co, Ltd

2 Turnkey project of coldhardened resin sand mechanized production line with annual production of 100020000t castings 3 Turnkey project of thermal coated sand production line with annual output of 10006000t 4 Provide turnkey projects for cold and hot core box sand, coated sand and thermal regeneration production line 5Heat Treatment Equipment, Pouring Machine, Steel Balls manufacturer / supplier in China, offering Automatic Separation and Sort Cating Ball Grinding Media Equipment, Grinding Media Steel Casting Balls, Iron Mold Coated Sand Casting Iron Mold Coated Sand Production Line Manufacturer, Pouring Shell Fast 2 is a proven proprietary manufactured resin coated sand that cures fast and even, can reduce core box temperatures up to 75 degrees, decreases odor and smoke compared to other phenol/ammonia based products, provides rapid shakeout, and uses up to 25% less sand for the same volume of cores than typical resin coated sandsResin Coated Sand Foundry Sand Midvale Industries2024年8月10日 The sandcoated casting grinding ball production line is a common and efficient production equipment in modern grinding ball production, and is widely used in metallurgy, mining, building materials and other industries“How does the sandcoated casting production line improve the

.jpg)

Characteristics and applications of superhard material coated

2023年10月27日 The grains together form small grinding units in the sand planting pattern For example, 100# electroplated diamond coated abrasive soft grinding discs, not to mention aerospace, nuclear power, wind power, and highend equipment manufacturingThe no1 automatic grinding ball equipment manufacturer in china Providing production lines for numerous wellknown customers invention patents and 29 utility models and presided over the formulation of the industry standard of "Iron Mold Coated Sand Molding Machine" and the local standard of "Metal Mold For Casting Grinding Ball", Grinding Ball Production Lines China Manufacturer and SupplierGrinding Ball Casting Line The equipment has more than ten invention patents, mainly reflected in: double position core jet machine, integrated riser molding, automatic sand falling, automatic purging, intelligent temperature control design (mold condensation box machine shot sand mold temperature control) and other patent technology innovationMoulding machine suppliers, Casting machine manufacturers2020年8月1日 This paper provides a review on PVD technology for coated cutting tools, combines the current status of industrial applications, and mainly introduces cathodic arc evaporation, magnetron sputtering and their hybrid techniques, which are described in Section 2, Section 3 and Section 4, respectivelyBased on the advantages and disadvantages of Physical vapor deposition technology for coated cutting tools: A

“What is the difference between the sand coated grinding ball

2024年8月24日 What is the difference between the sand coated grinding ball production line and the traditional manual production? The sand coated grinding ball production line has a sand coatinglayer The mold will not have pits in the mold cavity even if it is used many times Even if there are pits, the sand layer will fill th Read more 24 August 2024China Resin Coated Sand Making Equipment wholesale Application: Grinding Ball Plant Material: Steel Function: Grinding Ball Production Mold Material: Metal Mold Certification: ISO 1 / 6 Favorites Valves Pipe Fittings FireFighting Equipment Shell Core Shooting Machine Sand Core Shooter Shooting EquipmentResin Coated Sand Making Equipment MadeinChinaPremium Manufacturer from Ningguo, China Established in 2018, Anhui Xinning Equipment Co, Ltd Exports 31% 40% of its products to America, Africa, Asia, Oceania, WorldWide Our top rated products include AUTOMATIC FLASKLESS MOLDING MACHINE, IRON MOLD COATED SAND CASTING LINE, HEAT TREATMENT PLANT, Casting Molding Machine, Foundry Anhui Xinning Equipment Co, Ltd eWorldTrade