Cement plant powder

.jpg)

How Cement is Made Portland Cement

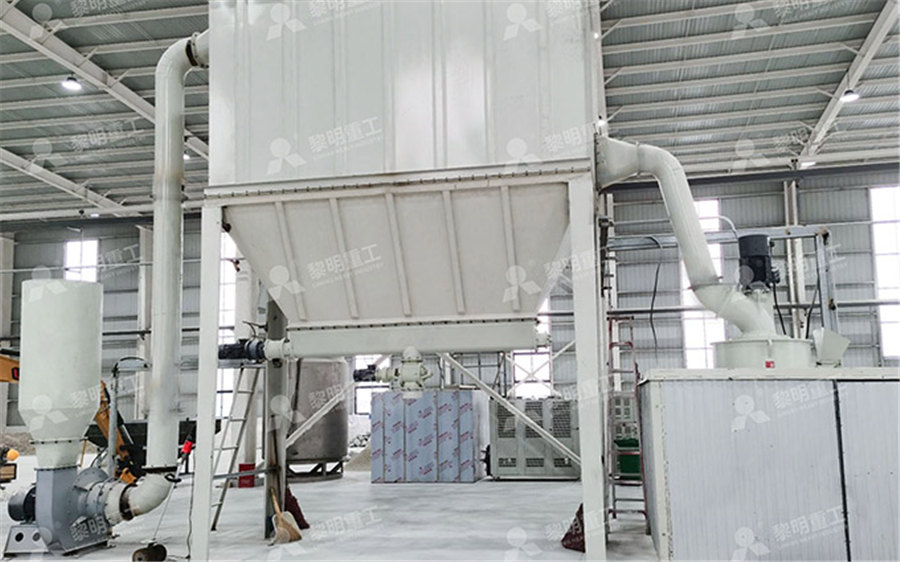

Cement is manufactured from materials heated together at high temperatures to form a rocklike substance that is ground into a fine powder Limestone, marl, and clay are commonly used sources of these primary elements Other materials 2024年11月16日 There are six main stages of the cement manufacturing process The raw cement ingredients needed for cement production are limestone (calcium), sand and clay How Cement is Made Cement Manufacturing Process2024年6月1日 This research examines the characteristics of Recycled Concrete Powder (RCP) and its potential use as a partial replacement for cement in concrete production Waste Recycled concrete powder on cement mortar: Physico 2020年8月25日 In the cement grinding process, the clinker is ground to a fine powder along with other materials, up to 5% gypsum or additional anhydrite is added to control the solidification time of the cement, and other compounds Cement Manufacturing Process AGICO

The Cement Manufacturing Process Thermo

2023年12月20日 Cement manufacturing is a complex process that begins with mining and then grinding raw materials that include limestone and clay, to a fine powder, called raw meal, which is then heated to a sintering temperature as Cemex produces different types of cement by grinding clinker and gypsum into an extremely fine powder We carefully control the proportions of these materials to produce the specific type of cement needed for each applicationCement Corporate Website CemexCement is a kind of powdery hydraulic inorganic cementitious material, which is the most basic and widely used building material in modern society Cement can be hardened in the air or in water, and can firmly bond sand and stone How Is Cement Produced in Cement Plants2024年11月23日 Raw materials in some plants are sampled automatically, and a computer calculates and controls the raw mix composition The largest rotary kilns have outputs exceeding 5,000 tons per day Grinding The clinker and Cement Extraction, Processing, Manufacturing

Cement Manufacturing—Technology, Practice, and

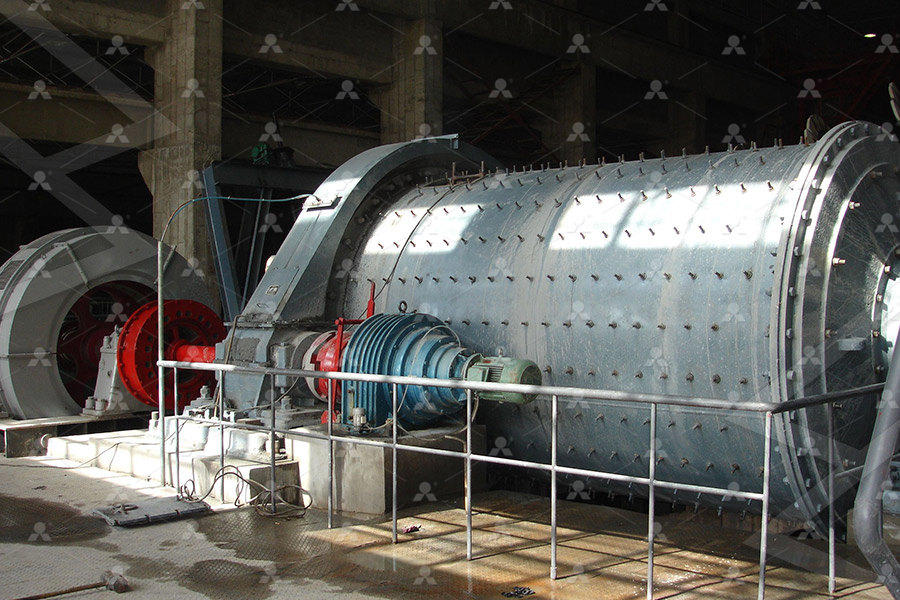

2021年11月16日 The major raw material used in cement manufacture is lime It is derived from materials such as limestone, chalk, marl, shale, and clay, which are obtained from mines by 2019年10月23日 Cement Plant: The Manufacturing Process worldcementassociation 1 Limestone (CaCO3) is taken from a quarry 2 4 3 The limestone is fed into a crusher and then stored until needed The clinker is mixed with additives, such as gypsum, and then ground in a cement mill, which creates cement The cement is then packed and distributed to consumersCement Plant: The Manufacturing Process 4 5 World Storage: Upon arrival at the cement plant, materials are stored separately to prevent contamination and to maintain quality This storage often takes place in large silos or stockpiles The final step in cement manufacturing is the Cement Making Guide: Steps, Impact Green 2023年12月20日 The clinker is ground to a fine powder in a cement mill and mixed with gypsum to create cement which enables the plant to reduce energy consumption by using exactly the amount of coal fuel required to meet the The Cement Manufacturing Process Thermo

Cement Corporate Website Cemex

We proudly use dry cement manufacturing in 96% of our global plants, which significantly optimizes water consumption Cemex produces different types of cement by grinding clinker and gypsum into an extremely fine powder We carefully control the proportions of these materials to produce the specific type of cement needed for each The cyclone preheater, also called cement preheater, suspension preheater, is a kind of preheater in cement plantAs the core equipment of dry method cement production line, cyclone preheater use suspension preheating to preheat and partly decompose the cement raw mix, shorten the length of the rotary kiln, fully mix raw mix and hot air in the kiln, increase heat exchange rate, Cyclone preheater in cement plant2024年1月18日 Once the clinker and additives have been milled into a fine cement powder, the cement is transported to storage silos and then to packaging and distribution facilities for shipment The resulting cement can be used for a wide range of construction applications, including the production of concrete, mortar, and other building materialsCement Production Demystified: StepbyStep Process and Concrete Plants Components; Cement Silos; CEMENT SILOS CEMENT AND POWDER SILOS PDF, 157 MB ILOS GALLERY View some photos of our range of ilos taken at our factories, global stocks and work sites Feel free to contact our sales team for more detailed information and referencesCement Silos MEKA Concrete Plants

.jpg)

Cahya Mata Sarawak Cement

2024年11月26日 The two cement plants are supported by 6,000 MT marine flat store terminals in Miri and Sibu, each with pneumatic cement conveying facilities which are in turn serviced by two (soon to be three) dedicated purpose built 4,000tonne DWT barges that continuously transport cement from the plants to the terminals Each barge is equipped with a fully Cement Plants located in Canada Statistic view For full access to the database, purchase The Global Cement Report TM, 15th Edition Purchase Summary Cement capacity (Mt) 21199; Integrated plants 15; Clinker plants 0; Grinding plants 1; This interactive chart requires a subscription to theCement Plants located in Canada from International Cement Ash Grove ships cement from twelve cement plants and its network of terminals located throughout the Midwest, Texas, and the Western United States, and is one of the largest cement producers in North America with the addition of operations in Florida, the US Great Lakes and Canada At Ash Grove, we stand together to reinvent the way our world Ash Grove Cement2023年11月3日 This study aims to evaluate the effect of RCP from a precast concrete plant on rheological and mechanical properties of cementitious pastes In the study, Portland cement was replaced by RCP in 10 The effect of recycled concrete powder (RCP)

Cement GB Breedon

4 天之前 Breedon operates two cement plants with a total capacity in excess of 2 million tonnes Our Hope cement plant in Derbyshire is recognised as the UK's largest and has been in operation for more than 90 years Our plant at 2020年8月25日 Cement equipment refers to all equipment in the cement plant, such as cement mill, cement crusher, cement kiln, cement silo, In the cement grinding process, the clinker is ground to a fine powder along with other Cement Manufacturing Process AGICO 2024年2月15日 OneCem® is a limestone blended cement manufactured using less clinker than traditional Portland cement By converting the StConstant Plant's production to OneCem, Lafarge Canada projects a reduction of about 60,000 tonnes of CO2 emissions in 2024 This equates to CO2 emissions from 16,267 passenger vehicles or 877,972 tree seedlings grown for Lafarge Canada Completes Full Transition to Greener Cement 4 天之前 The normal pH range of soil for plant growth is 55 to 65, but certain factors like the mixing of soil and cement or mixing of soil and concrete can imbalance the soil pH level, which in turn make the soil acidic, and affect the growth of plantsCan Cement Harm Plants? Yes! Here’s How Flourishing Plants

Optimizing Electrical Energy Consumption In Cement

2023年8月29日 sources of energy to Indian Cement Industry are coal and electrical power In cement industry Electrical energy is used for many operations like Crushing,Grinding,Rolling etc, The present paper deals with the methods and technologies that can be adopted in cement process plants to optimize Electrical energyCement conveyor refers to a belt conveyor in cement plant, which is necessary accessory equipment in the cement production line A belt conveyor is a kind of material handling equipment with strong adaptability, applied for conveying bulk density less than 167t / m³, it is mostly used for powder, granular, small lump materials, and bagged materials, such as sand, ore, coal, Cement Conveyor Belt Conveyor In Cement Plant AGICOIn addition to the vertical slag mill, other types of cement mill that can grind slag powder include: cement ball mill, pregrinding cement roller press, and cement roller press for final grinding For slag grinding plant, ball mill generally causes problems of dust accumulation, low grinding efficiency and high grinding temperatureSlag Grinding Plant GGBS Plant Slag Mill, Slag Cement Plant2023年10月30日 By carefully assessing and addressing each of the factors mentioned above, cement producers can make informed decisions and ensure the successful establishment and operation of their plants AGICO CEMENT is a professional cement engineering company, we can offer EPC solutions for cement factories if you need cement plant design, cement Guide To Cement Plants Site Selection

Decarbonising cement and concrete production: Strategies,

2024年6月1日 Implementing CCS in cement plants also provides a viable pathway for the industry to transition towards more environmentally friendly and lowcarbon cement production By capturing and storing CO 2, cement plants can continue producing this essential construction material while significantly reducing their environmental impact This is crucial 2023年10月30日 Cement powder should be stored in a dry place, away from moisture, and in wellsealed containers or bags to prevent contamination and the potential for an exothermic reaction with water Cement Powder Logistic Cement Logistics Guide to Hauling Cement 2019年9月27日 There are various types of cement crusher on the market, including jaw crusher, cone crusher, hammer crusher, impact crusher, and etc AGICO Cement can provide all types of cement crusher Our cement crusher Cement Euipment Overview Cement Making Raw mill is also known as cement raw mill, AGICO CEMENT supplies raw mill in cement plant,and other cement equipment with high quality and competitive price, welcome to ask! Skip to content +86 s Raw Mill, Cement Raw Mill, Raw Mill In Cement

Plants JK Cement

4 天之前 The White Cement plant was commissioned in 1984 at Gotan, Rajasthan, with an initial production capacity of 50,000 tons JK Cement Works, Muddapur Situated near Muddapur village of Taluka Mudhol, district Bagalkot (Karnataka, the unit has the latest state of the art technology to manufacture 35 Million tonnes of cement per annum2024年6月1日 Recycled concrete powder (RCP) is a type of waste material that has received more attention recently because of its potential to enhance the performance of cementbased composite products RCP is a finepowdered material consisting of a blend of Ordinary Portland Cement (OPC), pozzolans, other Supplementary Cementitious Materials (SCM) and fine Recycled concrete powder on cement mortar: Physico It is mainly used to complete the automatic packing of cement and other powder materials with good fluidity, such as fly ash, gypsum powder, cement additives, etc It is widely used in cement plants and other industries The cement packing machine can be divided into a fixed type and a rotary type The fixed type usually has 14 cement Cement Packing Machine – Rotary Cement Packing Machine Cement 2022年7月15日 1 Introduction With the accelerated construction process, the demand for readymixed concrete has increased dramatically, and readymixed concrete mixing plants have sprung up all over the world [1]Due to the lack of a longterm management system and disposal technology, the wastewater and solid waste from mixing plants are piled up randomly and the Experimental study on the effect of wastewater and waste

Tamilnadu Cements Corporation Limited

The third cement plant of TANCEM plant commenced its operation in 2019It is a most modern 1 million ton per annum and adopts stateoftheart technology and installed with advanced equipment such as pre calciner, crossbar coolerIts US network includes 10 cement plants, close to 50 strategically located cement terminals, nearly 50 aggregate quarries and more than 280 readymix concrete plants CEMEX USA has been repeatedly recognized for its efforts in sustainability and energy management, including earning US EPA ENERGY STAR ® Partner of the Year in 2019, 2020 CEMEX Location Finder Cemex USA CEMEX2019年11月6日 The dry process cement production line process raw materials into raw material powder and the moisture is less than 1% material and weight, and your drawings with details, you can send the drawing to s Detailed information is greatly helpful for us to give you the bestcustomized offer/quotation at the soonest timeWhy Choose Rotary Kiln In Cement Manufacturing Plant?2019年10月23日 Cement Plant: The Manufacturing Process worldcementassociation 1 Limestone (CaCO3) is taken from a quarry 2 4 3 The limestone is fed into a crusher and then stored until needed The clinker is mixed with additives, such as gypsum, and then ground in a cement mill, which creates cement The cement is then packed and distributed to consumersCement Plant: The Manufacturing Process 4 5 World

.jpg)

Cement Making Guide: Steps, Impact Green

Storage: Upon arrival at the cement plant, materials are stored separately to prevent contamination and to maintain quality This storage often takes place in large silos or stockpiles The final step in cement manufacturing is the 2023年12月20日 The clinker is ground to a fine powder in a cement mill and mixed with gypsum to create cement which enables the plant to reduce energy consumption by using exactly the amount of coal fuel required to meet the The Cement Manufacturing Process Thermo We proudly use dry cement manufacturing in 96% of our global plants, which significantly optimizes water consumption Cemex produces different types of cement by grinding clinker and gypsum into an extremely fine powder We carefully control the proportions of these materials to produce the specific type of cement needed for each Cement Corporate Website CemexThe cyclone preheater, also called cement preheater, suspension preheater, is a kind of preheater in cement plantAs the core equipment of dry method cement production line, cyclone preheater use suspension preheating to preheat and partly decompose the cement raw mix, shorten the length of the rotary kiln, fully mix raw mix and hot air in the kiln, increase heat exchange rate, Cyclone preheater in cement plant

Cement Production Demystified: StepbyStep Process and

2024年1月18日 Once the clinker and additives have been milled into a fine cement powder, the cement is transported to storage silos and then to packaging and distribution facilities for shipment The resulting cement can be used for a wide range of construction applications, including the production of concrete, mortar, and other building materialsConcrete Plants Components; Cement Silos; CEMENT SILOS CEMENT AND POWDER SILOS PDF, 157 MB ILOS GALLERY View some photos of our range of ilos taken at our factories, global stocks and work sites Feel free to contact our sales team for more detailed information and referencesCement Silos MEKA Concrete Plants2024年11月26日 The two cement plants are supported by 6,000 MT marine flat store terminals in Miri and Sibu, each with pneumatic cement conveying facilities which are in turn serviced by two (soon to be three) dedicated purpose built 4,000tonne DWT barges that continuously transport cement from the plants to the terminals Each barge is equipped with a fully Cahya Mata Sarawak CementCement Plants located in Canada Statistic view For full access to the database, purchase The Global Cement Report TM, 15th Edition Purchase Summary Cement capacity (Mt) 21199; Integrated plants 15; Clinker plants 0; Grinding plants 1; This interactive chart requires a subscription to theCement Plants located in Canada from International Cement

.jpg)

Ash Grove Cement

Ash Grove ships cement from twelve cement plants and its network of terminals located throughout the Midwest, Texas, and the Western United States, and is one of the largest cement producers in North America with the addition of operations in Florida, the US Great Lakes and Canada At Ash Grove, we stand together to reinvent the way our world