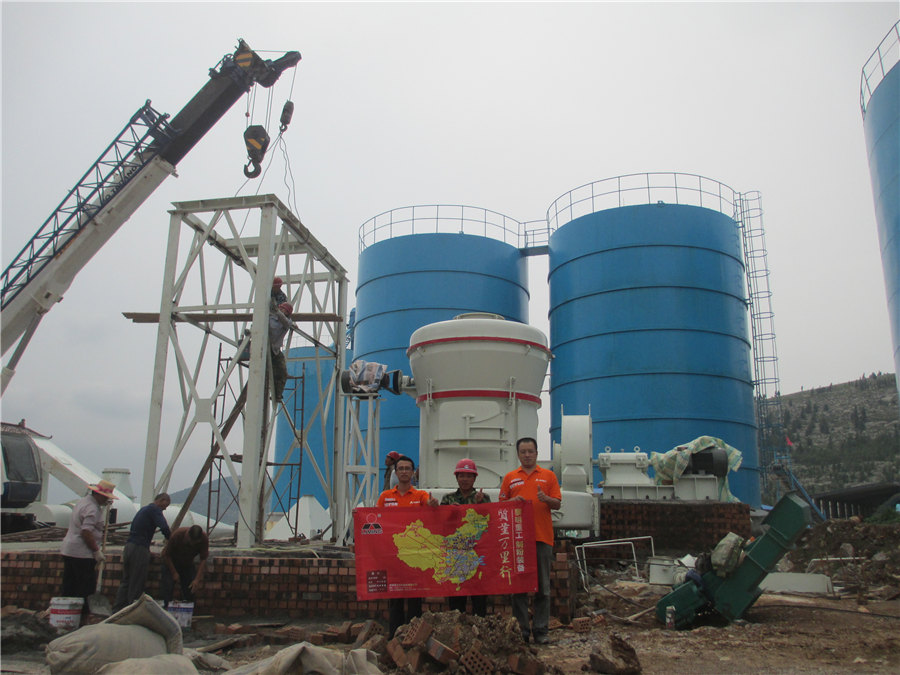

Molybdenum ore ore mill

Molybdenum Processing: Unlocking the Potential of a

2024年3月18日 Flotation is the most widely used method for molybdenum ore processing It relies on the differences in the surface properties of molybdenite and other minerals present in the oreBall or rod mills crush and grind the mined ore to fine particles, releasing molybdenite from the gangue (worthless rock) The grinding mills shown here reduce rocks from the size of soccer balls to the size of gravel Further ball Molybdenum Processing IMOA2020年12月3日 This study is conducted with the aim of investigating the efficiency of open and closedcircuit molybdenite ore comminution processes (primary and secondary mill, A process mineralogy approach to study the efficiency of 2014年10月15日 Runofmine molybdenum ore was sorted using a dual energy Xray transmission array Sorting thresholds permit optimization of Mo recovery and waste rejection Development of ore sorting and its impact on mineral processing

Molybdenum ore processingthe transition from ore to

2024年9月3日 The mining of molybdenum ore usually uses underground mining or openpit mining The ore produced is first initially crushed by a jaw crusher The broken ore is further 2013年1月1日 Schematic structure of the automatic control system for grinding process of coppermolybdenum ore: 1 ± control system for ore feed to the mill; 2 ± control system for Modern Systems of Automatic Control of Processes of 2016年7月1日 Simulation results indicated that the mill operated under nonoptimal conditions Adjusting the cut size of the classifier could increase the mill capacity by 50% A twostage ball Simulation and optimization of a twostage ball mill grinding 2017年8月26日 Today only about 40% of the world's molybdenum production originates from ore bodies where molybdenum is the primary material The best known of these are the Review of Molybdenum Recovery Processes Springer

Molybdenum Ore Beneficiation Process

2024年11月21日 Usually use the ball mill or rod millball in the ore milling process But there are also some processing flows adapted to use a semiselfgrinding process Flotation separation adopts priority flotation method Rough 2023年7月4日 The Yangjiazhangzi Molybdenum Mine in Liaoning province initially produced iron sulfide ore and leadzinc ore In the 1930s, this mine was plundered by Imperial Japan, and Modern Molybdenum Industry in China SpringerLinkThe wet pan mill is named by the diameter of roller Φ1300,Φ 1350,Φ 1400,Φ 1500,Φ 1600 is suitable for selection of iron ore, molybdenum ore ,lead ore ,zinc ore, antimony ore and so on Φ 850, Φ 900, Φ 1000,Φ 1100,Φ 1200 is suitable for selection of gold ore Above all, 1200a type is the most popular and widely use Advantages of wet Gold Ore Wet Pan Mill XKJ Group2024年10月1日 01 Coppermolybdenum ore coarse crushing and grinding The coppermolybdenum ore is first coarsely crushed and then transported to the ore storage pile The ore is initially ground in a semiautogenous ball mill, and the CopperMolybdenum Ore Beneficiation Process

.jpg)

On the possibility to process coppermolybdenum ore

2021年10月15日 Keywords: flotation, coppermolybdenum ore, flotation reagent, dispersion, concentrate, extraction Semushkina Larisa Valerievna Information about authors: process of grinding ore into a ball mill Sodium butyl xanthate and T92 were fed to the main and control coppermolybdenum flotation The liquid glass was2020年12月3日 An examination of the molybdenum, copper and iron grade changes over a 10day period for both mill on and off modes of closedcircuit mill showed that in the milloff mode, the plant circuit is in A process mineralogy approach to study the efficiency of 6 天之前 Common ones include grinding gold, copper, iron ore, molybdenum ore, feldspar ore, lithium, chrome, fluorite ore, etc Types: Mining ball mills are divided into two categories, Overflow ball mills: center discharge ball mills; Lattice type ball mills: Peripheral row ore type ball mills Batch small ball mill: control the particle size of the Ball Mill Mining Grinding Mill JXSC MachineryMolybdenum ore introduction: The molybdenum ore processing production process mainly includes three processes of crushing, grinding and beneficiationIn the process of crushing, the threestage closedcircuit crushing is a modern crushing method suitable for molybdenum ore, which can complete the work of ore crushing and partial dissociation, thereby improving the Molybdenum ore processing dewomachinery

CFB石灰石脱硫剂制备96.jpg)

OPTIMIZATION OF FLOTATION PARAMETERS FOR

FOR BENEFICATION OF A MOLYBDENUM ORE S Beste AYDIN, Alim GUL Mineral Processing Engineering Department, Faculty of Mines, Istanbul Technical University, Istanbul, Turkey, Abstract: The importance of molybdenum deposits has been increased in Turkey as well as the molybdenum industry in the world2016年5月5日 This molybdenum flotation circuit, based on 250500 tons per 24 hours is designed for lowgrade molybdenum ore having highgrade streaks and with pyritequartz gangueIt is also basically sound for many other friable sulphide ores, such as antimony, silver and even some lead ores The basic ideas stressed in this moly flotation flowsheet are the Molybdenum Ore Processing by Flotation 911Metallurgist2016年7月1日 Representative ore samples were collected from the molybdenum mine where the twostage ball milling circuit of the current investigation was operated Large lumps of the raw material were crushed in a jaw crusher, and separated into 2 Simulation and optimization of a twostage ball mill grinding 2016年7月1日 A twostage ball milling circuit for the grinding of molybdenum ore was investigated based upon the grinding kinetic model To this end, batch grinding tests at the laboratoryscale were conducted to obtain the specific rate of breakage and the primary breakage distribution in wet and dry environmentsSimulation and optimization of a twostage ball mill grinding

.jpg)

Development of ore sorting and its impact on mineral processing

2014年10月15日 The energy costs required to refine metal values contained in ore to concentrates constitute the majority of the cost to produce metals On average across the mining industry, 44% of the total electricity consumption is dedicated to crushing and milling activities (Fig 1)Size reduction operations, nearly 150 × 10 9 kW h, are the largest single consumer of 2012年1月5日 Preconcentration of Molybdenum from a Lowgrade Primary Mo Ore by Physical Beneficition T Sreenivas*, RR Venkatkrishnan Mineral Processing Division, Bhabha Atomic Research Centre, AMD Complex, Begumpet, Hyderabad, 500 016, India Abstract Studies on pre concentration of molybdenum values from a primary molybdenum ore deposit located in Preconcentration of Molybdenum from a Lowgrade 2024年11月21日 For lowgrade molybdenumcopper ore, while ensuring the grade and recovery rate of molybdenum concentrate, the comprehensive recovery of copper should also be consideredSometimes it is more Research On Coppermolybdenum Ore Flotation 2024年11月18日 A grinding machine crushes rock the size of footballs to the size of gravel, then uses a ball mill to further reduce the material to the size of cosmetic powder Thompson Creek molybdenum ore 2 Flotation In the flotation process, the ground ore/gangue powder is mixed with a liquid reagent and inflated Lowerdensity ores rise in the foam and How Is Molybdenum Mined and Processed?

.jpg)

Atmospheric Pollution from a Storage of Tungsten–Molybdenum Ore

2023年12月18日 Abstract— Experimental studies of the surface atmosphere pollution with mining and processing wastes of tungsten–molybdenum ore were carried out using an equipment devised for collecting aerosols above the surface of sands It has been established that toxic components formed during the decomposition of residual sulfide mineralization and products 2020年5月24日 The Keumseong molybdenum mine is located approximately 8 km south of Jecheon, and approximately 130 km southeast of the capital Seoul The Keumseong molybdenum deposits were discovered in 1966 by the state geological institute The ore is of a molybdenum calc skarntype that has been developed inPresorting of high grade molybdenum ore A case for 2023年2月15日 To process iron ore, molybdenum ore, lead ore, zinc ore, and antimony ore, you can use these types: Φ1300, Φ1350, Φ1400, Φ1500, Φ1600 How can a wet pan mill separate gold ore? A wet mill can be used together with a crusher and gravity equipment so that the sorting efficiency is higher 1 Wet pan mill works with jaw crusher/ hammer crusherWet Pan Mill: You Can Collect Gold for Only 900 DollarsTest of reducing slime of oxidized zinc ore by using stirring mill has been carried out 采用搅拌磨对兰坪氧化锌矿石进行了磨矿试验 The molybdenum ore, is in Heman provinces, is in the altered rock cataclastic and veinlet belt 河南某钼矿属蚀变破碎带——细 ore是什么意思ore的翻译音标读音用法例句爱词霸

Flotation technology of refractory lowgrade molybdenum ore

2013年3月1日 With molybdenum ore being increasingly depleted, the rational development and utilization of lean molybdenum ore has become an important research topic in the field of beneficiation [2] The Qingyang molybdenum ore in the paper is of low mining grade, containing Mo 0022% below the marginal grade (003%), and oxidation rate 2825%2013年1月1日 Modern Systems of Automatic Control of Processes of Grinding and Flotation of Coppermolybdenum Ore Author links open overlay panel V Morozov *, D Davaasambuu **, Z Ganbaatar **, L Delgerbat **, V When operating the regulating circuit, the mill ore/water ratio, the maintained ore/water ratio in the mill feed, is defined by the Modern Systems of Automatic Control of Processes of 2020年12月22日 The coarse molybdenum concentrate is reground in two or three stages, and the final molybdenum concentrate is obtained by four or five times of selection The flotation reagent of molybdenum ore uses nonpolar Mineral Processing 101 : Molybdenum Ore 2012年1月5日 Studies on preconcentration of molybdenum values from a primary molybdenum ore deposit located in Harur of Dharmapuri district, Tamilnadu were carried out by physical beneficiation techniques Inspite of Preconcentration of Molybdenum from a Low

.jpg)

How Is Molybdenum Mined and Processed? Fote Machinery

2023年4月27日 1 The crushed molybdenum ore is sent to a ball mill for grinding The molybdenum disulfide powder has a diameter of only a few microns 2 Then it is screened by a spiral classifier The qualified molybdenum powders are sent to the floatation machine, while the rest continues to be ground2019年7月15日 for example, stage orepreparation taking into account mineralogical and granulometric ore composition, elaboration of new beneficiation apparatus and schemes, improvement of schemes for minerals sepaTable 1 Process indicators of the world leading concentrating mills, processing coppermolybdenum ores Mill name, country Ore processing, Analysis of technological schemes and substantiation of 2024年11月25日 1 Crushing: The molybdenum ore is coarsely crushed by the jaw crusher, and then crushed to a reasonable particle size by the fine jaw crusher 2 Grinding: The feeder is evenly fed into the ball mill, and the ore is ground to below 200 mesh by the ball mill + classifierMake the particle size meet the requirements of flotation process 3 Flotation Molybdenum Flotation Process JXSC MachineryOre ball mill sometimes called ore grinding mill, is generally used in mineral processing concentrator, processing materials include iron ore, copper ore, gold ore, molybdenum ore and all kinds of nonferrous metal oreThe core function of the ore ball mill is to grind the materials, and also to separate and screen different mineral materials, and to separate the tailings, which is Buy Ore Ball Mill for Mineral Processing Iron Gold Ore Ball Mill

.jpg)

Simulation and optimization of a twostage ball mill grinding

2016年3月1日 Four methods of analyzing ball mill design were compared for opencircuit wet grinding of a phosphate ore, and the predicted mill capacities were compared to actual plant capacities for mills of 0 Molybdenum Concentrates Ore Importers – Reliable Molybdenum Concentrates Ore Importers Directory – Find Molybdenum Concentrates Ore Buyers and Importers and Trade Directory Info from Global » Free Online Chat The 2011 Import and Export Market for Unroasted On the demand side, exporters and strategic planners approaching the market in Africa face a molybdenum ore concentrates in africa – Grinding Mill China1984年12月1日 While about onehalf of the molybdenum in the ore was water soluble, only about 14% existed in this form in the tailings The major portion of the extractable molybdenum in the tailings appears to be associated with hydrous oxides of iron, and with alkaline earth sulfate precipitates a uranium ore storage area in Texas, and a uranium mill Leaching of molybdenum and arsenic from uranium ore and mill The wet pan mill is named by the diameter of roller Φ1300,Φ 1350,Φ 1400,Φ 1500,Φ 1600 is suitable for selection of iron ore, molybdenum ore ,lead ore ,zinc ore, antimony ore and so on Φ 850, Φ 900, Φ 1000,Φ 1100,Φ 1200 is suitable for selection of gold ore Above all, 1200a type is the most popular and widely use Advantages of wet Gold Ore Wet Pan Mill XKJ Group

.jpg)

CopperMolybdenum Ore Beneficiation Process

2024年10月1日 01 Coppermolybdenum ore coarse crushing and grinding The coppermolybdenum ore is first coarsely crushed and then transported to the ore storage pile The ore is initially ground in a semiautogenous ball mill, and the 2021年10月15日 Keywords: flotation, coppermolybdenum ore, flotation reagent, dispersion, concentrate, extraction Semushkina Larisa Valerievna Information about authors: process of grinding ore into a ball mill Sodium butyl xanthate and T92 were fed to the main and control coppermolybdenum flotation The liquid glass wasOn the possibility to process coppermolybdenum ore 2020年12月3日 An examination of the molybdenum, copper and iron grade changes over a 10day period for both mill on and off modes of closedcircuit mill showed that in the milloff mode, the plant circuit is in A process mineralogy approach to study the efficiency of 6 天之前 Common ones include grinding gold, copper, iron ore, molybdenum ore, feldspar ore, lithium, chrome, fluorite ore, etc Types: Mining ball mills are divided into two categories, Overflow ball mills: center discharge ball mills; Lattice type ball mills: Peripheral row ore type ball mills Batch small ball mill: control the particle size of the Ball Mill Mining Grinding Mill JXSC Machinery

Molybdenum ore processing dewomachinery

Molybdenum ore introduction: The molybdenum ore processing production process mainly includes three processes of crushing, grinding and beneficiationIn the process of crushing, the threestage closedcircuit crushing is a modern crushing method suitable for molybdenum ore, which can complete the work of ore crushing and partial dissociation, thereby improving the FOR BENEFICATION OF A MOLYBDENUM ORE S Beste AYDIN, Alim GUL Mineral Processing Engineering Department, Faculty of Mines, Istanbul Technical University, Istanbul, Turkey, Abstract: The importance of molybdenum deposits has been increased in Turkey as well as the molybdenum industry in the worldOPTIMIZATION OF FLOTATION PARAMETERS FOR 2016年5月5日 This molybdenum flotation circuit, based on 250500 tons per 24 hours is designed for lowgrade molybdenum ore having highgrade streaks and with pyritequartz gangueIt is also basically sound for many other friable sulphide ores, such as antimony, silver and even some lead ores The basic ideas stressed in this moly flotation flowsheet are the Molybdenum Ore Processing by Flotation 911Metallurgist2016年7月1日 Representative ore samples were collected from the molybdenum mine where the twostage ball milling circuit of the current investigation was operated Large lumps of the raw material were crushed in a jaw crusher, and separated into 2 Simulation and optimization of a twostage ball mill grinding

.jpg)

Simulation and optimization of a twostage ball mill grinding

2016年7月1日 A twostage ball milling circuit for the grinding of molybdenum ore was investigated based upon the grinding kinetic model To this end, batch grinding tests at the laboratoryscale were conducted to obtain the specific rate of breakage and the primary breakage distribution in wet and dry environments