Basalt dolomite milling process

.jpg)

Mechanochemical processing of silicate rocks to trap CO 2 Nature

2023年3月13日 Milling minerals rich in magnesium and iron within CO 2 gas has been proposed to capture carbon as metalcarbonates We conduct milling experiments in CO 2 and show After ball milling, the dunite showed the highest enhancement of CO 2 uptake (2781 μmol g −1 after 12 h of milling with 50 wt% ethanol), followed by the Ball Milling Effect on the CO2 Uptake of Mafic and 2018年6月15日 In this work, the mechanically activated method of wet ballmilling was tried to prepare highly efficient CO 2 sorbents from naturally occurring dolomite Two major operation Stabilized CO2 capture performance of wet mechanically activated 2015年3月1日 DOI: 101016/JPOWTEC201412046 Corpus ID: ; Carbon dioxide storage in olivine basalts: Effect of ball milling process @article{Rigopoulos2015CarbonDS, title={Carbon dioxide storage in olivine basalts: Effect of ball milling process}, author={Ioannis Rigopoulos and Klito C Petallidou and Michalis A Vasiliades and Andreas Delimitis and Carbon dioxide storage in olivine basalts: Effect of ball milling process

Carbon dioxide storage in olivine basalts: Effect of ball milling process

2015年3月31日 The ball milling process was (magnesite, siderite, dolomite, and also observed a large increase in specific surface area and porosity for olivinerich basalt particles by wet ball millingDolomite is a sedimentary rock containing more than 50 percent of the mineral dolomite by weight These rocks are composed of many distinct minerals The process of formation of rocks is different for various rocks Rocks are quarried from many years for various purposes You can check out Basalt vs Dolomite information and Basalt vs Dolomite Basalt vs Dolomite Compare Nature2018年11月7日 Adsorbed CO2 (μmol g −1 ) versus ball milling time (h) for the unmilled and ballmilled dunite, pyroxenite, basalt and dolerite samples (data from Rigopoulos et al [19,25,32,33])(PDF) Ball Milling Effect on the CO2 Uptake of Mafic and Ultramafic 2021年2月19日 The milling process factors influencing the particle size include grinding time, milling speed, the size of the balls and balls to powder weight ratio So far many studies have concentrated on the synthesis of ultrafine silica sand production, however not on the process parameters optimization study [ 10 ]Comparative Study on Improving the Ball Mill Process Parameters

Mechanochemical processing of silicate rocks to trap CO 2 Nature

2023年3月13日 This is because the trapping process is not, The average particle sizes for granite and basalt after milling were 159 µm M Thermal behavior of natural dolomite J Therm Anal 2022年11月30日 Results indicate that the particle size of dolomite has been reduced from 150μm to 2μm after subjected to ball milling process This shows that upon ball milling procedure, the size of dolomite (PDF) Size Reduction of Dolomite into NanoSize Range through Milling Therefore the moisture content affects and controls the productivity and performance of the raw milling process, Basalt(clay and shale) provides Al 2 o 3, Fe 2 o 3 and sio 2; DMC consume *Limestone (8991%) * Basalt (8%) Basic bricks have magnesia or dolomite as their major component and a secondary mineral such as alumina, zircon, Cement Manufacturing Process INFINITY FOR CEMENT EQUIPMENT2020年1月21日 For example, in basalt fiber melting, the melting point and viscosity of the melt are reduced by adding dolomite to the burden In analyzing the influence of new fluxing additives on the hightemperature reaction with the chromite components, use was made of the mathematical model of the CaO MgO Al 2 O 3 SiO 2 Fe 2 O 3 FeO equilibrium diagram [ Using Basalt Rocks for Agglomeration of Refractory Chromite

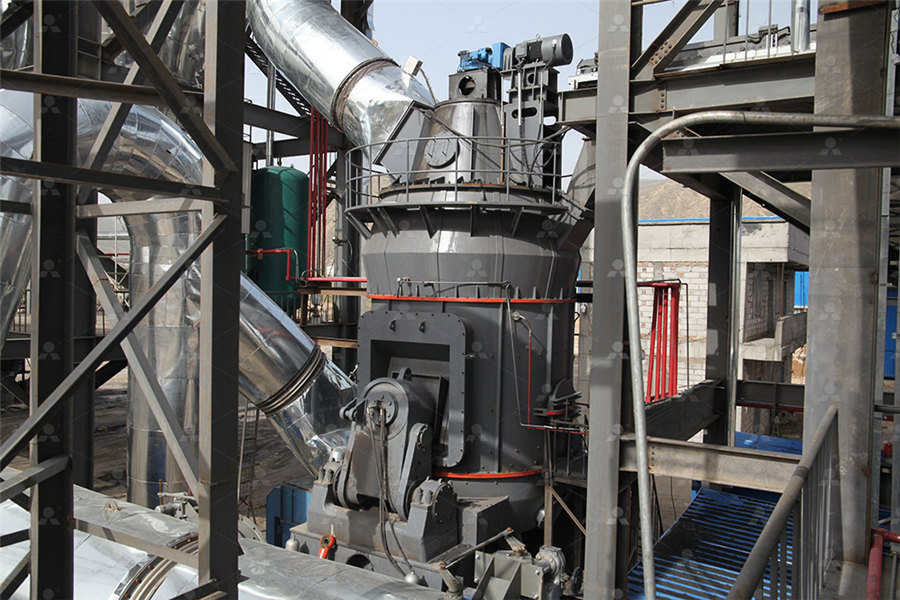

Industrial Milling Shanghai Zenith Company

Zenith provides kinds of grinding mills, including raymond mill, pendulum roller mill, vertical roller mill and ultrafine grinding mill, which can be used for limestone, coal, calcite, dolomite Industrial Milling Shanghai Zenith CompanyProcessed products such as dolomite blocks, dolomite powder, magnesium alloys, and cement are widely used in various industries Specifically, these applications span construction, steel, glass, ceramics, agriculture, and more Dolomite processing process includes two primary steps: crushing and screening, followed by grinding and classificationWhat is the dolomite processing process Grinding Accent the look of your home with this 8 x 8 square Basalt Honed Dolomite Tile The black color gives a nice touch to any room A satinsmooth finish with a natural look, honed finish tiles are a perfect fit for any room This square Basalt and Dolomite 8x8 Honed Tile Floor Decor2023年1月13日 In order to meet the requirements of different fields on the fineness of dolomite, Zenith develop various types of equipment, mainly including European coarse grinding mill for producing 640mesh dolomite powder, fine grinding mill (LM vertical roller mill, MTW European grinding mill, MTM medium speed trapezium mill) for producing 80400mesh dolomite powder How to Process Dolomite: Dolomite Crushing And Grinding Plant

.jpg)

Dolomite – Its Processing and Application in Iron and IspatGuru

2017年6月28日 Several different types of kilns are used for the calcination process These kilns can be rotary kilns or shaft kilns The type of the kiln to be selected strongly depend on the characteristics of the raw dolomite, anticipated production rate, cost of fuel, investment costs, available fuel, local conditions, infrastructure and other thingsMineral carbonation is considered to be the most stable mechanism for the sequestration of CO2 This study comprises a comparative review of the effect of ball milling on the CO2 uptake of ultramafic/mafic lithologies, which are the most promising rocks for the mineralization of CO2 Samples of dunite, pyroxenite, olivine basalt and of a dolerite quarry waste material were Ball Milling Effect on the CO2 Uptake of Mafic and Ultramafic2021年2月1日 Photomicrographs showing the batch melting and hot end fabrication process of wool boards (a, b) The raw basalt and dolomite in the storage yard; (c) The charging of raw mix basalt and dolomite into the Cupola; (d) The basalt cinder pouring out of the “siphon” exit; (e) The collection of cinder sample by a cinder spoon; (f) The cinder Optimization of microstructure of basaltbased fibers intended 2024年7月30日 Main purpose of milling process for fiber reinforced plastic is to shape and surface finish 10 The cases where composite parts are manufactured nearnet shape, meaning that the optimum parameters for climb milling of S2GFRP evidently aligns well with the conventional milling of its basalt counterpart, and vice versaExperimental and statistical damage analysis in milling of S2‐glass

Mineral Carbonation in Ultramafic and Basaltic Rocks

2016年5月12日 For our discussion, ultramafic rocks refer to peridotite, serpentinized peridotite, and serpentinite Peridotite broadly describes a group of dense, intrusive igneous rocks whose mineral assemblage is dominated by olivine and pyroxene (Sect 3)When peridotite rocks are in contact with water, they become partially (serpentinized peridotite) and wholly hydrated After ball milling, the dunite showed the highest enhancement of CO2 uptake (2781 µmol g−−1 μ after 12 h of milling with 50 wt% ethanol), followed by the olivine basalt (2221 µmol g−−1 after 4 h of μ − 1 − milling with 50 wt% ethanol), the pyroxenite (1556 µmol g after 4 h of milling with 50 wt% ethanol) μ and the dolerite waste material (969 µmol g−− 1 after 20 h of (PDF) Ball Milling Effect on the CO2 Uptake of Mafic and Create a new look for your home with this 11 x 11 diamond Giza Basalt Dolomite Geo Mosaic in black A satinsmooth finish with a natural look, honed finish tiles are a perfect fit for any room This diamondshaped stone decorative creates sharp lines and a unique designGiza Basalt Dolomite Geo Mosaic Floor and DecorProcess Optimisation for UD Basalt Fibre PC Composites Regarding UD composite preparation using compression moulding, significant fibre movements occurred when high temperature or pressure were applied, but poor composite quality resulting from insufficient consolidation was obtained if low processing pressure and temperature were usedProcessing and Mechanical Properties of Basalt FibreReinforced

Dolomite Sand Making Plant And Grinding Machine

2023年10月27日 Step 1: Turn Large stones into small stones Transport the bulk dolomite raw material into the jaw crusher by the vibrating feeder for the coarse crushing process, and then send it to the cone crusher for medium to fine 2023年4月23日 Basalt has a number of unique properties that make it useful for various applications For example, it is known for its durability, strength, and resistance to wear and erosion, making it ideal for construction materials such Basalt Properties, Formation, Composition, Uses2021年11月23日 Dolomite is a carbonate mineral, Raymond mill is often used to process materials with Mohs hardness below 93 and humidity below 6% The output of ball milling is more than 1600 tons, and the fineness of finished products is about 20200 mesh Product What Kind of Mill is Used to Grind Dolomite?2019年1月19日 Other stones that provide smaller volumes of crushed stone include basalt, dolomite, granite, marble, rhyolite, sandstone, and serpentine Mining of native sulfur deposits is accomplished by the Frasch process, which uses superheated water to melt the sulfur so that it can be pumped to the surfaceMineral Resources and Mining TSHA

.jpg)

Dolomite vs Basalt Compare Nature

The uses of Dolomite in construction industry include As a flux in the production of steel and pig iron, As a sintering agent in steel industry to process iron ore, As dimension stone, Cement manufacture, For road aggregate, Making natural cement, Manufacture of magnesium and dolomite refractories, Production of glass and ceramics, Serves as an oil and gas reservoir 2021年2月17日 Basalts from Çorlu Karatepe and dolomite from Kırklareli subjected to freezethawing (FT) cycles were studied, and the resulting changes were analyzed The unweathered rocks and those subjected to 50 FT cycles after every 10 cycles were tested for the water absorption by weight and volume, Pwave velocity, uniaxial compression strength, point load Effects of freezethawing cycles on the physical and mechanical For the process of making short basalt fibers by ballmilling,the process parameters were optimized by an orthogonal test,and the mechanism of fiber breakage was studiedThe test results have shown that the direct strike of big balls to the fibers,the shear between the balls and fibers,and the strike and scratch of small balls to the fibers are main factors causing fiber Optimization of Process Parameters for Making Short Basalt Rockwool fibers were synthesized at high temperatures using raw materials like basalt, diabase, limestone, and dolomite, which are combined and fed into a furnace where the melt is prepared and Manufacturing process of mineral wool ResearchGate

chinamineline

Road Railway Use Basalt Crushing Plant; Powder Milling Process; Magnetic Separating Process; Flotation Separating Process; mill machines and rotary kiln can process the materials after beneficiation to building materials such as: pebble, calcite, granite, quartz, concrete, dolomite, basalt, iron ore, limestone, 2015年3月1日 DOI: 101016/JPOWTEC201412046 Corpus ID: ; Carbon dioxide storage in olivine basalts: Effect of ball milling process @article{Rigopoulos2015CarbonDS, title={Carbon dioxide storage in olivine basalts: Effect of ball milling process}, author={Ioannis Rigopoulos and Klito C Petallidou and Michalis A Vasiliades and Andreas Delimitis and Carbon dioxide storage in olivine basalts: Effect of ball milling process2015年3月31日 The ball milling process was (magnesite, siderite, dolomite, and also observed a large increase in specific surface area and porosity for olivinerich basalt particles by wet ball millingCarbon dioxide storage in olivine basalts: Effect of ball milling processDolomite is a sedimentary rock containing more than 50 percent of the mineral dolomite by weight These rocks are composed of many distinct minerals The process of formation of rocks is different for various rocks Rocks are quarried from many years for various purposes You can check out Basalt vs Dolomite information and Basalt vs Dolomite Basalt vs Dolomite Compare Nature

(PDF) Ball Milling Effect on the CO2 Uptake of Mafic and Ultramafic

2018年11月7日 Adsorbed CO2 (μmol g −1 ) versus ball milling time (h) for the unmilled and ballmilled dunite, pyroxenite, basalt and dolerite samples (data from Rigopoulos et al [19,25,32,33])2021年2月19日 The milling process factors influencing the particle size include grinding time, milling speed, the size of the balls and balls to powder weight ratio So far many studies have concentrated on the synthesis of ultrafine silica sand production, however not on the process parameters optimization study [ 10 ]Comparative Study on Improving the Ball Mill Process Parameters 2023年3月13日 This is because the trapping process is not, The average particle sizes for granite and basalt after milling were 159 µm M Thermal behavior of natural dolomite J Therm Anal Mechanochemical processing of silicate rocks to trap CO 2 Nature2022年11月30日 Results indicate that the particle size of dolomite has been reduced from 150μm to 2μm after subjected to ball milling process This shows that upon ball milling procedure, the size of dolomite (PDF) Size Reduction of Dolomite into NanoSize Range through Milling

Cement Manufacturing Process INFINITY FOR CEMENT EQUIPMENT

Therefore the moisture content affects and controls the productivity and performance of the raw milling process, Basalt(clay and shale) provides Al 2 o 3, Fe 2 o 3 and sio 2; DMC consume *Limestone (8991%) * Basalt (8%) Basic bricks have magnesia or dolomite as their major component and a secondary mineral such as alumina, zircon, 2020年1月21日 For example, in basalt fiber melting, the melting point and viscosity of the melt are reduced by adding dolomite to the burden In analyzing the influence of new fluxing additives on the hightemperature reaction with the chromite components, use was made of the mathematical model of the CaO MgO Al 2 O 3 SiO 2 Fe 2 O 3 FeO equilibrium diagram [ Using Basalt Rocks for Agglomeration of Refractory Chromite Zenith provides kinds of grinding mills, including raymond mill, pendulum roller mill, vertical roller mill and ultrafine grinding mill, which can be used for limestone, coal, calcite, dolomite Industrial Milling Shanghai Zenith CompanyIndustrial Milling Shanghai Zenith Company