Magnesium ore crushing equipment

Magnesite flotation process and equipment LZZG

2024年10月25日 The main beneficiation equipment used in the separation stage of the magnesium ore beneficiation process is flotation machine, mixer, and concentrator The use of a single reverse flotation process cannot effectively 2023年5月12日 1 Crushing: Use a jaw crusher, roll crusher, and vibrating screen to form a twostageclosed circuit crushing system to crush the raw magnesite ore to 1mm 2 Calcination: Send the raw ore into a rotary kiln for calcination at a Magnesite Ore Processing: Separation and 2021年10月29日 Jaw Crusher – Coarse Crushing Jaw crushers are widely used as crushing equipment in the magnesite grinding production line It is mainly used for the primary crushing operation of the raw material magnesite so that the Magnesite Grinding Equipment Production LineCrushing: raw ore (less than 200mm) go through the two stages one close circuit process, which include jaw crusher and vibrating screen And then broken to 10~0mm In this stage, the main equipment is floatation, agitation tank, Magnesite (magnesium) Flotation Process

.jpg)

What You Need to Know About the Magnesite Flotation

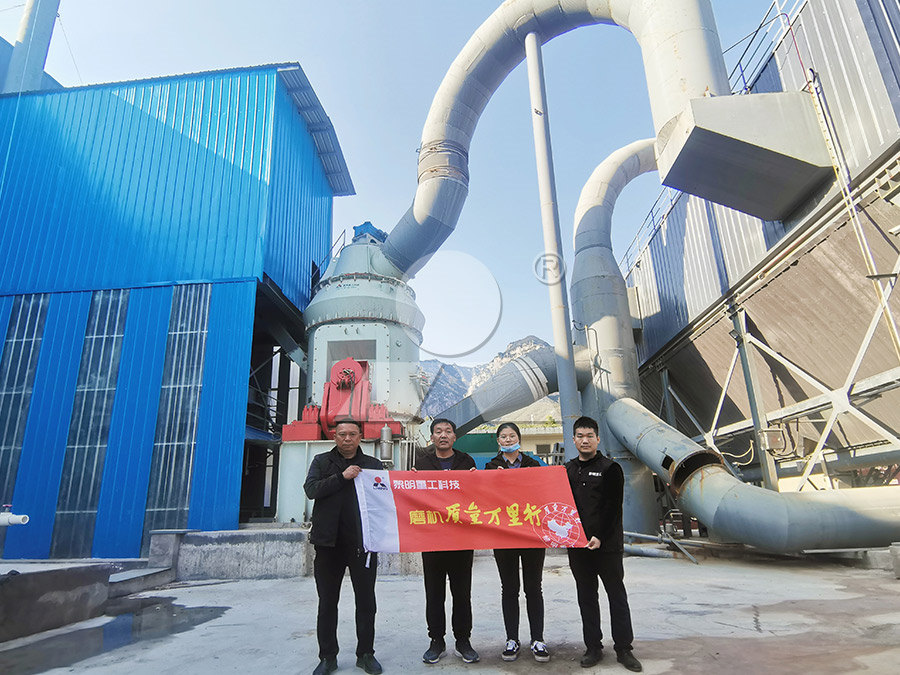

5 天之前 The main mineral processing equipment used in the separation stage of flotation process is flotation machine, mixing tank, and thickener The use of a single reverse flotation Chang Lei Cobble Stone crusher to fight some limestone in silicon containing large amount of rock, high crushing efficiency, strong wear resistance Easy maintenance, convenient for small [Hot Item] Grateful Magnesium Ore Crushing Machine in Peru2024年6月1日 As highgrade magnesite and brucite resources (hereinafter referred to as magnesiumcontaining minerals) are decreasing annually, developing flotation separation Research advancement of efficient flotation separation 2021年7月16日 Project name:Mg Smelting Plant with capacity of 10000tpa Project kick off:End of 2006 Contact with ZK Corp begins from: Oct 2009 EP Contract signed in: Jul Magnesium project for POSCO, Korea China Henan

How to choose magnesium ore ball mill? The

2023年8月2日 When choosing a magnesium ore ball mill, there are several factors to consider: Beneficiation Test: Conduct a beneficiation test on the raw magnesite ore to determine its hardness and physicochemical properties This Stedman impact crushers, mills, and grinders are used in nearly every mineral, ore, and mining application Whether you are processing iron ore, coal, rock, salt, wood chips, or clay – to name a few – we have your solution to size reduction Industrial Ore, Mineral, Slag Crusher Mineral 6 天之前 Applicable materials: Gold ore, iron ore, copper ore, molybdenum ore, leadzinc ore, aluminum ore, magnesium ore, and other metal ores Advantages: High output, uniform particle size, durable high manganese steel hammer and Stone Crushing Equipment Fote MachineryOre crushing and screening, grinding and classification are essential preparatory work before separation to get proper ore size Metalcess is the expert for ore test, process design and engineering and equipment selection and supplyOre Crushing and GrindingOre Beneficiation

Transformation of abundant magnesium silicate minerals for

2021年2月4日 Magnesium hydroxide is a sustainable material for CO2 sequestration, according to an acid digestion and electrolysis method using olivinerich silicate rocks in a fully recoverable systemStedman impact crushers, mills, and grinders are used in nearly every mineral, ore, and mining applicationWhether you are processing iron ore, coal, rock, salt, wood chips, or clay – to name a few – we have your solution to size reduction with our mineral crushing machines industrial ore slag crushersIndustrial Ore, Mineral, Slag Crusher Mineral Crushing 2021年2月20日 From ore crushing, grinding, ball pressing, reduction, to metal magnesium refining and casting ingots, the entire production line is fully continuous and automated Figure 1 of the industrial continuous production equipment for metallic magnesium provided in this article includes a feeding device 1, a reduction chamber 17, a crystallizer 21 Industrial Practice of Extracting Magnesium from Serpentine2023年8月7日 Manganese is a type of common metal mineral in nature More than 150 types of manganese minerals have been discovered so far, but only a small portion of manganese ore with mining and utilization value, mainly including pyrolusite, psilomelane, bog manganese ore, etc Manganese has become an essential strategic mineral resource among countries and apply in Five Common Types Of Manganese Ore Processing Solutions

Selecting the right type of crushing equipment Quarry

2016年4月7日 Most aggregate producers are well acquainted with the selection of crushing equipment, and know it is possible to select a piece of equipment based solely on spec sheets and gradation calculations However, theoretical conclusions must always be weighed against practical experience of the material at hand and of the operation, maintenance and economical 2024年9月25日 XKJ GROUP Ore crushing, jaw crusher, compound crusher, cone crusher, crushing station, mobile crushing station、Equipment Manufacturer Welcome to XKJ GROUP! Provide you with professional ore crushing solutions sales01@xkjgroup Tel Honor XKJ GROUP Ore crushing, jaw crusher, compound crusher 2023年2月15日 The raw nickel ore is always companied by clay and impurities The washing ore process can remove clay and impurities before crushing and beneficiation operations, which improves operating efficiency and helps to obtain highgrade nickel concentrate The ore washing equipment used in laterite ore mainly is a coarse and fine material screw washerThe Best Mining Equipment for Philippines Nickel Ore You The crushing system is the core system of the entire metal ore production line As the key equipment of the crushing system, the crusher plays an extremely important role in the product quality and stable operation of the entire production line Magnesium Ore Lead zinc Ore Chromite Magnetite Project Site Visit Guizhou Copper Ore Metal OreMining Equipment Manufacturer Vipeak Mining

Crushing and Grinding Equipment Common

2023年4月26日 The wearing parts of the jaw crusher mainly include movable jaws, tooth plates, eccentric shafts, and bearings The wear of the cone crusher is mainly the wear of the frame and the spherical bearing, the wear of the main Gold ore crushing equipment often consists of a pair of vertical jaws—one fixed and one movable—that exert immense pressure on the rock As the movable jaw moves towards the fixed jaw, the goldbearing ore is squeezed between them Gold Ore Crusher Montana Gold Outfitter2024年8月22日 Calcining Equipment Grinding Equipment Drying Equipment Conveying Equipment Dust Collecting Equipment Crushing Equipment Granulating equipment Screening Equipment Feeding Equipment Other Equipment Cement Projects Active Lime Project Magnesium Project Oil Fracturing Proppant Projec LECA Project GGBS Project Ore Dressing Crushing Equipment zkeqpt2023年3月13日 Then the crushed materials are sent to the grinding equipment, and the final particle size of the copper ore is reduced to 01502mm Copper ore crushing process 1 Beneficiation methods of copper sulfide ore Copper sulfide can be divided into single copper ore, copper sulfur ore, coppermolybdenum deposit, copper nickel, carrollite and so onHow to Process Copper Ore: Beneficiation Methods and Equipment

Magnesium Crusher Cones Crusher Mills, Cone Crusher, Jaw

Magnesium mining equipment contain magnesium ore crusher , Mobile Impact Crushers/Mobile Concrete Crusher from SHANGHAI SHANGHAI MG Heavy Euqipment Co,Ltd Address: No33 Shenxia Road, Malu Industrial Park, The main factory is located at Kumbet and consists of 2 shaft 1 rotary kilns with a combined calcination capacity of >36,000 tpa of CCM, post processing facilities (ie crushing, screening, magnetic separation, mixing, milling, packing, storage, forwarding), offices, laboratory quality control, earthmoving equipment maintenance workshopCorporate Calcined Magnesite Production, CCM, Magnesium 2 天之前 DOVE Equipment and Machinery with over 50 years manufacturing expertise, and the largest range of mining and minerals processing technologies is the recipient of ISO 9001: Ore feeding, Crushing (Coarse and Fine), Grinding (or milling), Sizing (screening and classification) and Concentration (separation and recovery) are the three most Hard Rock Mining Equipment Crushing Plants DOVE2024年8月7日 Types of Mineral Processing Equipment Crushing Equipment: Essential in mineral processing, crushing breaks down large ore blocks into smaller, manageable pieces for further processing Primary crushing is the reduction of significant ore particles into smaller bits using jaw crushers Key types include Jaw Crushers, which handle large rocks Mineral Processing Equipment for Mining Industry

Crushing and Grinding of Magnesite Mineral CM Mining

2024年2月19日 Magnesite is a mineral that is composed of magnesium carbonate It is a common mineral in the Earth’s crust and is found in sedimentary rocks, such as limestone and dolomite The common iron ore mining equipment are jaw crusher, cone crusher, hammer crusher, ball mill, fine grinding, etc Often workers prefer to choose a metallurgical 2023年3月15日 Serpentine is a general term for hydrous magnesiumrich silicate minerals, such as antigorite, lizardite, and chrysotile Their color is generally green, but also light gray, white or yellow SBM micropowder technology specializes in the production of industrial ore crushing and grinding equipment, various production line auxiliary Serpentine crushing and grinding processing production line 2024年2月18日 The first stage is primary crushing, which is done to reduce the size of the ore particles from a maximum size of 200 mm to a size of 1025 mm The second stage is secondary crushing, which is done to reduce the size of Crushing and grinding of magnesite mineral2021年9月10日 High energy consumption in ore crushing brings great challenges to the mining industry Microwave irradiation provides a promising solution for rock breaking However, there is currently a lack of detailed Study on Magnetite Ore Crushing Assisted by

.jpg)

Bentonite Processing Methods And Required

5 天之前 Dry beneficiation is generally used to process bentonite with better raw ore quality, or bentoniterich ore with montmorillonite content of more than 80%This method is to dry the raw ore in the sun, air dry it naturally or dry it in 2024年10月25日 The main beneficiation equipment used in the separation stage of the magnesium ore beneficiation process is flotation machine, mixer, and concentrator The use of a single reverse flotation process cannot effectively remove impurities from the ore, and the magnesium oxide content of the selected magnesium concentrate is still as high as 035%Magnesite flotation process and equipment LZZG2024年10月14日 Remark: For conversion from millimeter to mesh, please refer to mm to mesh Process 3: Calcinating dolomite rock The crushed dolomite is calcined in a rotary kiln, which is used for producing refractory materials, magnesium alloys, cement, etc Dolomite is calcined at 1500°C to obtain magnesiacalcium raw materials, such as dolomite sand, magnesiacalcium How to Process Dolomite Rock and What Is It Used for?2024年7月17日 Crushing is a multistage process that includes primary crushing, secondary crushing, and tertiary crushing Different types of crushing equipment are used at each stage to meet various crushing requirements Primary crushing breaks down large raw materials into mediumsized pieces for easier handling in subsequent processesTypes of Crushers: Choosing the Right One for Each Stage

.jpg)

Stone Crushers, Jaw Crusher, Hammer Crusher, Impact

2022年7月13日 Zhengzhou Turui Machinery Equipments Co, Ltd is a professional manufacturer of design, research, production, sales and installation for the integrated enterprise Our four product series include: Ore Beneficiation Equipment, Building Materials Equipment, Crushing Screening Equipment, Conveying Lifting EquipmentElectrorefining of magnesium uses magnesium chloride from magnesite or carnallite to produce high purity magnesium ingot In fused salt electrolysis, electrorefining of magnesium chloride generates chlorine, which can be used for Titanium production where TiO 2 is chloridized to TiCl 4 and then reduced to sponge Titanium when MgCl 2 returns Extraction of Magnesium Metalcess2024年10月7日 Welcome to Mechtech Inframine! Since 1987, we’ve been at the forefront of crushing and screening equipment innovation, providing highquality solutions for diverse industries we specialize in providing solutions for the crushing of coal, iron ore, limestone, and stone aggregates—essential materials for infrastructure projects such as Mechtech Inframine Home of Superior Crushing and Screening Equipment2024年4月8日 A jaw crusher is an essential crushing equipment in a lithium processing plant It has strong adaptability and is not affected by the hardness, humidity, structure, and other characteristics of the original ore during the crushing process Suggestion for selecting lithium ore sorting equipment Lithium ore sorting, also known as lithium ore Selection Of Lithium Ore Processing Plant Equipment

Stone Crushing Equipment Fote Machinery

6 天之前 Applicable materials: Gold ore, iron ore, copper ore, molybdenum ore, leadzinc ore, aluminum ore, magnesium ore, and other metal ores Advantages: High output, uniform particle size, durable high manganese steel hammer and Ore crushing and screening, grinding and classification are essential preparatory work before separation to get proper ore size Metalcess is the expert for ore test, process design and engineering and equipment selection and supplyOre Crushing and GrindingOre Beneficiation2021年2月4日 Magnesium hydroxide is a sustainable material for CO2 sequestration, according to an acid digestion and electrolysis method using olivinerich silicate rocks in a fully recoverable systemTransformation of abundant magnesium silicate minerals for Stedman impact crushers, mills, and grinders are used in nearly every mineral, ore, and mining applicationWhether you are processing iron ore, coal, rock, salt, wood chips, or clay – to name a few – we have your solution to size reduction with our mineral crushing machines industrial ore slag crushersIndustrial Ore, Mineral, Slag Crusher Mineral Crushing

.jpg)

Industrial Practice of Extracting Magnesium from Serpentine

2021年2月20日 From ore crushing, grinding, ball pressing, reduction, to metal magnesium refining and casting ingots, the entire production line is fully continuous and automated Figure 1 of the industrial continuous production equipment for metallic magnesium provided in this article includes a feeding device 1, a reduction chamber 17, a crystallizer 21 2023年8月7日 Manganese is a type of common metal mineral in nature More than 150 types of manganese minerals have been discovered so far, but only a small portion of manganese ore with mining and utilization value, mainly including pyrolusite, psilomelane, bog manganese ore, etc Manganese has become an essential strategic mineral resource among countries and apply in Five Common Types Of Manganese Ore Processing Solutions2016年4月7日 Most aggregate producers are well acquainted with the selection of crushing equipment, and know it is possible to select a piece of equipment based solely on spec sheets and gradation calculations However, theoretical conclusions must always be weighed against practical experience of the material at hand and of the operation, maintenance and economical Selecting the right type of crushing equipment Quarry2024年9月25日 XKJ GROUP Ore crushing, jaw crusher, compound crusher, cone crusher, crushing station, mobile crushing station、Equipment Manufacturer Welcome to XKJ GROUP! Provide you with professional ore crushing solutions sales01@xkjgroup Tel Honor XKJ GROUP Ore crushing, jaw crusher, compound crusher

.jpg)

The Best Mining Equipment for Philippines Nickel Ore You

2023年2月15日 The raw nickel ore is always companied by clay and impurities The washing ore process can remove clay and impurities before crushing and beneficiation operations, which improves operating efficiency and helps to obtain highgrade nickel concentrate The ore washing equipment used in laterite ore mainly is a coarse and fine material screw washerThe crushing system is the core system of the entire metal ore production line As the key equipment of the crushing system, the crusher plays an extremely important role in the product quality and stable operation of the entire production line Magnesium Ore Lead zinc Ore Chromite Magnetite Project Site Visit Guizhou Copper Ore Metal OreMining Equipment Manufacturer Vipeak Mining