Slag production line Slag production line Slag production line

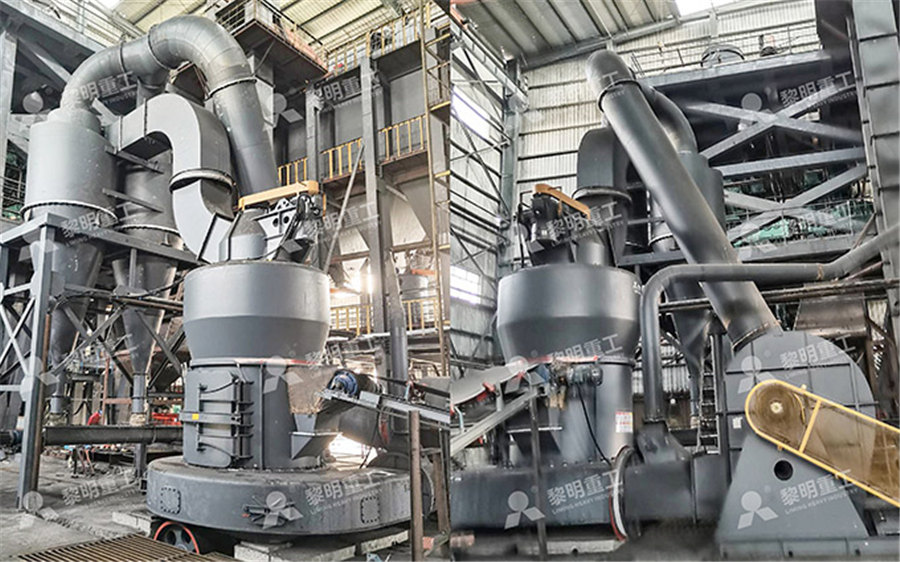

GGBS Production Line Slag Mill for Slag Powder

We can provide a variety of mill systems suitable for granulated ground blastfurnace slag (GGBS) grinding, including open circuit and closed circuit systems with ball mill as the core equipment, vertical roller mill (VRM) systems, and After the research of Xinxiang Great Wall Machinery Industry Waste Residue Powder Research Center, CHAENG can provide 200,0001,500,000t/a nickel slag production line project nickel slag production line CHAENGThe slag grinding production line is a production system specially used to process slag and make slag powder Slag, as a byproduct in the industrial production process, can be converted into Slag Grinding Production Line TAYMACHINERY2021年12月5日 The copper slag recovery production line is mainly used to extract copper metal from copper smelting slag It is suitable for various copper smelting slags It has high extraction efficiency, high effect, and low cost for Copper Slag Processing Production Line Flow Henan

Steel Slag Grinding Plant CHAENG

Steel slag below 5mm enters the grinding system and is ground by the GRMSS series steel slag vertical roller mill The produced steel slag powder has a specific surface area of 400500 2023年11月15日 Waste heat recovery from hot steel slag was determined in a granular bed through the combination of numerical simulation and an industrial test method First, the Waste heat recovery from hot steel slag on the production line Superfine slag powder production line is used to crush non flammable materials of which Mohs hardness is no more than seven degree and water content is less than 6% Except for the Superfine Slag Powder Production Line FTM Machinery2021年10月5日 Slag is a complex coproduct engineered by adding flux materials to extract impurities from molten iron and steel during manufacturing (Ilyushechkin et al, 2012, Yang et Production, characterisation, utilisation, and beneficial soil

Waste heat recovery from hot steel slag on the

2023年4月21日 Waste heat recovery from hot steel slag was determined in a granular bed through the combination of numerical simulation and an industrial test method First, the effective thermal conductivity2023年11月15日 Waste heat recovery from hot steel slag was determined in a granular bed through the combination of numerical simulation and an industrial test method First, the Waste heat recovery from hot steel slag on the production line AGICO CEMENT provides turnkey solution for blast furnace slag cement manufacturing, various types of cement are avaliable Get A FREE Qote! Skip to content +86 s about blog contact EN Slag Cement Production Line Blast Furnace Slag 2013年5月1日 Download Citation Study on Clinker Production Using Magnesium Slag on a 4500tpd Line Magnesium slag was used to produce cement clinker replacing part of limestone and sandstone with 11% contentStudy on Clinker Production Using Magnesium Slag on a 4500tpd Line

GGBS Production Line Slag Mill for Slag Powder

Product Name: GGBS Production Line / Slag Mill Capacity: 36100 Million Tons Annually Grinding Systems: These include the VRM (Vertical Roller Mill) system, the Ball Mill open circuit system, the Ball Mill closed circuit system, and the Waste heat recovery from hot steel slag on the production line: Numerical simulation, validation and industrial test Tianhua Zhang1,2), Longheng Xiao1), Guibo Qiu2), Huigang Wang2), , Min Guo1), Xiangtao Huo1), and Mei Zhang1), 1) State Key Laboratory of Advanced Metallurgy, School of Metallurgical and Ecological Engineering, University of Science and Technology Waste heat recovery from hot steel slag on the production line The dryprocess steel slag production process does not need to consume precious water resources After the steel slag is crushed, rod milled, and magnetically separated, the slag steel can be selfgrinding to obtain grade A and B scrap steel The iron content of the slag powder can reach more than 55%Steel slag recycling crushing and grinding production line2023年11月15日 Download Citation Waste heat recovery from hot steel slag on the production line: Numerical simulation, validation and industrial test Waste heat recovery from hot steel slag was determined in Waste heat recovery from hot steel slag on the production line

Waste heat recovery from hot steel slag on the production line

2023年1月18日 Waste heat recovery from hot steel slag was determined in a granular bed through the combination of numerical simulation and an industrial test method First, the effective thermal conductivity of the granular bed was calculated Then, the unsteadystate model was used to simulate the heat recovery under three different flow fields (Otype, Stype, and ensure foaming slag conditions, which increases energy efficiency of the EAF Due to the slag composition fluctuations, the slag foaming is sometimes hindered when the slag composition drifts to the composition area with low foamability Additionally due to changes in scrap melting, the timing of the carbon injection is hard to defineOnline slag composition analysis for electric arc furnaces2021年9月17日 The entire production line has completed the complete recycling of steel slag, which not only achieved profitability but also played a positive role in protecting the environment Therefore, the recycling and utilization of steel slag are strongly supported by the state1 Brief Introduction of Steel Slag Production Line2011年6月1日 PDF Electric arc furnace (EAF) steel slag, generated from carbon steel production process, is the most interesting from the asphalt technology point In line with the said, and (PDF) Defining of EAF steel slag application ResearchGate

Steel Slag Production Line Senya Crushers Solution

Steel slag crushing production line adopts jaw crusher for primary crushing, and uses hydraulic cone crusher for secondary and tertiary crushing, offering high crushing efficiency, low wear, energy saving and environmental protection, it has the features of high automation, 2018年4月20日 This work aims to develop another approach to the management of magnesium slag (MS) via the production of Portland cement clinker Thus, 0, 10, 20, 30, 40 and 50% limestone was replaced by MS and the clinker was sintered The burnability of the clinker, immobilization of heavy metals in the clinker, crystalline phases, micrograph of the clinker, the Approach to the management of magnesium slag via the production Nickel slag, manganese slag, vanadium and titanium slag, etc are industrial waste slags produced in the smelting process of nickeliron ore, vanadium and titanium ore, etc The stock is huge and the comprehensive utilization rate is Nickel Slag Production Line Zoomjo GroupAccueil Toutes Les Industries Machinerie Machines Métaux Et Métallurgie Four IndustrielLigne de production de titane Slag Sidebar Galerie La description; Commentaires Product Gallery faa9afea49ef Four Industriel Machinerie Machines Métaux Et Métallurgie Toutes Les IndustriesLigne de production de titane Slag – Procurement of exclusive

.jpg)

Application of Steel Slag as an Aggregate in Concrete Production

2023年8月25日 Steel slag is a solid waste produced in crude steel smelting, and a typical management option is stockpiling in slag disposal yards Over the years, the massive production of steel slags and the continuous use of residue yards have led to vast occupation of land resources and caused severe environmental concerns Steel slag particles can potentially be furnace inline layout is illustrated in Figure 2 The unit shown illustrates a twoinline submerged arc furnace configuration, which had been sold to a Brazilian client for the production of FeNi With a power rating of 120 MVA and a hearth dimension of 364 m x 134 m, the smelters represents the world largest submerged arc furnaces ever builtRectangular furnace design and revolutionary DCslag cleaning 2023年11月23日 A statistical analysis by EUROSLAG 67 shows that only 6 % of steel slag is used for global cement production Utilizing steel slag as a replacement in cement production or as a replacement for cement used in the concrete industry could significantly reduce CO 2 emissions 6872 FigLadle Furnace Slag: Synthesis, Properties, and Applications2002年11月11日 The results indicate the possibility of using waste furnace slag for the production of interlocking pavers to promote an ecofriendly and sustainable pavement infrastructure in line with the UN (PDF) Slag Cement Production in Nigeria ResearchGate

.jpg)

Nickel slag production line/ Nickel slag grinding mill/ Nickel slag

2019年1月18日 Ten thousand tons of nickel slag production line project equipment 2, the role of nickel slag grinding mill The recycling of high nickel slag not only reduces resource waste and environmental pollution, but also produces considerable economic benefitsblast furnace with the burden Slag contains also desulphurization products, such as calcium and magnesium sulphide The slag composition can be represented by the CaO – MgO – SiO 2 – Al 2 O 3 quaternary system at 10 to 15% Al 2 O 3 [1] Phase composition of blastfurnace slag consists of melilith (akermanite – 2CaO SiO 2 2MgO and SLAG IN THE PRODUCTION OF WROUGHT IRON2022年2月6日 Phase development during slag formation and reduction of Comilog and Assmang ores in a setup that simulates the conditions in an industrial SAF process under different coke bed temperatures, 1473 Phase Distribution During Slag Formation in Mn Slag powder is widely used in construction field It can replace 1040% of cement when configuring concrete The strength of concrete can reach above C60, which can increase the life of concrete, increase its strength, and reduce project Slag powder production line,GGBS production

.jpg)

Stainless Steel Slag/Nickel Slag Processing Line Forui

Introduce Stainless Steel Slag Processing IMAG2258 The solution is designed according to the nature characteristics of nickeliron slag, using the concept of recovering coarse particles before fine particles, which avoids the damage to 2024年6月12日 1 INTRODUCTION Blast furnace slag (BFS) and steel slag (SS), as industrial solid wastes produced in the process of steelmaking, account for 80%–90% of the total smelting slag [] BFS accounts for about 30% of pig iron output, [] while SS accounts for 10%–15% of the crude steel output [] SS comprises various slags, including basic oxygen furnace slag (BOFS) Recycling of iron and steel slag for carbon reduction and low 2019年8月28日 These differences in AF formation are clear with the increase of slag concentration in raw mixes The gehlenite and mayenite is observed at 1200 °C in claycontaining mixes along with belite phase, which is not observed in slagcontaining samples The introduction of slag intensifies the formation of belite phase at early burning stagesUse of Slags in the Production of Portland Cement Clinker2008年5月1日 Microstructure of steel slag used (a) Entrapped metallic Fe and anhedral C 3 S with decomposition (200 × ) (b) Finger C 2 S and skeletal C 3 S due to slow cooling (500 × )Utilization of steel slag for Portland cement clinker production

.jpg)

Slag Properties in the Primary Production Process of MnFerroalloys

2021年11月1日 The thermodynamic and kinetic properties of the carbothermic reduction of MnO in the fivecomponent slag, MnOSiO 2 CaOMgOAl 2 O 3 , is critical in the production process of Mnferroalloysslag, steelmaking slag, and granulated blast furnace (GBF) slag The study showed that replacing cement with EAF oxidizing slag deferred the hydration reaction at early ages, without any significant troubles in setting time, strength or shrinkage development Zhang et al (2019) [9] has studied the consequence of microstructure, hydraSustainable Use of Steel Industry Slag (SIS) for Concrete ProductionThe offline slag robot is mainly used in the offline zinc pot of the GL coated slab production line 32 Core equipment of offline slagremoving robot The offline slagremoving robot consists of Application Research of Slagremoving Robot for Zinc pot on Hot 2019年10月1日 The offline slag robot is mainly used in the off line zinc pot of the GL coated slab production line 32 The galvanizing line slagremoving robot will hav e a broad space for development in Application Research of Slagremoving Robot for Zinc pot on

Slag Cement Production Line Blast Furnace Slag

AGICO CEMENT provides turnkey solution for blast furnace slag cement manufacturing, various types of cement are avaliable Get A FREE Qote! Skip to content +86 s about blog contact EN 2013年5月1日 Download Citation Study on Clinker Production Using Magnesium Slag on a 4500tpd Line Magnesium slag was used to produce cement clinker replacing part of limestone and sandstone with 11% contentStudy on Clinker Production Using Magnesium Slag on a 4500tpd LineProduct Name: GGBS Production Line / Slag Mill Capacity: 36100 Million Tons Annually Grinding Systems: These include the VRM (Vertical Roller Mill) system, the Ball Mill open circuit system, the Ball Mill closed circuit system, and the GGBS Production Line Slag Mill for Slag Powder Waste heat recovery from hot steel slag on the production line: Numerical simulation, validation and industrial test Tianhua Zhang1,2), Longheng Xiao1), Guibo Qiu2), Huigang Wang2), , Min Guo1), Xiangtao Huo1), and Mei Zhang1), 1) State Key Laboratory of Advanced Metallurgy, School of Metallurgical and Ecological Engineering, University of Science and Technology Waste heat recovery from hot steel slag on the production line

Steel slag recycling crushing and grinding production line

The dryprocess steel slag production process does not need to consume precious water resources After the steel slag is crushed, rod milled, and magnetically separated, the slag steel can be selfgrinding to obtain grade A and B scrap steel The iron content of the slag powder can reach more than 55%2023年11月15日 Download Citation Waste heat recovery from hot steel slag on the production line: Numerical simulation, validation and industrial test Waste heat recovery from hot steel slag was determined in Waste heat recovery from hot steel slag on the production line 2023年1月18日 Waste heat recovery from hot steel slag was determined in a granular bed through the combination of numerical simulation and an industrial test method First, the effective thermal conductivity of the granular bed was calculated Then, the unsteadystate model was used to simulate the heat recovery under three different flow fields (Otype, Stype, and Waste heat recovery from hot steel slag on the production line ensure foaming slag conditions, which increases energy efficiency of the EAF Due to the slag composition fluctuations, the slag foaming is sometimes hindered when the slag composition drifts to the composition area with low foamability Additionally due to changes in scrap melting, the timing of the carbon injection is hard to defineOnline slag composition analysis for electric arc furnaces

1 Brief Introduction of Steel Slag Production Line

2021年9月17日 The entire production line has completed the complete recycling of steel slag, which not only achieved profitability but also played a positive role in protecting the environment Therefore, the recycling and utilization of steel slag are strongly supported by the state2011年6月1日 PDF Electric arc furnace (EAF) steel slag, generated from carbon steel production process, is the most interesting from the asphalt technology point In line with the said, and (PDF) Defining of EAF steel slag application ResearchGate