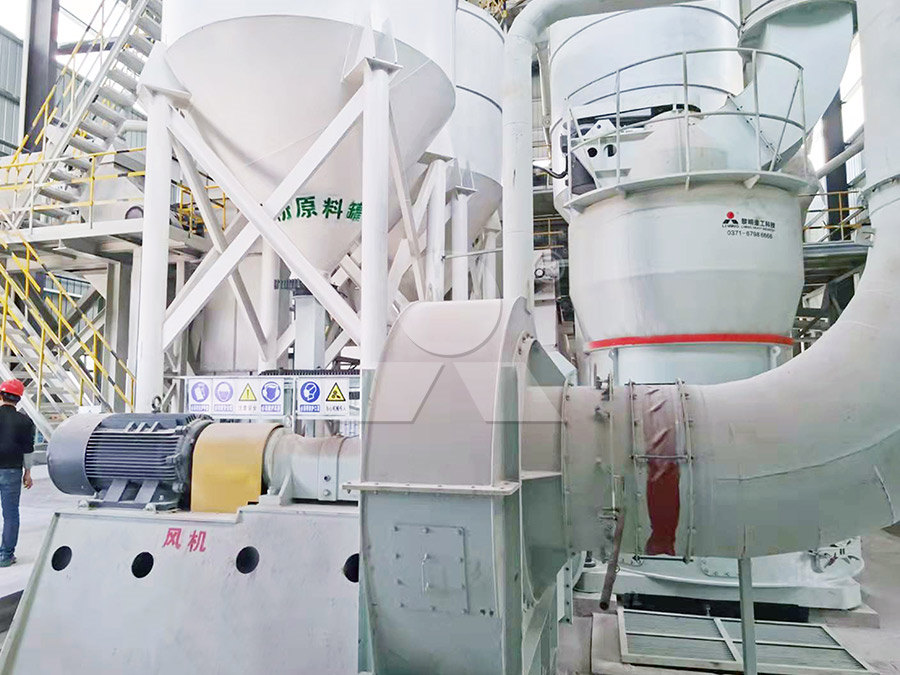

Ore grinding mill manufactured by Juxin

.jpg)

Xingyang Juxin Machinery Co, Ltd MadeinChina

China Juxin has formed a complete productionchain that takes crushers and ball mills as the main products and vibrating screen, vibratubg feeder, belt conveyor, etc As supplementary products2024年4月7日 Ball Mill Type: Ball mill; Max feeding size: 25mm; Capacity: ≥065t/h; Processing materials: cement,silicate product, new building materials, refractory materials, fertilizer, black, Ball Mill Juxin Machinery2024年11月11日 In this paper, based on the theory of the Bond ballmilling power index, Hou Ying (HY) wet ballmilling power index (W HY) test was carried out on Gongchangling Exploring the Link between HY Wet Ball Mill Work Index and Grinding 2023年7月20日 Ore grinding is a process to further reduce and disperse the ore particle size In the mineral processing industry, ore grinding is the particle size preparation before the Ore Grinding SpringerLink

Ball Mill Mining Grinding Mill JXSC Machinery

6 天之前 The ball mill is a tumbling mill that uses steel balls as grinding media Ball mills can be used in wet or dry systems for bulk and continuous milling, and are most widely used in small or largescale ore beneficiation plant Dry 2024年11月25日 We have supplied numberless of wet grinding rod mills for customer in coal chemical industry, to deal with the coal and petroleum coke material and prepare for the coal Ore Grinding MillSBM Industrial Technology Group5 天之前 The ball mill machine is known as a ball grinding machine It is a wellknown ore grinding machine and is widely used in mining, construction, and aggregate application JXSC started manufacture the ball mill grinder since Ball Mill JXSC MineralOur company is an importexport trade company specialized in the production, sales, installation of mineral equipment, environmental protection equipment and other ore grinding equipmentBall Mill Manufacturer, Mining Machinery, Mineral

Jxsc High Efficiency Gold Copper Ore Grinder Ball Mill Ball Mill

2024年11月25日 Jxsc High Efficiency Gold Copper Ore Grinder Ball Mill, Find Details and Price about Ball Mill Grinding Mill from Jxsc High Efficiency Gold Copper Ore Grinder Ball Mill 4 天之前 A wet grinding 4 x 10 center peripheral discharge rod mill used for producing fine aggregates Twelve 7 x 24 Compeb mills grinding cement clinker to a product of 1750 surface area, 90% passing a 200 mesh screen An 8 x 7 Grinding Mills 911Metallurgist2024年10月13日 Autogenous mills use the ore itself as the grinding media, while semiautogenous mills use a combination of ore and steel balls These mills operate by rotating a large drum filled with the ore, which impacts and grinds the particles against the mill walls Autogenous and semiautogenous mills are more energyefficient and are suitable for fine Understanding the operation of grinding mills in the mining 2024年10月13日 Effect of mill type on ore grinding performance Ball mills are widely used in the mining and metallurgical industries for the grinding of ores and other materials There are a wide variety of mill types available, each with its own advantages and disadvantages The performance of a ball mill can be affected by a number of factors, including the Factors affecting ores grinding performance in ball mills

How to choose a suitable ore powder grinding mill?

2023年10月17日 3 Ultrafine Powder Grinding Mill Ultrafine powder mill (threering / fourring mediumspeed micropowder mill) feed particle size ≤25 mm, production capacity 0545 t/h, production fineness 1503500 mesh,it is a highefficiency and lowconsumption ultrafine powder processing equipment that successfully replaces the traditional jet mill and complex process 2020年6月3日 The design of such grinding mills is extremely critical, requiring sophisticated software tools, proprietary calculation worksheets, and experienced technical engineers and drafters This blog will review how the mill design process has changed over the last 30 years While most of the changes have been positive, new issues and problems have risen in the How grinding mill design changed over the last 30 years3 天之前 Figure 1 : Grinding Power to produce various product sizes in a Ball Mill (9mm balls) and an Isa Mill (2 mm sand) (for KCGM pyrite concentrate) Chemistry Impacts The use of inert grinding media gives a crucial advantage to stirred milling in fine flotation and leaching applications Even if it were economic to grind to 10 microns in a steel Fine Grinding as Enabling Technology – The IsaMill2016年1月10日 HPGR in iron ore industry ThyssenKrupp HPGR mills have shown themselves good in iron ore industry The first HPGR was employed in iron ore mining industry in the 1990s in grinding iron concentrates for pelletizing That time the grinding rolls had smooth or ribbed wrought shells (lining) That technologyHIGH PRESSURE GRINDING ROLLS—A PROMISING AND

.jpg)

Copper ore grinding in a mobile vertical roller mill pilot plant

2015年3月10日 Within the scope of this study, the performance of VRM was compared with rodball mill circuit for copper ore grinding application The VRM tests were performed with mobile plant manufactured by Loesche GmbH and different operating modes 2018年12月24日 The amount of comminution or fineness of minerals in the mill can be described by various parameters, the most important of which is d80 (80% passing size)EVALUATION OF THE ALTERNATIVES FOR GOLD ORE GRINDING 2015年3月10日 DOI: 101016/JMINPRO201410002 Corpus ID: ; Copper ore grinding in a mobile vertical roller mill pilot plant @article{Altun2015CopperOG, title={Copper ore grinding in a mobile vertical roller mill pilot plant}, author={Deniz Altun and Carsten Gerold and Hakan Benzer and Okay Altun and Namık A Aydogan}, journal={International Journal of Copper ore grinding in a mobile vertical roller mill pilot plant2022年1月1日 The crushed ore then enters a grinding circuit consisting of six grinding mill lines Each line consists of a 122 m (40 ft) diameter × 11 m (36 ft) long AG mill with a 28 MW gearless motor in closed circuit with a pebble crusher and primary classifying minution and classification technologies of iron ore

.jpg)

Ore Grinding Mill zenithcrusher

2024年11月20日 Ball Mill The ball mill is the crucial equipment for conducting pulverizing operations after materials are crushed, widely employed for crushing and grinding various ores or other grindable materials In general, it is preferable to utilize an overflow ball mill for fine ore grinding fineness and a grate ball mill for coarse grindingMineral ore comminution is generally a feed preparation step for subsequent processing stages Grinding, the fine product phase of comminution, requires a large capital investment and frequently is the area of maximum usage of power and wear resistant materials Grinding is most frequently done in rotating drums utilizing loose grinding media, lifted by the rotation of the Rod and Ball Mills OneMine2014年10月1日 In a test performed in the Loesche test center in Germany, copper slag grinding saved 229% energy in an airswept model and 344% energy in an overflow model [13,14]Copper Ore Grinding in a Mobile Vertical Roller Mill Pilot Plant2014年9月1日 fines were also milled in a ball mill with 50% of grinding were manufactured by blending 2 which was preliminarily pretreated by high press roll grinding Manganese ore fines assaying Strengthening pelletization of manganese ore fines

Vertical Stirred Mill Mineral Processing Equipment CITIC HIC

2024年10月15日 Vertical stirred mill is a fine grinding equipment that covers advantages of low rotation speed, high reliability and long life cycle Since it is operated with wet grinding method, the mill requires no cooling system due to the low speed operation grinding efficiency of minerals by constantly searching for ways to improve and develop 2022年3月19日 An iron ore concentrate sample was ground separately in a pilotscale HPGR mill in multiple passes and a dry opencircuit ball mill to increase the specific surface area of particlesGrinding iron ore concentrate by using HPGR and ball mills Autogenous mills are grinding mills that use the ore itself as the grinding medium The ore is fed into the mill, and as it rotates, it crushes and grinds itself, producing a fine powder Autogenous mills are highly efficient and can produce fine particles quickly They are also versatile and can be used for both wet and dry grindingWHAT ARE GRINDING MILLS? Total System Solution TSSOur entire MPT equipment range is manufactured locally and inuse globally We are a proudly South African manufacturer Worldclass Ore Scrubbers and Grinding Mills built on modular skid frames Read More Classification Mill and float plant modularized in a standard 40ft container Wash Plant 60 TPH Manganese Plant Location MechProTech MPT – Designers And Suppliers Of: Mineral

.jpg)

Grinding Mill Parts JXSC Machine

2024年10月31日 The typical grinding mill includes the ball mill, rod mill, SAG mill, Raymond grinding mill, AG mill, vertical mill, etc, Due to the work impact, the quality of the grinding mill parts and components directly determines the 2020年1月9日 Actually the mill that was ordered has a nominal size of 22×7 ft and measures 213 ft inside of liners It was manufactured by the Hardinge Co who built a mill of this size for grinding Galena ore in Sweden, and it was to Jones Laughlin’s advantage to duplicate this design, since the computed capacity approached that requiredGrinding Iron Ore in a Wet Autogenous Mill 911MetallurgistChina Juxin has formed a complete productionchain that takes crushers and ball mills as the main products and vibrating screen, vibratubg feeder, belt conveyor, etc As supplementary products The major products are jaw crusher, impact crusher, hammer crusher, composite crusher, double roll crusher, sand making machine, vibrating screen Xingyang Juxin Machinery Co, Ltd MadeinChina2024年1月2日 Population balance model approach to ball mill optimization in iron ore grinding Patricia M C Faria1,2, Luís Marcelo Tavares2 and Raj K Rajamani3 1 Vale SA, Brazil 2 Department of Population balance model approach to ball mill

Grinding Media in Ball MillsA Review Preprints

2023年4月24日 Review Grinding Media in Ball MillsA Review Nyasha Matsanga 1,*, Willie Nheta 1 and Ngonidzashe Chimwani 2 1 Mineral Processing and Technology Research Centre, Department of Metallurgy, University of Johannesburg, POBOX 17011, Doornfontein 2028, South Africa; 2 Department of Mining Engineering, Florida Campus, 2021年5月8日 Kolev et al (2021) –In press Improving the energy efficiency in tumbling mills with the use of Relo grinding media (MDPI) • Lab trials conducted using a standard Bond ball mill (@ Wardell Armstrong) • Standard Bond ball mill procedures were followed –only the RELO media PSD and mass of charge adjusted to match spherical mediaRethinking Grinding Efficiency in Ball Mills RELO 2020年10月18日 An iron ore concentrate sample was ground separately in a pilotscale HPGR mill in multiple passes and a dry opencircuit ball mill to increase the specific surface area of particlesThe effects of iron ore concentrate grinding methods (HPGR As an excellent manufacturer of ore grinding equipment in China, we focus on the field of nonmetallic ore ultrafine powder, constantly update and improve equipment, pursue the ultimate, and create higher value for customers cone crushers, hammer crushers, etc), ore grinding mills (ultrafine grinding mills, vertical mills, superfine wet About Us SBM Ultrafine Powder Technology

.jpg)

Grinding Metso

With customer needs and operational risk at the core of design, the grinding mills, engineered mill liners, and robust trommels ensure the highest availability The extensive product support and optimization services help in maximizing the efficiency of your grinding mill, grinding circuit or entire grinding process2023年12月12日 Ball mills are used for the second stage of ore grinding in mining operations by proportioning ore piles Controlling the operating conditions of ball mills is one of the key factors for optimal (PDF) Control of ball mill operation depending on ball load and ore 4 天之前 A wet grinding 4 x 10 center peripheral discharge rod mill used for producing fine aggregates Twelve 7 x 24 Compeb mills grinding cement clinker to a product of 1750 surface area, 90% passing a 200 mesh screen An 8 x 7 Grinding Mills 911Metallurgist2024年10月13日 Autogenous mills use the ore itself as the grinding media, while semiautogenous mills use a combination of ore and steel balls These mills operate by rotating a large drum filled with the ore, which impacts and grinds the particles against the mill walls Autogenous and semiautogenous mills are more energyefficient and are suitable for fine Understanding the operation of grinding mills in the mining

Factors affecting ores grinding performance in ball mills

2024年10月13日 Effect of mill type on ore grinding performance Ball mills are widely used in the mining and metallurgical industries for the grinding of ores and other materials There are a wide variety of mill types available, each with its own advantages and disadvantages The performance of a ball mill can be affected by a number of factors, including the 2023年10月17日 3 Ultrafine Powder Grinding Mill Ultrafine powder mill (threering / fourring mediumspeed micropowder mill) feed particle size ≤25 mm, production capacity 0545 t/h, production fineness 1503500 mesh,it is a highefficiency and lowconsumption ultrafine powder processing equipment that successfully replaces the traditional jet mill and complex process How to choose a suitable ore powder grinding mill?2020年6月3日 The design of such grinding mills is extremely critical, requiring sophisticated software tools, proprietary calculation worksheets, and experienced technical engineers and drafters This blog will review how the mill design process has changed over the last 30 years While most of the changes have been positive, new issues and problems have risen in the How grinding mill design changed over the last 30 years3 天之前 Figure 1 : Grinding Power to produce various product sizes in a Ball Mill (9mm balls) and an Isa Mill (2 mm sand) (for KCGM pyrite concentrate) Chemistry Impacts The use of inert grinding media gives a crucial advantage to stirred milling in fine flotation and leaching applications Even if it were economic to grind to 10 microns in a steel Fine Grinding as Enabling Technology – The IsaMill

.jpg)

HIGH PRESSURE GRINDING ROLLS—A PROMISING AND

2016年1月10日 HPGR in iron ore industry ThyssenKrupp HPGR mills have shown themselves good in iron ore industry The first HPGR was employed in iron ore mining industry in the 1990s in grinding iron concentrates for pelletizing That time the grinding rolls had smooth or ribbed wrought shells (lining) That technology2015年3月10日 Within the scope of this study, the performance of VRM was compared with rodball mill circuit for copper ore grinding application The VRM tests were performed with mobile plant manufactured by Loesche GmbH and different operating modes Copper ore grinding in a mobile vertical roller mill pilot plant2018年12月24日 The amount of comminution or fineness of minerals in the mill can be described by various parameters, the most important of which is d80 (80% passing size)EVALUATION OF THE ALTERNATIVES FOR GOLD ORE GRINDING