Gypsum Raymond processing

Raymond® Imp™Mill Coperion

The Raymond® Series 3 Imp™ Mill is a versatile and dependable highspeed airswept swing hammer impact mill designed for fine and medium grinding of soft nonmetallic minerals, coals, various chemical compounds, food products and 2023年11月13日 Ball mills, Raymond mills, roller mills, and vertical mills are commonly used in gypsum processing The choice of mill depends on factors such as the fineness of the final Gypsum Manufacturing Process Gypsum Processing A roller mill is most effective processing materials that are 5 or less on the Mohs scale of hardness There are a few limitations, but the most practical are soft to medium hard materials They can also be used to prepare feed for systems Raymond® Roller Mills CoperionGrinding System: Raymond mill, bucket elevator and vibrating feeder The grinding process of gypsum generally selects Raymond mill for processing operations Raymond mill is good at high fineness grinding of nonflammable Gypsum Powder Manufacturing Gypsum

.jpg)

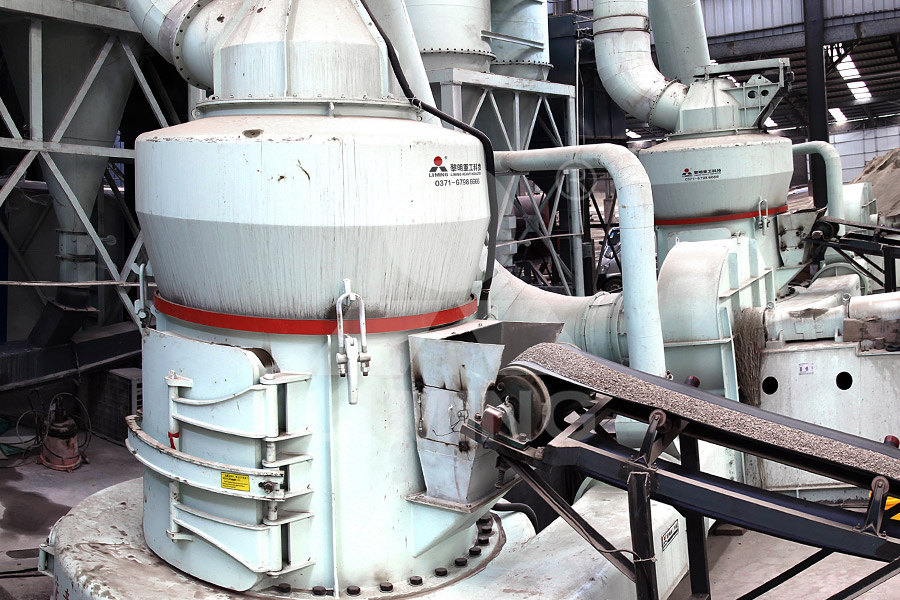

Utilizing raymond mill for processing 10TH desulfurization gypsum

2024年10月13日 The use of a Raymond mill for processing 10TH desulfurization gypsum powder is an efficient and environmentally friendly method With its high output, energy 1 天前 Mineral Processing Gypsum processing can be divided into three basic steps: (1) rock preparation, (2) calcining, and (3) formulating and manufacturing This is illustrated graphically with the flow chart in Figure 1 The specifics of Infrastructure and Construction Materials Guide The gypsum raymond mill is an extensively used machine in the field of limestone processing This guide provides an overview of the gypsum raymond mill, its applications, and the benefits Widely Used Gypsum Raymond Mill for Limestone2024年7月25日 The Raymond® Cage Mill Flash Drying system is designed for dry and deagglomerate materials that do not require size reduction The cage mill is a low energy raymondcagemillflashdryingsystem for gypsum

Gypsum processing plant for gypsum mining by SBM unisbm

SBM is the world's leading supplier of gypsum processing plants and technology for gypsum powder producers From gypsum processing plant design and project management to 2024年9月4日 Raymond Mill is a grinding machine used to crush and grind raw materials such as limestone, dolomite, gypsum, kaolin, marble, and more into fine powder It was invented by Raymond in 1906 and has been widely used in What is Raymond Mill? How Does It Work?2015年9月10日 1116 Gypsum Manufacturing 11161 Process Description12 Gypsum is calcium sulfate dihydrate (CaSO4 2H2O), a white or gray naturally occurring mineral Raw gypsum ore is processed into a variety of products such as a portland cement additive, soil conditioner, industrial and building plasters, and gypsum wallboard To produce plasters or1116 Gypsum Manufacturing US EPA1 天前 Gypsum processing can be divided into three basic steps: (1) rock preparation, (2) calcining, and (3) formulating and manufacturing This is illustrated graphically with the flow chart in Figure 1 The specifics of each Infrastructure and Construction Materials Guide

Utilizing raymond mill for processing 10TH desulfurization gypsum

2024年10月13日 The Raymond mill operates on the principle of centrifugal force and has several advantages, such as high output, energy efficiency, and environmental friendliness 3 The Use of Raymond Mill for Processing 10TH Desulfurization Gypsum Powder Grinding Process The Raymond mill is capable of processing 10TH desulfurization gypsum powder Our gypsum grinding machines includes all types of ball mills, Raymond mills, trapezium mill, and vertical mills for your different fineness requirements Gypsum processing plant includes mining, crushing, screening and grinding process SBM can offer gypsum mining, processing equipment like crusher, screen, grinding mill, belt conveyor for Gypsum processing plant for gypsum mining by SBM unisbm2024年10月13日 The Necessity of Grinding Mills in Gypsum Powder Processing: Gypsum ore, extracted from quarries, often contains impurities and needs to be processed to meet the quality standards required for different applications Raymond Mills: Raymond mills are widely used for the fine grinding of gypsum powder These mills feature a horizontal Gypsum powder processing: The role of grinding mills5 天之前 The Raymond mill is a versatile and reliable grinding machine, suitable for producing fine powders for a wide range of industrial applications Its efficiency, ease of maintenance, and ability to handle various materials make it a valuable asset in many industries [Introduction]: Raymond Mill has a strong performance of becoming a complete set with a production system Raymond Mill TAYMACHINERY

How To Set Up a Gypsum Powder Production Line From

2023年11月2日 Setting up a gypsum powder production line requires careful planning and a good understanding of the overall process Gypsum powder is widely used in the construction industry for making drywall, plaster, and other building materials Raymond mills typically produce gypsum powder with a particle size distribution of around 80325 mesh (0 2024年10月26日 Gypsum Powder Processing Plant Raymond Mill Price US$3,8850028,58000 / Piece: 1 Piece (MOQ) Product Details Customization: Available: Type: Raymond Mill: Motor Type: AC Motor: Start Order Request Contact Supplier Gypsum Powder Processing Plant Raymond Mill Price6 天之前 Materials: Raymond mill grinds minerals like gypsum and limestone, while ball mill processes metal ores and cement clinker b Output: Raymond mill produces less than ball mill but uses less power c Dust pollution: Raymond mill has cleaner dust control, whereas ball mill is larger, harder to manage, and causes more dust pollution dHighefficient Raymond Mill Fote MachineryThe Raymond® Vertical Mill is well adapted to the grinding of nonmetallic minerals and manufactured materials in the extreme fineness range Typicalmaterialsprocessed include graphite, limestone, cocoa powder, marble, kaolin,sugar, talc, certain synthetic resins, organic and inorganic colors, phosphate,chemicals, glass, enamel, food products, pharmaceuticals and a Raymond® Vertical Mill Coperion

Raymond® Roller Mills Coperion

The Raymond® Roller Mill is an airswept vertical ringroll mill withan integral classification system that A roller mill is most effective processing materials that are 5 or less on the Mohs scale of hardness Bentonite, Kaolin, Barytes, 2023年5月22日 Gypsum calcination process Gypsum products are widely used in construction, building materials, power plants, medicine and other fields Because of their green, environmental protection, energy saving, lightweight Gypsum calcination process MECRU Heavy The Raymond® Bowl Mill is considered the finest vertical rollermill available for pulverizing coal Each bowl mill system is designed to achieve thebest solution forthe processing application The mill, feeder, classifier, fan, cyclone,dust Raymond® Bowl Mill CoperionFly ash processing equipment Fly ash processing equipment typically includes a Raymond mill, as well as vibrating feeders, elevators, classifiers, dust collectors, and other related machinery These components work together to process and refine fly ash into the desired products for various applicationsFly Ash Processing Plant Ball Mill, Raymond Mill, EPC Project

raymondcagemillflashdryingsystem for gypsum

2024年7月25日 The Raymond® Cage Mill Flash Drying system is designed for dry and deagglomerate materials that do not require size reduction The cage mill is a low energy consumption unit that increases drying performance resulting in improved product quality Raymond® Cage Mill The cage design consists of an agitator type rotor enclosed2017年8月29日 of gypsum during its dehydration reaction with in situ synchrotron angledispersive Xray diffraction in a number of defined environments at room pressure The authors proved that the dehydration processes from gypsum to anhydrite proceeds via bassanite hemihydrate and canhydrite in very different heating environments Moreover,The dehydration process of gypsum under high pressure 2024年9月28日 >>Gypsum Powder Manufacturing Process 1 Raw Material Collection Gypsum rock (calcium sulfate dihydrate) is mined from quarries This raw material is essential for the subsequent processing stages 2 Crushing and PreProcessing The gypsum rock is crushed into smaller pieces, typically less than 20 mm, using jaw or impact crushersGypsum Powder Manufacturing Process Using HGM Micro 2013年5月21日 The gypsum calcining systems are designed to process natural gypsum from the local underground gypsum quarries A greenfield project To take over production from the old three calcining kettles, the new calcining line was designed for a plaster capacity of 14t/hr, utilising a Claudius Peters EM 47568 Gypsum Calcining Mill Innovative gypsum processing at GIPS AD Global Gypsum

.jpg)

Raymond Mill TAYMACHINERY

2024年11月26日 The Raymond mill is a versatile and reliable grinding machine, suitable for producing fine powders for a wide range of industrial applications Its efficiency, ease of maintenance, and ability to handle various materials make it a valuable asset in many industries [Introduction]: Raymond Mill has a strong performance of becoming a complete set with a 2017年5月8日 from flue gas desulphurisation; a process for cleaning up emissions from chimneys to reduce the quantity of sulphurous gases flowing into the atmosphere Dehydration: Rock into plaster Gypsum rock is converted into gypsum plaster by driving off some of the chemically combined water Heating gypsum at 120°C for one hour results in a hemihydrateGypsum processing and use Humanitarian Library2020年3月7日 The article provides the information on a new method of processing phosphogypsum (calcium sulfate) stacks into a conditioned gypsum binder substance(PDF) Phosphogypsum Processing Method2019年8月23日 Most of the world’s gypsum is produced by surfacemining operations In the United States, gypsum is mined in about 19 states The states producing the most gypsum are Oklahoma, Iowa, Nevada, Texas, and Gypsum Processing Equipment, Process Flow,

.jpg)

Raymond® Classifiers Coperion

Raymond® classifiers include a complete selection of static and dynamic classifiers in varying configurations designed for use as independent units or in circuit with pulverizing equipment to meet the exacting product specifications of your specific application2023年1月19日 Gypsum processing equipment Gypsum mining equipment is the mining equipment SBM provide for gypsum solution SBM gypsum mining equipment to process gypsum includes Jaw Crusher, Cone Crusher, Impact Crusher, Roller Crusher, Hammer Crusher, Trapezium Grinding Mill, LM series Vertical Grinding Mill, Raymond Mill and so onGypsum processing plant sbmchina2024年6月27日 The bentonite, dolomite, and gypsum powder processing plant in Guangdong, China, is a comprehensive facility designed to efficiently produce highquality ultrafine powders With a wellstructured layout and advanced machinery, including three HGM125 Micro Powder Grinding Mills, the plant can achieve precise particle sizes (6002000 mesh) at a Bentonite, Dolomite, and Gypsum Powder Processing PlantApply Rayco Gypsum with firm pressure on an even surface as an undercoat for a finish coat It can be applied up to 613 mm thick on walls in one coat and up to 10 mm on ceilings For thicker applications, use two coats Do not exceed 30 mm on walls and 20 mm on ceilings Allow 72 hours to dry, depending on thickness and weather conditionsProcess – Raycoindia Gypsum

.jpg)

Risks of soil chemical degradation from atmospheric gypsum

2024年10月10日 The gypsum powder released during gypsum extraction and processing is altering the soil chemical characteristics in the industrial gypsum sector of Grajaú MA There has been an increase in Ca levels in the surface soil layers, a reduction in Al 3+ saturation, and changes in the ratios of Ca, Mg, and K in areas closer to the industrial pole 4 天之前 Download the gypsum processing flow sheets Gypsum Processing Solutions Gypsum Dewatering Wet fluegas desulfurization (FGD) systems generally operate in a pH of 50 or above and require feed of reagent to remove sulfur Limestone slurry is the most commonly used reagent The quantity of slurry depends mostly on the sulfur levels in the coalGypsum Byproduct Processing Solutions WesTech The Raymond® Ultrafine Mill System is designed to produceextremely fine powders for use in various applications including coatings, fillers, andpigments The mill system will generate products as fine as 50% passing 2 microns or as coarse as 50% passing 20 micronsRaymond® Ultrafine Mill CoperionWhat is the price of gypsum Raymond mill? The following recommends a manufacturer with affordable price and excellent quality, that is Shanghai Clirik Machinery Co, Ltd The manufacturer is located in Shanghai, China, with many years of production history, rich technology and craftsmanship, and excellent quality assurance of equipment; also provides Gypsum Powder Processing Equipment: Stone Crusher and

.jpg)

1116 Gypsum Manufacturing US EPA

2015年9月10日 1116 Gypsum Manufacturing 11161 Process Description12 Gypsum is calcium sulfate dihydrate (CaSO4 2H2O), a white or gray naturally occurring mineral Raw gypsum ore is processed into a variety of products such as a portland cement additive, soil conditioner, industrial and building plasters, and gypsum wallboard To produce plasters or1 天前 Gypsum processing can be divided into three basic steps: (1) rock preparation, (2) calcining, and (3) formulating and manufacturing This is illustrated graphically with the flow chart in Figure 1 The specifics of each Infrastructure and Construction Materials Guide 2024年10月13日 The Raymond mill operates on the principle of centrifugal force and has several advantages, such as high output, energy efficiency, and environmental friendliness 3 The Use of Raymond Mill for Processing 10TH Desulfurization Gypsum Powder Grinding Process The Raymond mill is capable of processing 10TH desulfurization gypsum powder Utilizing raymond mill for processing 10TH desulfurization gypsum Our gypsum grinding machines includes all types of ball mills, Raymond mills, trapezium mill, and vertical mills for your different fineness requirements Gypsum processing plant includes mining, crushing, screening and grinding process SBM can offer gypsum mining, processing equipment like crusher, screen, grinding mill, belt conveyor for Gypsum processing plant for gypsum mining by SBM unisbm

Gypsum powder processing: The role of grinding mills

2024年10月13日 The Necessity of Grinding Mills in Gypsum Powder Processing: Gypsum ore, extracted from quarries, often contains impurities and needs to be processed to meet the quality standards required for different applications Raymond Mills: Raymond mills are widely used for the fine grinding of gypsum powder These mills feature a horizontal 5 天之前 The Raymond mill is a versatile and reliable grinding machine, suitable for producing fine powders for a wide range of industrial applications Its efficiency, ease of maintenance, and ability to handle various materials make it a valuable asset in many industries [Introduction]: Raymond Mill has a strong performance of becoming a complete set with a production system Raymond Mill TAYMACHINERY2023年11月2日 Setting up a gypsum powder production line requires careful planning and a good understanding of the overall process Gypsum powder is widely used in the construction industry for making drywall, plaster, and other building materials Raymond mills typically produce gypsum powder with a particle size distribution of around 80325 mesh (0 How To Set Up a Gypsum Powder Production Line From 2024年10月26日 Gypsum Powder Processing Plant Raymond Mill Price US$3,8850028,58000 / Piece: 1 Piece (MOQ) Product Details Customization: Available: Type: Raymond Mill: Motor Type: AC Motor: Start Order Request Contact Supplier Gypsum Powder Processing Plant Raymond Mill Price

.jpg)

Highefficient Raymond Mill Fote Machinery

6 天之前 Materials: Raymond mill grinds minerals like gypsum and limestone, while ball mill processes metal ores and cement clinker b Output: Raymond mill produces less than ball mill but uses less power c Dust pollution: Raymond mill has cleaner dust control, whereas ball mill is larger, harder to manage, and causes more dust pollution dThe Raymond® Vertical Mill is well adapted to the grinding of nonmetallic minerals and manufactured materials in the extreme fineness range Typicalmaterialsprocessed include graphite, limestone, cocoa powder, marble, kaolin,sugar, talc, certain synthetic resins, organic and inorganic colors, phosphate,chemicals, glass, enamel, food products, pharmaceuticals and a Raymond® Vertical Mill Coperion