Notes on bidding for ring roller grinding belt

.jpg)

Roll grinding procedures, wheels, belts, setup, end relief, tips

Valmet maintains a variety of wheels and belts The selection for a job corresponds to the product being worked on and grinder type: 1 For regrinding existing rubber covers, 32 36 grit wheels are 展开Typical grinding applications for internal and external rings are face grinding, centerless grinding, outside diameter (OD) and internal diameter (ID) grinding and superfi nishing ASSEMBLYTECHNICAL SOLUTIONS FOR GRINDINGInstructor: Ramesh Singh; Notes: Profs Singh/Melkote/Colton Grinding – Ex 11 • You are grinding a steel, which has a specific grinding energy (u) of 35 Ws/mm3 • The grinding wheel Grinding and Finishing IIT Bombay2021年5月5日 A grinding machine is a production machine tool used in the manufacturing industry in which the grinding wheel is attached in the tool post and the workpiece is fixed to the work table and when the operation starts it Grinding Machine: Definition, Parts, Working Principle,

G[R.jpg)

Practical Roll Techniques Grinding Balancing Valmet

2013年9月13日 As an integral part of a modern roll maintenance program, roll grinding and balancing uses machinery with accurate inspection and measurement equipment This paper • Standard grinding wheel marking system used to designate abrasive type, grit size, grade, structure, and bond material −Example: A46H6V • Also provides for additional Lesson 6 GRINDING AND OTHER ABRASIVE PROCESSES KSUAfter completing this unit, you should be able to: • Identify Surface Grinder • Identify Procedures • Describe Dressing the Wheel procedures • Describe the Ring Test • Describe replacing the Grinding Wheel • Describe procedure Chapter 5: Surface Grinder – Manufacturing Processes 2023年7月4日 Roller mill is a type of grinding equipment for crushing materials by pressure between two or more rolling surfaces or between rolling grinding bodies (balls, rollers) and a Roller Mill SpringerLink

.jpg)

2 µm 5 µm Loesche

• Combination of grinding roller with support roller as M+S system • New mill designation, LM 562+2 CS or LM 563+3 CS, depending on the number of roller pairs used (C = cement, S = This experts guide details everything you need to know about abrasive belts – from the materials, to the sizes and the colours to ensure you choose the right belt for your application What is an An experts guide to abrasive belts Moleroda Finishing Systems2023年12月4日 In general, increasing rolling resistance increases the force induced on the roller during grinding The effect of particle shape is more at low mill speeds when compared with the reduced roller and table gap and increased dam ring height The roller speed induced by friction is unaffected by the particle shape parametersNumerical Investigation of Vertical Roller Mill Operation Using Crawlertype Belt Conveyor; Crawlertype Screening Mobile; Wheeled Mobile Crushing HM ultrafine ring roller mill is a new type of ultrafine power processing equipment The customer’s site has 1 set of HM1300 Grinding Mill for 400 mesh D97 coarse powder producing, 1 set of HM980 and 1 set of HM1395 Ultrafine Mill for 8001500 mesh D97 HM Superfine Ring Roller Mill Grinding Mill Fertilizer

Grinding Machine: Definition, Parts, Working

2021年5月5日 The Grinding Machine is another most important machine in the manufacturing Industry Working Principle, Operation, Advantages, Application [Notes PDF] by Er Amrit Kumar May 5, 2021 in Manufacturing 2023年3月28日 The current research of abrasive belt grinding rail mainly focuses on the contact mechanism and structural design Compared with the closed structure abrasive belt grinding, openstructured abrasive belt grinding has excellent performance in dynamic stability, consistency of grinding quality, extension of grinding mileage and improvement of working efficiency Contact Mechanism of Rail Grinding with OpenStructured Abrasive Belt June 2022; ARCHIVE Proceedings of the Institution of Mechanical Engineers Part C Journal of Mechanical Engineering Science 19891996 (vols 203210) 236(2):1107(PDF) A comprehensive review on the grinding process: 5) Fabrication of the roller is effected by an auto device and 100% tested for its concentricity 6) Roller and supporting components/materials are manufactured to DIN/ AFNOR/ FEM/ ASTM/ CEMA standard 7) The casing is manufactured with highly composite, anti corrosive alloy 8) The roller is lubricated and free from maintenanceRubber Ring Coated Impact Idler Roller for Belt Conveyor

Roller Mill Springer

R Roller Mill Xiao Xiao1, Huang Lilong2 and Xu Kuangdi3 1Changsha Research Institute of Mining and Metallurgy, Changsha, China 2Changsha Research Institute of Mining and Metallurgy, Changsha, China 3Chinese Academy of Engineering, Beijing, China Roller mill is a type of grinding equipment for crushing materials by pressure between two orGrinding belt roller made from wearresistant, soft, fluted vulcan plastic for a better grip With a vibrationdamping core for single, POLYPTX spacer ring set (3) Read More Abrasive Belt 40 x 615mm 120 grit Con Read More NEXT DAY DELIVERY On orders before 3pmPOLYPTX grinding belt roller 85 x 70mm with flanges2024年6月7日 The ring roller mill has a unique design with a grinding ring and roller assembly The grinding ring is fixed on the inner wall of the mill while the roller assembly rotates around the ring As the roller assembly rotates, the material is fed into the mill and is ground between the grinding ring and rollers One of the advantages of the ring Ring Roller Mill Ultrafine calcium carbonate production equipment2019年10月8日 Roll grinding To maintain rubber covered rolls in the best operating condition frequent grinding must be performed Grinding restores the original properties and qualities of the cover Oxidation and surface checks, cuts or cracks are removed by grinding Before grinding any roll, the following steps should be taken and recorded: Crown measurementRoll grinding procedures, wheels, belts, setup, end relief, tips

.jpg)

Grinding Machines notes Chapter 5 GRINDING

Workpiece Mounted for Internal Grinding Listed below are the proper procedures and methods to perform internal grinding Internal grinding is done with the universal tool and cutter grinder with an internal grinding attachment (Figure 5 2024年2月18日 The roller ring is pressed and installed on the roller shaft with a tapered surface through a taper sleeve Good cooperation between the roller ring and the taper sleeve is required and cannot be too tight or loose If it is too Exploration on roller ring material selection for high 2024年5月8日 Robotic belt grinding is a productive method frequently used to finish intricate parts To address the challenges of ensuring grinding efficiency and quality due to the complexity of the robotic belt polishing process, a multialgorithm fusion–based intelligent decisionmaking method is proposed in this study The broad learning system (BLS) was utilized to construct Multialgorithm fusion–based intelligent decisionmaking method 2021年8月1日 Modelling of grinding force and material removal rate (MRR) has been widely investigated for wheel grinding which often has a preset cutting depth, but is rather lacking for sand belt grindingA novel material removal rate model based on single grain

General Archive O rings as drive belts? Practical Machinist

2004年12月30日 What is the ideal o ring material for use in low torque drive belt applications? The belts which came with the motorized spin grinding fixture are just about used up I have tried regular buna rubber and viton in the past Neither one lasted very 2011年2月2日 You can do this too, called "slack belt grinding", for a final finish Note the vacuum hose Belt is running in reverse, against the direction of rotation of the barrel, this plumes the grinding dust up and the vacuum grabs all of it Use the contact wheel to get the rubber roll round first, then finish with the slack belt if needed Experiment!General Grinding RubberHelp Practical Machinist£ÿÿ0 af=,¨ÎÄ 7ôǯ?ÿ~ pÎÿéõW Ò À ?ÀKxëQ »•Oƒ 9«AG8û†;Îe ‰âìcgÝqÖuœ]ÛÈ)ª“Œ3Ž³²âP Mc qVdÔÉ8óU d+• J¡ Qˆ7òÖJ2vÆ?ofý c ÉÊ o Ö[#c?û ™µ³öœ³?ýõˆÕ{òëiáÉ Ö–ôò¢ ¨'hjøýrÄ ‰DÒ²KFJ ˆß†l~ 6SA,D± ‡}ü MxÅãÃ$$ŠÆhn¥‘*¥ "Q´ L†j'Òþ˜^,!“š¬ £P —d`aä@D hlllDD`!fv0¶FDàçg*q1# ‘ƒ {Æ Design Of Mini Abrasive Vertical Belt Grinding Machine2020年8月1日 Therefore, belt grinding of complex workpieces extensively relies on manual grinding As shown in Fig 2, in a manual grinding process, skilled operators usually eliminate local gouges in an ingenious wayFirst, they partition a complex workpiece into several grinding regions, and then grind the workpiece region by region using either wheel face grinding (WFG) A robotic belt grinding approach based on easytogrind region

.jpg)

POLY PTX 800 Grinding Belt Roller 111 Abrasives Australia

We stock belt sizes 40x780mm pipe machines and 30×600 to suit our PTX machine with optional grinding belt roller 70mm wide, need to be used in conjunction with POLY PTX Spacer Ring set to secure onto shaft DIMENSIONS (MM) MATERIAL MAX SPEED (RPM) PKG UNIT ARTICLE NUMBER; Ø 85 x 70: Polyurethane vulculan with stainless steel flanges SMF800 KILN ROLLER GRINDING MACHINE; Portable belt grinding machine for onsite kiln and drier support roller restoration Revolutionize onsite kiln and drier support roller restoration with our Portable Belt Grinding Machine – a versatile and reliable solution for machining rotary kilns, coolers, dryers, granulators, and agglomeratorsSMF800 KILN ROLLER GRINDING MACHINE Solutions for on 2023年6月20日 As the working interface of tapered roller bearing, the raceway surface quality directly affects the working performance and service life of bearings In order to improve the surface quality of tapered roller bearing inner raceway grinding, improve the processing efficiency, and optimize the processing parameters, this paper conducted a study on the surface Surface roughness in grinding outer ring inner raceway of 2023年7月4日 Roller mill is a type of grinding equipment for crushing materials by pressure between two or more rolling surfaces or between rolling grinding bodies (balls, rollers) and a track (plane, ring, and table) The roller mill with several grinding rollers as working components rolls along the grinding ring or the grinding table to crush the Roller Mill SpringerLink

Abrasive Belt Grinder PDF Abrasive Grinding

Abrasive Belt Grinder Read online for free This document describes a project report on an abrasive belt grinding machine It was submitted by four students Haadi Mastim, Saad Halde, Sultan Ulde, and Mushal Khadas under the 2017年9月11日 Grinding and separation efficiency of vertical roller mill were evaluated In addition to these, performance figures of vertical roller mill and conventional closed ball mill circuit were comparedPerformance Evaluation of Vertical Roller Mill in Cement GrindingThis article explores the effects of parameters such as cutting speed, force, polymer wheel hardness, feed, and grit size in the abrasive belt grinding process to model material removal The process has high uncertainty during the interaction between the abrasives and the underneath surface, therefore the theoretical material removal models developed in belt grinding involve Modelling of Material Removal in Abrasive Belt Grinding Process2023年11月17日 Study on GrindingAffected Layer of OuterRing Inner Raceway of Tapered Roller Bearing(PDF) Study on GrindingAffected Layer of OuterRing

Polysius Roller Mills For grinding

4 Advantages of Polysius roller mills at a glance: xHigh operating reliability and availability, as well as easy system handling, due to the fact that grinding, drying and separation all take place in a single compact unit xConsistently high product quality with minimum energy requirement, due to the integrated highefficiencyLoeschefor SIGSlip ring sealing Free download as PDF File (pdf), Text File (txt) or read online for free The document discusses operation and maintenance of roller seals, including the sealing air system, roller maintenance, rocker arm maintenance, lever sealing maintenance, and table maintenance It also examines the condition of the SBI Nar 2 coal mill, including worn Loesche For SIG Slip Ring Sealing PDF2015年10月1日 An effective method based on the secondorder osculation principle is developed for grinding surface in this paper On the assumption that the elastic contact wheel of abrasive belt grinder is a Research on belt grinding for marine propeller blade based on Notes: 3037PAR is the full front roller assembly needed for replacement 38 *H1303738 ORING (S38) 1 39 *H1MATSE24039 SE240 CAP 1 40 *H1MATSE24040 THROTTLE LEVER 1 56 SE14036B 36 GRIT GRINDING BELT 10PC 1 T 57 SE14040B 40 GRIT GRINDING BELT SE240 1/2 X 18 AIR BELT SANDER Parts Breakdown Matco Tools

Numerical Investigation of Vertical Roller Mill Operation Using

2023年12月4日 In general, increasing rolling resistance increases the force induced on the roller during grinding The effect of particle shape is more at low mill speeds when compared with the reduced roller and table gap and increased dam ring height The roller speed induced by friction is unaffected by the particle shape parametersCrawlertype Belt Conveyor; Crawlertype Screening Mobile; Wheeled Mobile Crushing HM ultrafine ring roller mill is a new type of ultrafine power processing equipment The customer’s site has 1 set of HM1300 Grinding Mill for 400 mesh D97 coarse powder producing, 1 set of HM980 and 1 set of HM1395 Ultrafine Mill for 8001500 mesh D97 HM Superfine Ring Roller Mill Grinding Mill Fertilizer 2021年5月5日 The Grinding Machine is another most important machine in the manufacturing Industry Working Principle, Operation, Advantages, Application [Notes PDF] by Er Amrit Kumar May 5, 2021 in Manufacturing Grinding Machine: Definition, Parts, Working 2023年3月28日 The current research of abrasive belt grinding rail mainly focuses on the contact mechanism and structural design Compared with the closed structure abrasive belt grinding, openstructured abrasive belt grinding has excellent performance in dynamic stability, consistency of grinding quality, extension of grinding mileage and improvement of working efficiency Contact Mechanism of Rail Grinding with OpenStructured Abrasive Belt

(PDF) A comprehensive review on the grinding process:

June 2022; ARCHIVE Proceedings of the Institution of Mechanical Engineers Part C Journal of Mechanical Engineering Science 19891996 (vols 203210) 236(2):11075) Fabrication of the roller is effected by an auto device and 100% tested for its concentricity 6) Roller and supporting components/materials are manufactured to DIN/ AFNOR/ FEM/ ASTM/ CEMA standard 7) The casing is manufactured with highly composite, anti corrosive alloy 8) The roller is lubricated and free from maintenanceRubber Ring Coated Impact Idler Roller for Belt ConveyorR Roller Mill Xiao Xiao1, Huang Lilong2 and Xu Kuangdi3 1Changsha Research Institute of Mining and Metallurgy, Changsha, China 2Changsha Research Institute of Mining and Metallurgy, Changsha, China 3Chinese Academy of Engineering, Beijing, China Roller mill is a type of grinding equipment for crushing materials by pressure between two orRoller Mill SpringerGrinding belt roller made from wearresistant, soft, fluted vulcan plastic for a better grip With a vibrationdamping core for single, POLYPTX spacer ring set (3) Read More Abrasive Belt 40 x 615mm 120 grit Con Read More NEXT DAY DELIVERY On orders before 3pmPOLYPTX grinding belt roller 85 x 70mm with flanges

.jpg)

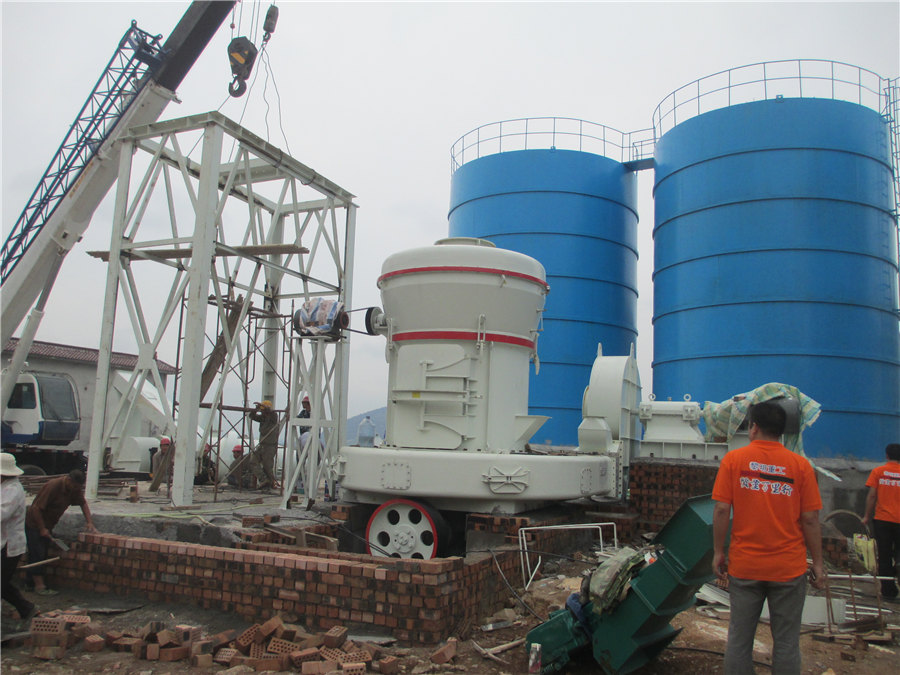

Ring Roller Mill Ultrafine calcium carbonate production equipment

2024年6月7日 The ring roller mill has a unique design with a grinding ring and roller assembly The grinding ring is fixed on the inner wall of the mill while the roller assembly rotates around the ring As the roller assembly rotates, the material is fed into the mill and is ground between the grinding ring and rollers One of the advantages of the ring 2019年10月8日 Roll grinding To maintain rubber covered rolls in the best operating condition frequent grinding must be performed Grinding restores the original properties and qualities of the cover Oxidation and surface checks, cuts or cracks are removed by grinding Before grinding any roll, the following steps should be taken and recorded: Crown measurementRoll grinding procedures, wheels, belts, setup, end relief, tips