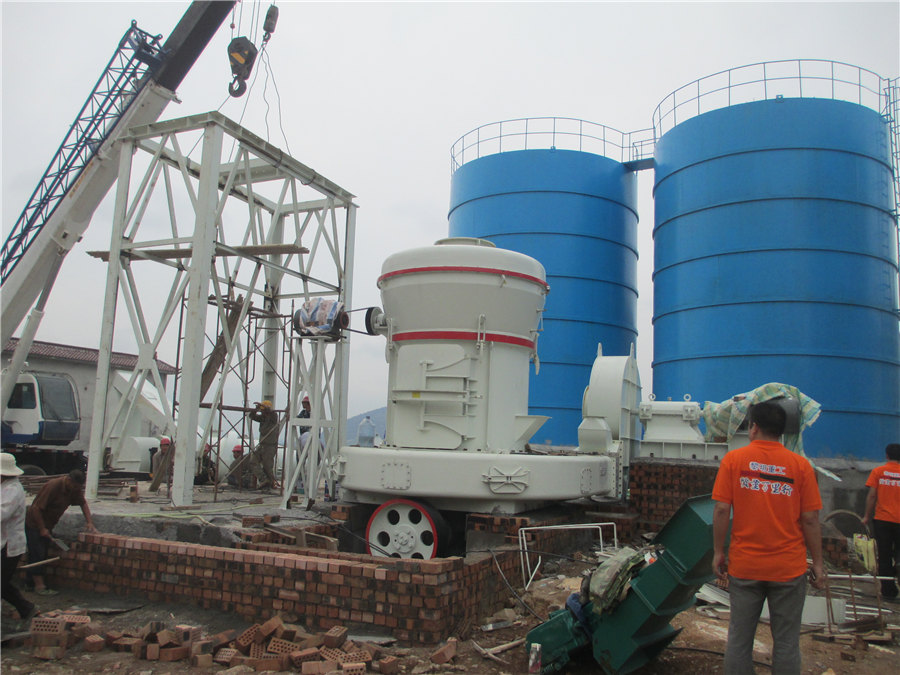

Mine 200 mesh coal pulverizer

A Comparison of Three Types of Coal Pulverizers

2024年8月22日 The ATRITA pulverizer is a highspeed, compactly designed machine which reduces raw coal to pulverized coal by the combination of crushing, impact and attrition The China Coal Pulverizers wholesale Select 2024 high quality Coal Pulverizers products in best price from certified Chinese Coal Machine manufacturers, Coal Equipment suppliers, Coal Pulverizers MadeinChina200Mesh MZ1000 3MZ200 2MZ200 Bowl Mill Coal Pulverizer with 100,200,400,1000g Bowl No reviews yet Jiangxi Victor International Mining Equipment Co, Ltd Custom manufacturer 8 yrs 200mesh Mz1000 3mz200 2mz200 Bowl Mill Coal Pulverizer 1 天前 A verticaltype pulverizer bites into coal between a rotating table and roller to pulverize the coal through the action of crushing and grinding Mitsubishi Power offers a varied lineup from small to high capacity through two types of Pulverizers Mitsubishi Power

.jpg)

WorldProven Coal Pulverizer Technology Debuts in the

2024年8月22日 When operating at boiler MCR, each mill had a coal throughput of approximately 53,000 #ffir Specified product fineness was 70% thru 200 mesh and 98% thru 50 mesh2020年8月28日 Contrary to the typical industry opinion that 7580% passing 200mesh coal fineness is not required for acceptable unit performance on a coal fired boiler, Storm A case study of how vertical spindle pulverizer 2024年11月25日 Mechanically pulverizing coal into a fine powder enables it to be burned like a gas, thus allowing more efficient combustion Transported by an air or an air/gas mixture, Coal Pulverizer2020年8月27日 Pulverizer throughput is determined by the coal fineness desired for a given coal However, compromising on coal fineness when your pulverizer isn’t up to snuff can “Blueprint” Your Pulverizer for Improved Performance

.jpg)

“Blueprint” Your Pulverizer for Improved Performance

2020年8月27日 that article explained, the capacity of a coal pulverizer is a complex function of the fuel fineness desired, the coal’s Hargrove Grindablity Index (HGI), and the coal’s raw feed fuel and greater than passing of 200 mesh requires the maximum pressure of the grinding elements Keep in mind that in operation there is no metaltometal 2024年8月22日 Flow and temperature of primary air are automatically adjusted to match coal feed rate and coal moisture Potential for pulverizer fires significantly reduced Integral fan purges the pulverizer of coal dust after the coal feed is stopped As raw coal and primary air enter the crusher section during startup,RILEY POWER’S ATRITA COAL PULVERIZERS RELIABLE 2011年10月1日 A sample set of results from a vertical air swept pulverizer with a static classifier might be 9925% passing 50 mesh (297 µm), 8738% passing 100 mesh (149 µm), 7212% passing 140 mesh (105 µm Improved Coal Fineness Improves Performance, Reduces Emissions2 天之前 Excessive coal spillage is a hazardous situation which can plug the pyrites discharge chute thus allowing a coal buildup in the millside and increasing the potential for a pulverizer fire 2 Operating a coal pulverizer for an extended period of time with outlet temperature below specification is hazardous since the coal may not be properly Bowl Mill Coal Pulverizer COAL HANDLING PLANTS

Innovative Combustion Technologies, Inc

2018年6月3日 200 Mesh and 999% passing 200 Mesh improves fuel distribution as well as unburned Carbon in flyash After coal fineness is determined by sieving, fineness data should by plotted against the Rosin and Rammler formula This plot is utilized to verify the representativeness of the coal sample and sieving A representative sample will plot as a2020年11月1日 Most utility coalfired boilers are also pulverizedcoal boilers, by definition using coal pulverized to a fine size, generally 70% passing 200 mesh (75 µm) In the most common pulverizer designs, coal is pulverized in a ball and race mill (Fig 1) with the fine coal entrained in the airflow, carried out of the top of the pulverizer, and Geochemical partitioning from pulverized coal to fly ash and Introduction This article concerns itself with vertical grinding mills used for coal pulverization only (coal pulverizers), although vertical grinding mills can and are used for other purposes The 3D model in the saVRee database represents a vertical grinding bowl millOther grinding mill types include the ball tube mill, hammer mill, ball and race mill, and , roll and ring millVertical Grinding Mill (Coal Pulverizer) Explained saVReeMine Mesh for Metal and Coal Mining support is an essential product that plays a vital role in the safety and stability of mining operations It is a type of mesh that is fabricated from highquality steel or other alloys to provide reinforcement and support to the roofs and walls of the underground mines where metal or coal mining takes placeMine Mesh for metal and coal mining

.jpg)

Coal Pulverizer Price MadeinChina

Coal Pulverizer Price Select 2024 high quality Coal Pulverizer Price products in best price from certified Chinese Long Ball Mill manufacturers, Ball Grinder suppliers, wholesalers and factory on MadeinChina Fineness: 50200 Mesh Voltage: 220V/380V Capacity: 15500 Kg/H Weight: 30320 Kg 1 / 6 Favorites Upgrade your Mining 2024年11月14日 The vibrating screen is a kind of mine classification machine for ore, mine, sand, gravel, coal, slurry, etc which consists of a screen and a vibrator Generally below 50 mesh for the coarse screen, and 80 mesh for the Vibrating Screen Mine Screening Equipment2024年11月25日 Introduction Laboratory Pulverizer is a small lab grinding machine for grinding the ore/material samples into powder, which has been widely used in the laboratory of the geology, mining, metallurgy, coal, power, Laboratory 3mz200 Mini Vibrating Pulverizer for Industrial Heating BERNARD LEWIS PhD, ScD (Cantab), GUENTHER von ELBE PhD (Berlin), in Combustion, Flames and Explosions of Gases (Second Edition), 1961 Pulverized coal consists mostly of particles capable of passing through a 200mesh screen, which corresponds to diameters of 74 microns and lowerPulverised Coal an overview ScienceDirect Topics

Pulverizers 101: Part I POWER Magazine

2011年8月1日 The pulverizer will then have the capability to produce pulverized coal that is 70% passing 200 mesh fineness (Figure 2, red line) This is commonly expected performance for this model pulverizer2022年8月18日 Minimum coal fineness level of 6070 % passing 200 mesh and less than 1% remaining on 50 mesh should be maintained [1] Figure 8 shows the results of Coal fineness The results show the 200mesh fineness Corner Point Port 1 Port 2 SQRT Port 1 SQRT Port 2 1 140 160 118 126 2 150 150 122 122 3 170 140 130 118 4 170 150 130 122AN EXPERIMENT ANALYSIS OF COAL PULVERIZER ON coal passing through 200 mesh (75 µm) is weighed and the HGI is derived from the empirical equation: HGI = 693W +13 where W is the weight of crushed coal passing through 200 mesh (75 µm) Indian bituminous types of coal have an HGI ranging between 45 to 70 Moisture content and volatile matter in the coal also affect the HGI valuesA Study on 500 MW Coal Fired Boiler Unit’s Bowl Mill 2024年10月31日 Trommel screen with capacity from 0350 T/H, feed size up to 90mm Mainly applications for mediumfine materials grading screening in the mining industry, quarry, chemical industry, usually equipped with 60200 mesh sieve, and water flush pipeTrommel Screen Mineral, Coal, Mud Classifying JXSC

.jpg)

Pulverizer Plant OM Aspects eecpowerindia

2013年12月6日 Fineness of pulverised coal More the fineness less is the capacity 70% through 200 mesh Number of opening per linear inch 50 mesh sieve will have 2500 openings per square inch Volatile content below 16% would required higher degree of fineness iE75 to 80% through 200 mesh sieve, whereas the higher volatile coalsFuel preparation for a pc boiler occurs in a mill, where coal is typically reduced to 70% through a 200mesh (74μm) screen Figure 2 shows a particlesize distribution from a bowlmill grinder typically used in power plants A typical utility specification for particle size distribution of the coal is that 70% of the mass should pass through a 200mesh screen, which is equivalent to 70% Pulverized Coal Boiler an overview ScienceDirect Topics2019年2月4日 To remove high density inorganics from coal during pulverization To classify coal particles to the required level of fineness, normally 70 % through 200 mesh and less than 2% on 50 mesh Coal parameters affecting pulverizer output While selecting a pulverizer, the coal characteristics play an important roleCoal Pulverising in Boilers idconlineRaw coal is fed to pulverizer from the coal feeder via a center feed pipe The coal is grounded between the three grinding rollers and the rotating table in the pulverizer Pulverized coal is simultaneously dried by the drying gas fed from bottom part of pulverizer and carried into the separator fixed at the top of pulverizerCoal Pulverizers an overview ScienceDirect Topics

.jpg)

Coal Pulverizer – Power Plant Pall Corporation

23 小时之前 Many coal pulverizer designs do not incorporate any filtration in their lube circuits The pulverizers that do not incorporate filtration use coarse filtration such as 40micron cleanable mesh or 200micron cleanable, stacked disk filters Such OEMsupplied filtration is often unable to keep up with the inherently high ingression rate2024年3月7日 To classify coal particles to the required level of fineness, normally 70 % through 200 mesh and less than 2% on 50 mesh; Coal parameters affecting pulverizer output While selecting a pulverizer, the coal characteristics play an important role The Hardgrove index, total moisture, input coal size, output fineness, and mill wear have direct Coil Pulverizers for Boilers Bright Hub Engineering2019年3月20日 2 (Two) Reconditioned #453 CE Raymond Bowl Mill Coal Pulverizers rated at a base capacity 11,500 Lbs/Hr on 55 grindibility coal pulverized to 70% minus 200 mesh (Each mill is capable of grinding down to 90% minus 200 mesh as well as grinding a 40 hardgrove but at a lower rating) Check nowce raymond bowl mills Stone Pulverizer2024年11月20日 【MP Series Coal Pulverizer】 The MP series coal pulverizer is based on the mechanical principle of highspeed rotation to complete the supply, crushing, and wind simultaneously The coal is crushed to 003006 fine powder particles, which are sent into the furnace by the wind blades with a water column pressure of 100290 mm Form Coal Pulverizer Injection Machine JXSC Machine

.jpg)

Coal pulverisation with vertical roller mills Engineer Live

2013年2月1日 In general, coal pulverisers are designed to achieve the maximum rated capacity grinding a design coal with a grindability of 55 HGI and 812 per cent moisture and achieving a discharge fineness of 70 per cent passing a 200 mesh screen (74 micron) and 995 per cent passing a 50 mesh screen Variation of the coal hardness and/or moisture content 2007年7月15日 A Loesche LSKS dynamic classifier (Figure 1) was retrofitted to each of four Babcock ‘ Wilcox (B’W) Model 10E10 ring and ball pulverizers at EON’s RatcliffeonSoar Power Station in the UKDynamic classifiers improve pulverizer performance and more2023年11月20日 News/Company News/200 mesh coal pulverizer grinding mill delivery site 200 mesh coal pulverizer grinding mill delivery site 20/11/2023 admin HGM series ultrafine grinding mill is used by customers to grind pulverized coal, with an output of 5tph, and a finished powder fineness of 200 mesh It is used as raw material for calcining lime200 mesh coal pulverizer grinding mill delivery site2024年6月27日 Coal Pulverizer Figure 1: Simplified diagram detailing a directfired coal burning system 1 EPRI study on large coal fired utility boilers (greater cleanable mesh or 200micron cleanable, stacked disk filters Such OEMsupplied filtration is often unable to keep up with the inherently high ingression rate This resultsImproving Coal Pulverizer Performance and Reliability

.jpg)

“Blueprint” Your Pulverizer for Improved Performance

2020年8月27日 that article explained, the capacity of a coal pulverizer is a complex function of the fuel fineness desired, the coal’s Hargrove Grindablity Index (HGI), and the coal’s raw feed fuel and greater than passing of 200 mesh requires the maximum pressure of the grinding elements Keep in mind that in operation there is no metaltometal 2024年8月22日 Flow and temperature of primary air are automatically adjusted to match coal feed rate and coal moisture Potential for pulverizer fires significantly reduced Integral fan purges the pulverizer of coal dust after the coal feed is stopped As raw coal and primary air enter the crusher section during startup,RILEY POWER’S ATRITA COAL PULVERIZERS RELIABLE 2011年10月1日 A sample set of results from a vertical air swept pulverizer with a static classifier might be 9925% passing 50 mesh (297 µm), 8738% passing 100 mesh (149 µm), 7212% passing 140 mesh (105 µm Improved Coal Fineness Improves Performance, Reduces Emissions2 天之前 Excessive coal spillage is a hazardous situation which can plug the pyrites discharge chute thus allowing a coal buildup in the millside and increasing the potential for a pulverizer fire 2 Operating a coal pulverizer for an extended period of time with outlet temperature below specification is hazardous since the coal may not be properly Bowl Mill Coal Pulverizer COAL HANDLING PLANTS

Innovative Combustion Technologies, Inc

2018年6月3日 200 Mesh and 999% passing 200 Mesh improves fuel distribution as well as unburned Carbon in flyash After coal fineness is determined by sieving, fineness data should by plotted against the Rosin and Rammler formula This plot is utilized to verify the representativeness of the coal sample and sieving A representative sample will plot as a2020年11月1日 Most utility coalfired boilers are also pulverizedcoal boilers, by definition using coal pulverized to a fine size, generally 70% passing 200 mesh (75 µm) In the most common pulverizer designs, coal is pulverized in a ball and race mill (Fig 1) with the fine coal entrained in the airflow, carried out of the top of the pulverizer, and Geochemical partitioning from pulverized coal to fly ash and Introduction This article concerns itself with vertical grinding mills used for coal pulverization only (coal pulverizers), although vertical grinding mills can and are used for other purposes The 3D model in the saVRee database represents a vertical grinding bowl millOther grinding mill types include the ball tube mill, hammer mill, ball and race mill, and , roll and ring millVertical Grinding Mill (Coal Pulverizer) Explained saVReeMine Mesh for Metal and Coal Mining support is an essential product that plays a vital role in the safety and stability of mining operations It is a type of mesh that is fabricated from highquality steel or other alloys to provide reinforcement and support to the roofs and walls of the underground mines where metal or coal mining takes placeMine Mesh for metal and coal mining

.jpg)

Coal Pulverizer Price MadeinChina

Coal Pulverizer Price Select 2024 high quality Coal Pulverizer Price products in best price from certified Chinese Long Ball Mill manufacturers, Ball Grinder suppliers, wholesalers and factory on MadeinChina Fineness: 50200 Mesh Voltage: 220V/380V Capacity: 15500 Kg/H Weight: 30320 Kg 1 / 6 Favorites Upgrade your Mining