Large watercoal slurry ball mill helps new energy industry develop better

.jpg)

Helping to reduce mining industry carbon emissions: A step

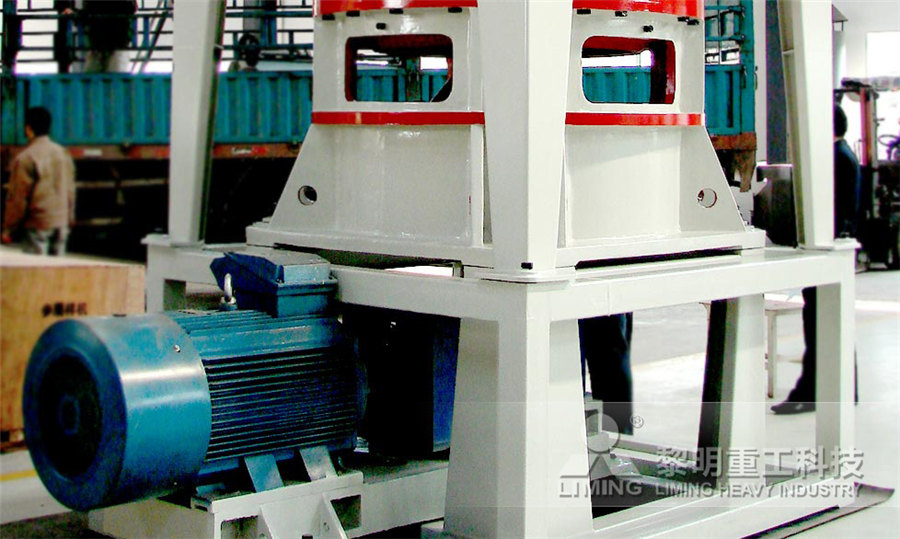

2022年3月30日 HPGR circuits can reduce the hard rock mining industry’s CO 2 emissions by up to 435% compared to SAG/Ball mill circuits Analysis of published data has confirmed that lower specific grinding forces result in an improvement in the comminution efficiency of HPGRs2020年4月3日 The prepared coal–water slurry consisted of 23% to 50% Lochiel coal and 40% Bowman’s coal The authors found that the solid concentration affected the nature of the Potential of Coal–Water Slurries as an Alternative Fuel 2018年2月1日 This introductory study presents the analysis of the environmental, economic and energy performance indicators of burning highpotential coal water slurries containing Coalwater slurries containing petrochemicals to solve Coal water slurry ball mill is grinding equipment specially used for coal water slurry production Its specifications, structure and working conditions must meet the requirements of coal water slurry production scale, production process Coal Water Slurry Ball Mill

CoalWaterSlurries an overview ScienceDirect Topics

The coalwater slurry (CWS) is a potential new form of fuel for application in power boilers and industrial furnaces The single suspended coalwater slurry droplets have been burned in hot 2024年6月3日 In recent years, the use of ball milling to synthesize biochariron based materials has become an emerging and promising method due to its low cost, environmental Research progress on synthesis mechanism and performance 2024年5月10日 Coalwater slurry (CWS), a mixture of pulverized coal, water, and additives, is a clean liquid coalbased fuel for gasification Superhydrophobic surface modification using a Preparation of highconcentration coalwater slurry based 2019年10月1日 In this study, experimental data for wet and dryground coal samples under wet and dry grinding are characterized by commonly used distribution functions First, both the R Wet and dry grinding of coal in a laboratoryscale ball mill: Particle

.jpg)

The Technology and Application of a New Type of Coal Water Slurry

2021年9月30日 For high efficient and clean utilization of coal and to reduce requirement on water slurry particle size, a new type of coal water slurry (CWS)fired CFB boiler technology 2022年10月24日 For the coal power sector, using sludge and reclaimed water will reduce operational costs, and more notably, reduce GHG emissions/freshwater consumption per kWh Benefits of infrastructure symbiosis between coal power and 2012年6月1日 The paper presents an overview of the current methodology and practice in modeling and control of the grinding process in industrial ball mills Basic kinetic and energy models of the grinding (PDF) Grinding in Ball Mills: Modeling and Process ControlBMA's supply line of crystallization equipment also includes a slurry mill operating by the ball mill principle, using hardened steel pebbles EPC solutions for individual plant components or whole factories in the sugar and food Slurry mill BMA's supply line of crystallization

.jpg)

(PDF) Optimization of inmill ball loading and slurry solids

2012年12月1日 The inmill load volume and slurry solids concentration have significant influence on the ball mill product size and energy expenditure Hence, better energy efficiency and quality grind can only 2022年5月30日 To that end, China will focus on building major wind power and photovoltaic power stations in desert areas, integrate new energy exploitation and utilization with rural revitalization, promote new energy application in industry and construction sectors, and guide the whole society to consume green energy A new electricity system adapting to China to develop highquality new energy in new era State The Ball Mill is supplied with 1300 pcs, 6mm dia of stainless steel balls AISI316 motor 3 phase inline Helical ge ared motor power 037 KW (05 HP) 380/440 Volt 50/80 H2 Capacitay 6 litersted on baseJual Slurry Ball Mill oleh CV Kessa Teknik2015年10月15日 A) Total Apparent Volumetric Charge Filling – including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls – expressed as a percentage of the net internal mill volume (inside liners) B) Overflow Discharge Mills operating at low ball fillings – slurry may accumulate on top of the ball charge; causing, the Total Charge Calculate Ball Mill Grinding Capacity 911Metallurgist

Transformation and Development of the CoalBased

2022年4月10日 12 The status quo of the coalfired power industry China’s coalfired power industry is generally characterized by “large stock, new units and high efficiency” In 2020, the installed capacity of coalfired power units reached 108 TW, accounting for 49% of the total in China, of which highly efficient and largepower2023年12月28日 The safety factor is low, the service life is short, etc, and these will inevitably affect the continuous production of the ball mill Therefore, the overall performance of the ball mill is better 3 The ball mill is of good quality The better the quality of the ball mill, the more stable the performance of the ball mill will be during Factors Affect The Output and Quality of Ball Mills And How Ball Mill Introduction There are three main stages to mineral processing in the mining industryThese are: Comminution (crushing and grinding); Beneficiation (separation and concentration); Smelting and refining; Ball mills are employed in the comminution stage as grinding machines (size reduction)The purpose of grinders in the mining industry is to reduce Ball Mill (Ball Mills Explained) saVRee saVRee2018年2月1日 The new energy industry is a representative of strategic emerging industry, and is the strategic and pilot industry of the national economy The new energy industry plays a very important role in driving economic growth, adjusting industrial structure and transforming the mode of economic development (Wei et al, 2010) Moreover, it is the key Assessing the development of China's new energy industry

.jpg)

Tracing the technological trajectory of coal slurry

2022年8月23日 Coal slurry pipeline transportation is an important way to realize green coal logistics However, there are still challenges in understanding the cognitive aspects of coal slurry pipeline 2021年7月1日 The characteristics of the energy structure of rich coal, less oil and less gas, coupling with a high external dependence on oil and natural gas and the emphasis on the efficient and clean utilisation of coal, have brought opportunities for coal chemical industry However, with the largescale popularisation of coal gasification technology, the Review of the characteristics and graded utilisation of coal 2012年4月17日 The ball load and pulp load have a significant influence on the ball mill product size and production capacity To improve the circuit performance at industrial scale these variables must be (PDF) Effect of Slurry Density on Load Dynamic 2023年4月23日 Comminution is a very important and resultdetermining step in mineral processing This is because further downstream processes in the beneficiation chain depend entirely on it(PDF) Grinding Media in Ball MillsA Review ResearchGate

(PDF) Performance optimization of an industrial ball mill for

2017年1月1日 An increase of over 10% in mill throughput was achieved by removing the ball scats from a single stage SAG mill These scats are non spherical ball fragments resulting from uneven wear of balls 2021年6月1日 This paper analyzes the market failure and system failure among the new energy industry from the perspective of the theory of equilibrium, theory of evolution, and finally two solution ideas are (PDF) In the era of lowcarbon economy, how will the new energy Controlling the rheology of the slurry can also improve ball mill performance This includes factors such as viscosity, density, and the addition of dispersants Challenges and Solutions in Ball Mill Optimization Despite the benefits of ball mill optimization, there are Key Factors for Ball Mill Optimization in the Mining Industry2021年2月2日 ATTRITOR GRINDING MILLS AND NEW DEVELOPMENTS Robert E Schilling , M Yang UNION PROCESS INC which enables us to see how the Attritor fits into the family of mills For example, ball mills use large media, normally 1/2” or larger, and run at a low (1050) rpm but also requires large amounts of energy • Eliminate Waste Liquid ATTRITOR GRINDING MILLS AND NEW DEVELOPMENTS

(PDF) Comminution a Heart of Mineral Processing

2021年7月6日 The estimated model parameters were transferred into the simulation and optimization platform, integrated extraction simulator (IES) to estimate through constraintbased simulations the impact of 2021年11月18日 Green strategies in formulating, stabilizing and pipeline transportation of coal water slurry in the framework of WATERENERGY NEXUS: A state of the art review November 2021 Energy Nexus 4:Green strategies in formulating, stabilizing and pipeline 2021年11月15日 In order to better fulfil the responsibility in the construction of China's modern energy system, ensure the safety of energy supply, complete the steady transformation of energy structure and promote sustainable development, the coal industry needs to establish a development index to clearly depict its comprehensive development level and directionHow will China's coal industry develop in the future? A 2018年10月1日 Energyintensive manufacturing industries (EIMIs) (Napp et al, 2014), which are EIIs in manufacturing applications, take advantage of largescale facilities and equipment in production and have a higher energy consumption than any other industries (Song and Oh, 2015)In EIMIs, the production chain consists of continuous flow and discrete flow A big data driven analytical framework for energyintensive

.jpg)

Ball Mill an overview ScienceDirect Topics

where Ω E is the energycorrected ball wear rate, g per kWh, d R is the diameter of the largest balls in the mill (the recharge size), mm, K d E is the linear wear rate of balls, µm per kWh t −1, Ai is the Bond abrasion index determined in a laboratory test (unitless), F 80 is the feed 80% passing size of the ore, µm, and pH is the water Ball mills have been used for the preparation of coal–oil and conventional coal–water slurry fuels, also in large sizes up to a capacity of 50 tonnes of coal per hour (Austin et al, 1984) The Szego Mill has not yet been scaled up to large sizes, but its further development includes combining coal beneficiation with the grinding taskCoalWater Fuel an overview ScienceDirect Topics2021年4月25日 Coal water slurry gasification is a main source of hydrogen in the developing hydrogen economy Moreover, biomass and waste can be added, making gasification process greener To expand the application of coal water slurry and gasification process, it is necessary to understand the microstructure in this large particle suspension system In this paper, the Aggregating structure in coal water slurry studied by eDLVO 维普中文期刊服务平台,是重庆维普资讯有限公司标准化产品之一,本平台以《中文科技期刊数据库》为数据基础,通过对国内出版发行的15000余种科技期刊、7000万篇期刊全文进行内容组织和引文分析,为高校图书馆、情报所、科研机构及企业用户提供一站式文献服务。水煤浆应用现状及技术进展【维普期刊官网】 中文期刊

Slurryability and flowability of coal water slurry: Effect of

2021年11月10日 The utilization of coal in the form of coal water slurry is a better and efficient method to control the harmful pollutants viz NOx and SOx Coal water slurry is a complex, high energy density, multiphase fuel which is then pulverized using a lab scale ball mill The pulverized coal has a maximum size of 250 μm The sample is sieved 2022年2月15日 Naturally, the large variety of raw materials found in the USA and China result from the massive area of both countries, amounting to over 9 million km 2 (Brown et al, 2020)The wide range of latitude and longitude determines a broad climatic spectrum for those countries, which is conducive to the conditions for the formation of raw materials in the past Waste management in the mining industry of metals ores, coalThe coal is removed by using a coal extraction technique involving rotary drums that shear coal, shale, and fire clay from the coal seam After removing large noncoal fragments, water is added to the raw coal to produce a 12 percent coal slurry to separate the remaining shale, fire clay, and other particles from the coalOptimized Pump Systems Save Coal Preparation Plant 2012年6月1日 The paper presents an overview of the current methodology and practice in modeling and control of the grinding process in industrial ball mills Basic kinetic and energy models of the grinding (PDF) Grinding in Ball Mills: Modeling and Process Control

Slurry mill BMA's supply line of crystallization

BMA's supply line of crystallization equipment also includes a slurry mill operating by the ball mill principle, using hardened steel pebbles EPC solutions for individual plant components or whole factories in the sugar and food 2012年12月1日 The inmill load volume and slurry solids concentration have significant influence on the ball mill product size and energy expenditure Hence, better energy efficiency and quality grind can only (PDF) Optimization of inmill ball loading and slurry solids 2022年5月30日 To that end, China will focus on building major wind power and photovoltaic power stations in desert areas, integrate new energy exploitation and utilization with rural revitalization, promote new energy application in industry and construction sectors, and guide the whole society to consume green energy A new electricity system adapting to China to develop highquality new energy in new era State The Ball Mill is supplied with 1300 pcs, 6mm dia of stainless steel balls AISI316 motor 3 phase inline Helical ge ared motor power 037 KW (05 HP) 380/440 Volt 50/80 H2 Capacitay 6 litersted on baseJual Slurry Ball Mill oleh CV Kessa Teknik

Calculate Ball Mill Grinding Capacity 911Metallurgist

2015年10月15日 A) Total Apparent Volumetric Charge Filling – including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls – expressed as a percentage of the net internal mill volume (inside liners) B) Overflow Discharge Mills operating at low ball fillings – slurry may accumulate on top of the ball charge; causing, the Total Charge 2022年4月10日 12 The status quo of the coalfired power industry China’s coalfired power industry is generally characterized by “large stock, new units and high efficiency” In 2020, the installed capacity of coalfired power units reached 108 TW, accounting for 49% of the total in China, of which highly efficient and largepowerTransformation and Development of the CoalBased 2023年12月28日 The safety factor is low, the service life is short, etc, and these will inevitably affect the continuous production of the ball mill Therefore, the overall performance of the ball mill is better 3 The ball mill is of good quality The better the quality of the ball mill, the more stable the performance of the ball mill will be during Factors Affect The Output and Quality of Ball Mills And How Ball Mill Introduction There are three main stages to mineral processing in the mining industryThese are: Comminution (crushing and grinding); Beneficiation (separation and concentration); Smelting and refining; Ball mills are employed in the comminution stage as grinding machines (size reduction)The purpose of grinders in the mining industry is to reduce Ball Mill (Ball Mills Explained) saVRee saVRee

Assessing the development of China's new energy industry

2018年2月1日 The new energy industry is a representative of strategic emerging industry, and is the strategic and pilot industry of the national economy The new energy industry plays a very important role in driving economic growth, adjusting industrial structure and transforming the mode of economic development (Wei et al, 2010) Moreover, it is the key