Burley Hughes grinding roller material

三辊研磨机 研磨与分散 布勒集团 Bühler Group

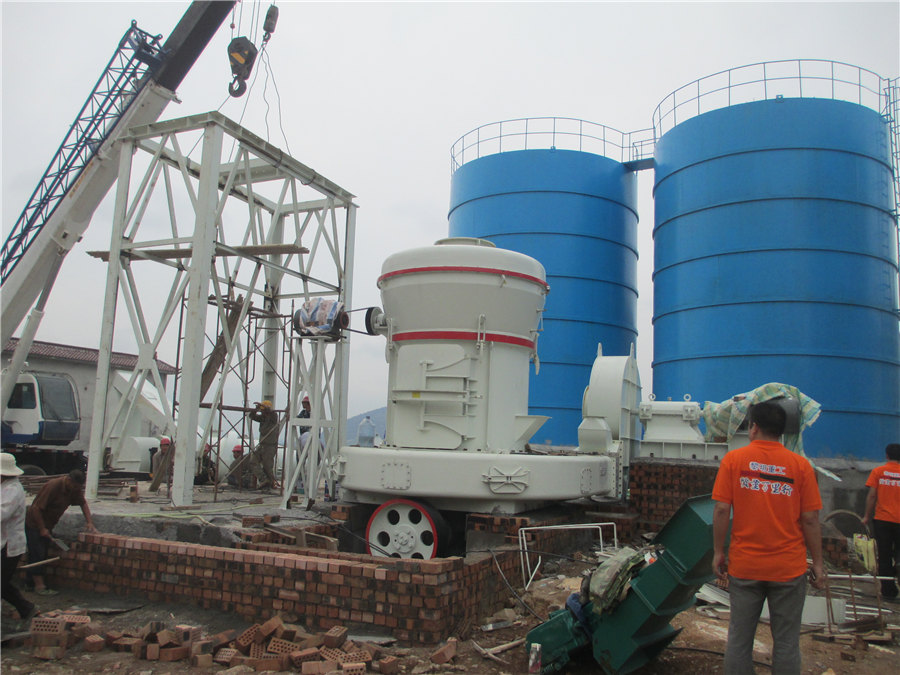

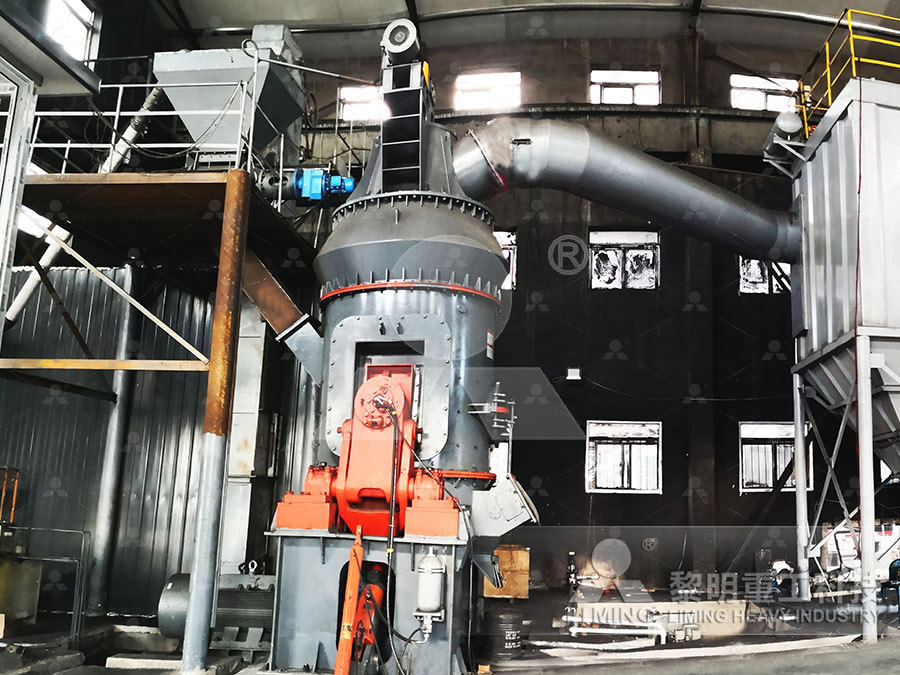

布勒三辊研磨机特性:(三次研磨)具有可靠、原料高产以及对污染物和温度敏感物料柔和分散等突出特性。Bühler roller mills consistently and safely grind wheat, corn, rye, barley, spelt and other grains We offer a wide range of roller mills and optional functionsRoller Mills Milling Bühler GroupOur roller grinding unit OLFS allows you an onsite refurbishing of the roller surfaces in your flaking mill, without removing the rollers It’s a rugged and easytomount automatic machine, designed to provide precise grinding results, OLFS Roller Grinding Unit Bühler Group2023年10月20日 contrast to conventional rolls, the Bühler VIVA roller technology is designed to be operated at different roller pressures and accordingly cover the whole pressure range Trias The threeroll demands dam

Diorit Roller Mill MDDY/Z Bühler Group

2023年10月23日 Bühler’s Diorit four or eightroller mill consistently and safely grinds wheat, corn, rye, barley, spelt and other grains Diorit 2019 is ready for the digital age Stateoftheart 1988年4月1日 The first HCroller mill is serving as a premilling unit for cement clinker In the finemilling mode the underflow from the classifier is recirculated to the HCroller mill The A first survey of grinding with highcompression roller mills2022年5月31日 The vertical roller mill (VRM), including powder separation and crushing subsystems, is used extensively for intermediate crushing of minerals in several industries such Analysis of vertical roller mill performance with changes in material 2023年7月4日 Roller mill is a type of grinding equipment for crushing materials by pressure between two or more rolling surfaces or between rolling grinding bodies (balls, rollers) and a Roller Mill SpringerLink

.jpg)

Wet Grinding and Dispersing Equipment Bühler

Bühler's wet grinding and dispersing solutions include cuttingedge bead mills and threeroll mills, supported by unrivalled process and application expertise2020年11月11日 This article introduces roller mills and explains how they efficiently grind friable materials to a uniform final particle size while using relatively little energyRoller mills: Precisely reducing particle size with greater 2024年4月11日 The appropriate type of material rollers can be selected ,enhancing industrial efficiency ,maximize operational efficiency and reliability : [ protected] Phone:+86 Unusual noises, such as grinding or squeaking, often signal internal bearing failure Roller rotation issues, where rollers are stuck or turn with Conveyor Roller Material Rollers in Various Sizes2013年3月13日 To be of horizontal and inclined grinding table integrating cone type grinding roller; To be of static and dynamic combined high efficiency cage type separator for mill internal classifying; To be of relative independently pressing to the material by each grindingTRM SERIES CEMENT VERTICAL ROLLER MILL TRM

.jpg)

GRINDING TECHNOLOGY COURSE The Cement Institute

2024年11月4日 A 6week modular course is designed to give the course attendee a solid understanding of the grinding system and its auxiliary equipment The purpose of the training is to Identify and understands necessary known and unknown information towards the completed cycle of the grinding system, whether it is a ball mill, vertical mill, or crushing process2016年1月4日 As the pregrinder, vertical roller mill is often used considering its great grinding efficiency Fig Raw material grinding system Results Table Effect of implementing raw material pregrinder By this production increasing, it is expected that operation in the daytime can be shortened and then power cost can be reduced Cost estimationVertical roller mill for raw Application p rocess materialsThe roller is one of the main parts of a highpressure grinding roller, which is a type of highly efficient ore crushing equipment Its working life is strongly affected by the materials used In A first survey of grinding with highcompression roller mills2013年3月13日 Development of trp roller press Year of 1985, to start the research of roller press; Year of 1989, the initial TRP100/25 roller press was operated in Hu’nan Dongjiang Cement Plant; Year of 1992, to set up TRP40/10 roller press experimentROLLER PRESS AND BALL MILL COMBINED GRINDING

RAW MATERIAL GRINDING ITadipatri’s big sixer Loesche

2017年8月13日 support for the grinding rollers permitted the design of mills with two, three and four grinding rollers There is no need for an additional supporting frame to brace the rollers to each other inside the mill The design of mill model LM 634 in the mid1990s, which had an arrangement of four grinding rollers on a grinding track of f63m, was2020年8月12日 This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coalfired power plant In a power plant, the coal mill is the critical equipment, whose An investigation of performance characteristics and 2024年5月16日 rotating rollers, whereby the ore is chokefed between the rollers The feed material is compressed from the bulk density to 70–85 % of the real density and the individual particles are exposed to very high pressure Comminution takes place in the packed material bed rather than through The highpressure grinding roller press (HPGR) is HighPressure Grinding Roller Presses for Minerals 2024年1月3日 Grinding and separation efficiency of vertical roller mill were evaluated In addition to these, performance figures of vertical roller mill and conventional closed ball mill circuit were comparedPerformance Evaluation of Vertical Roller Mill in Cement

Material analysis of the fatigue mechanism of rollers in tapered roller

2018年5月18日 Rolling contact fatigue is the main failure mechanism of tapered roller bearings This study investigated the fatigue mechanism of rollers in a tapered roller bearing that failed in a runtofailure test Roller microstructure and crack morphology were investigated through scanning electron microscopy A microhardness test was performed to investigate the strain 2013年3月13日 TRM型原料辊磨系统 Trm series raw vertical roller mill system 3 TRM型原料辊磨采用带旋风收尘器和循环风机 的流程,磨机有物料外循环系统。混合料由喂料皮 带经三道锁风阀(或回转下料器)喂入辊磨,在辊TRM SERIES CEMENT VERTICAL ROLLER MILLTRM This paper introduces the large raw material roller press finish grinding system developed by Tianjin Cement Industry Design Research Institute Ltd, which adopts newly developed equipment and process technology, such as the large Industrial application of large raw material roller 2019年7月17日 lower grinding limits of roller diameter will be made to good use by generating new weighting arm However, the amount of top roller pressure for the new roller diameter as well as for roller diameter after grinding cycles is still the same and no effort is taken to vary and optimize the top arm pressure II MATERIALS AND METHODS A MaterialAn Investigation on the Effect of Top Roller Cot Grinding

Analysis of vertical roller mill performance with changes in material

2022年5月31日 Analysis of vertical roller mill performance with changes in material properties and operating conditions using DEM Author links open overlay panel Chang Liu a, Zuobing Chen a, Weili Zhang b, Ya Mao a, Pengyun Xu c, Qiang Xie a The diameter of the millstone and grinding roller are 600 mm and 340 mm respectively, and the angle between the 2013年3月13日 生料粉磨技术发展 TRP辊压机装备技术 DEVELOPMENT OF RAW GRINDING TECHNOLOGY TRP ROLLER PRESS TECHNOLOGY AND EQUIPMENT 1 2 生料粉磨是水泥生产过程的一个重要环节。于 上世纪80年代中期问世的辊压机是一种比较理想的TRP ROLLER PRESS FOR FINAL RAW MATERIAL 2024年8月6日 In mineral processing, roller mills are invaluable for grinding hard, abrasive materials into fine particles preparing them for further processing or extraction The cement industry also relies heavily on these mills for grinding limestone, clinker, and other components into the fine powder that becomes cementBall Mills Vs Roller Mills Midwest Hardfacing2024年6月7日 The nonmetallic mineral grinding ring roller mill pulverizes nonmetallic minerals into fine powder It is designed and developed based on many years of research and experience in grinding mill production When the material passes through the gap between the grinding roller and the grinding ring, the material will be crushed by the impact Ring Roller Mill Ultrafine calcium carbonate production

High Pressure Grinding Roller Market Size Forecast By 2031

High Pressure Grinding Roller Market was valued at USD 2996 million in 2023 and is projected to reach USD 46329 million, with a CAGR of 560% by 2031 as they consume less energy and generate less waste compared to traditional grinding methods By enhancing material processing efficiency, HPGRs help industries meet stringent regulatory 2022年1月23日 This work concentrates on the energy consumption and grinding energy efficiency of a laboratory vertical roller mill (VRM) under various operating parametersAnalysis and Optimization of Grinding Performance of Vertical Roller 2017年10月27日 The power ingesting of a grinding process is 5060% in the cement production power consumption The Vertical Roller Mill (VRM) reduces the power consumption for cement grinding approximately 3040% associated with other grinding mills The process variables in cement grinding process using VRM are strongly nonlinear and having large timePROCESS CONTROL FOR CEMENT GRINDING IN The HPGR (high pressure grinding rolls/rollers) is the core equipment of the high pressure grinding process The machine reduces particles by compressing and crushing the feed between two counter rotating, parallel rollers with a small HPGR – High pressure grinding rolls/rollers

Roll grinderHiecise precision equipment

2023年5月15日 MK84125Ⅲ25 Mk84125 Ⅲ 25 fully automatic CNC roller grinder has the characteristics of high precision, high surface grinding quality, strong stability and easy operation It can grind cylindrical roller surface, 2024年9月18日 High Pressure Grinding( Roller Presses ) With our Roller Presses, the grinding pressure is transferred from the hydraulic system via the movable roll to the material bed and absorbed in a stable, closed machine frame A key feature is the mounting of the rollers in oillubricated cylindrical roller bearingsHigh Pressure Grinding Roller (HPGR) High Pressure Grinding Roller Where HPGR technology has replaced traditional methods of crushing and grinding (ie SAG and/or ball mills), customers have seen energy savings of up to 40%, and substantially improved mineral liberation The unique bearing arrangement of the Enduron® HPGR delivers marketleading bearing life and is designed to protect against premature failure, with proven Enduron® High Pressure Grinding Rolls (HPGR) Weir Weir 2015年3月15日 Vertical roller mill (VRM) is a largescale grinding equipment, which is used to grind raw materials from block/granule into powder Due to harsh production environment and inconsistent raw Research of iron ore grinding in a verticalrollermill

.jpg)

Grinding of particlereinforced metal matrix composite materials

2024年8月15日 In general, there are three forms of material removal: brittle, ductile, and mixed Numerous studies have demonstrated that the removal of materials in the ductile domain can yield highprecision and highquality grinding surfaces [17,18,19]In the grinding process of PMMCs, owing to the different mechanical properties between the reinforcement phase and The doubledisc straightgroove (DDSG) grinding method is a new precision machining method for the rolling surface of bearing cylindrical rollers by using a flat grinding disc and a straight Grinding principles of the DDSG method for cylindrical rollers2023年11月14日 The material of traditional grinding roller is usually high chromium cast iron or hardfacing Due to the characteristics of the material, the hardness is generally around HBW 650 Ceramic grinding rollers are embedded with highhardness, industrial wearresistant ceramics in the wear area of traditional highCeramic Grinding Roller Qiming Castingkindly contact Us on Incepted in the year 2002 at Ahmedabad (Gujarat, India), we “Bajrang Grinding ” are a Sole Proprietorship firm that is an affluent manufacturer of a wide array of Stainless Steel Roller, Rubber Roller, Calender Roller, Aluminum Roller, Hydraulic Piston, etc Apart from this we also impart Precision Job Work We provide these products as per the Bajrang Grinding Manufacturer of Rubber Roller Industrial Roller

Conveyor Roller Material Rollers in Various Sizes

2024年4月11日 The appropriate type of material rollers can be selected ,enhancing industrial efficiency ,maximize operational efficiency and reliability : [ protected] Phone:+86 Unusual noises, such as grinding or squeaking, often signal internal bearing failure Roller rotation issues, where rollers are stuck or turn with 2013年3月13日 To be of horizontal and inclined grinding table integrating cone type grinding roller; To be of static and dynamic combined high efficiency cage type separator for mill internal classifying; To be of relative independently pressing to the material by each grindingTRM SERIES CEMENT VERTICAL ROLLER MILL TRM 2024年11月4日 A 6week modular course is designed to give the course attendee a solid understanding of the grinding system and its auxiliary equipment The purpose of the training is to Identify and understands necessary known and unknown information towards the completed cycle of the grinding system, whether it is a ball mill, vertical mill, or crushing processGRINDING TECHNOLOGY COURSE The Cement Institute2016年1月4日 As the pregrinder, vertical roller mill is often used considering its great grinding efficiency Fig Raw material grinding system Results Table Effect of implementing raw material pregrinder By this production increasing, it is expected that operation in the daytime can be shortened and then power cost can be reduced Cost estimationVertical roller mill for raw Application p rocess materials

A first survey of grinding with highcompression roller mills

The roller is one of the main parts of a highpressure grinding roller, which is a type of highly efficient ore crushing equipment Its working life is strongly affected by the materials used In 2013年3月13日 Development of trp roller press Year of 1985, to start the research of roller press; Year of 1989, the initial TRP100/25 roller press was operated in Hu’nan Dongjiang Cement Plant; Year of 1992, to set up TRP40/10 roller press experimentROLLER PRESS AND BALL MILL COMBINED GRINDING 2017年8月13日 support for the grinding rollers permitted the design of mills with two, three and four grinding rollers There is no need for an additional supporting frame to brace the rollers to each other inside the mill The design of mill model LM 634 in the mid1990s, which had an arrangement of four grinding rollers on a grinding track of f63m, wasRAW MATERIAL GRINDING ITadipatri’s big sixer Loesche2020年8月12日 This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coalfired power plant In a power plant, the coal mill is the critical equipment, whose An investigation of performance characteristics and

.jpg)

HighPressure Grinding Roller Presses for Minerals

2024年5月16日 rotating rollers, whereby the ore is chokefed between the rollers The feed material is compressed from the bulk density to 70–85 % of the real density and the individual particles are exposed to very high pressure Comminution takes place in the packed material bed rather than through The highpressure grinding roller press (HPGR) is 2024年1月3日 Grinding and separation efficiency of vertical roller mill were evaluated In addition to these, performance figures of vertical roller mill and conventional closed ball mill circuit were comparedPerformance Evaluation of Vertical Roller Mill in Cement