Slag concrete mix ratio

.jpg)

Utilization of copper slag as fine sand replacement in concrete

2024年11月26日 The study encompasses the optimization of concrete mix proportions by considering the varying levels of copper slag content (20%, 30%, and 40%), watercement ratio (035, 040, and 045), and curing days (7, 14 and 28 days) It can be ascertained from the 2024年11月6日 Utilizing normalstrength concrete with a compressive strength of 35 MPa and a 045 watertocement ratio, fifteen mix designs were tested, varying RA and PSC replacement Optimizing sustainable concrete mixes with recycled 2017年9月21日 This report addresses the use of slag cement as a separate cementitious material added along with portland cement in the production of concrete This report does not 233R17: Guide to the Use of Slag Cement in Concrete 2024年5月2日 Studies have shown that incorporating steel slag in concrete and asphalt mixes can lead to improved compressive strength, splitting tensile strength, and durability Moreover, Utilization of steel slag as partial replacement for coarse

.jpg)

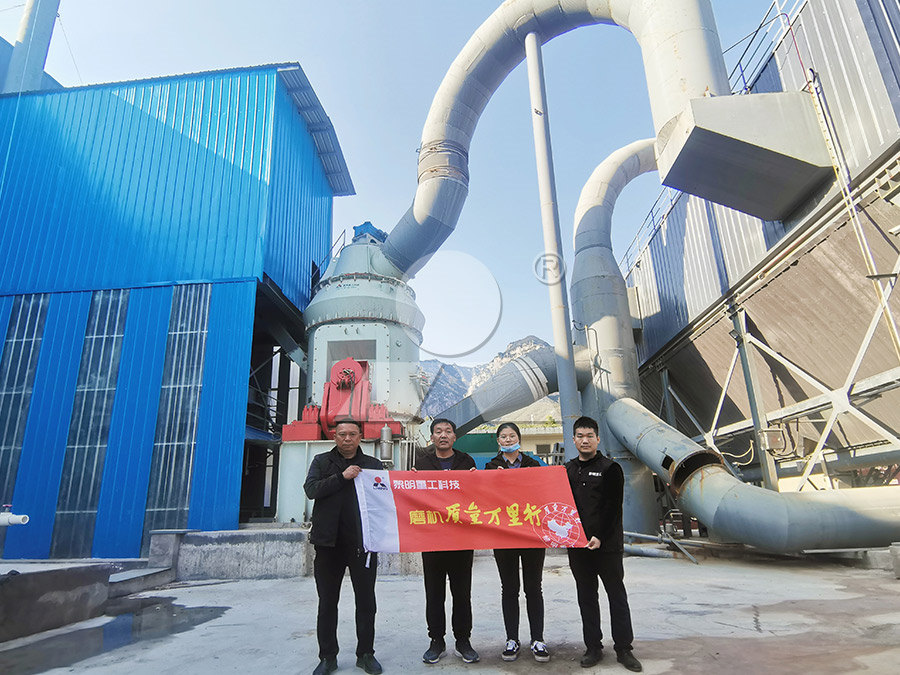

Mix ratio of cave slag concrete Download

This article starts with the characteristics of cave slag tailings, proposes to optimize the quality of the concrete production process and product structure by improving the composition of 2018年10月1日 The procedure involves three steps: 1) the determination of coarse and fine aggregate ratio according to close packing model; 2) the determination of liquid phase (water A mixture proportioning method for the development of 2018年10月30日 Two types of slag differing in their physical and chemical properties are investigated The test parameters include the level of cement replacement (30, 50 and 70% by The influence of slag properties, mix parameters and curing temperature 2020年10月9日 In concrete mix design, the watercement ratio is responsible for binding all constituents of concrete together If the watercement proportion is higher, it brings about (PDF) Effect of WaterCement Ratio on Mix Design and

Application of Fly Ash and Slag Generated by Incineration of

2020年4月22日 The main components of fly ash, slag, and concrete crystallites were analyzed using XRD with a mix ratio of B20C30 This analysis demonstrates the feasibility of replacing 2024年2月6日 The use of slagbased alkaliactivated concrete (AAC) could effectively address the issues of resource extraction and carbon emissions caused by traditional Portland cement Early mechanical properties and strength calculation method of slag 2023年4月13日 Slag cement Material to build our future Product description Heidelberg Materials Slag Cement conforms to ASTM C989/AASHTO M 302 standard specifications for “Slag Cement as a Constituent in Concrete and Mortars” and CSA A3001 “Cementitious Material for Use in Concrete” Slag has cementitious properties similar to portland cementSlag cement Heidelberg MaterialsTherefore, there is a need to develop sustainable concrete which either directly or indirectly reduces CO 2 emissions One way to achieve this is by limiting the consumption of cement to the maximum extent, by partially replacing it with supplementary cementitious materials (SCMs), which are majorly industrial byproducts and by optimizing the mix designs [21], [22], [23]Approach to design sustainable alkaliactivated slag recycled

.jpg)

A Comprehensive Review on the Ground

2022年7月18日 In the last few decades, the concrete industry has been massively expanded with the adoption of various kinds of binding materials As a substitute to cement and in an effort to relieve ecofriendly difficulties linked 2016年3月1日 Concrete Mix Design Calculations Concrete Mix Design) pmu l S ( t s a Ct •We = Water cement ratio concretepipe Water cement ratio Water needs to be drinkable or meet ASTM 1602 45 lbs of 045 expressed as decimal water 100 lbs of cement 1/22/2014 3 5 • Specific GravityConcrete Mix Design Calculations2023年11月4日 The lack of a code for preparing onepart geopolymer concrete (GPC) is one of the major obstacles to its wide use This study adopted one of the most common methods for preparing ordinary concrete, the ACI method, taking into account the most important variables affecting this method and then modified it to suit onepart GPC Three different sizes of A Practical Mix Design Method of Ground Granulated BlastFurnace Slag 2024年8月7日 In this paper, steel slag powder was used to replace part of the cement in road concrete, and group tests were carried out on coarse aggregates with different water–cement (W/C) ratios, different steel slag parameters, and different particle sizes A sample of 100 mm × 100 mm × 100 mm was prepared and cured for 3 days, 7 days, and 28 days In addition, the Preparation and Performance Testing of Steel Slag Concrete

.jpg)

Concrete Mix Ratio Calculator

1 天前 A Concrete Mix Ratio Calculator is a tool designed to help construction professionals, DIY enthusiasts, and anyone involved in building projects to determine the optimal proportions of ingredients needed to create highquality concrete The calculator takes into account the specific requirements of the project, such as strength, durability, and workability, and provides a 2024年6月12日 Alkali Activated Slag Concrete (AASC) has been a sustained research activity over the past two decades Its promising characteristics and being environmentally friendly compared to Ordinary Effect of binder and activator composition on the NatureThe American Concrete Institute (ACI) has recently published ACI 233R17 Guide to the Use of Slag Cement in Concrete and Mortar As slag cement use is rising in the US, understanding how slag cement works best in various situations is increasingly important for contractors and engineersThe guide covers information on slag cement chemical properties and product ACI Publishes Guide to the Use of Slag Cement in Concrete 2023年11月19日 what is the 1:2:3 mix ratio for concrete? The mix ratio of 1:2:3 consists of 1 Part cement, 2 Parts sand, and 3 Parts stone (plus some water) to make a concrete mix you can use for most any building project The way you measure the ratio could be in shovels, buckets, or wheel barrows As long as you're consistent you'll get a good strong mixWhat are the Correct Concrete Mixing Ratios Ratio Chart

.jpg)

Granulated Blast Furnace Slag and its Effects on

2021年12月7日 place This same study purports that the ideal ratio of slag cement is between 25% to 50% given its effect on flowability and strength, finding that in high performance concrete, slag is actually beneficial in the workability of the mix (ElTawil et al, 2018) Slag in high performance concreteConcrete Mix 124 Ratio Concrete mix 124 is a generalpurpose concrete mix that can be used for a variety of applications, including setting posts, pouring foundations, and laying sidewalks What Is Cement Used For? Of course, we Concrete Mix Ratio: What’s In A Cement Mix And Fly ash and Slag will typically be 18% cheaper than Portland cement When a mix includes 20% fly ash, this will provide savings of 35% in cost The advantage of slag is its ability to substitute more of cement Giving savings of up to 9% in Why use Fly Ash and Slag in Concrete? Bay In Missouri, a 70% slag concrete mix was successfully used in a bridge pier and abutment mass concrete project (Richardson, 2006) The Slag Cement Association If the Portland cement/slag ratio in the coarse fraction examined is not the same as in the whole cement, a correction can be applied by estimating the content of the reference Slag Concrete an overview ScienceDirect Topics

.jpg)

Concrete Mix Ratio: Everything You Need to Know

2024年8月17日 This mix ratio (one part cement, two parts sand, and three parts aggregate) is widely used for general construction purposes, such as small concrete projects and nonloadbearing structures 1:3:6 This ratio (one part cement, three parts sand, and six parts aggregate) is often used for foundations and large concrete masses where strength is a 2024年8月30日 The use of geopolymer as a cementitious material for geopolymer concrete (GPC) is beneficial for the sustainable development and green transformation of the construction industry Geopolymer concrete has many advantages, such as high strength, heat and corrosion resistance, low hydration heat, and carbon emissions This paper adopted the water–binder The Influence of Fly Ash and Slag on the Mechanical 2024年10月23日 The results indicate that the optimal mix proportion for HSGPC includes 15% fly ash content, 1030% silica fume content, alkali activator ratio of 25, and a NaOH molar concentration of 10 M Mix proportion design and carbon emission assessment of Concrete mix designing is the process of selecting the right amount of constituent materials to produce a mixture with the desired properties it shows that the value calculated based on the water to cement ratio and water content is governing Note 11 The eleventh note is related to the use of maximum aggregate size of 150 mm with a slump Concrete Mix Design Calculator (Based on the ACI Code)

Concrete Mix Ratio: Proportions, Types, and Guide UltraTech Cement

4 天之前 The concrete mix ratio is a fundamental aspect of construction that affects buildings' strength, durability, and costeffectiveness Understanding and using the correct concrete mix proportions, cement mix, and types of concrete mix ratio can significantly impact the quality of a construction project For those looking to ensure the best Concrete Mix Ratio: Max size of aggregates (mm) Water for dry aggregates (liter)* Water for aggregates condition from dry to moist batch (liter)* Water for best consistency (liter)* Small precast work, fence posts, poles, garden furniture and other work of Recommended Concrete Mixes for Various Types of 2018年2月22日 Concrete specimens of 100 mm cubical size were cast and precured for 30 days in plain water before exposure to different seawater environments Physical aspects regarding the deterioration of OPC and slag concrete of cement slag Strength behavior of concrete using slag with cement in 2024年11月1日 Optimizing mix design methods for using slag, ceramic, and glass waste powders in ecofriendly geopolymer mortars as the high Ca/Si ratio from slag dominates, but the low Si/Al ratio due to limited GP reactivity results in a poorly condensed Adesanya E, Ohenoja K, Luukkonen T, Kinnunen P, Illikainen M Onepart geopolymer cement from Optimizing mix design methods for using slag, ceramic, and

.jpg)

Axial compression stressstrain relationship of lithium slag

2024年10月3日 Raw materials Masonry cement with a grade of 325 was used in this work The LS used is shown in Fig 1(a) The coarse aggregate consisted of natural crushed stone ranging in size of 5–20 mmThese mix ratios are decided based on type of construction and mix designs However, building codes provides nominal and standard concrete mix ratios for various construction works based on experience and testing These types of concrete mix ratios are discussed in this article Types of Concrete Mix Ratio Mix Designs Nominal Concrete Mix Types of Concrete Mix Ratio Design and their Strengths2023年11月3日 The percentage of superabsorbent polymer (SAP) by weight of cement was also varied to 01, 02, and 03% Concrete mix with 01% SAP and 40% steel slag dosage exhibited superior mechanical properties the mix design is 1:164:304 and the w/c ratio is 045 for maintaining workability for the control mix The substitution ratios of steel Strength and Durability Properties of Steel Slag Incorporated 2022年6月15日 As per the standards of IS 10262:2019 [23], the mix design of concrete adopted in the current study is M25 grade of concrete Traditional method of mixing is illustrated below by considering 1m3 of concrete as per the mix proportions given in Table 5 by considering Mix IDGBS 10: 1 The replacement of cement by 30 kg of slag byGround Granulated Blast Furnace Slag as a Cement

Effect of Binder Content and Solution/Binder Ratio on Alkali

Use of alkaliactivated slag concrete (AASC) in replacing conventional concrete has become an environmentally friendly alternative construction technique Alkali activation of fly ash and ground granulated blast furnace slag (GGBFS) using NaOH and Na2SiO3 is well documented in the literature GGBFS activated with alkaline solution produces less workable concrete with quick 2024年11月15日 The superplasticizer/cement ratio, blast furnace slag/cement ratio, and fly ash/cement ratio are three other crucial mix proportion parameters, with contributions to the model of 189 %, 165 %, and 148 % respectively It is evident that the watercement ratios in the optimal mix proportions predominantly range between 027 and 032, while Compressive strength prediction of highperformance concrete In India, the best concrete mix ratio for RCC roof slab, beams and columns in residential buildings is 1:2:3 In a typical concrete mix ratio of 1:2:3, 1 part cement is mixed with 2 parts sand and 3 parts aggregate by volumeBest concrete mix ratio for roof slab, beam and column2023年6月17日 Copper slag in concrete has the capability to give both environmental and economic benefits to the copper slag has a lower surface porosity than sand and may require a lower waterbinder ratio when used to prepare the concrete mix In Fig 3 X and Y axis shows the sieve size and % of passing CS and the FA as per IS 383: 1970 Strength assessment of concrete with copper slag as fine

Slag cement Heidelberg Materials

2023年4月13日 Slag cement Material to build our future Product description Heidelberg Materials Slag Cement conforms to ASTM C989/AASHTO M 302 standard specifications for “Slag Cement as a Constituent in Concrete and Mortars” and CSA A3001 “Cementitious Material for Use in Concrete” Slag has cementitious properties similar to portland cementTherefore, there is a need to develop sustainable concrete which either directly or indirectly reduces CO 2 emissions One way to achieve this is by limiting the consumption of cement to the maximum extent, by partially replacing it with supplementary cementitious materials (SCMs), which are majorly industrial byproducts and by optimizing the mix designs [21], [22], [23]Approach to design sustainable alkaliactivated slag recycled 2022年7月18日 In the last few decades, the concrete industry has been massively expanded with the adoption of various kinds of binding materials As a substitute to cement and in an effort to relieve ecofriendly difficulties linked A Comprehensive Review on the Ground 2016年3月1日 Concrete Mix Design Calculations Concrete Mix Design) pmu l S ( t s a Ct •We = Water cement ratio concretepipe Water cement ratio Water needs to be drinkable or meet ASTM 1602 45 lbs of 045 expressed as decimal water 100 lbs of cement 1/22/2014 3 5 • Specific GravityConcrete Mix Design Calculations

A Practical Mix Design Method of Ground Granulated BlastFurnace Slag

2023年11月4日 The lack of a code for preparing onepart geopolymer concrete (GPC) is one of the major obstacles to its wide use This study adopted one of the most common methods for preparing ordinary concrete, the ACI method, taking into account the most important variables affecting this method and then modified it to suit onepart GPC Three different sizes of 2024年8月7日 In this paper, steel slag powder was used to replace part of the cement in road concrete, and group tests were carried out on coarse aggregates with different water–cement (W/C) ratios, different steel slag parameters, and different particle sizes A sample of 100 mm × 100 mm × 100 mm was prepared and cured for 3 days, 7 days, and 28 days In addition, the Preparation and Performance Testing of Steel Slag Concrete 1 天前 A Concrete Mix Ratio Calculator is a tool designed to help construction professionals, DIY enthusiasts, and anyone involved in building projects to determine the optimal proportions of ingredients needed to create highquality concrete The calculator takes into account the specific requirements of the project, such as strength, durability, and workability, and provides a Concrete Mix Ratio Calculator2024年6月12日 Alkali Activated Slag Concrete (AASC) has been a sustained research activity over the past two decades Its promising characteristics and being environmentally friendly compared to Ordinary Effect of binder and activator composition on the Nature

ACI Publishes Guide to the Use of Slag Cement in Concrete

The American Concrete Institute (ACI) has recently published ACI 233R17 Guide to the Use of Slag Cement in Concrete and Mortar As slag cement use is rising in the US, understanding how slag cement works best in various situations is increasingly important for contractors and engineersThe guide covers information on slag cement chemical properties and product 2023年11月19日 what is the 1:2:3 mix ratio for concrete? The mix ratio of 1:2:3 consists of 1 Part cement, 2 Parts sand, and 3 Parts stone (plus some water) to make a concrete mix you can use for most any building project The way you measure the ratio could be in shovels, buckets, or wheel barrows As long as you're consistent you'll get a good strong mixWhat are the Correct Concrete Mixing Ratios Ratio Chart