Slag mineral grinding machinery process flow

.jpg)

Slag Grinding Production Line TAYMACHINERY

2024年11月9日 The slag grinding production line is a production system specially used to process slag and make slag powder Slag, as a byproduct in the industrial production process, can be converted into valuable resources through grinding processing and used in cement XKJ Group production line Mineral Grinding Production Line equipment column provides you with the advantages, parameters, quotes, picture information of each Slag Grinding line seriesSlag Grinding line mining processing machine XKJ Group2021年11月10日 The ball mill slag grinding process mainly includes openflow and loopflow production processes The openflow process is to grind the dried slag through a ball mill and Slag Grinding Process chaengco2017年8月11日 Grinding of cement clinker and granulated blast furnace slag in roller grinding mills (vertical airswept grinding mills) is a technology introduced by Loesche The first use of a 2 µm 5 µm Loesche

Intelligent process control system for predicting operating

2024年1月31日 This study develops an intelligent datadriven approach for optimising slag grinding systems Slag grinding exhibits complex nonlinear dynamics that challenge control 2017年8月12日 Selective grinding and classification of the mineral fraction to the desired fineness, and treatment and preconcentration of the metal content are performed Loesche Mills for Metal Recovery and Filler Production 2016年11月22日 Generally, depending on the process applied, two pathways can be differentiated for recovery of metal from slags The first way includes processes resulting in Innovative approaches for an optimized processing of 2022年10月20日 Grinding options for slag and pozzolan While the use of supplementary cementitious materials is increasingly popular, the use of granulated blastfurnace slag and GRINDING Grinding options for slag and pozzolan PEC

.jpg)

Detailed performance analysis of the wet extractive grinding process

2021年9月1日 In this paper, the wet extractive grinding method for efficient recovery of calcium from steelmaking slags was studied This work supports the Sustainable Development Goal of 2019年12月9日 Air blast granulation involves pouring/tapping molten slag at a controlled rate to a gutter and spreading slag flow as a film This slag is subsequently broken up and atomized Granulation and Heat Recovery from Metallurgical Slags2023年2月15日 Slag bricks Slag brick production process Slag brick is made by mixing, watering, grinding and pressing slag and limestone In the production process of slag brick, the particle size of the slag is generally smaller than 8 How to Process Slags (with detailed process)?2017年2月8日 Materials The smelting slag used in this study was obtained from a copper plant in China Mineralogical analysis, performed using scanning electron microscope (SEM) and energy dispersive Xray spectroscope (EDS), polarizing microscope and Xray diffraction (XRD), indicated that fayalite (Fe 2 SiO 4) and magnetite (Fe 3 O 4) phases were major components The Recovery of Copper from Smelting Slag by Flotation Process

.jpg)

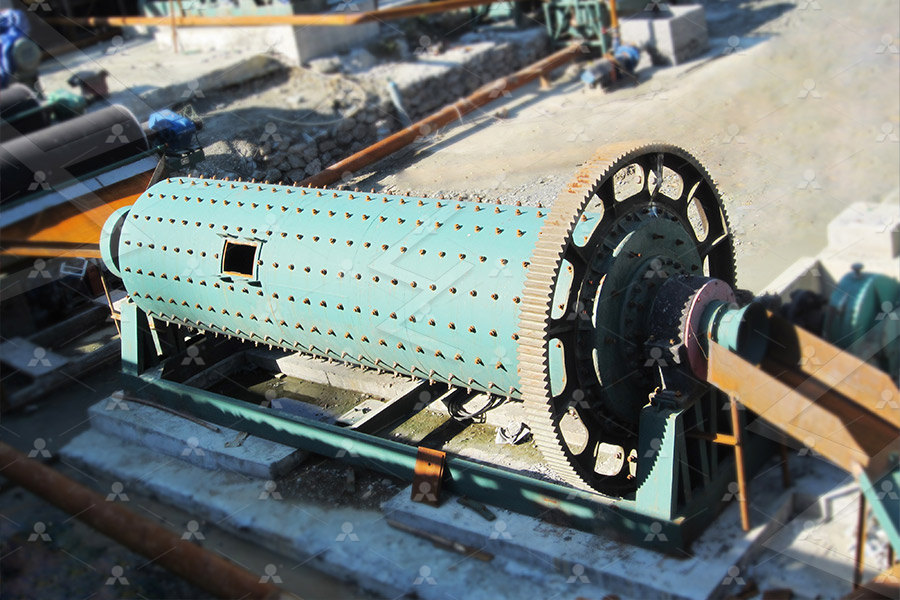

Mineral Processing Equipment for Mining Industry

2024年8月7日 Key Considerations for Choosing Mineral Processing Equipment Selecting the right equipment involves evaluating several factors: Mineral Type and Characteristics: The type and properties of the mineral affect equipment 2023年11月6日 It is highquality equipment for processing slag powder AFRICA English MIDDLEEAST NORTH AFRICA English COMMONWEALTH OF INDEPENDENT STATES Ore residue after mineral processing or smelting is called slag The slag containing SiO₂ is acid slag, and Al₂O₃ and CaO are mostly alkaline slag simple process flow, high grinding Slag mill, slag powder mill, slag uZhengzhou Vanguard Machinery 2021年11月11日 Slag is also called molten slag The melt that floats on the surface of liquid substances such as metals during the pyrometallurgical process is composed mainly of oxides (silicon dioxide, aluminum oxide, calcium oxide, magnesium oxide), and often contains sulfides and a small amount of metal Slag Introduction The composition of the slag is adjusted Recycle Metal From Slag: The Recycling Process JXSC Machine2023年12月27日 Steel slag processing plant flow Therefore, the common steel slag grinding equipment is steel slag ball mills Magnetic separator; The purpose of the steel slag process is to recover useful ironcontaining components, including bulk iron, granular iron, and fine iron tetroxide Due to the strong magnetism of the above components, the Steel Slag Processing Plant Equipment Selection

.jpg)

Copper Slag Beneficiation Process Equipment JXSC Machine

2024年1月3日 Coarse crushing + hemispherical grinding (complete white grinding) + ball milling process (semiwhite grinding process) 2 Copper Slag Sorting According to the characteristics of copper slag, the domestic mineral processing process for processing copper slag has the following characteristics: high concentration grinding, rapid flotation after 2022年6月14日 minerals Article Iron Recovery from Discarded Copper Slag in a RHF Direct Reduction and Subsequent Grinding/Magnetic Separation Process Zhicheng Cao 1,2, Tichang Sun 1,*, Xun Xue 1,2 and Zhanhua Liu 2 1 Key Laboratory of HighEfficient Mining and Safety of Metal Mines, Ministry of Education, University of Science and Technology Beijing, Beijing Iron Recovery from Discarded Copper Slag in a RHF In this study, the grinding characteristics of untreated and pretreated converter steel slag were compared with respect to iron mineral phases, grinding efficiency, particle size distribution, and The technical flow process of recycling ironrich phases in steel slag 2024年3月12日 Leading Technology: We have advanced steel slag processing technology and equipment that can efficiently and environmentally recycle steel slag Rich Experience: With over 40 years of experience in steel slag processing and machinery manufacturing, we have provided professional solutions and services to numerous clients in the fieldSteel Slag Recycling: The Definitive Processing Solution

Granulation and Heat Recovery from Metallurgical Slags

2019年12月9日 Conventionally, little chemical adjustments are made to the slag prior to its processing for subsequent use or disposal However, recent attempts have looked into modifying the chemical composition of slag while hot, to render its chemistry and properties suitable for highvalue products or recovery of minerals/metals from slag [11, 12]Nonetheless, the majority of 2024年2月3日 Fine slag (FS) is an unavoidable byproduct of coal gasification FS, which is a simple heap of solid waste left in the open air, easily causes environmental pollution and has a low resource utilization rate, thereby restricting the development of energysaving coal gasification technologies The multiscale analysis of FS performed in this study indicates typical grain size Multiscale analysis of fine slag from pulverized coal 2024年1月31日 Additionally, machine breakdowns often pose threats to the safety of workers Consequently, it is crucial to optimise the control of slag grinding systems, whether from a system optimisation control or safety Intelligent process control system for predicting 2024年11月15日 The slag grinding production line is a production system specially used to process slag and make slag powder Slag, as a byproduct in the industrial production process, can be converted into valuable resources through grinding processing and used in cement mixtures, highperformance concrete admixtures, etcSlag Grinding Production Line TAYMACHINERY

.jpg)

The Effect of Removing HardtoGrind Minerals from Steel Slag

2023年8月22日 Grinding is usually used to increase the specific surface area of steel slag to improve its activity However, due to the large amount of hardtogrind minerals in steel slag, a large amount of energy is wasted in the grinding process Therefore, the current investigation aims to remove the hardtogrind minerals in steel slag as much as possible to explore the 2022年7月20日 Process flow of limestone sand production line 1 Process flow of limestone manufactured sand Sand making: Through the crushed limestone, part of it is directly sent to the stockpile as a finished product, and the other part is crushed and made sand by the sand making machine Screening: The vibrating screen is also responsible for distinguishing the finished Limestone crushing, sand making and grinding process2022年12月15日 Roughly 10% of the CO2 emissions from iron and steel making are attributable to the direct release of CO2 from the thermal decomposition of carbonates to produce flux, mainly CaO, used for Enhancing CO2 Mineralization Rate and Extent of Iron and Steel Slag 2023年12月15日 Coal gasification is an important method that cleanly utilizes coal resources Unfortunately, coal gasification slag, a byproduct of the gasification process, has long been regarded as a solid waste (Xue et al, 2023; Gao et al, 2023a)Approximately 33 million tons of coal gasification slag is produced annually in China, which is either stockpiled or buried owing Recovery of residual carbon from coal gasification fine slag

VRM – AMCL Machinery Limited

InBuilt Reliability for Cement Plant Application: Raw Material, Cement, Slag, Coal and Minerals In May 2019, AMCL signed an exclusive Licensing Agreement for the design, manufacture, erection, commissioning and after sales service with UBE Machinery Corporation, Ltd (UBE) of VRMs in India, Bangladesh and Nepal2024年11月12日 Carbon dioxide mineral sequestration with steelmaking slag is a promising method for reducing carbon dioxide in a largescale setting Existing calcium oxide or calcium hydroxide in steelmaking slag can be easily leached by water, and the formed calcium carbonate can be easily wrapped on the surface of unreacted steelmaking slag particlesCarbon Dioxide Sequestration via Steelmaking Slag 2019年5月23日 Compared with the grinding of other materials, steel slag grinding is poorer, and it is difficult to guarantee the granularity of steel slag cement Hence, to enhance the application of steel slag in cement, more research and exploration have been made on the grinding of steel slag in recent years 641 Grinding of Steel Slag 1 Grinding Comprehensive Utilization Technology of Steel SlagCurrent systems for steel slag grinding that include ball mill systems, vertical mill systems and roller press systems on the market The ball mill system has high energy consumption, high noise and small singleunit capability, but the ball How is the steel slag vertical mill grinding process?

.jpg)

Titanium Slag Production Process: Technologies

2023年11月8日 Mineral raw materials for titanium production Grinding and magnetic separation of titanium slag; Desulfurization, alloying, and carbonization of associated metal; Recycling of waste energy Process flow diagram of Slag Grinding Plant Equipment Our Slag grinding process Our solution covers all steps including equipment installation, operation, production, maintenance, we will send technicians to guide the training until the customer is satisfied Enhance your mineral processing with our Industrial Slag Grinding Plant Partner with us for a Slag Grinding Plant Manufacturers NT Engitech2022年10月20日 Grinding options for slag and pozzolan While the use of supplementary cementitious materials is increasingly popular, the use of granulated blastfurnace slag and pozzolans presents extra challenges to the grinding process A careful assessment of grinding options available is key to efficient grinding operationsGRINDING Grinding options for slag and pozzolan PEC 2023年2月15日 Principle: Talc can be purified by flotation separation because the talc surface is hydrophobic while the associated minerals are hydrophilic Process: (1) First, crush and grind talc to separate talc from the associated minerals; (2) Then, send talc to a ball mill for wet grinding 90%95% of talc has a particle size less than 0074mm and is How to Process Talc (the Softest Mineral)? Fote Machinery

.jpg)

Loesche Mills for Metal Recovery and Filler Production

2017年8月12日 to the grinding process Small amounts of the mineral fraction still naturally adhere to the metal fraction discharged in the downward direction If necessary these mineral particles can be separated in subsequent sorting steps With this operating principle it is possible to recover nearly 100% of the metals Operating principle of metal recovery2020年7月16日 A PG2D grinding machine with a disk diameter of 230 mm and a rotation speed of 700 r min −1 was used for the grinding test, and the grinding time was 5, 10, and 20 min, respectively During grinding, the gasquenched steel slag abrasive and fluid were dispersed between the workpiece and the substrate, which exerted a certain pressure on the Structure characterization and grinding performance of gas 2021年12月5日 1 Using a Crusher for Crushing; 2 Using a Mill for Grinding; 3 Using a Trommel Screen for Screening; SITE FOR DELIVERY OF EQUIPMENT Gongyi Forui Machinery Factory is a highquality enterprise specializing in the production of beneficiation equipment Over the years, it has produced gravity beneficiation, magnetic separation, flotation, and other COPPER SLAG PROCESSING PRODUCTION LINE FLOW Henan Forui Machinery The open circuit grinding process is the earliest slag powder grinding technology It has the advantages of simple process, low technical requirements for operators, and low investment cost The unit power consumption of this system is about 100kWh/t per grinding slag with a specific surface area of 450m 2 /kg Disadvantages include low GGBS Production Line Slag Mill for Slag Powder Grinding

.jpg)

How to Process Slags (with detailed process)?

2023年2月15日 Slag bricks Slag brick production process Slag brick is made by mixing, watering, grinding and pressing slag and limestone In the production process of slag brick, the particle size of the slag is generally smaller than 8 2017年2月8日 Materials The smelting slag used in this study was obtained from a copper plant in China Mineralogical analysis, performed using scanning electron microscope (SEM) and energy dispersive Xray spectroscope (EDS), polarizing microscope and Xray diffraction (XRD), indicated that fayalite (Fe 2 SiO 4) and magnetite (Fe 3 O 4) phases were major components The Recovery of Copper from Smelting Slag by Flotation Process2024年8月7日 Key Considerations for Choosing Mineral Processing Equipment Selecting the right equipment involves evaluating several factors: Mineral Type and Characteristics: The type and properties of the mineral affect equipment Mineral Processing Equipment for Mining Industry2023年11月6日 It is highquality equipment for processing slag powder AFRICA English MIDDLEEAST NORTH AFRICA English COMMONWEALTH OF INDEPENDENT STATES Ore residue after mineral processing or smelting is called slag The slag containing SiO₂ is acid slag, and Al₂O₃ and CaO are mostly alkaline slag simple process flow, high grinding Slag mill, slag powder mill, slag uZhengzhou Vanguard Machinery

Recycle Metal From Slag: The Recycling Process JXSC Machine

2021年11月11日 Slag is also called molten slag The melt that floats on the surface of liquid substances such as metals during the pyrometallurgical process is composed mainly of oxides (silicon dioxide, aluminum oxide, calcium oxide, magnesium oxide), and often contains sulfides and a small amount of metal Slag Introduction The composition of the slag is adjusted 2023年12月27日 Steel slag processing plant flow Therefore, the common steel slag grinding equipment is steel slag ball mills Magnetic separator; The purpose of the steel slag process is to recover useful ironcontaining components, including bulk iron, granular iron, and fine iron tetroxide Due to the strong magnetism of the above components, the Steel Slag Processing Plant Equipment Selection2024年1月3日 Coarse crushing + hemispherical grinding (complete white grinding) + ball milling process (semiwhite grinding process) 2 Copper Slag Sorting According to the characteristics of copper slag, the domestic mineral processing process for processing copper slag has the following characteristics: high concentration grinding, rapid flotation after Copper Slag Beneficiation Process Equipment JXSC Machine2022年6月14日 minerals Article Iron Recovery from Discarded Copper Slag in a RHF Direct Reduction and Subsequent Grinding/Magnetic Separation Process Zhicheng Cao 1,2, Tichang Sun 1,*, Xun Xue 1,2 and Zhanhua Liu 2 1 Key Laboratory of HighEfficient Mining and Safety of Metal Mines, Ministry of Education, University of Science and Technology Beijing, Beijing Iron Recovery from Discarded Copper Slag in a RHF

The technical flow process of recycling ironrich phases in steel slag

In this study, the grinding characteristics of untreated and pretreated converter steel slag were compared with respect to iron mineral phases, grinding efficiency, particle size distribution, and 2024年3月12日 Leading Technology: We have advanced steel slag processing technology and equipment that can efficiently and environmentally recycle steel slag Rich Experience: With over 40 years of experience in steel slag processing and machinery manufacturing, we have provided professional solutions and services to numerous clients in the fieldSteel Slag Recycling: The Definitive Processing Solution