Nickel ore Namibia ore powder machine

Mapping Namibia’s nascent nickel projects The Extractor

2024年4月1日 Namibia’s nickel reserves are nowhere near those of South Africa, Zimbabwe, or Madagascar, but something is happening According to the Nickel Institute, the world’s nickel 2024年1月19日 By exploring the different stages involved, we will shed light on the techniques, challenges, and advancements in the nickel processing industry 1 Nickel Usage in Batteries and Other Applications 2 Nickel Deposits and The Comprehensive Guide to Nickel Processing2024年8月17日 The paper presents a comprehensive analysis of leading trends in nickel powder production techniques The physical and technological properties of nickel powders are Production Techniques and Physical and Technological 2022年5月15日 After its delivery, one ton of the ore is processed to produce 15–25 kg of nickel, and coal has to be burned, and slag waste is generated that requires disposal Therefore, it is Processing of oxidized nickel ores using sintering, roasting

(PDF) Advanced Review on Extraction of Nickel

2019年1月10日 Nickel extraction from primary resources such as ores/minerals (sulfides, arsenides, silicates, and oxides) including the unconventional one viz, the polymetallic sea nodules, and variousSulfide ores are crushed and ground in order to liberate nickel minerals from the waste materials by selective flotation In this process, the ore is mixed with special reagents and agitated by mechanical and pneumatic devices that Nickel processing Extraction, Refining, Alloying 2021年3月29日 Experiments were conducted to establish the optimal conditions to extract nickel from laterite ores using the sulfationroastingleaching process Various parameters were Roasting and Leaching Behavior of Nickel Laterite Ore2024年2月3日 In this work, Ni–Co–Fe powder with nickel, cobalt, and iron grades of 1198%, 118%, and 7013%, respectively, was obtained from a limonitic laterite ore via rotary kiln Phosphoric Acid Leaching of Ni–Co–Fe Powder Derived from

(PDF) Nickel laterite deposits – geological

2002年1月1日 This paper reviews the nature and genesis of nickel laterite mineralisation, and describes the relationship between deposit characteristics (both geological and nongeological) and the successful5 天之前 After the ground copper ore powder is sent to the flotation machine, various elements rich in it will react with various chemical solvents added in the flotation machine The flotation machine separates the copper ore from the Copper Ore Processing Plants, Flow And 2 天之前 Ultrafine Grinding, a professional solution provider of nanometer powder production Sole Solution Provider with 70+ technical monopolies; Professional Solution Provider for production line/process from grinding to drying, depolymerizing, coating/modifying, and also spheroidizing; CostEfficiency: low energy consumption, low media consumption, low Graphite/Paint/Nickel Iron Ore Powder Coating Line/Coating 2024年1月19日 Nickelbased cathode materials, such as nickelcobaltaluminum (NCA) and nickelmanganesecobalt (NMC), provide high energy density and improved performance (Nickel Ore) 2 Stainless Steel Production Nickel is a The Comprehensive Guide to Nickel Processing

.jpg)

Nickel Ore Beneficiation And Equipment JXSC Machinery

2024年11月21日 (2) Nickel laterite ore in nickel oxide ore has high iron content, low silicon and magnesium content, and 12% nickel content; while nickel silicate ore has low iron content, high silicon and magnesium content, and 1640% nickel content At present, the development and utilization of nickel oxide ore is mainly based on nickel laterite ore Nickel oxide ore treatment 2024年11月23日 What is an iron Powder Briquetting Machine? FTM Machinery iron powder briquetting machine, also known as metal powder briquette press machine, is a kind of briquetting machine for processing metal ore powders and recovering slag With the help of highpressure rollers, it can easily press the dry powder into balls of various shapes and sizesIron Powder Briquetting Machine Fote Machinery2023年4月25日 In the nickel ore processing plant, different types of nickel ore need mineral processing procedures and mining equipment based on the characteristics and composition of the ore Therefore, it is necessary to conduct beneficiation tests, design a feasible nickel ore beneficiation process, and then equip corresponding mining machines2 Types of Nickel Ore: Processing Methods and Equipment2021年3月29日 Abstract Nickel is mostly extracted from sulfide ores, however, laterite ores account for over 60 pct of all nickel resources in the world, and despite its predominance, there is no wellestablished process to extract nickel from such ores Nickel in laterites is hosted in many different compounds such as oxides, hydroxides, and silicates minerals The sulfationroasting Roasting and Leaching Behavior of Nickel Laterite Ore

Preparation of Ferronickel from Nickel Laterite Ore via Semi

2018年8月19日 The nickel laterite ore was dried at 120 °C for 2 h in an oven and ground to 100% passing 0074 mm The ground nickel laterite was mixed to homogeneously with pulverized coke The mixture was then briquetted into a cylinder (Φ30 mm × 10 mm) by powder tablet press machine with a pressure of 15 MPa (nothing was used as a binder for the 2021年12月2日 A new process of extracting silica from laterite nickel ore by hydrothermal treatment with sodium hydroxide as reaction auxiliary agent was proposed The mineralogical transformation and silicon extraction kinetics of laterite nickel ore in alkaline hydrothermal treatment were studied The effects of reaction temperature (175 ~ 250℃), molar ratios of Alkaline Hydrothermal Treatment and Leaching Kinetics of2024年5月11日 The effect of microwave treatment on the grinding and flotation performance of a typical copper–nickel sulfide ore was evaluated, based on the determination of its microwave absorption capability, grinding and flotation indexes such as crack percentage, mineral liberation degree, particle size distribution, relative work index (RWI), metal enrichment ratio and Microwave Treatment of Copper–Nickel Sulfide Ore for 2024年11月21日 1 Crushing and screening: The raw ore is transported to the mine warehouse by the mine car for storage, and then sent to the jaw crusher through the vibration feeding machine for a stage of crushing The crushed Ore Flotation Process Solution JXSC Machinery

Selective Reduction of Laterite Nickel Ore JSTAGE

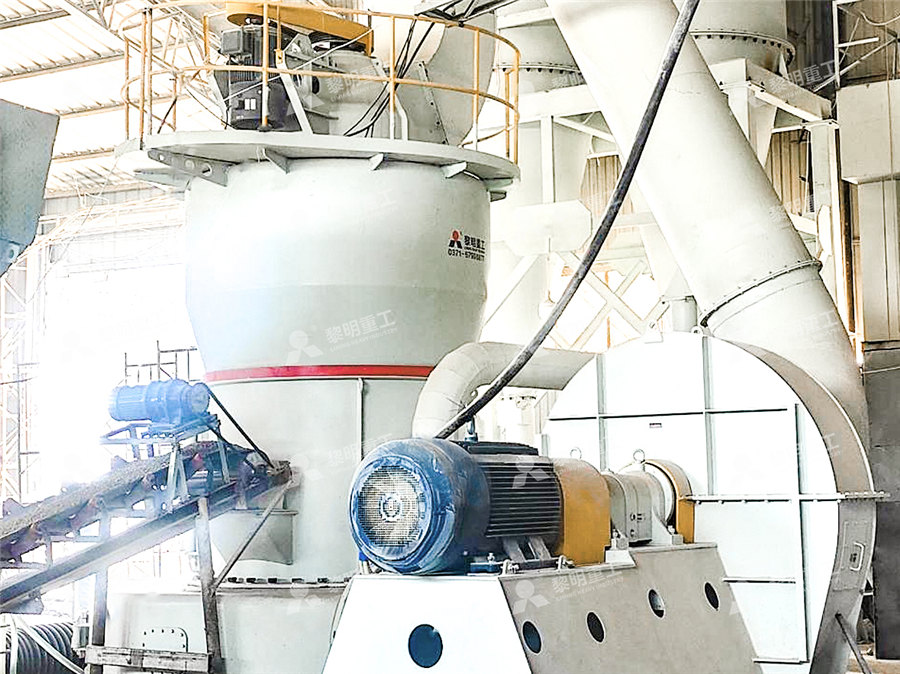

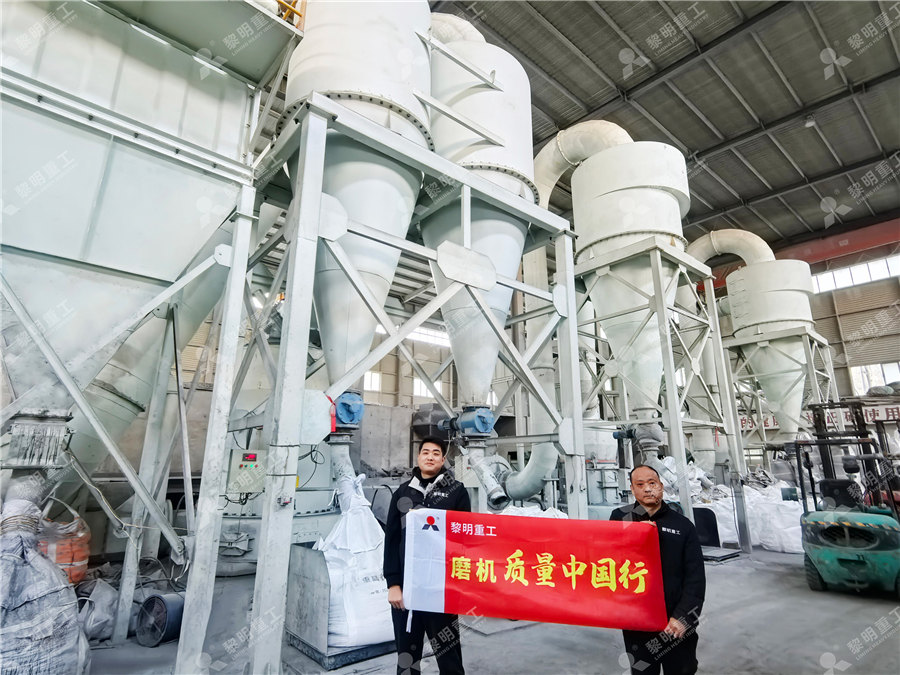

nickel ore is the highest dehydroxylation process compared to other lateritic nickel ore types It occurs at temperatures of 261270°C, while the removal of the hydroxyl group in the limonite nickel ore occurs at a temperature of 400600°C12) The removal of hydroxyl groups in chlorite (Fe,Mg,Al) 3(Si,Al) 2O 5(OH) 4 starts at 602°C and 2019年1月10日 Processing options for various types of nickel ore and their products (Adapted from Crundwell et al, 2011) Highpressure acid leaching (HPAL) process flowsheet operating at Moa Bay (Adapted from (PDF) Advanced Review on Extraction of Nickel 2017年8月16日 Nickel, a valued metal, mainly exists as nickel oxide in laterite nickel ore Furthermore, a large part of the laterite nickel ore is lowgrade saprolitic ore In this paper, a research on preparing ferronickel alloy from lowgrade saprolitic laterite nickel ore using metallized reductionmagnetic separation was studied In the research, the carbothermic Preparing FerroNickel Alloy from LowGrade Laterite Nickel Ore 2023年1月5日 Nickel ore processing equipment is nickel ore grinding equipment After the nickel ore is processed into powder, it will have better utilization value Because nickel ore has good chemical stability, ductility, melting resistance, high temperature resistance and other characteristics, so it is widely used in ceramics, military manufacturing, atomic energy,Nickel ore powder processing and grinding equipment

Ore: Generation, Quarrying, and Automatic Mining

2002年12月25日 The Survey Tools are good for getting in the rough area of a Mineral Node, but to narrow in on the center some Core Samples will be needed For that, place down a Core Sample Drill, supply power, and RightClick the machine It'll play a short drilling animation before the machine can be RightClicked again to pull out the Core Sample2020年6月1日 The nickel laterite ore employed in this study was from Sulawesi Island, Indonesia The raw ore was dried at 110 °C and then broken by a jaw crusher before being ground by a centrifugal grinding machine to −100 mesh Table 1 provides the ore compositions as determined by Xray Fluorescence Spectrometer (XRF)Preparation of highgrade ferronickel from lowgrade nickel Exports In 2022, Namibia exported $163M in Copper Ore, making it the 35th largest exporter of Copper Ore in the world At the same year, Copper Ore was the 9th most exported product in Namibia The main destination of Copper Ore exports from Namibia are: Netherlands ($773M), Belgium ($598M), China ($183M), Germany ($412M), and Malaysia ($2 Copper Ore in Namibia The Observatory of Economic 2022年4月11日 research is derived from the Jinchuan nickel ore, China After crushing and grinding, the ore powders bags The chemical composition of the ore powder in ppm was measured by an xray fluorescence analyzer (S8 TIGER II; Germany) and is shown in supplementary Table SI It can be seen that the content of nickel and copper is 362% and Direct Extraction of Nickel and Copper from LowGrade

Separation and recovery of iron and nickel from lowgrade

2020年11月1日 The laterite ore powder was mixed homogenously with pulverized coal and the CaO reagent powder in a certain proportion The amount of pulverized coal was mixed with a reducing agent according to the carbon to oxygen ratio (FC/O) of 10 and a ternary basicity ((CaO + MgO)/SiO 2) of 10 FC/O is the mole ratio of fixed carbon in coal to reducible Exports In 2022, Namibia exported $163M in Copper Ore, making it the 35th largest exporter of Copper Ore in the world At the same year, Copper Ore was the 9th most exported product in Namibia The main destination of Copper Ore exports from Namibia are: Netherlands ($773M), Belgium ($598M), China ($183M), Germany ($412M), and Malaysia ($2 Copper Ore in Namibia The Observatory of Economic 2022年4月11日 research is derived from the Jinchuan nickel ore, China After crushing and grinding, the ore powders bags The chemical composition of the ore powder in ppm was measured by an xray fluorescence analyzer (S8 TIGER II; Germany) and is shown in supplementary Table SI It can be seen that the content of nickel and copper is 362% and Direct Extraction of Nickel and Copper from LowGrade 2020年11月1日 The laterite ore powder was mixed homogenously with pulverized coal and the CaO reagent powder in a certain proportion The amount of pulverized coal was mixed with a reducing agent according to the carbon to oxygen ratio (FC/O) of 10 and a ternary basicity ((CaO + MgO)/SiO 2) of 10 FC/O is the mole ratio of fixed carbon in coal to reducible Separation and recovery of iron and nickel from lowgrade

.jpg)

The Use of Tecflote Family Collectors in Copper–Nickel Ore

2022年3月15日 Abstract Tecflote nonionic organic agents are investigated as potential flotation collectors for copper–nickel sulfide ores Adsorbability of four Tecflote agents having differentstructure alkyl radicals and different numbers of functional groups is analyzed The efficiency of the agents toward copper and nickelbearing minerals is estimated in nonfrothing flotation of 2021年10月24日 Nickel laterite ore is used to produce nickel metal, predominantly to manufacture stainless steel as well as nickel sulfate, a key ingredient in the batteries that drive electric vehiclesNickel Laterites—Mineralogical Monitoring for Grade 2020年3月1日 This article discusses multielement quantification in pressed pellets of copper‑nickel ore powders using laserinduced breakdown spectroscopy (LIBS) Thirtytwo copper‑nickel samples were used in this study 10 ml (~14–17 g) of each sample of copper‑nickel powder was granulated using a hydraulic press The samples were then analyzed Quantification of copper, nickel and other elements in coppernickel 2023年11月11日 Nickel is widely used in industrial processes and plays a crucial role in many applications However, most of the nickel resource mainly exists as nickel oxide in laterite nickel ore with complex composition, resulting in difficulty in upgrading the nickel content using physical separation methods In this study, highgrade ferronickel concentrates were obtained through HighGrade Ferronickel Concentrates Prepared from Laterite Nickel Ore

Advanced Ore Powder Dryer Fote Machinery(FTM)

2023年4月20日 Applications of Ore Powder Dryer Machine Ore powder dryer or mineral powder dryer is widely used in building materials, metallurgy, mineral processing, chemical industry, cement and other industries, which is mainly used for drying wet and heavy materials such as mineral powder, slag, limestone, clay, sand, quartz sand, grain slag, etc Fote ore powder 2023年1月19日 Nickel is a kind of silvery white ferromagnetic metal firstly separated by Swedish mineralogist AF Cronstedt in 1751 It is in the eighth group of the fourth period in the periodic table of elements, with atomic number of 28, atomic weight of 5871, density of 89 g/cm 3 (20 ℃), melting point of 1455 ℃, and boiling point of 2915 ℃ The most stable oxidation state of nickel An Overview of Nickel Utilization from Laterite Ore2020年1月24日 The paper focuses on leaching of complex copper–cobalt–nickel ore from Mwinilunga district in Zambia, containing 06% Cu, 021% Co, 26% Fe, and 013% Ni Mineralogical examination of the ore using scanning electron microscope (SEM) showed that copper, cobalt, and nickel exist in fine particles of heterogenite and limonite mineral phasesLeaching of Copper, Cobalt, and Nickel from Complex Ore5 天之前 After the ground copper ore powder is sent to the flotation machine, various elements rich in it will react with various chemical solvents added in the flotation machine The flotation machine separates the copper ore from the Copper Ore Processing Plants, Flow And

Graphite/Paint/Nickel Iron Ore Powder Coating Line/Coating

2 天之前 Ultrafine Grinding, a professional solution provider of nanometer powder production Sole Solution Provider with 70+ technical monopolies; Professional Solution Provider for production line/process from grinding to drying, depolymerizing, coating/modifying, and also spheroidizing; CostEfficiency: low energy consumption, low media consumption, low 2024年1月19日 Nickelbased cathode materials, such as nickelcobaltaluminum (NCA) and nickelmanganesecobalt (NMC), provide high energy density and improved performance (Nickel Ore) 2 Stainless Steel Production Nickel is a The Comprehensive Guide to Nickel Processing2024年11月21日 (2) Nickel laterite ore in nickel oxide ore has high iron content, low silicon and magnesium content, and 12% nickel content; while nickel silicate ore has low iron content, high silicon and magnesium content, and 1640% nickel content At present, the development and utilization of nickel oxide ore is mainly based on nickel laterite ore Nickel oxide ore treatment Nickel Ore Beneficiation And Equipment JXSC Machinery2024年11月23日 What is an iron Powder Briquetting Machine? FTM Machinery iron powder briquetting machine, also known as metal powder briquette press machine, is a kind of briquetting machine for processing metal ore powders and recovering slag With the help of highpressure rollers, it can easily press the dry powder into balls of various shapes and sizesIron Powder Briquetting Machine Fote Machinery

.jpg)

2 Types of Nickel Ore: Processing Methods and Equipment

2023年4月25日 In the nickel ore processing plant, different types of nickel ore need mineral processing procedures and mining equipment based on the characteristics and composition of the ore Therefore, it is necessary to conduct beneficiation tests, design a feasible nickel ore beneficiation process, and then equip corresponding mining machines2021年3月29日 Abstract Nickel is mostly extracted from sulfide ores, however, laterite ores account for over 60 pct of all nickel resources in the world, and despite its predominance, there is no wellestablished process to extract nickel from such ores Nickel in laterites is hosted in many different compounds such as oxides, hydroxides, and silicates minerals The sulfationroasting Roasting and Leaching Behavior of Nickel Laterite Ore2018年8月19日 The nickel laterite ore was dried at 120 °C for 2 h in an oven and ground to 100% passing 0074 mm The ground nickel laterite was mixed to homogeneously with pulverized coke The mixture was then briquetted into a cylinder (Φ30 mm × 10 mm) by powder tablet press machine with a pressure of 15 MPa (nothing was used as a binder for the Preparation of Ferronickel from Nickel Laterite Ore via Semi 2021年12月2日 A new process of extracting silica from laterite nickel ore by hydrothermal treatment with sodium hydroxide as reaction auxiliary agent was proposed The mineralogical transformation and silicon extraction kinetics of laterite nickel ore in alkaline hydrothermal treatment were studied The effects of reaction temperature (175 ~ 250℃), molar ratios of Alkaline Hydrothermal Treatment and Leaching Kinetics of

.jpg)

Microwave Treatment of Copper–Nickel Sulfide Ore for

2024年5月11日 The effect of microwave treatment on the grinding and flotation performance of a typical copper–nickel sulfide ore was evaluated, based on the determination of its microwave absorption capability, grinding and flotation indexes such as crack percentage, mineral liberation degree, particle size distribution, relative work index (RWI), metal enrichment ratio and