Autoclaved limestone brick equipment

Autoclaved LimeSand Brick Production Line China Autoclaved Brick

2024年1月10日 Business Range: Construction Decoration, Industrial Equipment Components, Manufacturing Processing Machinery, Metallurgy, Mineral Energy, Tools Limestone Crusher, Find Details and Price about aac production equipment autoclaved brick equipment from Limestone Crusher Hanan Chuangxin Building Material Equipment Co, LtdLimestone Crusher China aac production equipment and autoclaved brick China Autoclaved Brick Equipment wholesale Select 2024 high quality Autoclaved Brick Equipment products in best price from certified Chinese Brick Making Machine manufacturers, China Autoclaved Brick Equipment, Autoclaved Brick Equipment 2023年10月26日 Autoclaved Aerated Concrete (AAC) masonry is one of the most interesting solutions Several studies have been published so far to investigate the influence of raw Autoclaved aerated concrete masonry for energy efficient

.jpg)

China Autoclaved Limesand Brick Machine, China Autoclaved

China Autoclaved Limesand Brick Machine Select 2023 high quality China Autoclaved Limesand Brick Machine products in best price from certified Chinese Good Service Machine 2015年10月1日 Autoclaved Aerated Concrete Masonry Units (AAC) are ultra lightweight concrete blocks with a unique cellular structure that provides superior energy efficiency, fire AUTOCLAvED AERATED CONCRETE MASONRy UNITSEnvironmental Protection Autoclaved Aerated Concrete Aac Block Production Equipment for Sale No reviews yet Shandong Dongfeng Shuanglong Machinery Co, Ltd Custom manufacturer 12 Environmental Protection Autoclaved Aerated Concrete Aac 2024年11月21日 The manufacturing of autoclaved aerated concrete products demands high standards for mixing and dosing of the aggregates, the control of the fermentation process and Sand lime brick production Autoclave control system Masa Group

.jpg)

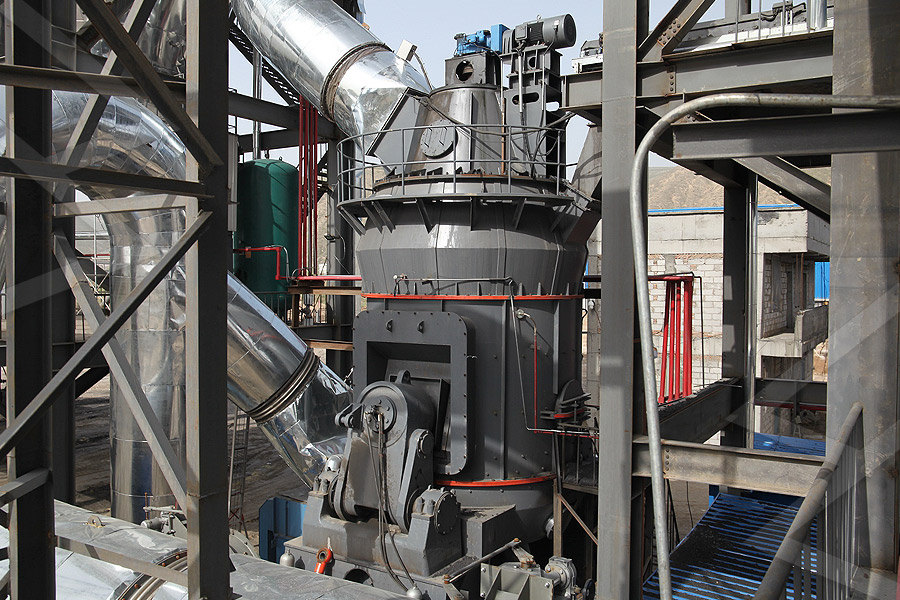

Production process of autoclaved limesand brick equipment

Production process, autoclaved limesand bricks (hereinafter referred to as limesand bricks) are ordinary limesand bricks made of sand and lime as the main raw materials, pigments and The production of autoclaved limesand bricks is an ordinary limesand brick made of sand and lime as the main raw material, pigments and admixtures are allowed, prepared from blanks, Production of autoclaved limesand brick equipment2020年1月30日 Brick manufacturing is an essential part of the construction industry, but it contributes heavily to environmental degradation As pointed out by Murmu and Patel [1], a brick kiln emits about 70–282 g of carbon dioxide, 0001–029 g of black carbon, 029–578 g of carbon monoxide (CO) and 015–156 g of particulate matter per kilogram of bricks fired, depending Ecological bricks from dimension stone waste and polyester resin2024年5月24日 Brick Blot focuses on and practices a sustainability approach and, therefore, incorporates innovative construction materials like autoclaved aerated concrete (AAC) blocks for project construction Post navigationGuide to Autoclaved Aerated Concrete Blocks

.jpg)

An Introduction to Autoclaved Aerated Concrete (AAC)

2020年12月2日 Lime powder required for AAC production is obtained either by crushing limestone to fine powder at AAC factory or by directly purchasing it in powder form Although purchasing lime powder might be little costly, manymanufacturers opt for it rather than investing in lime crushing equipment like ball mill, jaw crusher,Autoclaved Aerated Concrete is an ecofriendly and certified green building material which is lightweight, loadbearing, highinsulating, durable building blocks and 3 times lighter when compared to red bricks Sign Up Join TheConstructor to ask questions, answer questions, write articles, and connect with other people Limestone is Autoclaved Aerated Cement Blocks (AAC Blocks)Properties 2019年11月7日 The autoclaved aerated concrete (AAC) block or cellular lightweight concrete brick has emerged as the best alternative of clay brick as a sustainable building material Further, the kilns meant for heat treatment source in clay brick create air pollution and are replaced by steambased heat treatment, socalled autoclave, in the AAC production Manufacturing of Autoclaved Aerated Concrete (AAC): 2018年5月26日 13 Steps Involved in manufacturing process There are mainly four steps involves in manufacturing process of AAC Bricks: 1 Raw Material Preparation: Fly ash : Fly ash is mixed with water to form fly ash slurry Fly Ash is usually a byproduct of thermal power plants and is an important raw material in the manufacture of AAC Blocks Slurry thus formed is AutoClaved concrete bricks(AAC) seminar ppt SlideShare

.jpg)

(PDF) Analysis of autoclaved aerated concrete (AAC) blocks

2020年7月18日 However, the clay brick is produced by drying and firing clay or shale raw material, forming a sintered porous structure [55], [56], [57] Also, the AAC contains cement, but it is lightweight to We are a leading manufacturer of Autoclaved Aerated Concrete (AAC) blocks wire mesh AAC blocks are also known as Lightweight Blocks Goa, Udupi Support@coneccfo Call us now +91 HOME; these blocks are almost 70% lighter than Traditional Clay bricks and 40% lighter than the CLC Blocks, AAC blocks have a superior finish Lightweight AAC Blocks Manufacturer in Karnataka India2020年12月2日 Lime powder required for AAC production is obtained either by crushing limestone to fine powder at AAC factory or by directly purchasing it in powder form Although purchasing lime powder might be little costly, manymanufacturers opt for it rather than investing in lime crushing equipment like ball mill, jaw crusher,An Introduction to Autoclaved Aerated Concrete (AAC)2023年3月16日 Autoclaved aerated bricks (AAC) These AAC bricks are made with a mixture of cement, fly ash, lime, aeration agents and water involving an aeration It is obtained either by crushing limestone in the AAC factory to a fine powder or by buying it straight from a seller in powder form c Cement: In this AAC bricks, 53 grade OPC is used from A Review on Autoclaved Aerated Concrete (Aerocon

BrickRelief Finish Lime Slurry BioLime

Commonly known as German Schmear, BrickRelief Finish is made of premium quality marblewhite limestone, geopolymer chemistry and natural plantbased biopolymers BioLime BrickRelief Finish will preserve brick masonry by 2023年12月2日 AAC Block Properties Manufacturing Process Merits and Demerits Precautionary Measures Cracks Final Words Construction and Infrastructure projects today can recognize even the most intricate and What is an AAC Block Properties, Process, This paper presents comparative analysis of clay bricks and fly ash based autoclaved aerated concrete (AAC) block properties, methodology, process and material required for preparing fly ash based Cost Comparative Analysis for AAC Blocks and 2022年2月3日 Limestone is obtained by crushing it to a fine powder at an AAC factory or by acquiring it in powder form straight from a merchant Aluminium Powder: Aluminium Powder mix in concrete and this powder works as an fast as compare to clay brick [3,7] Autoclaved Aerated Concrete block have large size so speed of construction is obviously increaseUse of Autoclaved Aerated Concrete Blocks as Energy

.jpg)

Study on preparation and performance of brickconcrete

2024年8月15日 This research aims to prepare autoclaved aerated concrete (AAC) by using brickconcrete recycled sand powder (BCSP) as siliceous material The effects of BCSP content (0–100 %), fineness (258∼452 m 2 /kg), brickconcrete (B/C) ratio (10:0∼5:5), cement content (15–23) and CaOtoSiO 2 (Ca/Si) ratio (069–094) on the performance of brickconcrete 2021年6月13日 Hence, to reduce the adverse effects of brick on nature, Autoclaved Aerated Concrete was invented at the mid of 1920 by a Swedish architect Johan Axel Eriksson Autoclaved aerated concrete (AAC) is made with fine Lime powder is obtained either by crushing limestone to fine powder at AAC factory or by directly purchasing it from the market Autoclaved Aerated Concrete IARJSET3 Third is the compressive strength calculation between conventional brick and autoclaved Material Clay Brick Cement Sand Mason Worker AAC Block AAC Mortar Mason Worker aerated concrete block using method of sampling and testing 4 Fourth is the power consumption cost saving calculation of AAC block compared with conventional brick 5Beneficial Usage of Autoclaved Aerated Concrete Block23 小时之前 What is Autoclaved Aerated Concrete? The simplest way to describe autoclaved aerated concrete is with a metaphor It is a bit like baking, except instead of producing a loaf of bread or cake, you are making a special form of concrete Here are the ingredients in AAC: Cement; Lime; Water; Aluminum powder; Fly ash or silica sandAutoclaved Aerated Concrete (AAC Blocks)

Brick and Glass Waste Valorisation in the Manufacture of

2018年4月13日 have higher values of compressive strength and thermal conductivity as compared with AAC with brick waste Keywords: autoclaved aerated concrete, glass waste, brick waste, properties Autoclaved aerated concrete (AAC) is a light building material with high porosity (6090%) [1,2]; due to it’s specific microstructure (not connected, round pores AAC Block Making Equipment AAC is a kind of light cellular silicate products Main material based on Silicon materials ( sand, fly ash,gangue contains silicon)and Calcium(cement and lime),mix with foaming agent (Aluminium AAC Block Making Equipment crusherschina2024年8月15日 This research aims to prepare autoclaved aerated concrete (AAC) by using brickconcrete recycled sand powder (BCSP) as siliceous material The effects of BCSP content (0–100 %), fineness (258∼452 m 2 /kg), brickconcrete (B/C) ratio (10:0∼5:5), cement content (15–23) and CaOtoSiO 2 (Ca/Si) ratio (069–094) on the performance of brickconcrete Study on preparation and performance of brickconcrete 2012年7月1日 The autoclaved brick is made by 36 wt% modified desulfurized ash, 24 wt% fly ash, 32 wt% sand and 8 wt% stones The watersolid ratio is 010 limestone is introduced in the boiler for SemiDry Desulfurization Ash Modification and Application in Autoclaved

.jpg)

Autoclaved Aerated Concrete IARJSET

2021年6月13日 Hence, to reduce the adverse effects of brick on nature, Autoclaved Aerated Concrete was invented at the mid of 1920 by a Swedish architect Johan Axel Eriksson Autoclaved aerated concrete (AAC) is made with fine Lime powder is obtained either by crushing limestone to fine powder at AAC factory or by directly purchasing it from the market 2024年10月12日 Autoclaved Aerated Concrete Block Manufacturing Equipment, Find Details and Price about AAC Block Equipment Concrete Block Machine from Autoclaved Aerated Concrete Block Manufacturing Equipment Changzhou Mingjie Building Material Equipment Manufacturing Co, Ltd (up to 20%) structural cost savingBeing 8 times the size of a clay Autoclaved Aerated Concrete Block Manufacturing Equipment2023年1月8日 many benefits could be achieved by using cement bypass dust in the production of bricks, including economic bricks for building, reducing the dependency on natural resources, reducing pollution and reducing negative impacts on the environment Keywords: CBPD; free CaO; autoclaved products; lime binder replacement; sand–lime bricks 1 Cement Bypass Dust as an Ecological Binder Substitute 3 Third is the compressive strength calculation between conventional brick and autoclaved Material Clay Brick Cement Sand Mason Worker AAC Block AAC Mortar Mason Worker aerated concrete block using method of sampling and testing 4 Fourth is the power consumption cost saving calculation of AAC block compared with conventional brick 5Beneficial Usage of Autoclaved Aerated Concrete Block

Autoclaved Aerated Concrete (AAC Blocks)

23 小时之前 What is Autoclaved Aerated Concrete? The simplest way to describe autoclaved aerated concrete is with a metaphor It is a bit like baking, except instead of producing a loaf of bread or cake, you are making a special form of concrete Here are the ingredients in AAC: Cement; Lime; Water; Aluminum powder; Fly ash or silica sand2013年3月25日 Sand Lime Bricks or Decorative bricks are made of sand and lime mixed with sand brick making process in india manufacturer for lime handling equipment co in autoclaved limesand brick production linesand lime bricks manufacturing process Mining Quarry 2018年4月13日 have higher values of compressive strength and thermal conductivity as compared with AAC with brick waste Keywords: autoclaved aerated concrete, glass waste, brick waste, properties Autoclaved aerated concrete (AAC) is a light building material with high porosity (6090%) [1,2]; due to it’s specific microstructure (not connected, round pores Brick and Glass Waste Valorisation in the Manufacture of 2020年1月30日 Brick manufacturing is an essential part of the construction industry, but it contributes heavily to environmental degradation As pointed out by Murmu and Patel [1], a brick kiln emits about 70–282 g of carbon dioxide, 0001–029 g of black carbon, 029–578 g of carbon monoxide (CO) and 015–156 g of particulate matter per kilogram of bricks fired, depending Ecological bricks from dimension stone waste and polyester resin

Guide to Autoclaved Aerated Concrete Blocks

2024年5月24日 Brick Blot focuses on and practices a sustainability approach and, therefore, incorporates innovative construction materials like autoclaved aerated concrete (AAC) blocks for project construction Post navigation2020年12月2日 Lime powder required for AAC production is obtained either by crushing limestone to fine powder at AAC factory or by directly purchasing it in powder form Although purchasing lime powder might be little costly, manymanufacturers opt for it rather than investing in lime crushing equipment like ball mill, jaw crusher,An Introduction to Autoclaved Aerated Concrete (AAC)Autoclaved Aerated Concrete is an ecofriendly and certified green building material which is lightweight, loadbearing, highinsulating, durable building blocks and 3 times lighter when compared to red bricks Sign Up Join TheConstructor to ask questions, answer questions, write articles, and connect with other people Limestone is Autoclaved Aerated Cement Blocks (AAC Blocks)Properties 2019年11月7日 The autoclaved aerated concrete (AAC) block or cellular lightweight concrete brick has emerged as the best alternative of clay brick as a sustainable building material Further, the kilns meant for heat treatment source in clay brick create air pollution and are replaced by steambased heat treatment, socalled autoclave, in the AAC production Manufacturing of Autoclaved Aerated Concrete (AAC):

.jpg)

AutoClaved concrete bricks(AAC) seminar ppt SlideShare

2018年5月26日 13 Steps Involved in manufacturing process There are mainly four steps involves in manufacturing process of AAC Bricks: 1 Raw Material Preparation: Fly ash : Fly ash is mixed with water to form fly ash slurry Fly Ash is usually a byproduct of thermal power plants and is an important raw material in the manufacture of AAC Blocks Slurry thus formed is 2020年7月18日 However, the clay brick is produced by drying and firing clay or shale raw material, forming a sintered porous structure [55], [56], [57] Also, the AAC contains cement, but it is lightweight to (PDF) Analysis of autoclaved aerated concrete (AAC) blocks We are a leading manufacturer of Autoclaved Aerated Concrete (AAC) blocks wire mesh AAC blocks are also known as Lightweight Blocks Goa, Udupi Support@coneccfo Call us now +91 HOME; these blocks are almost 70% lighter than Traditional Clay bricks and 40% lighter than the CLC Blocks, AAC blocks have a superior finish Lightweight AAC Blocks Manufacturer in Karnataka India2020年12月2日 Lime powder required for AAC production is obtained either by crushing limestone to fine powder at AAC factory or by directly purchasing it in powder form Although purchasing lime powder might be little costly, manymanufacturers opt for it rather than investing in lime crushing equipment like ball mill, jaw crusher,An Introduction to Autoclaved Aerated Concrete (AAC)

A Review on Autoclaved Aerated Concrete (Aerocon

2023年3月16日 Autoclaved aerated bricks (AAC) These AAC bricks are made with a mixture of cement, fly ash, lime, aeration agents and water involving an aeration It is obtained either by crushing limestone in the AAC factory to a fine powder or by buying it straight from a seller in powder form c Cement: In this AAC bricks, 53 grade OPC is used from