Lithium ore powder processing spodumene ore powder grinding process

Hard Rock Spodumene Lithium Processing

2023年12月27日 Saltworks’ modular concentrating, refining, and converting (CRC) technologies provide a costefficient and rapid pathway to produce highyield, batterygrade lithium carbonate or lithium hydroxide Both process flows, 2022年3月25日 Flotation is used to generate a high grade spodumene concentrate (7585% spodumene) suitable for lithium extraction Minimize the cost of roasting Lithium can be Hard Rock Lithium Processing SGS2024年7月9日 However, the traditional approach to process spodumene is costly and energyintensive, requiring the mineral be transformed from its natural α to β phase at >1000 °C Acid leaching is then applied, followed by Direct Lithium Extraction from αSpodumene 2023年6月25日 In this study, a novel lithium extraction method was proposed for α spodumene by combining activated roasting and sulfuric acid leaching First, the thermodynamics of the An effective method for directly extracting lithium from αspodumene

.jpg)

Aspects of Spodumene Lithium Extraction

2024年9月30日 The calcination decrepitation reaction of spodumene with limestone (roasting process) involves three distinct steps : (i) decomposition of limestone at temperatures ranging from 750 to 800 °C, resulting in the 2022年10月31日 This work investigates the energy efficiency of different grinding circuits used for upgrading the lithium content in the finer fraction of the calcined spodumene oreLithium deportment by size of a calcined spodumene ore2024年2月3日 In this work, we examine a novel mechanochemical process for rapid lithium extraction from lithiumrich spodumene ore We demonstrate multiple mechanochemically Mechanochemical Extraction of Lithium from αSpodumene 2023年2月1日 The beneficiation of spodumene using Dense Media Separation (DMS) and froth flotation, the most widely adopted techniques, have been appraised The application of Recovery of lithium from spodumenebearing pegmatites: A

Revisiting the Traditional Process of Spodumene Conversion

2018年8月19日 Since 1950, the traditional process has been dominating the production of lithium compounds from spodumene ores to sustain the lithium market because of its 2023年9月8日 FTM Machinery provides lithium ore processing equipment to produce lithium concentrates for use in batteries, electronics, and more the raw lithium ore undergoes a crushing and grinding process in sequence to The Most Effective Lithium Ore Processing 2021年2月1日 Lithium mica and spodumene (Dessemond et al, 2019;Su et al, 2020), as representatives of lithium ore resources are usually recovered by the sulfuric acid method (Rioyo et al, 2022; Yelatontsev Processing of lithium ores: Industrial technologies and case studies 2024年7月9日 With increasing battery demand comes a need for diversified Li sources beyond brines Among all Libearing minerals, spodumene is most often used for its high Li content and natural abundance However, the traditional Direct Lithium Extraction from αSpodumene

.jpg)

Recovery of lithium from spodumenebearing pegmatites: A

2023年2月1日 This phase transformation process from α to γ spodumene is reported to occur in the temperature range of 700–900 °C, followed by a transformation into βspodumene between 900 and 950 °C, beyond which spodumene fuses [24, 27] Higher temperature increases the porosity of the ore on account of its volumetric expansion, reduces the 2023年4月7日 This is a common flowchart for spodumene processing! 01 Spodumene crushing operation According to the principle of "more crushing and less grinding", spodumene processing adopts a threestage and one closedcircuit crushing process The broken particle size is controlled below 15 mm Spodumene crushing equipment you needGreen Battery Minerals How to Get Lithium from Spodumene2020年6月22日 the spodumene crystals present in the ore The coarser the spodumene, the coarser the particle size at which physical separation can be used, thus reducing energy consumption during crushing and grinding Dense medium separation (DMS) will typically be used down to ~05 mm, but ~1 mm is a more suitable size for efficient DMS processingLithium Ore Processing – an Overview of the Current and 2023年5月27日 Ball milling is one such technique that has proven to be highly effective in lithium ore processing +86 Balltopowder ratio is a critical parameter that affects the efficiency of the milling process A higher balltopowder ratio can lead to more efficient grinding, but it can also cause excessive wear on the milling balls and Ball Milling in Lithium Ore Processing: A Comprehensive Guide

.jpg)

Aspects of Spodumene Lithium Extraction Techniques MDPI

2024年9月30日 The resulting concentration is then utilized to recover Li via a combined heat treatment and chemical processing methods Froth flotation is the most often used method for spodumene and other ore beneficiation It is a process that uses mineral surface characteristics to concentrate Li minerals from pegmatite ores Reverse and direct flotation 2020年4月12日 This SuperPro Designer example analyzes the production of Lithium from Spodumene Ore The results include detailed material and energy balances, equipment sizing, capital and operating cost (PDF) Lithium Extraction from Spodumene Ore ResearchGate2021年5月1日 The role of lithium in chemical and nuclear industries could hardly be overestimated (Babenko et al, 2007)World lithium consumption in 2019 was estimated as ~58∙10 3 tons, with an increase of 18% compared with the previous year (National Minerals Information Center, 2020)Nevertheless, excluding the USA, worldwide lithium production in 2019 Processing of lithium ores: Industrial technologies and case 2023年7月27日 Abstract: The carbothermal reduction process of spodumene ore effectively separates Al and Si components from spodumene ore while also extracting lithium (Li) The high valueadded sputum heat reduction process of spodumene ore was proposed Fe 2O 3 was used as an auxiliary agent Si is combined with Fe to form SiFe alloy and Al is enriched in theComprehensive utilization of spodumene ore through

Assessment of Lithium Pegmatite Ore Bodies to

2018年8月18日 to Processing for the Extraction of Lithium Mark G Aylmore Abstract Various processes have been developed using a combination of elevated temperature and chemical treatment processing to recover Li from silicate minerals To facilitate further process development, a comprehensive understanding of the5 天之前 Different lithium ores have different properties, and the lithium content and mineral composition in minerals are different, so lithium ore beneficiation methods are also different The lithium beneficiation process is mainly used Lithium Processing Plant, Equipment JXSC To extract lithium from spodumene, a process known as spodumene flotation is used 01 Spodumene Flotation Process The spodumene flotation process starts with the crushing of the spodumene ore into smaller pieces This makes it easier to extract the lithium mineral The crushed ore is then ground into a fine powder and mixed with water to form Spodumene Flotation Flowsheet: A Guide to Lithium Ore Processing2024年11月27日 Spodumene ore naturally occurs in the crystal structure of monoclinic alpha form (αform) In order to extract lithium from the ore via the leaching process, however, the ore’s crystal structure must be in the tetragonal beta form (βform)¹ This conversion is achieved through decrepitation, or the shattering of the crystal structureThe Role of Calcination in the Extraction of Lithium from Spodumene

.jpg)

Hard Rock Lithium Processing SGS

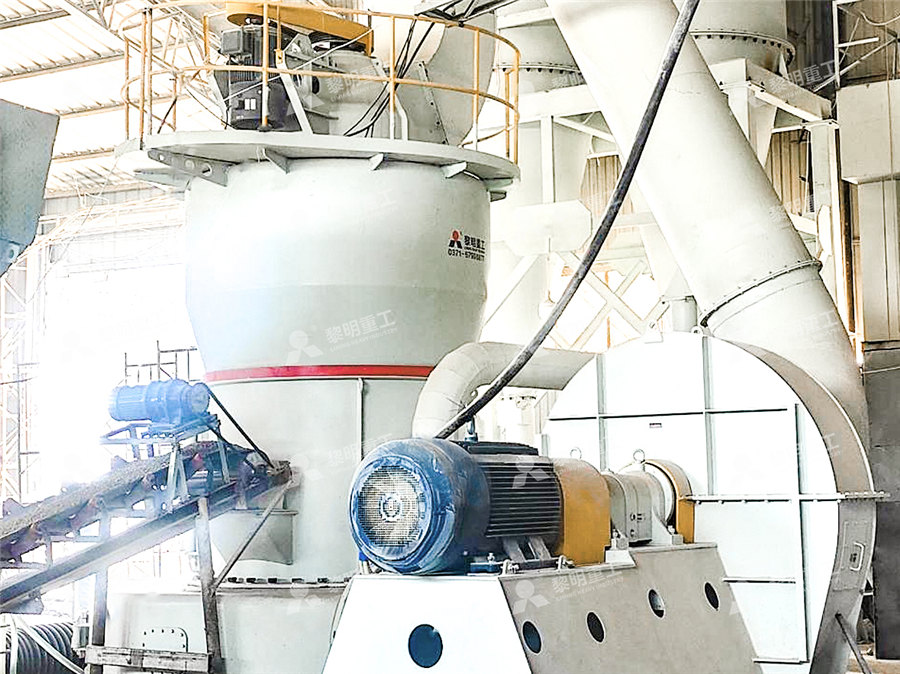

Spodumene has a theoretical Li2O content of 803% Due to its high lithium content, spodumene is considered the most important lithium ore mineral A typical run of mine ore can contain 12% Li 2 O, while a typical spodumene concentrate suitable for lithium carbonate production contains 67% Li 2 O (75% 87% spodumene) Higher grade concentrates2024年7月9日 Lithium ore grinding mills are the devices used to grind lithium ore into fine powder SBM's lithium ore grinding machines are mainly divided into four categories: Raymond mill, ultrafine mill, ball mill and vertical mill Spodumene: The most important lithium ore, with a chemical composition of LiAl(SiO3)2 It is usually green or yellow Lithium Ore Grinding Mills SBM Ultrafine Powder TechnologyDOI: 101016/jpowtec2023 Corpus ID: ; Study on the unequalprobability comminution of spodumene and feldspar during the grinding process of lithium ore @article{Guo2023StudyOT, title={Study on the unequalprobability comminution of spodumene and feldspar during the grinding process of lithium ore}, author={Wang Guo and Xiahui Gui Study on the unequalprobability comminution of spodumene 2022年8月2日 The ongoing drive and demand for greenenergy revolution has reflected in attendant increase in the demand for strategic and critical metals and elements such as lithium, tantalum, cobalt, and A Review of Characterization Techniques and Processing

A New Method for Producing Hydrogen, Lithium Metal,

2023年2月6日 produce lithium salts and metal lithium, highpurity silicon and metal aluminum, and regenerate hydrogen A job well worth doing Experimental Process and Materials Experimental Process Figure 1 is the experimental process for the production of highpurity silicon, hydrogen and lithium metal from spodumene Spodumene ore powder was taken2022年12月26日 How is lithium ore processed? Lithium ore generally needs to be processed by crushing, grinding, flotation and some auxiliary equipment to get finished products The specific processing process is: lithium ore enters jaw crusher for coarse crushing and then the material is crushed by cone crusher for a second time, and then enters the vibrating Lithium ore is how to process crushing, grinding equipment?2023年11月1日 Drill core halves or quarters from mineral exploration campaigns were sampled at the Whabouchi site Identification of the lithological units was previously done by Nemaska Lithium's geologists Two units were sampled: the spodumenepegmatite (SP) ore and the minor spodumenepoor (barren) pegmatite (considered as wasterock, BP)Geochemistry and mineralogy of a spodumenepegmatite lithium ore 2018年8月19日 To facilitate further process development, a comprehensive understanding of the deportment of lithium and associated minerals in potential ore bodies and linking the mineralogy to the fundamental processes of minerals liberation and extraction is essential to allow the industry to predict the response of ore reserves to metallurgical treatment Assessment of Lithium Pegmatite Ore Bodies to Determine

.jpg)

Sintering Mechanism and Leaching Kinetics of LowGrade Mixed Lithium

2024年9月19日 With the rapid development of new energy fields and the current shortage of lithium supply, an efficient, clean, and stable lithium resource extraction process is urgently necessary In this paper, various advanced detection methods were utilized to conduct a mineralogical analysis of the raw ore and systematically study the occurrence state of lithium; 2024年10月28日 The escalating demand for lithium has intensified the need to process critical lithium ores into batterygrade materials efficiently This review paper overviews the transformation processes and cost of converting critical lithium ores, primarily spodumene and brine, into highpurity batterygrade precursors We systematically examine the study findings Transformations of Critical Lithium Ores to BatteryGrade2020年8月12日 The sulfuric acid process is the dominant technology for lithium extraction from spodumene However, this process generates huge quantities of waste residue and needs hightemperature pretreatmentLithium Extraction from Spodumene by the Traditional Sulfuric 6 天之前 The method is based on the fact that when natural spodumene is roasted at about 1100 °C, its crystals change from αtype to βtype, and at the same time, the volume expands and is easily broken into powder, so that spodumene and gangue can be obtained by selective grinding and screening separation between mineralsProgress of Five Spodumene Beneficiation Methods

.jpg)

Processing Spodumene by Froth Flotation for Lithium

2023年2月21日 The Lithium Ore Process Fatty acid or soap flotation of spodumene is one well established recovery method, but pulverized or ground particle surface conditions generally necessitate preflotation treatment This involves high density agitation with cleaning agents such as sodium silicofluoride, trisodium phosphate, or sodium sulphide with The process is undertaken at atmospheric pressure and modest temperature, followed by a series of impurity removal steps at progressively higher pH levels and the subsequent precipitation of lithium carbonate The process contrasts with the far more energy intensive processing of spodumene concentrates, which requires high temperature Processing Technology Cornish Lithium Plc2023年10月6日 The process of extracting lithium from mines primarily revolves around extracting lithiumbearing minerals, notably spodumene, through an intricate interplay of mining and processing methodologies Initially, ore containing lithium is excavated from subterranean depths and subjected to rigorous physical separation techniques to eliminate Sustainable Lithium Extraction: How is Lithium Mined and 2023年9月8日 FTM Machinery provides lithium ore processing equipment to produce lithium concentrates for use in batteries, electronics, and more the raw lithium ore undergoes a crushing and grinding process in sequence to The Most Effective Lithium Ore Processing

Processing of lithium ores: Industrial technologies and case studies

2021年2月1日 Lithium mica and spodumene (Dessemond et al, 2019;Su et al, 2020), as representatives of lithium ore resources are usually recovered by the sulfuric acid method (Rioyo et al, 2022; Yelatontsev 2024年7月9日 With increasing battery demand comes a need for diversified Li sources beyond brines Among all Libearing minerals, spodumene is most often used for its high Li content and natural abundance However, the traditional Direct Lithium Extraction from αSpodumene 2023年2月1日 This phase transformation process from α to γ spodumene is reported to occur in the temperature range of 700–900 °C, followed by a transformation into βspodumene between 900 and 950 °C, beyond which spodumene fuses [24, 27] Higher temperature increases the porosity of the ore on account of its volumetric expansion, reduces the Recovery of lithium from spodumenebearing pegmatites: A 2023年4月7日 This is a common flowchart for spodumene processing! 01 Spodumene crushing operation According to the principle of "more crushing and less grinding", spodumene processing adopts a threestage and one closedcircuit crushing process The broken particle size is controlled below 15 mm Spodumene crushing equipment you needGreen Battery Minerals How to Get Lithium from Spodumene

Lithium Ore Processing – an Overview of the Current and

2020年6月22日 the spodumene crystals present in the ore The coarser the spodumene, the coarser the particle size at which physical separation can be used, thus reducing energy consumption during crushing and grinding Dense medium separation (DMS) will typically be used down to ~05 mm, but ~1 mm is a more suitable size for efficient DMS processing2023年5月27日 Ball milling is one such technique that has proven to be highly effective in lithium ore processing +86 Balltopowder ratio is a critical parameter that affects the efficiency of the milling process A higher balltopowder ratio can lead to more efficient grinding, but it can also cause excessive wear on the milling balls and Ball Milling in Lithium Ore Processing: A Comprehensive Guide2024年9月30日 The resulting concentration is then utilized to recover Li via a combined heat treatment and chemical processing methods Froth flotation is the most often used method for spodumene and other ore beneficiation It is a process that uses mineral surface characteristics to concentrate Li minerals from pegmatite ores Reverse and direct flotation Aspects of Spodumene Lithium Extraction Techniques MDPI2020年4月12日 This SuperPro Designer example analyzes the production of Lithium from Spodumene Ore The results include detailed material and energy balances, equipment sizing, capital and operating cost (PDF) Lithium Extraction from Spodumene Ore ResearchGate

Processing of lithium ores: Industrial technologies and case

2021年5月1日 The role of lithium in chemical and nuclear industries could hardly be overestimated (Babenko et al, 2007)World lithium consumption in 2019 was estimated as ~58∙10 3 tons, with an increase of 18% compared with the previous year (National Minerals Information Center, 2020)Nevertheless, excluding the USA, worldwide lithium production in 2019