Bluestone grinding machine working principle and maintenance

.jpg)

Grinding Machine: Definition, Parts, Working Principle, Operation

2021年5月5日 The Grinding Machine is another most important machine in the manufacturing Industry Today we will study the Definition, Parts, Working Principle, Operation, Advantages, Application of the Grinding machine in detail Lets start with the definition first, Grinding Application Of Cold Working Process The cold working process is used to Cold Working Process2021年8月9日 Bluestone is a common stone in gravel factories and can be used in building materials, road construction, and mechanized gravel production after being processed by Bluestone Crushers and Grinding MillsBluestone Processing 2015年1月1日 Different grinding processes defining grinding machines: classification according to 1st level of grinding machines, criterion “cutting motion” which corresponds to the 3rd level Grinding Machines SpringerLink

Grinding Machines Springer

2023年2月10日 Grinder Definition A grinding machine is a machine for material removal with geometrically nondefined, bonded cutting edges, where the relative movement between tool 2018年10月1日 The working principle of a grinding machine is quite easy to understand In a grinding machine, there is an electric motor which supplies power to the grinding wheel with the help of a belt and pulleyGrinding Machine: Types, Parts, Working2017年1月1日 Grinding machines require highly sophisticated maintenance of metalworking fluids, which typically require the same space as the grinding machine The driving force Recent developments in grinding machines ScienceDirectWorking Principle of Grinding Machine The grinding machine works on the principle of the grinding process This is a machining process in which finishing work is carried out on the workpiece In this process, a solid object composed Types of Grinding Machine: Parts, Working

.jpg)

How to Maintain the Grinding Machine?

2020年5月27日 Grinding machine maintenance: The surface of the permanent magnetic casting chuck or electromagnetic chuck is the basis for whether the grinding accuracy of the work piece can meet the requirements, and it should 2023年11月28日 In bluestone crushing, impact crushers are usually used as secondary or tertiary crushing equipment to break small pieces of bluestone into finer particles To sum up, What are the common machines for crushing bluestone?Explore the working principle, types, parts, applications, advantages, and recent developments of ball mill grinding machines Ball mill grinding machine offer several advantages, including: Versatility: Easy Maintenance: Ball mills are Ball Mill Grinding Machines: Working Principle, 2024年7月2日 With regular evaluation and necessary maintenance, your bluestone over concrete surface will continue to enhance the aesthetics and functionality of your outdoor space for years to come Step 9: Enjoying Your How to Lay Bluestone Over Concrete 10 Easy

.jpg)

Working Principle of Boring Machines InSitu

2022年7月28日 Learn about the working principles of boring machines in our latest article +44 (0)1788 [ protected] Worldwide 24/7 Emergency Machining Response Click Here To Call InSitu Machining Solutions have 2023年5月18日 A centerless grinding machine is a machine tool that uses CNC technology to grind the surface of a workpiece using grinding tools Most grinders use highspeed rotating grinding wheels for grinding, while a few use other grinding tools such as oilstones, abrasive belts, and free abrasives for processing, such as honing machines, ultraprecision machining Guide to Centerless Grinding Machine: Advantages, Working Principle 2021年8月27日 The grinding wheel is the most important and unique part of the electrochemical grinding machine It is connected to the negative terminal of the power supply and acts as the cathode The working principle of electrochemical grinding is When a metal surface is acted upon with an electrolyte under a high current, the metal surface gets Electrochemical Grinding: Definition, Parts or Construction, Working 2020年7月21日 36 Rail Grinding Machine 37 Switch Grinding Machine 38 Milling Machine 39 Rail Inspection Vehicle (RIV) 310 Utility Vehicle (UTV) 311 Rail Borne Maintenance Vehicle 312 Muck Disposal Unit (MDU) Chapter 4 : Planning and Deployment of Machines 4447 40 Annual Planning of Deployment 41 Prerequisite for Deployment of Track MachinesINDIAN RAILWAYS HANDBOOK ON TRACK MACHINES

Mixer grinder ppt PPT SlideShare

2021年5月18日 The working principle is that the motor converts electricity to mechanical energy using a coil and magnetic field to rotate the blades at high speed Higher wattage motors between 5001000W are recommended for home use The document discusses construction, working, applications, maintenance and advantages and disadvantages of mixer grinders 2020年5月19日 Grinding machines produce flat, cylindrical, and other surfaces by means of highspeed rotating abrasive wheels A grinding machine or grinder is an industrial power tool that uses an abrasive wheel for cutting often used in fabrication and construction work Daily maintenance of Grinding Machines The principle of selecting a grinding What Is A Grinding Machine? How Should The Daily Maintenance of 2014年10月25日 4 Principle of the Surface grinding machine • Surface grinding is used to produce a smooth finish on flat surface It is a widely used abrasive machining process in which a spinning wheel covered in rough particles cuts chips of metallic or nonmetallic substance from a work piece, making a face of it flat or smoothSurface grinding machine PPT SlideShare2023年7月21日 Grinding Machine and Its Grinding Process A machine tool that uses a grinding wheel or other abrasive tool to perform grinding operations on a workpiece is called a “grinding machine” Grinding machines are mainly used for processing quenched and hardened steel parts Through grinding, high precision and low roughness surfaces can be obtainedBoring, Planing, and Grinding Machines: A Comprehensive

.jpg)

Surface grinding machine PPT SlideShare

2014年10月25日 4 Principle of the Surface grinding machine • Surface grinding is used to produce a smooth finish on flat surface It is a widely used abrasive machining process in which a spinning wheel covered in rough particles cuts 2024年11月21日 For the portable grinder, the rotor is inside the grinding machine, and the power switch is located beside the handle of the grinder So, the switch must be pressed before the grinder works For grinders that feature an electric motor, the motor rotates at a certain rpm (from 150 to 1500 RPM, it may change according to the type of grinding What is Grinding Machine? its Diagram and How it Works2023年7月21日 Grinding Machine and Its Grinding Process A machine tool that uses a grinding wheel or other abrasive tool to perform grinding operations on a workpiece is called a “grinding machine” Grinding machines are mainly used Boring, Planing, and Grinding Machines: A 1 Cylindrical Grinder: Used for grinding the cylindrical surfaces of bearing rings 2 Centerless Grinder: Operates without centers or chucks, suitable for grinding bearing races 3 Internal Grinder: Specifically designed for grinding the inner diameter of bearing rings 4 External Grinder: Used for grinding the outer diameter of bearing Working principle of bearing grinding machine

Drilling Machine: Working Principles, Types, Operations,

2024年11月7日 Working Principle of Drilling Machines The working principle of any drilling machine remains almost similar When power is supplied to the motor, the spindle rotates, causing the attached stepped pulley to also rotate as shown in the image below Fig 1: Working of a Drilling Machine2023年5月3日 Regular maintenance of angle grinders helps to keep the angle grinder in good shape and condition On the other hand, poor maintenance causes you to have not just a shabby looking tool, but a poor performing tool In this discussion on angle grinder maintenance, we shall be examining the how and the need for angle grinder maintenanceAngle Grinder Maintenance Care: All You Need to Know2022年10月17日 Principle Ball mill principle work on Impact and Attrition Both are responsible for size reduction, rapidly moving balls are used for reducing the size of brittle materials Impact: Impact mean pressure exerted by two heavy objects Attrition: Reduced the size of the materials when they colloid by heavy weight (Ball) Construction:Ball Mill; Principle, Working, and Construction » Pharmaguddu2018年10月1日 Working principle of Grinding Machine The working principle of a grinding machine is quite easy to understand In a grinding machine, there is an electric motor which supplies power to the grinding wheel with the help of a belt and pulley The parts are designed in such a way that minimum maintenance is needed Pros Cons; ️ High Power:Grinding Machine: Types, Parts, Working Operations (With

.jpg)

Cylindrical Grinding Machine: Types, Process Working Principle

2024年11月19日 What is Cylindrical Grinder? Cylindrical Grinding Machine: Types, Process Working Principle : Cylindrical grinders are employed to slice or cut very precise and subtle finishes on materials such as aluminum, carbide, steel or other metals They are especially used to work on cylindrical surfaces, rods or other cylindrical work pieces2022年6月24日 Grinding is a manufacturing process which significantly contributes in producing high precision and durable components required in numerous applications such as aerospace, defence and automobiles(PDF) A comprehensive review on the grinding process: 2023年5月5日 A grinding machine consists of the following parts: 1 Base – The base of the grinding machine supports the other parts of the machine It is made of cast iron and rests on a flat foundation 2 Column – The column is a Grinder Machine – Working, Types, Applications, 2023年8月29日 Grinding wheel maintenance of grinding machine is essential for ensuring the efficiency, effectiveness, and safety of the grinding process Regular maintenance tasks can help extend the lifespan of the grinding wheel and prevent any potential issues that may arise during operation The following are some key maintenance tasks for tool grinder wheels: Inspect the Grinding wheel maintenance and maintenance of grinding

Grinding Machine: Definition, Types, Parts,

Bench Grinding Machine: Parts, Working What is Bench Grinding Machine? It is the most common type of grinding machine found in tool rooms and workshops It is used to sharpen the tools, grind the workpiece surface and remove 2024年9月27日 Machine Rigidity: The rigidity of the grinding machine impacts its stability under load, with higher rigidity enhancing precision and surface finish Wheel Dressing and Truing : Regular dressing and truing of the wheel restore cutting ability, extend wheel life, and maintain grinding accuracyWhat is Grinding: Definition, Types, Uses, and Working Process2024年11月26日 Principle A centrifuge is a device that accelerates gravitational separation of substances that differ significantly in their masses Maintenance Cleanliness of a centrifuge is important in minimizing the possible spread of infectious agents such as hepatitis viruses or mycobacteria In case of breakage the racks and the chamber of the Laboratory Centrifuge: Principle, Components, Uses, Types, Working Principle of Grinding Machine The grinding machine works on the principle of the grinding process This is a machining process in which finishing work is carried out on the workpiece In this process, a solid object composed of abrasive particles is given a relative motion with the workpiece Due to this relative motion when these Types of Grinding Machine: Parts, Working Principle Grinding

.jpg)

How it Works: Crushers, Grinding Mills and Pulverizers

2017年6月2日 Table Source: Wikipedia (Crushers) Cone crushers use a spinning cone that gyrates in the bowl in an eccentric motion to crush the rock between the cone surface, referred to as the mantle, and the crusher bowl linerGyratory crushers are very similar to cone crushers, but have a steeper cone slope and a concave bowl surface As the gap between the bowl liner Working Principle of Grinding Machine Grinding machines employ a rotating abrasive wheel that removes material from the workpiece through abrasion The grinding wheel is composed of abrasive particles bonded together, which vary in size, shape, and Grinding Machine: Learn its working, types, and applications3 Plunge Grinding Machine The plunge grinding machine is a type of outside diameter machine In the plunge grinding machine the grinding wheel moves radially towards the substance 4 Creep Feed Grinding Machine The creep feed grinding machine eliminates a full chunk of the substance through the grinding wheel all at onceCylindrical Grinding Machine: Types, Process Working Principle 2021年10月21日 Hello friends In this article, I am going to explain the key aspects of a cylindrical grinding machine (eg parts, types, uses, etc) The cylindrical grinding machine is basically a type of grinding machine like a surface grinding machine, tool and cutter grinding machine, centerless grinding machine, etc So let's get startedCylindrical Grinding Machine: Working, Parts, Types, Uses

.jpg)

Grinding machine PPT Free Download

2020年8月12日 3 Grinding Machine The grinding machine is a kind of tool which is used for grinding work pieces Grinding machine it makes use of an abrasive wheel in the form of a cutting tool The rough surface of the abrasive Explore the working principle, types, parts, applications, advantages, and recent developments of ball mill grinding machines Ball mill grinding machine offer several advantages, including: Versatility: Easy Maintenance: Ball mills are Ball Mill Grinding Machines: Working Principle, 2021年9月13日 Preventive maintenance will either be set on a usage or time based schedule With preventive maintenance you gain a reduced unplanned downtime and increased longevity 2 Reactive Maintenance Reactive Machinery Maintenance: Guide, Types2024年7月2日 With regular evaluation and necessary maintenance, your bluestone over concrete surface will continue to enhance the aesthetics and functionality of your outdoor space for years to come Step 9: Enjoying Your New Bluestone Surface After all the hard work and careful maintenance, it’s time to enjoy your new bluestone surfaceHow to Lay Bluestone Over Concrete 10 Easy Steps (2024)

Working Principle of Boring Machines InSitu Machining

2022年7月28日 Learn about the working principles of boring machines in our latest article +44 (0)1788 [ protected] Worldwide 24/7 Emergency Machining Response Click Here To Call InSitu Machining Solutions have many years of experience providing highly effective boring services for machinery maintenance2023年5月18日 A centerless grinding machine is a machine tool that uses CNC technology to grind the surface of a workpiece using grinding tools Most grinders use highspeed rotating grinding wheels for grinding, while a few use other grinding tools such as oilstones, abrasive belts, and free abrasives for processing, such as honing machines, ultraprecision machining Guide to Centerless Grinding Machine: Advantages, Working Principle 2021年8月27日 The grinding wheel is the most important and unique part of the electrochemical grinding machine It is connected to the negative terminal of the power supply and acts as the cathode The working principle of electrochemical grinding is When a metal surface is acted upon with an electrolyte under a high current, the metal surface gets Electrochemical Grinding: Definition, Parts or Construction, Working 2020年7月21日 36 Rail Grinding Machine 37 Switch Grinding Machine 38 Milling Machine 39 Rail Inspection Vehicle (RIV) 310 Utility Vehicle (UTV) 311 Rail Borne Maintenance Vehicle 312 Muck Disposal Unit (MDU) Chapter 4 : Planning and Deployment of Machines 4447 40 Annual Planning of Deployment 41 Prerequisite for Deployment of Track MachinesINDIAN RAILWAYS HANDBOOK ON TRACK MACHINES

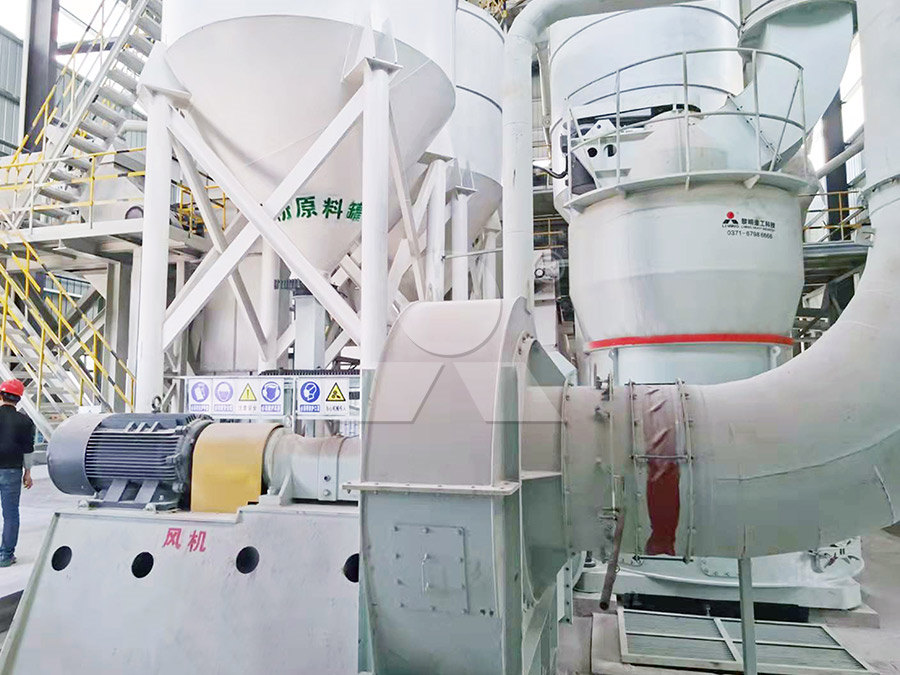

CFB石灰石脱硫剂制备96.jpg)

Mixer grinder ppt PPT SlideShare

2021年5月18日 The working principle is that the motor converts electricity to mechanical energy using a coil and magnetic field to rotate the blades at high speed Higher wattage motors between 5001000W are recommended for home use The document discusses construction, working, applications, maintenance and advantages and disadvantages of mixer grinders 2020年5月19日 Grinding machines produce flat, cylindrical, and other surfaces by means of highspeed rotating abrasive wheels A grinding machine or grinder is an industrial power tool that uses an abrasive wheel for cutting often used in fabrication and construction work Daily maintenance of Grinding Machines The principle of selecting a grinding What Is A Grinding Machine? How Should The Daily Maintenance of