Does dry nickel slag powder making machinery make money

Hydrometallurgical nickel and cobalt plants and processes

nickel powder can also be produced in autoclaves by using hydrogen reduction technology The new Metso Outotec anodeinabag technology for nickel electrowinning offers an environmentally friendly electrowinning process by significantly reducing nickel emissions and notably Because nickel slag is a molten coproduct of ferronickel production, its use in highway construction reduces the need to use natural materials, resulting in less exploitation of natural Nickel Slag an overview ScienceDirect TopicsAfter using vertical grinding to grind nickel slag into micro powder, it is beneficial to recover nickel iron and obtain considerable economic benefits; At the same time, the screened finished micro Nickel slag powder processing solutionLIMING HEAVY INDUSTRY 2019年6月18日 Slag produced as a byproduct in industrial processes, contains considerable metals contents, which need to be recovered to avoid environmental contamination In present (PDF) Metallurgical Processing Strategies for Metals Recovery from

CFB石灰石脱硫剂制备96.jpg)

Recovery of Valuable Metals from Nickel Smelting Slag Based on

2021年9月19日 Nickel smelting slag contains valuable metals including nickel and copper Failure to recycle these metals wastes resources, and disposal of nickel slag in stockpiles Steelmaking slag includes the following: slag produced in the hotmetal pretreatment processes (desiliconization, dephosphoriza tion, desulfurization, etc), slag flowing out from the converter Processing and Reusing Technologies for Steelmaking Slag2022年3月7日 During the ball milling process, a ball milling machine was used to mix the dried undisturbed nickel slag with a certain proportion of solid alkali activator As can be seen from Preparation of onepart alkaliactivated nickel slag binder using an 2024年4月15日 In pyrometallurgy process involving drying, calcination and reductive smelting steps, Saprolite ore is subjected in an electric arc furnace to produce Fe–Ni alloy and Ni matte Artificial Slags with Modulated Properties for Controlled Nickel

State of the art in nickel smelting: direct Outokumpu nickel

2008年6月1日 In the DON process, high grade nickel matte of low iron content is produced in the flash smelting furnace directly without subsequent converting The metal values in the 2023年9月5日 Therefore, powder preparation technology is continuously evolving and innovating to meet the requirements for particle size and performance 2 Preparation Methods of Metal Powder: 21 Physicochemical Metal Powder Preparation Methods and Principles: A 2020年6月29日 Instruments used in the study (a) The ball mill of the WZM15 × 2 model (b) Cement gel sand bending compression testing machine The Effect of Activators on the Mechanical Properties Find production technology for making , and connect directly with leading machine manufacturers worldwide Connect with manufacturers of powder processing solutions and find production technology to build or improve your Powder Manufacturing Equipment Making

Nickel Slag MadeinChina

Nickel Slag Powder Grinder/Powder Crusher/Powder Grinder US$ 60000 / Piece 1 Piece Mine,Quarry,Sand Making Line Materials: Granite,Marble,Basalt,Limestone,Quartz,Pebble,Rock Outlet Size: 1848mm Discover the perfect addition to your Metal Recycling Machine with our Nickel SlagIn China, 2021年2月22日 Slag, as shown in Fig 1, is the 16th ingredient of highperformance concrete production [22], called supplementary cementitious materials (SCM) [23], that can enhance the strength and durability of concrete [2]The highly fine slag powder, with a surface area of 400–600 m 2 /kg and a bulk density of 1200 kg/m 3, can be mixed with free lime to replace 40% to 65% Slag uses in making an ecofriendly and sustainable concrete: A how to make blast furnace slag cement? Recently, Slag has become an important mixing material of cement, grind ability of slag is very poor In general, the slag powder is processed by the slag grinding plant in advance, and slag powder will be sent into the cement plant for making slag cement, so it is particularly important to select the appropriate slag grinding plantSlag Cement Production Line Blast Furnace Slag Cement Making2020年5月19日 This research aims to use highmagnesium nickel slag crushed into a powder as a replacement for cement and to study their properties and microstructure in concreteA Study of the properties and microstructure of highmagnesium nickel

.jpg)

Quartz Processing Mastering the Art of Stone to Powder

2024年5月30日 Quartz Crushing Jaw crushers are the ideal choice for primary crushing of quartz ore, effectively breaking down the highhardness mineral Subsequently, cone crushers (or impact crushers) further reduce the quartz to below 25 mm Quartz Grinding The finely crushed quartz particles are conveyed by bucket elevators to storage bins, then fed into quartz ball The slag powder used in the experiment is not from mining materials The slag used is the result of the material that has been burned in the Blast Furnace The slag powder produced is then substituted with cement to make slag cement paste with high compressive strength and low penetration of chloride ionsUTILIZATION OF SLAG POWDER FOR CEMENT SUBSTITUTION This research aims to prepare powder of nickel slag from furnace machine, identify, and analyze of the elements or compounds containing in the sampleXRD pattern of powder furnace nickel slag ResearchGate2024年4月28日 Steel slag powder + Portland cement + reactive magnesia: binding materials: 0036–0039 mm: CO 2 with a concentration of 999% was introduced for curing at a CO 2 gas pressure of 01 MPa 386 (1 d) — Steel A Review on the Carbonation of Steel Slag: Properties,

Applications of Steel Slag Powder and Steel Slag

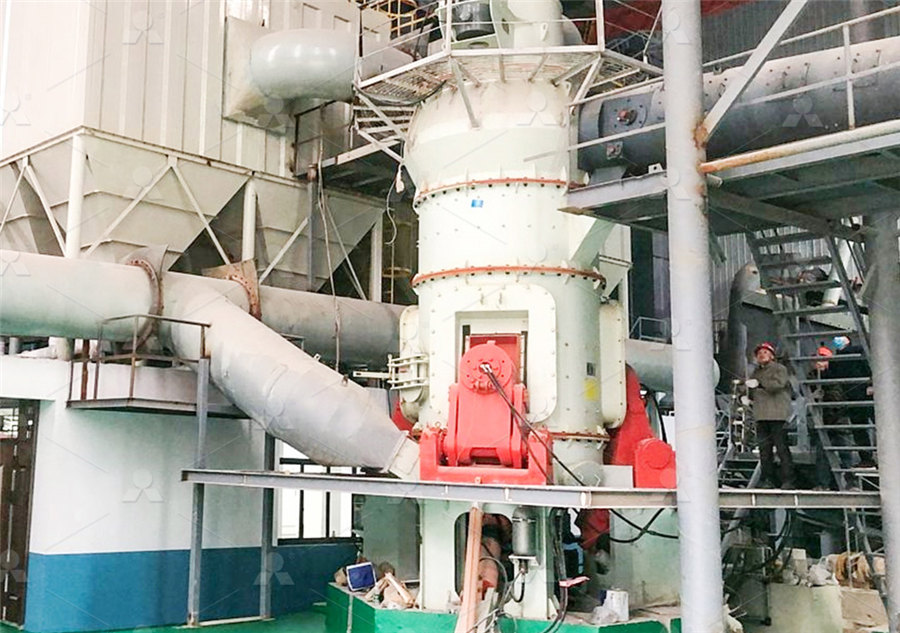

2018年1月30日 1 Introduction Steel slag is a byproduct of steel manufacturing []Approximately 160 kg of steel slag is generated per ton of steel produced []The common chemical compounds in steel slag are SiO 2, CaO, Fe 2 O 3, Al 2 O tial to adjust nickel slag to separate ‘FeO’ and to obtain a higher activity36,37) As studied by Li et al, network modifiTable 1 Chemical compositions of nickel slag and aluminum dross (wt%) Compositions ‘FeO’ CaO MgO SiO 2 Al 2O 3 Al AlN Na 2O Ni Co Cu S Nickel slag 5131 358 841 3160 – – – – 016 008 022 120Recycling Nickel Slag by Aluminum Dross: Ironextraction and SRM series vertical roller mill is a powder grinding equipment This powder grinding plant integrates grinding, drying, grading and conveying, with simple structure and compact It is used for grinding limestone, raw meal, slag, Nickel slag, manganese slag, cement, ground granulated blastfurnace slag, GGBS powder, fly ash, coal, clinker etcVertical roller millBaichy Machinery2024年3月8日 Nickel powder should be stored in a cool, dry place away from heat, light, and moisture It’s also important to keep the powder container sealed to prevent contamination Metal Powder Making Equipment; Other Related Link; Production method of NickelBased Powder Additive

A Crucial Step Toward Carbon Neutrality in Pyrometallurgical

2023年11月8日 Nickel is an important nonferrous metal which is widely used in machinery, architecture, steelmaking, military, and other fields due to its physical and chemical properties [1,2,3]During the production of nickel, about 6–16 tons of nickel smelting slag is generated per ton of nickel produced [1, 4]The slag usually contains some valuable elements such as 2017年4月23日 The most usual method is to finely grind together 100 parts of dry granulated slag and 10 parts of slaked lime, giving what is really a slag cement of lower limecontent A small amount of water is added to the material and mixed to a stiff pug and passed on to suitable brick or pipemaking machineryHow to Make Cement From BlastFurnace Slag 911Metallurgist2024年6月5日 Pseudocolor magnetic resonance imaging of ferronickel slag powder soil cement in a freshwater environment (PDF) Performance of Ferronickel Slag Powder Soil Cement under 2024年6月5日 Ferronickel slag is the solid waste slag produced by smelting nickel–iron alloy After grinding ferronickel slag into powder, it has potential chemical activity It can partially replace cement and reduce the amount of cement, and is conducive to environmental protection The mechanical properties of soil cement were investigated through the compressive strength test Performance of Ferronickel Slag Powder Soil Cement under

.jpg)

Knowledge Global Slag

Paper 9 Advanced cyclone systems for maximizing fine slag powder recovery: Pedro Araujo: Advanced Cyclone Systems Paper 10 Characterisation of SlagRec dry granulated EAF slag: Roberto Roberti Universitý degli Studi di Brescia) Paper 11 Gebr Pfeiffer vertical roller mill MVR New levels of slag grinding: York Reichardt: Gebr Pfeiffer AG2023年8月26日 Soft soil foundations in marine environments are under coupling actions of seawater erosion and dry–wet cycles due to tides Ferronickel slag is a solid waste produced in the smelting of ferronickel alloys To recycle industrial A Study on Mechanical Properties of Modified 2017年9月28日 Winnermac high pressure dry powder briquetting machine is perfect for making coal powder, charcoal dust, lime powder, fluorite, aluminum powder, iron powder, steel slag, ferrosilicon powder Dry Powder Briquetting Machine LinkedIn2022年5月1日 Keywords Permeability Test, FerroNickel Slag Powder, Impermeability, Clean Water, Marine Environment, Pore Structure Permeability coefficient (fresh water) Permeability coefficient (sea water)Investigation of ferronickel slag powder for marine

.jpg)

Nickel Powder:Types, Uses, Specs, and Suppliers

2024年4月3日 Nickel powder is made up of small nickel particles, typically less than 100 microns in size It has a gray color and metallic luster Nickel powder is produced by various methods including carbonyl decomposition, electrolytic deposition, atomization and reduction of nickel salts2022年9月7日 Slag Dryer Application : Slag dryer is developed from rotary drum dryer Raw Slag Dryer Machine is widely used in building materials, metallurgy, mineral processing, chemical, cement and other industries, mainly for the raw blast furnace slag, limestone, clay, sand, quartz sand, granulating slag and other wet materials with high intensitySlag Dryer Rotary Drying Machine Rotary Dryer, Drying Machine2021年1月1日 In addition, the XRay Fluorescence (XRF) test results by Astutiningsih et al showed the same results with the examination using SEM: nickel slag powder was dominated by silica (Si), calcium (Ca), and magnesia (Mg) shown in Fig 1, this is similar to the research by Bouaissi et al that found in the nickel slag particles Si, Mg and Ca were the dominant Experimental Study on Blast Furnace Nickel Slag Powder and O serviço do Google, oferecido sem custo financeiro, traduz instantaneamente palavras, frases e páginas da Web do português para mais de cem outros idiomasGoogle Tradutor

Google Translate

Google's service, offered free of charge, instantly translates words, phrases, and web pages between English and over 100 other languages2022年3月7日 Figure 6 shows Comparison of XRD patterns of Na 2 SiO 3 activated nickel slag powder under different ball milling processes and undisturbed nickel slag powder after milling It was found that after common ball milling of Na 2 SiO 3 and nickel slag, there was a new spinel (MgAl 2 O 4 ) diffraction peak in the alkaliactivated nickel slag powder of onetime deliveryPreparation of onepart alkaliactivated nickel slag binder using 2024年7月29日 The mineral dry separation method is a technique for the comprehensive utilization of steel slag In this process, two products, ie, steel slag powder with high activity (reaches 75% of the cementitious activity of pure cement) and inert mineral material, are obtained by crushing and separating steel slag 12,13 If wet magnetic separation is adopted, the active Magnetic separation characteristics of steel slag powder in a 2023年9月5日 Therefore, powder preparation technology is continuously evolving and innovating to meet the requirements for particle size and performance 2 Preparation Methods of Metal Powder: 21 Physicochemical Metal Powder Preparation Methods and Principles: A

The Effect of Activators on the Mechanical Properties

2020年6月29日 Instruments used in the study (a) The ball mill of the WZM15 × 2 model (b) Cement gel sand bending compression testing machine Find production technology for making , and connect directly with leading machine manufacturers worldwide Connect with manufacturers of powder processing solutions and find production technology to build or improve your Powder Manufacturing Equipment MakingNickel Slag Powder Grinder/Powder Crusher/Powder Grinder US$ 60000 / Piece 1 Piece Mine,Quarry,Sand Making Line Materials: Granite,Marble,Basalt,Limestone,Quartz,Pebble,Rock Outlet Size: 1848mm Discover the perfect addition to your Metal Recycling Machine with our Nickel SlagIn China, Nickel Slag MadeinChina2021年2月22日 Slag, as shown in Fig 1, is the 16th ingredient of highperformance concrete production [22], called supplementary cementitious materials (SCM) [23], that can enhance the strength and durability of concrete [2]The highly fine slag powder, with a surface area of 400–600 m 2 /kg and a bulk density of 1200 kg/m 3, can be mixed with free lime to replace 40% to 65% Slag uses in making an ecofriendly and sustainable concrete: A

.jpg)

Slag Cement Production Line Blast Furnace Slag Cement Making

how to make blast furnace slag cement? Recently, Slag has become an important mixing material of cement, grind ability of slag is very poor In general, the slag powder is processed by the slag grinding plant in advance, and slag powder will be sent into the cement plant for making slag cement, so it is particularly important to select the appropriate slag grinding plant2020年5月19日 This research aims to use highmagnesium nickel slag crushed into a powder as a replacement for cement and to study their properties and microstructure in concreteA Study of the properties and microstructure of highmagnesium nickel 2024年5月30日 Quartz Crushing Jaw crushers are the ideal choice for primary crushing of quartz ore, effectively breaking down the highhardness mineral Subsequently, cone crushers (or impact crushers) further reduce the quartz to below 25 mm Quartz Grinding The finely crushed quartz particles are conveyed by bucket elevators to storage bins, then fed into quartz ball Quartz Processing Mastering the Art of Stone to PowderThe slag powder used in the experiment is not from mining materials The slag used is the result of the material that has been burned in the Blast Furnace The slag powder produced is then substituted with cement to make slag cement paste with high compressive strength and low penetration of chloride ionsUTILIZATION OF SLAG POWDER FOR CEMENT SUBSTITUTION

.jpg)

XRD pattern of powder furnace nickel slag ResearchGate

This research aims to prepare powder of nickel slag from furnace machine, identify, and analyze of the elements or compounds containing in the sample