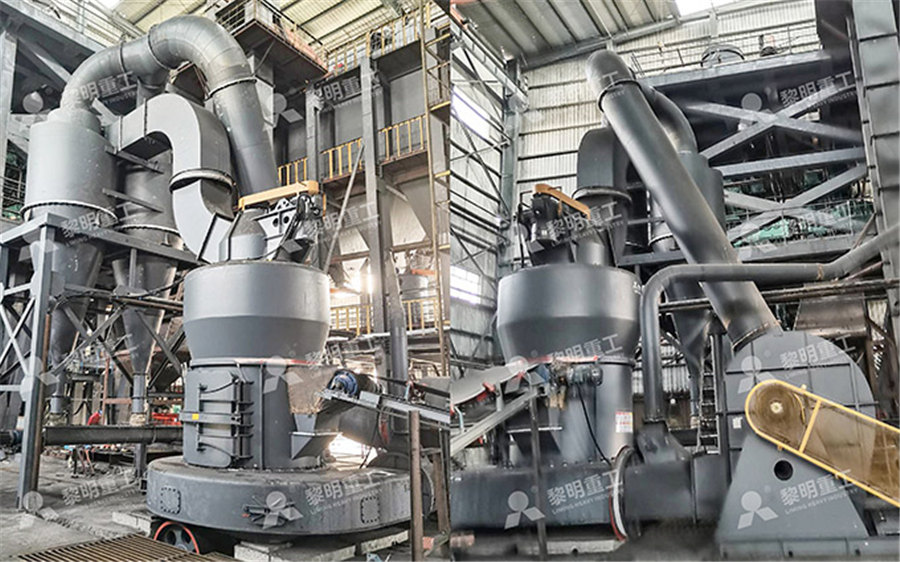

HOME→How to adjust the size of prepowder grinding sand powder vertical mill fine sand powder equipment Prepowder grinding sand powder vertical mill fine sand powder equipment How to adjust the size of prepowder grinding sand powder vertical mill fine sand powder equipment

How to adjust the size of prepowder grinding sand powder vertical mill fine sand powder equipment Prepowder grinding sand powder vertical mill fine sand powder equipment How to adjust the size of prepowder grinding sand powder vertical mill fine sand powder equipment

Basics Size Reduction Fine Ultrafine Size Reduction

Size reduction is, essentially, the breaking down of materials from a few large particles, usually to a fine powder There are three different kinds of powders that result from a size reduction process These kinds relate to the particle sizes within each powder They are: coarse, medium, and fine2021年7月11日 After describing the air classifier mill’s applications, operation, and common variations, this article explains how you can adjust the mill’s operation to control the final How to operate an air classifier mill to meet your fine From lab/pilot to production requirements, Hosokawa Micron Powder Systems offers a complete line of size reduction technologies Whether you call it size reduction, micronization, milling, pulverizing, jet milling, air milling, or simply Size Reduction Milling Hosokawa Micron 2023年10月9日 Sample processing involves reducing the material size to ensure samples for homogeneity and extraction into a suitable matrix for analysis The most common method for Principles of Sample Preparation by Grinding or

BALL MILLS Ball mill optimisation Holzinger Consulting

2021年3月12日 As grinding accounts for a sizeable share in a cement plant’s power consumption, optimisation of grinding equipment such as ball mills can provide significant cost 2023年7月10日 The review provides an overview of the different techniques for size reduction and the impact of energy requirements on the choice of stirred mills It also discusses the factors, including the design, operating parameters, EnergyEfficient Advanced Ultrafine Grinding of 2017年11月30日 Powder Grinding Conical Mill Our industry leading UniMill removes irregularities from the material during the grinding process and achieves a narrow particle size distribution (PSD) We supply a range of mill sizes for Powder Grinding Particle Size Reduction Mills2017年9月1日 For example – if particle shape affects hydrophobicity, can mill operating conditions be adjusted to produce particles with shape characteristics which are more Fine grinding: How mill type affects particle shape characteristics

.jpg)

Evolution of grinding energy and particle size during dry ball

2020年10月1日 The energy efficiency of dry fine grinding process of powders dramatically declines with decreasing particle size, and represents a growing concern in various cutting The internal uses PLC intelligent control, the external uses the touch screen to display and adjust the system parameters in real time Modular excuses are reserved, and the scalability is strong, which can quickly realize the CLUM Ultrafine Vertical Grinding MillBrief Introduction HGM Ultra fine grinding mill (also called micro powder mill, superfine powder grinding mill, ultra fine powder grinder) is designed by SBM RD department on the basis of multiple innovations and testing It has been Ultra Fine Grinding Mill SBM Ultrafine Powder Our main products include ultrafine vertical roller mill, ultrafine grinding mill, stone powder production equipment, Welcome to consult +17 [ protected]SBM Ultrafine Powder Technology Industrial

Basics Size Reduction Fine Ultrafine Size Reduction

These kinds relate to the particle sizes within each powder They are: coarse, medium, and fine This webinar will discuss the size reduction of material to create fine powders Click here to view a webinar on coarse and medium grinding There is really only one way to mill product so that it results in a fine powder This is through impact 2023年1月28日 The best grind size for espresso depends on the type of espresso machine you use Generally speaking, a fine grind is best for espresso machines that apply high pressure and temperature to the beans A slightly coarser grind will work better for lowpressure and lowtemperature machinesGrind Setting for Espresso: A Beginner’s Guide to the Perfect 2021年3月12日 the mill liner It also needs to optimise the grinding process Clinker grain sizes depend on precrusher settings but are in some cases still up to 50mm when fed to the ball mill and therefore, it is necessary to adjust the grinding tools accordingly The more that alternative fuels are used in the clinker production process, the finer and henceBALL MILLS Ball mill optimisation Holzinger ConsultingThe limestone powder ultrafine vertical roller mill is mainly used in the production of limestone powder The Ultrafine vertical mill integrates crushing, drying, grinding and conveying, which is especially suitable for largescale production of ultrafine Limestone Powder Ultrafine Vertical Roller Mill

Grinding Mill Ultrafine Powder Equipment Supplier

2024年8月29日 Our main products include ultrafine powder grinding mill, vertical roller mill, roller grinding mill, stone powder production equipment, Welcome to consult It is typically produced by crushing and grinding raw bauxite ore into a fine particle size to facilitate its use in various applications Production: Bauxite powder is produced through where T is the grinding time to reach a certain median particle size, K is a constant that depends upon the material being processed, the type of media and the particular mill being used, D is the diameter of the media, and N is the shaft rpm This equation shows that total grinding time is directly proportional to media or ball diameter and inversely proportional to the square root of Solids Choose the Right Grinding Mill Chemical Processing2024年4月2日 1 Feeding: Bauxite ore is fed into the HGM micro powder grinding mill through the feeding device, typically via a conveyor belt or a bucket elevatorThe material is evenly and continuously fed into the grinding chamber of the mill 2 Grinding: Inside the grinding chamber, the bauxite ore is subjected to a series of grinding processesThe grinding rollers and rings in How does HGM micro powder grinding mill process bauxite?2024年8月1日 3 Types of Ball Mill Media for Black Powder When producing black powder using a ball mill, the type of grinding media used plays a crucial role in the efficiency and quality of the final product Different types of media have Effective Ball Mill Media for Superior Black

.jpg)

(PDF) SIZE REDUCTION BY GRINDING METHODS

2017年3月4日 The objective of this lesson is to provide the details of size reduction methods involved in mineral processing using grinding methods and equipment No caption available +42024年11月23日 The powder grinding machine is a grinding mill that can efficiently grind rocks, minerals, or coal All grinding mills can precisely adjust the powder fineness from 80 mesh to 3,000 mesh It is an upgraded Powder Grinding Mills Engineered by FTM Fote Google's service, offered free of charge, instantly translates words, phrases, and web pages between English and over 100 other languagesGoogle Translate2017年9月1日 The first stirred mill was installed in the platinum industry in 2002, and by the year 2010, forty stirred mills had been installed at various platinum operations in South Africa, and these led to a step change in flotation recoveries (Rule, 2011, Rule, 2010)Over the last decade, approximately 200 Automated Scanning Electron Microscopy (AutoSEMEDS) systems have Fine grinding: How mill type affects particle shape characteristics

Guide [Updated] Efficient Powder Grinding Hypixel Forums

2024年9月22日 Powder Hoarder Perk: Gives +6% more powder during Mining Fiesta Further Tips: Always farm powder during a 2x Powder Event, as it doubles your overall powder gains Even if the 2x Powder Event ends in your current lobby, you can lobbyswap and often find another event lasting 1015 minutes in the new lobby Two Options for Powder Grinding: 12017年6月2日 Table Source: Wikipedia (Crushers) Cone crushers use a spinning cone that gyrates in the bowl in an eccentric motion to crush the rock between the cone surface, referred to as the mantle, and the crusher bowl linerGyratory crushers are very similar to cone crushers, but have a steeper cone slope and a concave bowl surface As the gap between the bowl liner How it Works: Crushers, Grinding Mills and Pulverizers2021年11月27日 Composition of The Powder Grinding Mill The powder grinding mill is composed of a host, a classifier, a blower, a finished cyclone separator, a pipeline device, and a motor The main host machine is composed of a frame, an air inlet volute, a blade, a grinding roller, a grinding ring, a cover, and a motorWhat is Powder Grinding Mill? JXSC Machine2023年7月10日 The present literature review explores the energyefficient ultrafine grinding of particles using stirred mills The review provides an overview of the different techniques for size reduction and the impact of energy requirements on the choice of stirred mills It also discusses the factors, including the design, operating parameters, and feed material properties, EnergyEfficient Advanced Ultrafine Grinding of Particles

How many methods can be used to adjust the thickness of

2023年12月15日 At the same time, it is necessary to keep the equipment clean and maintained, regularly check the operation of the equipment and the wear and tear of components, and promptly replace damaged components and perform maintenance to ensure the normal operation and production quality of the equipment2020年1月7日 The ultrafine powder vertical roller mill produced by Vsunny are applicable to the processing of dry powder Our company has improved the roller, grinding table, diversion system and inner cycle system Its products have a Ultrafine Powder Vertical Roller Mill Powder 2018年6月1日 This paper provides a broad overview of the fine grinding of wood First, wood breakage mechanisms and the mechanisms of size reduction are presented, followed by fine grinding techniques and wood pretreatment methods A comparison of the specific energy consumption of wood fine grinding in both a gaseous and liquid environment is illustratedFine grinding of wood – Overview from wood breakage to For ball mills grinding OPC to a fineness of up to around 3600 cm2/g (Blaine) grinding aid is usually not required; it may not even be feasible considering the cost of grinding aid However, a vertical roller mill for cement grinding Cement grinding Vertical roller mills VS ball mills

.jpg)

Google 翻譯

Google 提供的服務無須支付費用,可讓您即時翻譯英文和超過 100 種其他語言的文字、詞組和網頁。克拉蘇特文 (西格陵蘭文)Powder Grinder Machine A pulverizer or grinder is a mechanical device for the grinding of many different types of materials When you pulverize something, you break it up until it becomes dust or powder We offer grinders for both laboratory analysis and industrial production, which grind the powder into ultra finePowder Grinder Machine Powder Milling Equipment2023年8月23日 Grinders can vary, including the same model You need to adjust the grind size based on the following factors Use a coarser grind size the longer the coffee is in contact with the water Cold brew coffee takes 12 hours to brew and uses the coarsest grind setting of all the brewing methods Use a finer grind size for shorter brewing timesThe Complete Coffee Grind Size Guide For Every Coffee Drink2024年11月26日 How Powder Grinding Equipment Works When working with applications involving powder coating, grinding systems primarily use an air classifying mill to reduce particle size At the beginning of this process, a storage hopper dispenses extruded chips of powder coating via screw feeder into the grinding equipmentBasics of Powder Coating Particle Size and Distribution Prater

Powder Grinding Particle Size Reduction Mills Hanningfield

2017年11月30日 The grinding of material into a powder is necessary in pharmaceutical, biotech, nutraceutical, food, cosmetic and chemical processing to create a high quality product Manufacturers require milling equipment that delivers reproducible results and creates a fine and consistent particle size2024年7月27日 The most common grind size you’ll come across When you buy preground coffee, it’s usually a fine grind size (unless otherwise stated) In terms of consistency, it’s a little finer than table salt Suits these brew methods: Espresso Brewing (with or without a machine) The Aeropress (with a 12 minute brew time) Stovetop espresso; 7The Last Coffee Grind Size Chart You’ll Ever Need! Home 2015年4月9日 The material can pass through to the proceeding section, but the balls cannot This ensures that the smaller particles are attacked by the smaller grinding media Ball mill is a versatile grinding mill and has a wide range of applications The mill can vary in size from small batch mills up to mills with outputs of hundreds of tons per hourGrinding Mills and Their Types IspatGuruThe internal uses PLC intelligent control, the external uses the touch screen to display and adjust the system parameters in real time Modular excuses are reserved, and the scalability is strong, which can quickly realize the CLUM Ultrafine Vertical Grinding Mill

Ultra Fine Grinding Mill SBM Ultrafine Powder

Brief Introduction HGM Ultra fine grinding mill (also called micro powder mill, superfine powder grinding mill, ultra fine powder grinder) is designed by SBM RD department on the basis of multiple innovations and testing It has been Our main products include ultrafine vertical roller mill, ultrafine grinding mill, stone powder production equipment, Welcome to consult +17 [ protected]SBM Ultrafine Powder Technology Industrial These kinds relate to the particle sizes within each powder They are: coarse, medium, and fine This webinar will discuss the size reduction of material to create fine powders Click here to view a webinar on coarse and medium grinding There is really only one way to mill product so that it results in a fine powder This is through impact Basics Size Reduction Fine Ultrafine Size Reduction2023年1月28日 The best grind size for espresso depends on the type of espresso machine you use Generally speaking, a fine grind is best for espresso machines that apply high pressure and temperature to the beans A slightly coarser grind will work better for lowpressure and lowtemperature machinesGrind Setting for Espresso: A Beginner’s Guide to the Perfect

.jpg)

BALL MILLS Ball mill optimisation Holzinger Consulting

2021年3月12日 the mill liner It also needs to optimise the grinding process Clinker grain sizes depend on precrusher settings but are in some cases still up to 50mm when fed to the ball mill and therefore, it is necessary to adjust the grinding tools accordingly The more that alternative fuels are used in the clinker production process, the finer and henceThe limestone powder ultrafine vertical roller mill is mainly used in the production of limestone powder The Ultrafine vertical mill integrates crushing, drying, grinding and conveying, which is especially suitable for largescale production of ultrafine Limestone Powder Ultrafine Vertical Roller Mill2024年8月29日 Our main products include ultrafine powder grinding mill, vertical roller mill, roller grinding mill, stone powder production equipment, Welcome to consult It is typically produced by crushing and grinding raw bauxite ore into a fine particle size to facilitate its use in various applications Production: Bauxite powder is produced through Grinding Mill Ultrafine Powder Equipment Supplierwhere T is the grinding time to reach a certain median particle size, K is a constant that depends upon the material being processed, the type of media and the particular mill being used, D is the diameter of the media, and N is the shaft rpm This equation shows that total grinding time is directly proportional to media or ball diameter and inversely proportional to the square root of Solids Choose the Right Grinding Mill Chemical Processing

How does HGM micro powder grinding mill process bauxite?

2024年4月2日 1 Feeding: Bauxite ore is fed into the HGM micro powder grinding mill through the feeding device, typically via a conveyor belt or a bucket elevatorThe material is evenly and continuously fed into the grinding chamber of the mill 2 Grinding: Inside the grinding chamber, the bauxite ore is subjected to a series of grinding processesThe grinding rollers and rings in