Zm80n mediumspeed coal mill diagram

Schematic of medium speed coal mill [5]

Medium speed mills are widely used in largescale thermal power plants, which run at a setting speed of 50∼300 r/min, owing to their efficiency The schematic of a medium speed coal millIn this paper, a brannew GAIFCMIDHGF assessment method is proposed Genetic algorithm (GA) is first applied to optimize initial parameters, which is fundamental and significant step to obtainThe structure of MPS mediumspeed coal mill Schematic diagram of the working principle of MPS medium speed coal mill [1] [] Aiming at the typical faults in the coal mills operation process, the kernel extreme learning machine diagnosisSchematic diagram of the working principle of 2017年8月1日 This paper is organized as follows: section one opens with a brief introduction of coal mills; section two deduces and establishes the nonlinear differential equations of coal Modeling of a medium speed coal mill ScienceDirect

.jpg)

Modelling and control of pulverizing system considering coal

2015年2月1日 A mediumspeed directfired pulverizing system includes a coal feeder, coal mill, pulverized coal separator, primary air duct, and burners The operating principle of an MPS 2017年8月1日 The work presented in this paper focuses on modeling Mill Parter Shiptype coal mills that are widely used in the coalfired power plants in China The unknown model Modeling of a medium speed coal mill,Powder Technology Download scientific diagram Schematic structure of the MPS mediumspeed mill from publication: Application of ModelBased Deep Learning Algorithm in Fault Diagnosis of Coal Mills TheSchematic structure of the MPS mediumspeed 2020年3月1日 The technology can effectively improve the adaptability of the pulverizing system to the coal type and realize the dynamic equalizing control of the airpowder Key words: 中速磨煤机制粉系统优化技术研究及应用

.jpg)

Modeling of a medium speed coal mill Semantic Scholar

2017年8月1日 This paper presents a multisegment coal mill model that covers the whole milling process from mill startup to shutdown This multisegment mathematical model is derived 2017年8月1日 This model can be used to estimate the key parameters that are difficult to measure or cannot be measured: 1) coal powder or raw coal contents in coal mills, which can Modeling of a medium speed coal mill ScienceDirect2017年8月1日 MPStype medium speed coal mills are widely used in the thermal power plants in China They are designed and manufactured by the German company Babcock This kind of coal mill has the characteristics of low energy consumption and smooth output and has a small effect on abrasive wear and an overhaul period [13], [14] In this study, MPS180HPII Modeling of a medium speed coal mill ScienceDirect2017年5月1日 Gao et al [5] established a dynamic model for a medium speed coal mill based on mass and energy balance and predicted the dynamic performance of a coal mill Wang et al [6] developed an approach Modeling of a medium speed coal mill ResearchGate

.jpg)

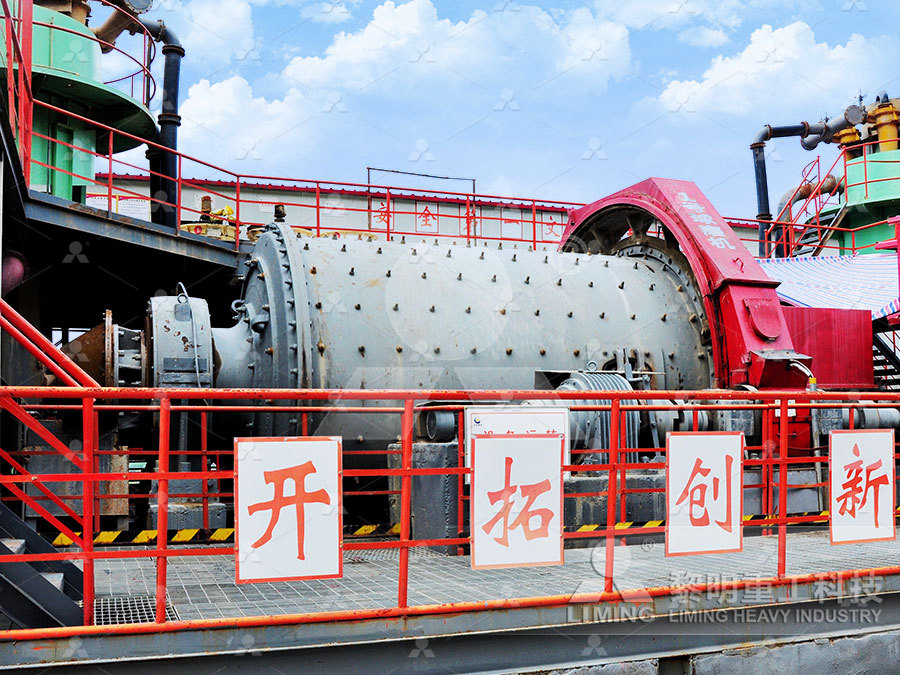

MPG Medium Speed Coal Mill北方重工 NHI

MPG medium speed coal mill is the product of upgrading MPS and MP medium speed coal mills In 1984, it cooperated with Germany Babcock Company for Liaoning Chaoyang Power Plant 2 × 200MW unit Augmentation Project provides 12 sets of MPS 212 medium speed coal mills, from which production and manufacture of MPS medium speed coal mills began 2015年8月1日 Schematic of mill control for (a) low speed mills and (b) medium speed mills The controls included are – (1) coal flow control, (2) air flow control and (3) outlet temperature control Download: Download fullsize image; Fig 5 SAMA Nomenclature [11] – (a) PID controller (b)Bias with automanual station (c) Signal processing symbolsReview of control and fault diagnosis methods applied to coal mills1 上海意丰科技开发有限公司, 上海市 闵行区 2 大唐国际吕四港发电有限责任公司, 江苏省 南通市 收稿日期: 出版日期: 发布日期: 作者简介:陈刚(1970), 男, 高级工程师, 主要研究方向为燃煤火电机组中制粉系统性能优化, 包括BBD双进双出钢球磨煤机、HP磨煤机、MPS磨煤 中速磨煤机制粉系统优化技术研究及应用2011年8月1日 13112 Mediumspeed mill Mediumspeed mills are smaller than lowspeed units and are generally of the vertical spindle construction The speed of the grinding section of these mills is usually 75–225 rpm They operate on the principles of crushing and attrition Pulverization takes place between two surfaces, one rolling on top of the otherMill Speed an overview ScienceDirect Topics

.jpg)

Modelling and control of pulverizing system considering coal

2015年2月1日 The mediumspeed coal mill pulverizing system is widely used in coalfired power plants in China Thus, the study of the operating characteristics, construction of the model, and optimization of control system are important Block diagram of coal mill predictive control The parameters of the predictive controller are as follows: sampling 2023年10月20日 and a medium speed coal mill in a coal fired power plant are This work is licensed under a Creative Commons Attribution 40 License For more information, see https://creativecommons A novel multimode Bayesian method for the process A control oriented model was then developed by Fan (1994) and Fan and Rees (1994) In 2009, coal flow and outlet temperature of mill were modelled using mass and heat balance equations for startup Sectional view of MBF coal mill Download Scientific Diagram2020年4月7日 The mediumspeed coal mill system is mainly composed of ra w coal bunker, coal feeder, coal mill, primary fan, sealing fan, hot and c old air regulating valves The coal feeder(PDF) Modeling of Coal Mill System Used for

Pulveriser in Thermal Power Plant Bowl Mill

2021年8月5日 Medium speed mills like bowl mill; High speed impact mill; The slow speed and medium speed mills are selected for coals ranging from subbituminous to anthracite The highspeed mills are used mainly for lignite Grinding of coal, petcoke, clay, limestone, quicklime, gypsum, and many other materials and remote control of grinding pressure and classifier rotor speed ensure a fully automatic operation of the MPS mill even with varying raw Coal mill, gypsum mill, clay mill, etc Pfeiffer sbm diagram for zgm113n coal millzgm95 type roller mill size Beijing Power Plant Vertical Mill DescriptionAtox coal mill 200 300 1500 3000 100 200 45 60 ms small size big energy savings 2 proven technology today the airswept vertical roller mill is the standard solution for coal grinding installations and thanks to our continuous refinement of the atox coal mill over the years sbm/sbm diagram for zgm113n coal millmd at main A simple energy balance model of the coal mill is derived in (Odgaard and Mataji 2006), this model is based on a more detailed model found in (Rees and Fan 2003)In this model the coal mill is seen as one body with the mass m mThe following variables are defined: T(t) is the temperature in the coal dust flow in the mill, ṁ PA (t) is the primary air mass flow, T PA (t) is Coal Mill an overview ScienceDirect Topics

Mathematical validation and comparison of ball tube

2023年6月10日 literature In this context the coal mill operations and the model coefficients of a medium speed vertical bowl mill and a low speed horizontal ball tube mill located in two distinct coal based power plants in northern India are compared The onsite data is physically obtained from the two plants A coal mill model2024年3月15日 HPSeriesMediumSpeedBowlMill 703 Free download as Powerpoint Presentation (ppt), PDF File (pdf), Text File (txt) or view presentation slides online HP Series Medium Speed Bowl Mill is used to grind, dry and separate raw coal into qualified fineness for combustion in steam boilers It consists of a grinding bowl, grinding rollers, spring loading HP Series Medium Speed Bowl Mill2021年1月28日 A Novel MultiMode Bayesian Method for the Process Monitoring and Fault Diagnosis of Coal MillsA Novel MultiMode Bayesian Method for the ProcessThe block diagram for online mill condition monitoring system is shown in Fig 12 established a dynamic model for a medium speed coal mill based on mass and energy balance and predicted the Working process of a Tubeball mill Download Scientific Diagram

Fault analysis and optimization technology of HP bowl type medium speed

2021年8月1日 HP type medium speed coal pulverizer produced by Shanghai heavy machinery works has been widely used in recent years, with common faults in operation, short maintenance cycle and heavy taskCoal obtained from the Catalagzi thermal power station was prepared into a −2360 +1700 µm mono size fraction and ground for different times in a laboratoryscale stirred media millLaboratoryscale stirred mill Download The cylindrical shell, grinding media, and material being ground all play important roles in the performance of a ball mill The diagram provided gives a visual representation of the components of a typical ball mill Critical Speed of Ball Ball Mill Principle, Application, Uses, Critical Figure 5 depicts the schematic diagram and actual pictures of the studied coal mill For a general medium speed coal mill, the raw materials are transported by the coal feeder into the internal Schematic diagram of the medium coal mill

.jpg)

A unified thermomechanical model for coal mill operation

2015年11月1日 Medium speed mills constitute the largest number of mills used for pulverizing coal in a thermal power plant These mills include bowl mills, roller mills, ball – race mills, etc The details about its operation are provided in ( Rees Fan (2003) , Wikipedia (2014) , Coal pulverization (2005) , Central Electricity Generating Board (1971) )2022年7月26日 learning machine; coal mill; fault diagnosis 1 Introduction Coal mills are important equipment of the coal pulverizing system The structure of the MPS mediumspeed coal mill is shown in Figure1[1] As can be seen from Figure1, the raw coal entering the coal mill through the coal falling pipe is squeezed and ground byFault Diagnosis of Coal Mill Based on Kernel Extreme 2023年5月8日 Modeling of medium speed coal mill,” Powder Technology 318 The coal pulverizer mills at the coalfired power station PLTU Rembang are the main equipment in the boiler that supports the reliability of the generating unit Skip to Main Coal pulverizer mill system modeling for failure simulation2009年9月1日 The coal mill used in the coalfired power plants is modeled in view of the controller design rather than the educational simulator The coal mass flow and the outlet temperature are modeled by reinvestigating the mass balance and heat balance models physically The archived data from a plant database are utilized to identify the model Modeling and Parameter Identification of Coal Mill

Review of control and fault diagnosis methods applied to coal mills

2015年8月1日 Mill problems originate mainly due to poor controls or faults occurring within the milling system As discussed by GQ Fan and NW Rees [3], the control of mills remains very simple in most of the power plants due to the fact that the mill system is highly nonlinear with strong coupling among the variables and it is very difficult to measure some important 2024年8月22日 The BTM is a lowspeed mill that primarily grinds coal by impact and attrition The VRM is a medium speed mill that grinds coal by compression and, because of the low coal inventory in the mill and flat grinding surfaces, develops shearing action as well For both mills a constant centrifugal force is maintained The speedA Comparison of Three Types of Coal Pulverizers2023年7月4日 Raymond mill is mainly used to grind coal, nonmetallic ore, glass, ceramics, cement, gypsum, pesticide, chemical fertilizer, and other materials The product particle size is 0045–0125 mm Column Mill The column mill is a vertical mill using high speed, medium pressure, and continuous, repeated grinding It consists of the belt pulley,Roller Mill Springer2017年8月1日 MPStype medium speed coal mills are widely used in the thermal power plants in China They are designed and manufactured by the German company Babcock This kind of coal mill has the characteristics of low energy consumption and smooth output and has a small effect on abrasive wear and an overhaul period [13], [14] In this study, MPS180HPII Modeling of a medium speed coal mill ScienceDirect

Modeling of a medium speed coal mill ResearchGate

2017年5月1日 Gao et al [5] established a dynamic model for a medium speed coal mill based on mass and energy balance and predicted the dynamic performance of a coal mill Wang et al [6] developed an approach MPG medium speed coal mill is the product of upgrading MPS and MP medium speed coal mills In 1984, it cooperated with Germany Babcock Company for Liaoning Chaoyang Power Plant 2 × 200MW unit Augmentation Project provides 12 sets of MPS 212 medium speed coal mills, from which production and manufacture of MPS medium speed coal mills began MPG Medium Speed Coal Mill北方重工 NHI2015年8月1日 Schematic of mill control for (a) low speed mills and (b) medium speed mills The controls included are – (1) coal flow control, (2) air flow control and (3) outlet temperature control Download: Download fullsize image; Fig 5 SAMA Nomenclature [11] – (a) PID controller (b)Bias with automanual station (c) Signal processing symbolsReview of control and fault diagnosis methods applied to coal mills1 上海意丰科技开发有限公司, 上海市 闵行区 2 大唐国际吕四港发电有限责任公司, 江苏省 南通市 收稿日期: 出版日期: 发布日期: 作者简介:陈刚(1970), 男, 高级工程师, 主要研究方向为燃煤火电机组中制粉系统性能优化, 包括BBD双进双出钢球磨煤机、HP磨煤机、MPS磨煤 中速磨煤机制粉系统优化技术研究及应用

.jpg)

Mill Speed an overview ScienceDirect Topics

2011年8月1日 13112 Mediumspeed mill Mediumspeed mills are smaller than lowspeed units and are generally of the vertical spindle construction The speed of the grinding section of these mills is usually 75–225 rpm They operate on the principles of crushing and attrition Pulverization takes place between two surfaces, one rolling on top of the other2015年2月1日 The mediumspeed coal mill pulverizing system is widely used in coalfired power plants in China Thus, the study of the operating characteristics, construction of the model, and optimization of control system are important Block diagram of coal mill predictive control The parameters of the predictive controller are as follows: sampling Modelling and control of pulverizing system considering coal 2023年10月20日 and a medium speed coal mill in a coal fired power plant are This work is licensed under a Creative Commons Attribution 40 License For more information, see https://creativecommons A novel multimode Bayesian method for the process A control oriented model was then developed by Fan (1994) and Fan and Rees (1994) In 2009, coal flow and outlet temperature of mill were modelled using mass and heat balance equations for startup Sectional view of MBF coal mill Download Scientific Diagram