Water slag micro powder crushing

Effect of water quenched silicomanganese slag as fine

2024年7月1日 The rapid cooling of melted SMS by water quenching produces porous particles (016–5 mm) called water quenched silica manganese slag (WQSMS) The current research 2024年11月1日 Considering the characteristics of metallurgical processes and the migration properties of impurity elements under the influence of electric fields, this review introduces a Recent research progress on recycling metallurgical waste slag 2023年11月29日 Wet granulation is a potential method to develop artificial aggregates In this paper, the granulation of recycled alkaliactivated slag powders with different particle size (d Recycling alkali activated slag into artificial aggregate: 2023年7月19日 The shrinkage of the slagbased geopolymer increases with the increase in ratio of water to slag powder, and the porosity also increases, resulting in a decrease in compactness after(PDF) Mechanical Properties of SlagBased

(PDF) Effect of Crsolidified/stabilized Water

2023年11月8日 The results demonstrate that the addition of sludge increases the grindability of waterquenched slag, with a specific surface area increasing from 971m²/kg to 1125m²/kg, and a glass phase2023年12月11日 The composite micronized powder is prepared by using blast furnace slag (BFS), waterquenched manganese slag (WQMS), manganese tailing slag (MTS) and desulfurization gypsum (DG) and grinding aid (GA) Preparation and Performance of UltraFine High 2011年3月17日 The invention relates to a production process of steel slag micropowder, which comprises the following steps: enabling wet steel slag powder with water content of 5% and Production process of steel slag micropowder Semantic 2023年9月8日 The current study encompasses the production of alkaliactivated artificial aggregates through coldbonding pelletization technique using three different raw materials, Producing of alkaliactivated artificial aggregates by

Characteristics of Recycled Micro Powder Produced Using

2021年7月11日 The specific surface area of recycled micro powder prepared by grinding recycled aggregate for 30 min is more than 500 m 2 /kg, which is greater than that of cement, The influences of slag gradation, slag particle size, and slag content on the optimum water content and maximum density of slag–clay mixtures were determined Meanwhile, the effects of slag content,Laboratory Tests on Compaction and Crushing Behaviors 2023年6月27日 Steel slag powder and construction waste have received widespread attention for their resource utilization as solid waste This article uses steel slag powder and recycled concrete aggregates to prepare controlled lowstrength materials (CLSM) The study investigates the influence of steel slag powder replacing cement and recycled aggregates on the Effect of Steel Slag Powder on the Performance of 2023年4月10日 Tang W J Effect of Micropowder Mixture of Steel Slag and Gr anulated Blast Furnace Slag on Cement and Concrete Proper ties[D] China University of Geosciences, Beijing, 2009 ( in Chinese ) Effect of Steel Slag Powder Content and Curing Condition on

A Review on the Carbonation of Steel Slag: Properties,

2024年4月28日 Steel slag is a byproduct of the steel industry and usually contains a high amount of fCaO and fMgO, which will result in serious soundness problems once used as a binding material and/or aggregates To relieve this negative effect, carbonation treatment was believed to be one of the available and reliable methods By carbonation treatment of steel 2018年1月30日 1 Introduction Steel slag is a byproduct of steel manufacturing []Approximately 160 kg of steel slag is generated per ton of steel produced []The common chemical compounds in steel slag are SiO 2, CaO, Fe 2 O 3, Al 2 O 3, and MnO [3, 4]The major mineral components of steel slag are C 3 S, C 2 S, C 4 AF, RO phase, and freeCaO [5, Applications of Steel Slag Powder and Steel Slag Aggregate 2022年11月11日 Steel slag is generally regarded as a supplementary cementitious material in cementbased materials, which is conducive to the realization of the goal of carbon peak and carbon neutralization However, the lower cementitious activity and poorer volume stability of steel slag limit its high dosage in cementbased materials In this paper, steel slag ultrafine powder Laboratory Preparation and Performance Characterization of Steel Slag 2020年7月1日 The slag grinding system is the core of the slag powder control system, which con sists of batching station, conveyor belt, vertical mill, hot gas generator , dust collector and product warehouseAnalysis and multiobjective optimization of slag powder

Effects of Steel Slag Powder Content and Curing Condition

2023年5月21日 The accumulation of steel slag and other industrial solid wastes has caused serious environmental pollution and resource waste, and the resource utilization of steel slag is imminent In this paper, alkaliactivated ultrahighperformance concrete (AAMUHPC) was prepared by replacing ground granulated blast furnace slag (GGBFS) powder with different 2021年11月3日 The technological factors required to improve the operational properties of granulated metallurgical slags demanded in the building industry have been analyzed In order to satisfy these factors, a new technology for hydrovacuum granulation of slag melts (HVG) has been developed It is shown that the main advantage of the proposed HVG process is the A new technological approach to the granulation of slag 2024年1月12日 Steel slag is a byproduct of the steel production process, accounting for approximately 15% of the whole crude steel output [1]The accumulation of untreated steel slag not only occupies a significant amount of land but also leads to the leaching of heavy metal ions (such as vanadium, chromium, arsenic, lead, cadmium), polluting surrounding water sources Review Accelerated carbonation of steel slag: A review of 2024年2月3日 Slag Micro Powder Processing The processing of slag micro powder can be divided into the following steps: Crushing: The slag is first crushed into a size that can be fed into the grinding mill Grinding: The slag is then Slag Micro Powder Processing Grinding

.jpg)

Characteristic and mechanism of efficient phosphate

2024年4月1日 The slag micropowder, The slag powder, Portland cement, gypsum, and coal ash were blended in a specific mass ratio of 40:23:7:30 to form a mixture Next, the mixture was agitated with varying watertocement ratios ranging from 40% to 60% until it became a slurry After crushing and grinding the clumpy PC/SP/CAH, three particle sizes 2023年7月26日 In view of the large capacity demand of customers with an annual output of tons of slag micro powder, the engineer equipped the production line with LM353N Vertical Mill and LM172N Vertical Mill, which is energysaving equipment combined with mature vertical mill technology, successful experience and technological innovationWater Slag Grinding Project Used For Mine Backfill in Fujian, 2023年8月30日 The analysis of Table 9 shows that when the strength of the UHPC filled with steelslag micro powder increased from 120 MPa to 130 MPa, 140 MPa, 150 MPa, and 160 MPa, respectively, the ultimate flexural bearing capacity of the member increased by 16%, 32%, 49%, and 66%, respectively, and the rate of the increase in the flexural bearing Research on the Flexural Performance of Steel Pipe Steel Slag Powder 2021年7月1日 The addition of tailings powder improves the working performance of concrete and slightly improves the strength Due to the large amount of cement used in ultrahighperformance concrete, physical (PDF) Effect of Iron Tailings and Slag Powders on Workability

(PDF) Effect of Crsolidified/stabilized Waterquenched Slag

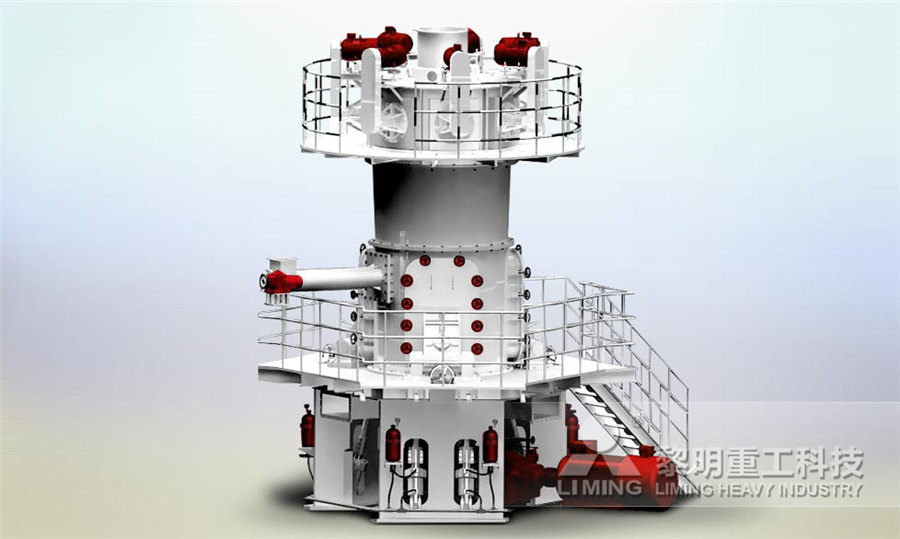

2023年11月8日 This article presents an original study into the feasibility of using blast furnace slag and stainless steel pickling sludge to produce solidified/stabilized Cr slag micropowder and its 2023年7月1日 Steel slag powder (SSP) was selected as an inorganic micro powder filler instead of limestone powder (LSP) to prepare asphalt mastic in this paper Firstly, the microscopic characteristics of SSP and LSP such as particle size distribution, surface morphology, phase composition and chemical composition were characterized by laser particle size Creep and fatigue properties of asphalt mastic with steel slag powder After rapid cooling with air or water, it forms granular particles, which are called granulated blast furnace slag, abbreviated as slag LM slag vertical mill is a specialized equipment for grinding industrial waste into powder It integrates crushing, conveying, grinding, and drying, making it an ideal equipment for producing slag micro The role and advantages of slag micro powder limingmill2023年9月8日 A—weight of ovendry aggregates, B—weight of saturated surfacedry aggregates after 24 h of water immersion Aggregate crushing and impact value The crushing and impact strength tests of aggregates were conducted as per IS 2386:1963 part 4 The crushing value is the resistance shown by the aggregates against the gradually applied Producing of alkaliactivated artificial aggregates by

.jpg)

Steel slag recycling crushing and grinding production line

The magnetic steel slag washing, ball mill, magnetic separation, purification process, comprehensive recycling technology of slag and complete set of equipment can not only realize water recycling, but also the purification grade of steel slag is high (TFe > 90%), and the taste of ironcontaining slag powder is up to 55% The iron slag powder 2023年11月9日 The slag micropowder and Class F Grade I fly ash used in this test were purchased from a processing plant near the mine (Zhanteng Mineral Products Processing Factory, Shijiangzhuang, China) The slag and fly ash Experimental Study of the Freezendash;Thaw 2023年2月1日 It is reasonable that a glazelikely protective layer could form on gangue surface after calcination with mineral powders, which could reduce the water absorption and crushing rate of coal gangue Mineral powders contained natural ore powder (eg Kfeldspar and wollastonite) and industrial waste powder (eg blast furnace slag and fly ash)Enhancement of coal gangue performance by surface micro 2023年2月1日 Results showed that after calcining with mineral powders, the crushing rate of coal gangue decreased from 168 % to 161132 %, and water absorption decreased from 529 % to 274390 %, among which the coal gangue treated by Kfeldspar and blast furnace slag had the lowest water absorption (274 %), reducing by 482 % compared to raw coal gangueEnhancement of coal gangue performance by surface micro

.jpg)

Steel Slag Processing Plant Equipment Selection

2023年12月27日 The price of processed steel slag powder is relatively higher, and it is the source of profit for the complete steel slag processing plant Brick factories and cement plants will need the iron powder and purchase it The crushing processing and reuse of steel slag are profitable and have a protective effect on the environment, so the Coarse powder grinding mill is engaging in crushing various rocks and stones into coarse powder and small particles, such as calcite, etc To avoid the plugging of the crusher, the proportion of water for the crushing materials is no more than 20% Main Specification of Coarse Powder Mill The three ring medium speed micro powder mill Coarse Powder Grinding Mill SBM Ultrafine Powder 2021年2月5日 Effects of air drying/freeze drying combined ultra‐micro‐crushing on total chlorophyll in barley grass powder at different times Note: Different letter means significant differences (p ≤ (PDF) Comparison of hydrability, antioxidants, microstructure2024年7月30日 Steel manufacturers around the world are looking for ways to produce higher quality, lowersulfur steel This requires an additional desulfurization step using the Kambara reactor (KR) during steel production As a side effect, the Kambara reactor’s slag processing generates emissions that are captured and concentrated in dust collectors such as bag filters, Recycled Kambara reactor slag powder as a sustainable

Slag mill, slag powder mill, slag uZhengzhou Vanguard

2023年11月6日 Slag grinder (also called slag micropowder mill and slag superfine mill) is a largescale grinding machine, which Vanguard absorbs advanced European technology and designs and improves VPM3 Series Combined Mobile Crushing Plant; VPE Series Mobile Crushing Plant; The activity of alkaline slag is higher than that of acid slag Slag has 2021年11月29日 Dark green SM slag was supplied from the water quenching granular slag of an SM alloy enterprise in Ningxia The SM slag was ground for 10, 20, 25, and 30 min using a sealed sample preparation mill The D 50 values of the SM slag were 1212, 6344, 5406, and 5343 µm, respectively, as determined using Mastersizer 2000 laser particle size Preparation and Characterization of the Functional Properties 2022年4月29日 Concrete is the universally accepted building material for all types of construction and is the most commonly used material after water The developments in concrete has led to the evolution of many types of concretes like geopolymer concrete, selfcompacting concrete, fibre reinforced concrete Selfcompacting concrete is a special type of concrete Mechanical properties of selfcompacting concrete using steel slag The influences of slag gradation, slag particle size, and slag content on the optimum water content and maximum density of slag–clay mixtures were determined Meanwhile, the effects of slag content,Laboratory Tests on Compaction and Crushing Behaviors

Effect of Steel Slag Powder on the Performance of

2023年6月27日 Steel slag powder and construction waste have received widespread attention for their resource utilization as solid waste This article uses steel slag powder and recycled concrete aggregates to prepare controlled lowstrength materials (CLSM) The study investigates the influence of steel slag powder replacing cement and recycled aggregates on the 2023年4月10日 Tang W J Effect of Micropowder Mixture of Steel Slag and Gr anulated Blast Furnace Slag on Cement and Concrete Proper ties[D] China University of Geosciences, Beijing, 2009 ( in Chinese ) Effect of Steel Slag Powder Content and Curing Condition on 2024年4月28日 Steel slag is a byproduct of the steel industry and usually contains a high amount of fCaO and fMgO, which will result in serious soundness problems once used as a binding material and/or aggregates To relieve this negative effect, carbonation treatment was believed to be one of the available and reliable methods By carbonation treatment of steel A Review on the Carbonation of Steel Slag: Properties, 2018年1月30日 1 Introduction Steel slag is a byproduct of steel manufacturing []Approximately 160 kg of steel slag is generated per ton of steel produced []The common chemical compounds in steel slag are SiO 2, CaO, Fe 2 O 3, Al 2 O 3, and MnO [3, 4]The major mineral components of steel slag are C 3 S, C 2 S, C 4 AF, RO phase, and freeCaO [5, Applications of Steel Slag Powder and Steel Slag Aggregate

Laboratory Preparation and Performance Characterization of Steel Slag

2022年11月11日 Steel slag is generally regarded as a supplementary cementitious material in cementbased materials, which is conducive to the realization of the goal of carbon peak and carbon neutralization However, the lower cementitious activity and poorer volume stability of steel slag limit its high dosage in cementbased materials In this paper, steel slag ultrafine powder 2020年7月1日 The slag grinding system is the core of the slag powder control system, which con sists of batching station, conveyor belt, vertical mill, hot gas generator , dust collector and product warehouseAnalysis and multiobjective optimization of slag powder 2023年5月21日 The accumulation of steel slag and other industrial solid wastes has caused serious environmental pollution and resource waste, and the resource utilization of steel slag is imminent In this paper, alkaliactivated ultrahighperformance concrete (AAMUHPC) was prepared by replacing ground granulated blast furnace slag (GGBFS) powder with different Effects of Steel Slag Powder Content and Curing Condition 2021年11月3日 The technological factors required to improve the operational properties of granulated metallurgical slags demanded in the building industry have been analyzed In order to satisfy these factors, a new technology for hydrovacuum granulation of slag melts (HVG) has been developed It is shown that the main advantage of the proposed HVG process is the A new technological approach to the granulation of slag

Review Accelerated carbonation of steel slag: A review of

2024年1月12日 Steel slag is a byproduct of the steel production process, accounting for approximately 15% of the whole crude steel output [1]The accumulation of untreated steel slag not only occupies a significant amount of land but also leads to the leaching of heavy metal ions (such as vanadium, chromium, arsenic, lead, cadmium), polluting surrounding water sources