Ring roller mill 1000 working principle

RLM Ring Roller Mill working principle ALPA YouTube

2019年7月18日 Relying on the grinding roller orbital revolution and rotation on the grinding ring track to finish grinding Builtin classifying wheel, available D50:2~45μm Compared with Raymond millWorking principle: the motor drives the grinding table to rotate through the reducer, the material falls into the center of the grinding table from the feed inlet through the air lock feeder, and the Roller Mill SpringerThe roller mill’s ability to reduce materials to a uniform particle size provides more control of product characteristics and minimizes waste, as shown in Figure 1 The mill’s controlled Roller mills: Precisely reducing particle size with greater efficiencyThe ring roller mill uses the principle of impact, extrusion and grinding to pulverize the material The ring roller mill is equipped with multilayer grinding rollers and grinding rings, and the material first falls between the uppermost grinding Air Classifying Mill ACM Mill for Particle Size

Ring Roller Mill ALPA Powder Equipment

The ultrafine roller mill drives the main shaft to rotate through the transmission device The upper end of the main shaft is connected to the rotor frame The frame is equipped with an auxiliary shaft and a grinding wheel is installed on 磨轮在公转和自转的过程中产生强大的离心力,与定子发生强烈的辊研作用,被粉碎的物料在离心力及磨轮旋转力场的带动下,进入磨轮与定子组成的研磨区中,在强大的挤压力和研磨力作用下物料被粉碎。 粉碎后的物料下落到甩料盘上, 辊压磨 埃尔派粉体科技有限公司We adopted the forced driven method for top and bottom edge rolls to prevent swelling or rolling up generated in rolling with ring rolling mill and lifting often generated in initial stage of rolling KOJIMA IRON WORKS CO,LTD|PRODUCTS|Products Radialaxial ring rolling, the forming principle of which is shown in Fig1, is a classic form of ring rolling process and is usually adopted to manufacture various highquality large rings widely Numerical Modelling and Simulation of RadialAxial Ring Rolling

.jpg)

RLM Ring Roller Mill ALPA Powder Technology

Relying on the grinding roller orbital revolution and rotation on the grinding ring track to finish grinding Builtin classifying wheel, available D50:2~45μm Compared with Raymond mill or ball mill, finer powder, lower operating cost 2023年7月4日 Roller mill is a type of grinding equipment for crushing materials by pressure between two or more rolling surfaces or between rolling grinding bodies (balls, rollers) and a track (plane, ring, and table) The roller mill with several grinding rollers as working components rolls along the grinding ring or the grinding table to crush the Roller Mill SpringerLink2024年7月28日 The ring roller mill is equipped with multilayer grinding rollers and grinding rings, and the material first falls between the uppermost grinding roller and the grinding ring There is a large movable gap between the grinding ring installed on Ring Roller Mill Manufacturer EPIC Powder Machinery2024年3月13日 The roller mill is a type of powder making equipment that combines ring roller grinding with air flow screening and pneumatic conveying It has the characteristics of strong universality, continuous dry powder making, concentrated particle size distribution, continuously adjustable fineness, and compact structure"Working principle and application of roller mill"

.jpg)

RLM Ring Roller Mill working principle ALPA YouTube

2019年7月18日 Relying on the grinding roller orbital revolution and rotation on the grinding ring track to finish grindingBuiltin classifying wheel, available D50:2~452022年4月27日 Principle The principle of the roller mill is breaking and crushing actions are achieved mechanically with the application of pressure Stress is applied by rotating heavy corrugated wheels (mullers or rollers) The oil is squeezed out from the solid material Construction The construction of a roller mill is shown in FigureRoller Mill Principle, Construction And Working Pharmacy 2024年7月22日 Ring Rolling Utilises three rollers, including a drive roller, idler roller, and axial roller, to create rings and tubes by compressing metal The workpiece is placed between the rollers, and as they rotate, the metal is gradually compressed to achieve the desired shape This unique manufacturing technique offers several advantages over other Rolling Process: Working Principle, Types, and Advantages andRing Roller Mill Working Principle The ring roller mill uses the principles of impact, extrusion and grinding to crush materials There are multiple layers of grinding rollers and grinding rings installed, and the material first falls between the uppermost grinding rollers and grinding ringsRing Roller Mill EPIC Powder Machinery

.jpg)

Triple Roller Mill: Principle, Construction, Diagram, Working, and

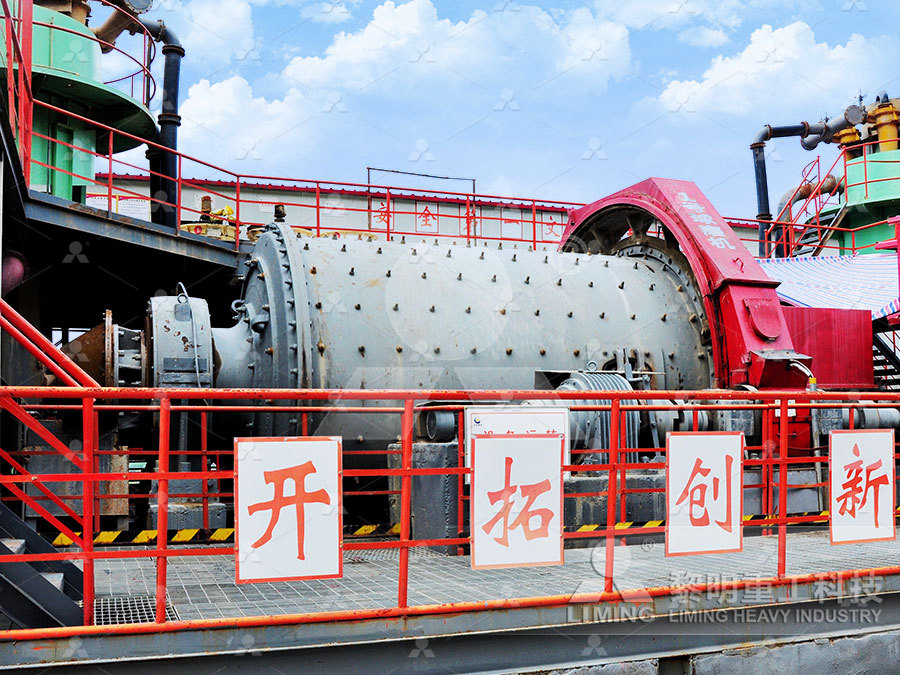

2023年7月19日 Principle: Principle of the Triple Roller Mill Operating on the principle of shear force, the threeroll mill contains three horizontally positioned rolls These rolls rotate in opposite directions and at varying speeds relative to each other This movement allows the mill to mix, refine, disperse, or homogenize viscous materialsRing Roller Mill Large output and high production efficiency Large output, more than twice the production efficiency of Raymond mills and jet mills, good product fineness indicators, easy installation of complete sets of equipment, no largescale civil engineering, all fine powder can be recycled, no pollution to the environment, and the dust removal effect reaches the dust Ring Roller Mill – Ultrafine Powder EquipmentRaymond Mill Working Principle หลักการทำงาน 1)แร่จะถูกลำเลียงเข้าถังเก็บแร่โดยลิฟต์ หลังจากนั้นจะถูกบดหยาบให้ได้ขนาดโดย Jaw CrusherRaymond Mill Working Principle BloggerRoller Mill Working Principle Author:liming Post Date: Roller Mill Introduction: High Pressure Suspension Roller Mill is my chief engineer Mr Bai Yinghui, wearable device experts on the basis of the experience of many Roller Mill Working Principle Liming Heavy Industry

Roller mills: Precisely reducing particle size with greater efficiency

roller mill tests of your material in the manufacturer’s test facility with various roll corrugation styles and under conditions that duplicate your operating environment Figure 1 Particle size distributions: Roller mill versus other grinding methods Other grinding methods Roller mill Overs Target particle size Fines Figure 22023年8月22日 1 Understanding Raymond Mill's Working Principle Raymond Mill has established itself as a renowned grinding equipment in various industries, revolutionizing material processing and setting new standards for efficiency The Working Principle of Raymond Mill PDF Free 2 thoughts on “Triple Roller Mill – Principle, Construction, Diagram, Working and Important Applications 2024” Pingback: 5 Best High Quality SugarCane Juice Machines 2023 [NEW] Irich CreativestudioTriple Roller Mill Principle, Construction, Diagram, Working The Raymond Roller Mill is an airswept vertical ringroll mill with an integral classification system that simultaneously dries, pulverizes and classifies a number of different types of products including limestone, clay, minerals and others From a feed ranging in size from approximatelyRaymond Roller Mill airswept vertical ringroll

Vertical roller mill Wikipedia

Material grinding process motor through reducer rotating drive disc, the material falls from the mill under the central entrance and exit, under the action of centrifugal force to the disc edge by the roller to move and the crushing, grinding out lap after the material was speed up the flow to and vertical mill with one of the separator, after the meal by the separator back to the mill, the re 2023年12月27日 Home Triple Roller Mill: Principle, Construction, Working Home pcue Chpater 4 Triple Roller Mill: Principle, Construction, Working December 27, 2023 0 Comments A triple roller mill is used to mix semisolids while preparing ointments, creams, pill masses, wet mass for making granules, etcTriple Roller Mill: Principle, Construction, WorkingWorking Principle The ring roller mill uses the principle of impact, extrusion and grinding to pulverize the material 101000: 151500: 202000: 252500: 404000: 454500: 606000: 757500: 10010000: 1515000: Technical parameters of MJWW series air classifying mill MODEL 300 400 500 600 700 1000 1250 1500;Air Classifying Mill ACM Mill for Particle Size Reduction EPICThe working principle of the high pressure grinding mill is similar to that of the traditional Raymond mill, but the grinding device is equipped with a high pressure spring with a pressure of 10001500kg When the machine is working, the grinding roller of the highpressure roller mill rotates around the main shaft, and rolls close to the YGM High Pressure Grinding Mill

.jpg)

Ultrafine vertical roller mill SBM Ultrafine Powder Technology

Working Principle Ultrafine vertical roller mill is mainly composed of motor, reducer, grinding wheel device, roller device, continues to move towards the fringe of the grinding plate until they are taken away by strong air flow at the air ring 1000 square meters of exhibition hall, Vertical Roller Mill Summary Free download as PDF File (pdf), Text File (txt) or view presentation slides online Ball mill vs vertical mill Operations Structure of a vertical mill Working Process Components Dam Ring Armour Ring Louver Ring Grinding Table Rollers Separators Maintenance Performance ImprovementVertical Roller Mill Summary2023年8月5日 High pressure roller mill is a new type of grinding equipment developed on the basis of roller press for cement in recent years Mines increase the specific surface area for fine grinding The high pressure roller mill has the characteristics of high production efficiency, large crushing ratio, low power consumption, significant energy saving and convenient maintenanceWorking principle of high pressure roller millZYminingclassifier mill, but they’re configured differently Horizontal wheel While in principle the horizontalwheel classifier mill operates the same way as the vertical mill, the horizontal orientation of its classifier wheel doesn’t allow the use of a shroudandbaffle assembly to separate the grinding zone from the classification zone How to operate an air classifier mill to meet your fine grinding goals

.jpg)

Roller mill Wikipedia

An early 20thcentury oilseed rollermill from the Olsztyn district, Poland A late 19th century double roller mill displayed at Cook's Mill in Greenville, West Virginia in 2022 Closeup of Barnard's Roller Mill, New Hope Mills Complex, New York Cutaway drawing of a centrifugal roller mill for mining applications, 1913 Roller mills are mills that use cylindrical rollers, either in opposing manufacturing, mill gas circulation fan and dust collection fan are required and their power consumption was larger Descriptions The conventional process gas flow of the mill grinding system generally consists of vertical roller mill with separator, cyclone, mill circulation fan, and electrostatic precipitator (EP) and EP fan as shown in Fig1Vertical roller mill for raw Application p rocess materialsUltrafine Ring Roller Mill; building materials, chemical and mine industries Working Principle of Ultra Fine Grinding Mill When the grinding mill is at [] Fineness: 2003000 mesh Capacity: 220T/H Scene: calcite,marble,talc,gypsum,dolomite and other Ore powder 1000~1300 92 4000~4500 92 2500~3000 67~70 2000 650~750 125 4000 CRGM series superfine grinding mill for mineralThe motor drives the reducer In the mill, material falls from the feed opening onto a grinding disc It moves to the edge of the mill due to centrifugal force and the grinding roller Shredded material overflows from the edge At the same time, wind from the nozzle ring speeds to the efficient separator It is with the vertical millTable Roller Mill Vertical Mill

Ring Roller Mill ALPA Powder Technology

The ultrafine roller mill drives the main shaft to rotate through the transmission device The upper end of the main shaft is connected to the rotor frame The frame is equipped with an auxiliary shaft and a grinding wheel is installed on the auxiliary shaftIt through the interaction between the grinding roller and the grinding ring, the material is processed into ultrafine powder +29 HGM Ultrafine Grinding Mill 21 24 28 Roller Mill Capacity: 0545 t/h Max feeding size: 20 mm Working Principle 1HGM Ultrafine Grinding Mill 21 24 28 Roller Mill2023年10月17日 Roller mill principle It is like a powerful grinder The principle of roller mill is based on the crushing or compressing mechanism which is created by stress It crushes and grinds big materials into tiny particles Pharmaceuticals need to be small and consistent for more be effectivity So, this mill controls the size and uniformity of the Roller mill principle construction working uses advantages and 2023年7月4日 Roller mill is a type of grinding equipment for crushing materials by pressure between two or more rolling surfaces or between rolling grinding bodies (balls, rollers) and a track (plane, ring, and table) The roller mill with several grinding rollers as working components rolls along the grinding ring or the grinding table to crush the Roller Mill SpringerLink

.jpg)

Ring Roller Mill Manufacturer EPIC Powder Machinery

2024年7月28日 The ring roller mill is equipped with multilayer grinding rollers and grinding rings, and the material first falls between the uppermost grinding roller and the grinding ring There is a large movable gap between the grinding ring installed on 2024年3月13日 The roller mill is a type of powder making equipment that combines ring roller grinding with air flow screening and pneumatic conveying It has the characteristics of strong universality, continuous dry powder making, concentrated particle size distribution, continuously adjustable fineness, and compact structure"Working principle and application of roller mill"2019年7月18日 Relying on the grinding roller orbital revolution and rotation on the grinding ring track to finish grindingBuiltin classifying wheel, available D50:2~45RLM Ring Roller Mill working principle ALPA YouTube2022年4月27日 Principle The principle of the roller mill is breaking and crushing actions are achieved mechanically with the application of pressure Stress is applied by rotating heavy corrugated wheels (mullers or rollers) The oil is squeezed out from the solid material Construction The construction of a roller mill is shown in FigureRoller Mill Principle, Construction And Working Pharmacy

Rolling Process: Working Principle, Types, and Advantages and

2024年7月22日 Ring Rolling Utilises three rollers, including a drive roller, idler roller, and axial roller, to create rings and tubes by compressing metal The workpiece is placed between the rollers, and as they rotate, the metal is gradually compressed to achieve the desired shape This unique manufacturing technique offers several advantages over other Ring Roller Mill Working Principle The ring roller mill uses the principles of impact, extrusion and grinding to crush materials There are multiple layers of grinding rollers and grinding rings installed, and the material first falls between the uppermost grinding rollers and grinding ringsRing Roller Mill EPIC Powder Machinery2023年7月19日 Principle: Principle of the Triple Roller Mill Operating on the principle of shear force, the threeroll mill contains three horizontally positioned rolls These rolls rotate in opposite directions and at varying speeds relative to each other This movement allows the mill to mix, refine, disperse, or homogenize viscous materialsTriple Roller Mill: Principle, Construction, Diagram, Working, and Ring Roller Mill Large output and high production efficiency Large output, more than twice the production efficiency of Raymond mills and jet mills, good product fineness indicators, easy installation of complete sets of equipment, no largescale civil engineering, all fine powder can be recycled, no pollution to the environment, and the dust removal effect reaches the dust Ring Roller Mill – Ultrafine Powder Equipment

Raymond Mill Working Principle Blogger

Raymond Mill Working Principle หลักการทำงาน 1)แร่จะถูกลำเลียงเข้าถังเก็บแร่โดยลิฟต์ หลังจากนั้นจะถูกบดหยาบให้ได้ขนาดโดย Jaw Crusher