Mechanical limestone for producing calcium carbonate

Evaluation of precipitated CaCO3 produced from locally

2024年5月16日 There are two primary sources of calcium carbonate worldwide: GCC and PCC 9 GCC is extracted from the Earth and exists in various forms like calcite, aragonite, vaterite, limestone, chalk,2024年1月19日 Substituting Portland cement (PC) clinker with limestone has been demonstrated to effectively reduce CO 2 emissions while enhancing the properties of cement Maximising the benefits of calcium carbonate in sustainable 2024年9月27日 Limestone calcined clay cement (LC 3) is a relatively new [15] ternary blend class composed of limestone (LS), OPC and calcined clay (CC), which enables synergistic Phase development and mechanical strength of limestone 2024年9月1日 This study introduces a novel approach for preparing gradient carbonated materials by partially calcined limestone (PCL), which is calcined below full calcination Role of partial limestone calcination in carbonated lime

Hydration mechanism of limestone calcined clay cement

2024年8月9日 This paper investigates four separate binder systems: Ordinary Portland Cement (OPC), OPC incorporating 30 % calcined CG, OPC with 15 % limestone addition, and 2024年6月23日 The aim of this work is to develop a method for producing soluble calcium ions through two waste sources, limestone powder derived from aggregate quarries and acetic acid derived from fast pyrolysis of Sustainable Biocement Production via 2024年1月25日 Substituting Portland cement (PC) clinker with limestone has been demonstrated to effectively reduce CO2 emissions while enhancing the properties of cement Maximising the benefits of calcium carbonate in 2023年6月14日 One proposed strategy for CO 2 reduction includes the use of functional limestone fillers, which reduce the amount of portland cement in concrete without Structure and Properties of PortlandLimestone Cements

.jpg)

Experimental analysis on calcination and carbonation process in calcium

2023年3月28日 This work investigates calcium looping employing limestone obtained directly from several cement factories in Indonesia to observe the carbonabsorption characteristics of 2023年3月21日 Using Ca (CH 3 COO) 2 (prepared from limestone waste) as a calcium source resulted in a 3187% lower MICP cost compared to using CaCl 2 An unconfined compressive strength (UCS) test was conducted to Feasible Utilization of Waste Limestone as a 2016年3月1日 The calcium carbonate (CaCO 3) precipitation process is a straightforward and easily controllable mechanism of MICP that can produce high concentrations of CaCO 3 in short period of time (Dhami et al 2013a)Urease influences the chemical process associated with the formation of biominerals through four different parameters (Hammes and Verstraete 2002) Formations of calcium carbonate minerals by bacteria and its 2022年8月1日 With the presence of calcium ion, calcium carbonate (CaCO 3) is deposited in the form of calcite within sand particles and binds them together One of the most important factors affecting MICPbased soil improvement is the capability of bacteria to induce CaCO 3 precipitation within sand particles and pores ( Rahman et al, 2020 )A sustainable production of biocement via microbially induced calcium

.jpg)

Optimization of calcium carbide residue utilization for producing

2023年10月28日 Ammonium acetate's significance underscores its dual role in both the leaching and carbonation processes This process yielded calcium carbonate with particle sizes smaller than 100 nm, with a purity of 98% and a single vaterite phase The calcium carbide residue demonstrated an impressive CO 2 uptake rate of 235% Ammonium acetate exhibited 2024年8月21日 We are manufacturer of Calcium Carbonate, Limestone Feed Grade, Plaster of Pairs Silica Sand products Calcium Carbonate is added to plastics to improve their mechanical properties and reduce Understanding the role of limestone in the manufacturing process is crucial for producing highquality calcium carbonate products efficiently and The Ultimate Guide Calcium Carbonate Manufacturing Process2005年7月1日 A new type of process for producing highpurity calcium carbonate from waste cement powder was developed The process consists of two main reactions; extraction of calcium in the form of calcium ions from waste cement powder in a water slurry by pressurized CO2 (typically at several MPa), and precipitation of calcium carbonate (CaCO3) from the extracted Development of a process for producing high‐purity calcium carbonate 2020年12月22日 Chemically, limestone is calcium carbonate It is a sedimentary rock formed from the shells and skeletons of marine creatures which fell to the bottom of ancient seas These were turned into rock by the pressure of more sediments forming on top of them The next video shows a modern industrial plant for producing quicklime, calcium oxidelimestone, quicklime and slaked lime chemguide

Frontiers Biogenic calcium carbonate derived from waste

2022年11月16日 1 Research Centre for Biocomposite Materials for Medical, Agricultural and Food Industry, Suranaree University of Technology, Nakhon Ratchasima, Thailand; 2 School of Polymer Engineering, Suranaree University of Technology, Nakhon Ratchasima, Thailand; Biogenic calcium carbonate derived from waste shells has received significant attention in the 2020年6月15日 Microbially induced calcium carbonate precipitation (MICP) is a process that has emerged as an alternative and sustainable ground improvement approach in geotechnical and civil engineering for improving the mechanical properties of soil Ureaseproducing bacteria accelerate the process of MICP by converting urea into ammonium and carbonates Application of microbially induced calcium carbonate precipitation 2023年12月26日 When heated, calcium carbonate undergoes a chemical reaction called thermal decomposition, producing calcium oxide (quicklime) and carbon dioxide gas 15 Calcium carbonate also known as? Calcium carbonate is also known as limestone when occurring naturally in rocks, and it is a major component of chalk and marbleCalcium Carbonate(CaCO3) Limestone Formula, Structure, 2024年10月1日 Synergizing Portland Cement, highvolume fly ash and calcined calcium carbonate in producing selfcompacting concrete: A comprehensive investigation of rheological, mechanical, and microstructural Synergizing Portland Cement, highvolume fly ash and calcined calcium

.jpg)

Microbially induced calcium carbonate precipitation through

2024年6月10日 Background Microbially induced calcium carbonate precipitation has been extensively researched for geoengineering applications as well as diverse uses within the built environment Bacteria play a crucial role in producing calcium carbonate minerals, via enzymes including carbonic anhydrase—an enzyme with the capability to hydrolyse CO2, commonly Caves form in limestone (calcium carbonate), and occasionally in dolomite (calcium magnesium carbonate), when water containing dissolved carbon dioxide (carbonic acid) seeps into rock crevices and joints They grow when water Limestone caves The Australian Museum2024年10月2日 Calcium carbonate is biologically and chemically distinct from plastics and is not classified as a microplastic Naturally, calcium carbonate exists in the form of limestone, a rock that contains a minimum of 50% calcium Improvements in the utilization of calcium 2021年2月14日 Mechanical and Durability Properties of Portland Limestone Cement (PLC) Incorporated with Nano Calcium Carbonate (CaCO3) different grades is explored for producing Portland limestone cement Mechanical and Durability Properties of Portland Limestone

.jpg)

Feasible Utilization of Waste Limestone as a Calcium Source

2023年3月21日 Microbialinduced CaCO3 precipitation (MICP) is an innovative and rapidly developing technology for sand solidification The idea for this research project was built based on the concept of sustainable development and environmental protection The specific material used for solidification was soluble calcium ions generated by the reaction of limestone waste, a kind 2022年3月1日 The calcium carbonate in the limestone is known to react with tricalcium aluminate (C 3 A) to form carbonateAFm (Voglis et al, 2005) which forms denser a denser cement matrix, the reaction is limited by the C 3 A content of the Portland cement and calcium carbonate added in excess is inert (Matschei et al, 2007)The physicochemical properties of Portland cement blended with calcium 2024年11月12日 Uptodate report, based on Q2 2024 data, examining Calcium Carbonate production costs from Limestone, including Calcium Carbonate plant capital cost and operating costs See free preview plastics, paints, and rubber industries as a filler and coating agent, offering enhanced brightness and improved mechanical properties The resulting Calcium Carbonate Production from Limestone IntratecusReports about calciteforming proteins primarily focus on proteins involved in avian egg shell production In egg shells, hundreds of proteins are involved in nucleating calcite, increasing the concentration of calcium and carbonate near the nucleation site and assembling and orienting amorphous calcium carbonate to form calcite (77, 130 Microbially Induced Calcium Carbonate Precipitation by

Experimental Investigation on the Combination of EnzymeInduced Calcium

2024年1月31日 This paper proposes a technique for producing underground backfilling materials using enzymeinduced calcium carbonate precipitation (EICP) technology to address the growing ecological security concerns caused by coal mining To augment the mineralization impact of EICP, diverse levels of organic substances, including yeast extract, peptone, and skimmed 2023年2月14日 Product Name: Calcium Carbonate Lime stone Calcium carbonate is one of the most widely used minerals today It has many uses in a wide variety of industrial and commercial applications such as plastics, paints, adhesives, drilling fluids, glass manufacturing, soil and paper Calcium carbonate accounts for more than 4% of the earth's crustProduct Name: Calcium Carbonate Lime stone Saudi 2020年7月30日 The calcium carbonate was synthesized with the temperatures of 65, 100, 150, 200 and 234°C mechanical protection and a controlled gas impure minerals like limestone, chalk, marble,(PDF) Calcium Carbonate Synthesis, 2021年1月1日 Lime is a product derived from the thermal decomposition of limestone (mainly calcium carbonate, CaCO3) into quicklime (CaO) and carbon dioxide (CO2), also called calcination(PDF) Natural and enhanced carbonation of lime

.jpg)

Synthesis and characterization of precipitated calcium carbonate

2024年3月29日 CaCl2 solution and Ca(OH)2 slurry, both prepared from marble waste (MARWAS), were carbonated with CO2 gas in the presence of cetyltrimethylammonium bromide (CTAB), sodium dodecyl sulfate (SDS), Teepol610s, Triton X100, and Tween80 as the surface modifiers in a semibatch foambed reactor (FBR) to synthesize ultrafine or submicron 2021年12月20日 The Importance of Calcium Carbonate Calcium carbonate (CaCO3) comprises more than 4% of the earth’s crust and is found worldwide Its most common natural forms are chalk, limestone, and marble (produced by the sedimentation of small fossilized shellfish, snails, and coral over millions of years)Calcium Carbonate Manufacturing Process and Equipment2005年7月1日 A new type of process for producing highpurity calcium carbonate from waste cement powder was developed The process consists of two main reactions; extraction of calcium in the form of calcium Development of a process for producing high‐purity calcium carbonate Calcium Carbonate Formula It is a chemical compound with the chemical formula CaCO 3; It is a white insoluble powderlike substance which occurs naturally in minerals, chalk, marble, limestone, calcite, shells, pearl, etc; Medicinally, it is used as an antacid or as a Limestone: Calcium Carbonate (CaCO3) Uses, Preparation,

Structure and Properties of PortlandLimestone Cements

2023年6月14日 Portland cement is one of the most used materials on earth Its annual production is responsible for approximately 7% of global carbon dioxide (CO 2) emissionsThese emissions are primarily associated with (1) the burning of fossil fuels to heat cement kilns and (2) the release of CO 2 during limestone calcination One proposed strategy for CO 2 reduction 2022年4月12日 Limestone is a sedimentary rock comprised chiefly of calcium carbonate (CaCO3) Deposits are extensive around the world Therefore, there is a high variability of limestone deposits Typically, they are formed in two main environmentsCalcium Carbonate (Calcite) SpringerLink2024年10月30日 Sedimentary rock Limestone Formation, Calcium Carbonate, Fossils: Limestones originate mainly through the lithification of loose carbonate sediments Modern carbonate sediments are generated in a variety of environments: continental, marine, and transitional, but most are marine The presentday Bahama banks is the best known modern Sedimentary rock Limestone Formation, Calcium CarbonateOn the other hand, Chaurasia et al (2019) studied the metabolism of ureolytic Bacillus megaterium, B pasteurii, and a nonureolytic Bacillus cohnii in the absence of a substrate, nutrients and their effect on mechanical properties of concrete They observed that in the absence of nutrient sources, bacteria used an alternate pathway and further, bacteria served as a Microbially Induced Calcium Carbonate Precipitation (MICP)

.jpg)

Formations of calcium carbonate minerals by bacteria and its

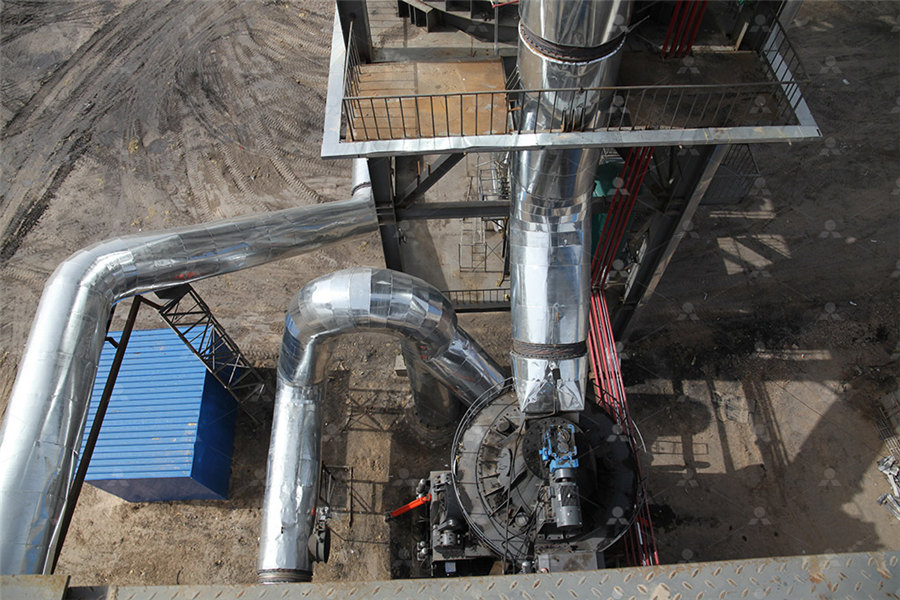

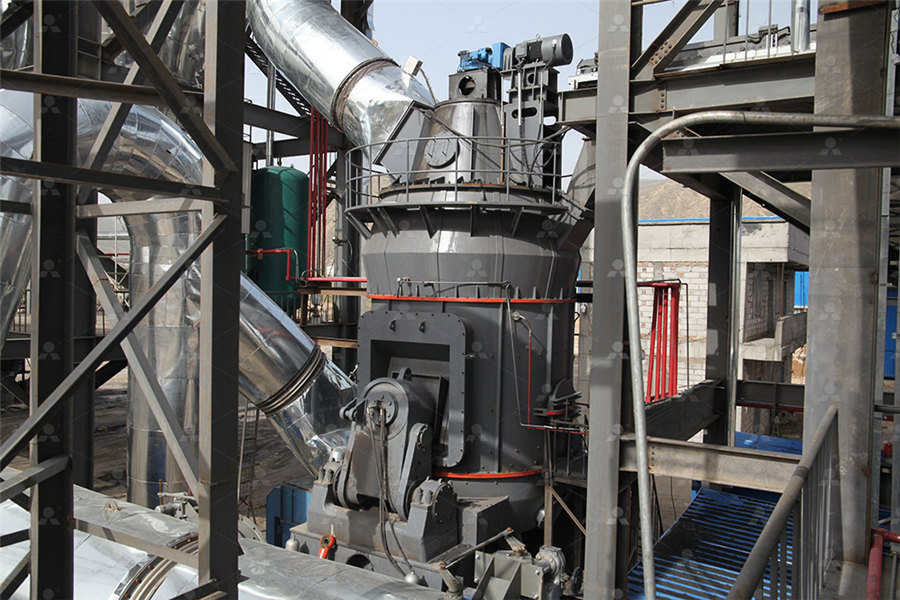

2016年3月1日 The calcium carbonate (CaCO 3) precipitation process is a straightforward and easily controllable mechanism of MICP that can produce high concentrations of CaCO 3 in short period of time (Dhami et al 2013a)Urease influences the chemical process associated with the formation of biominerals through four different parameters (Hammes and Verstraete 2002) 2022年8月1日 With the presence of calcium ion, calcium carbonate (CaCO 3) is deposited in the form of calcite within sand particles and binds them together One of the most important factors affecting MICPbased soil improvement is the capability of bacteria to induce CaCO 3 precipitation within sand particles and pores ( Rahman et al, 2020 )A sustainable production of biocement via microbially induced calcium 2023年10月28日 Ammonium acetate's significance underscores its dual role in both the leaching and carbonation processes This process yielded calcium carbonate with particle sizes smaller than 100 nm, with a purity of 98% and a single vaterite phase The calcium carbide residue demonstrated an impressive CO 2 uptake rate of 235% Ammonium acetate exhibited Optimization of calcium carbide residue utilization for producing 2024年8月21日 We are manufacturer of Calcium Carbonate, Limestone Feed Grade, Plaster of Pairs Silica Sand products Calcium Carbonate is added to plastics to improve their mechanical properties and reduce Understanding the role of limestone in the manufacturing process is crucial for producing highquality calcium carbonate products efficiently and The Ultimate Guide Calcium Carbonate Manufacturing Process

Development of a process for producing high‐purity calcium carbonate

2005年7月1日 A new type of process for producing highpurity calcium carbonate from waste cement powder was developed The process consists of two main reactions; extraction of calcium in the form of calcium ions from waste cement powder in a water slurry by pressurized CO2 (typically at several MPa), and precipitation of calcium carbonate (CaCO3) from the extracted 2020年12月22日 Chemically, limestone is calcium carbonate It is a sedimentary rock formed from the shells and skeletons of marine creatures which fell to the bottom of ancient seas These were turned into rock by the pressure of more sediments forming on top of them The next video shows a modern industrial plant for producing quicklime, calcium oxidelimestone, quicklime and slaked lime chemguide2022年11月16日 1 Research Centre for Biocomposite Materials for Medical, Agricultural and Food Industry, Suranaree University of Technology, Nakhon Ratchasima, Thailand; 2 School of Polymer Engineering, Suranaree University of Technology, Nakhon Ratchasima, Thailand; Biogenic calcium carbonate derived from waste shells has received significant attention in the Frontiers Biogenic calcium carbonate derived from waste 2020年6月15日 Microbially induced calcium carbonate precipitation (MICP) is a process that has emerged as an alternative and sustainable ground improvement approach in geotechnical and civil engineering for improving the mechanical properties of soil Ureaseproducing bacteria accelerate the process of MICP by converting urea into ammonium and carbonates Application of microbially induced calcium carbonate precipitation

Calcium Carbonate(CaCO3) Limestone Formula, Structure,

2023年12月26日 When heated, calcium carbonate undergoes a chemical reaction called thermal decomposition, producing calcium oxide (quicklime) and carbon dioxide gas 15 Calcium carbonate also known as? Calcium carbonate is also known as limestone when occurring naturally in rocks, and it is a major component of chalk and marble2024年10月1日 Synergizing Portland Cement, highvolume fly ash and calcined calcium carbonate in producing selfcompacting concrete: A comprehensive investigation of rheological, mechanical, and microstructural Synergizing Portland Cement, highvolume fly ash and calcined calcium