Large powder mill Calcite ore ore properties Formulate powder processing test plan

Raymond mill in the processing of calcite class ore CSDN博客

2014年4月29日 Over the years, the master of ultrafine powder processing equipment technology , the traditional raymond mill application process in the various issues thorough technological innovation2020年5月1日 The problem of lowgrade ore cost and a low utilization rate can be effectively solved by employing a largescale ball mill Therefore, effectively improving the grinding Enhancing the capacity of largescale ball mill through process 2023年6月1日 Various powder shear testers and methods that permit a more thorough and precisely defined assessment of powder flow properties have been developed to correlate the A concise summary of powder processing methodologies for Mineral calcite was ground by dry milling using two Fritsch mills: planetary P4 (milling at 20°C) and vibrating cup P9 (milling at 20°C) Steel equipment was used for the milling In particular, XRD line profile analysis of calcite powders produced by

Powder Characterization and Testing Elsevier

2013年12月20日 cal parameters coupled with the physical properties enables evaluation of the behavior of powder during processing that is accomplished by their consolidation The 2020年5月1日 The production capacity of the largescale ball mill in the concentrator is a crucial factor affecting the subsequent separation and the economic benefits of the operation The Enhancing the capacity of largescale ball mill through process 2013年8月7日 In this work, a planetary ball milling was used to modify the surface properties of calcitebased material from waste oyster shell under the rotational speed of 200–600 rpm, grinding time of 5–180 min and sample Microstructural Characterization of CalciteBased 2018年1月18日 The goal of this paper is to outline the approach and the development, results and initial implementation of the predictive spatial modelling of key parameters related to Predicting Mill Ore Feed Variability Using Integrated

Dry Fine Grinding of Calcite Powder by Stirred Mill

2013年4月11日 In this study, the effects of various operating parameters, such as grinding time (min), stirrer speed (rpm), feed quantity (% of ball weight), and ball filling ratio (%) on fine fundamental to understand how ore textures influence the generation of ore particles and their properties This contribution outlines the processes used to generate and concentrate ore All About Particles: Modelling Ore Behaviour in Mineral 2024年10月13日 The initial step in ore powder production is the reduction of ore size, which is accomplished by crushers Jaw crushers, cone crushers, and impact crushers are commonly used to break down the ore into manageable pieces 2 Grinding Mills Grinding mills are central to the powder production process The following types of mills are widely Advancements in ore powder production process 2019年8月28日 The object of the study was apatitenepheline ore of the Khibiny deposits group (Russia) and phosphate ore of the AbuTartur deposit (Egypt) For the development of beneficiation schemes and modes, complex studies were Mineralogical and Technological Aspects of

Enhancing the capacity of largescale ball mill through process

2020年5月1日 The main aim of this study is to improve the processing capacity of the largescale ball mill Taking a Φ549 × 883 m ball mill as the research object, the reason for the low processing capacity of the ball mill was explored via process mineralogy, physicochemical analysis, workshop process investigation, and the power consumption method2022年10月20日 Iron ore handling, which may account for 20–50% of the total delivered cost of raw materials, covers the processes of transportation, storage, feeding, and washing of the ore en route to or during its various stages of treatment in the mill Since the physical state of iron ores in situ may range from friable, or even sandy materials, to monolithic deposits with hardness of Iron Ore Processing, General SpringerLinkMedia Attributions; Metal deposits are mined in a variety of different ways depending on their depth, shape, size and grade Relatively large deposits that are quite close to surface and somewhat regular in shape are mined using openpit mine methods (Figure 815 in Section 81)Creating a giant hole in the ground is generally cheaper than making an underground 82: Mining and Ore Processing Geosciences LibreTexts2018年1月18日 The process plant consists of a 26 ft 65 MW SAGBall mill circuit feeding a conventional carbon in leach (CIL) circuit Three ore types have been defined at Ban Houayxai based on the weathering profile—oxide, transitional and primary Average throughputs were assigned to these ore types, based on test work within the feasibility study and Predicting Mill Ore Feed Variability Using Integrated

Simulating the Impact of Ore Competence Variability on Process

2019年9月24日 The Extended Drop Weight Test (ExDWT) improves understanding concerning sources of variation in ore competence through the value chain This technique measures and describes the variability in ore 2021年8月5日 Recommendations for calcite industrial ultrafine powder grinder: Calcite can be ground into powder by industrial milling equipment, and calcite powder has a wide range of uses Common calcite powder has 3000 mesh, 2500 mesh, 2000 mesh, 1000 mesh, 1500 mesh, 1250 mesh, 800 mesh, and so on They are applicable to different fieldsCalcite Industrial Ultrafine Powder Grinder SBM Mill2023年6月1日 The Powder Flow Tester evaluates powder flow properties in industrial processing equipment rapidly and efficiently [40, 41] Flow Function, Wall Friction, Bulk Density and Time Consolidation Test with Flow Function, Arching diameter, Rathole Dimension, Hopper Half Angle, etc be determined and calculated with the help of simple function in A concise summary of powder processing methodologies for PDF On Jul 11, 2018, Sandra Lúcia de Moraes and others published Iron Ore Pelletizing Process: An Overview Find, read and cite all the research you need on ResearchGate(PDF) Iron Ore Pelletizing Process: An Overview ResearchGate

Copper Ore Processing Plants, Flow And

6 天之前 Copper industrial minerals include: natural copper, chalcopyrite, chalcocite, tetrahedrite, azurite, malachite, etc Chalcopyrite (a compound of copper, sulfur, and iron) is mined mainly, followed by chalcocite and bornite If 2023年4月21日 Calcite ball mills have several uses in the building materials, chemicals, and mineral processing industries, as well as for grinding a wide range of ores and other materials Improve the physical properties of minerals Calcite Processing SBM Mill CrusherComminution is the process of reducing the particle size of an ore to liberate the ore minerals from the gangue minerals Thus, comminution strongly controls the overall efficiency of a mineral processing operation Even though blasting as the first step of extracting an ore from the ground is also a form of comminution, the focus hereAll About Particles: Modelling Ore Behaviour in Mineral 2023年2月15日 It is commonly crushed by a jaw crusher and hammer crusher, then ground by a Raymond mill and superfine mill Talc powder processing: 1 Coarse crushing: First, the talc ore is evenly sent to a jaw crusher through a vibrating feeder for coarse crushing; 2 Drying: Then the crushed ore is sent to a dryer through a bucket elevator for dying;How to Process Talc (the Softest Mineral)? Fote Machinery

Powder Characterization and Testing Elsevier

2013年12月20日 cal parameters coupled with the physical properties enables evaluation of the behavior of powder during processing that is accomplished by their consolidation The procedures described in standards are used to determine the technological properties of powders in delivery condition To evaluate powder properties the standard moni2023年9月6日 Different types of grinding mills, such as ball mills, Raymond mills, or ultrafine vertical mills, can be used for this purpose 5 Classification: The milled talc powder is classified or separated into different particle sizes using air classifiers or sieving techniques This step ensures that the final product has a consistent particle size Talcum Powder Production Process mzenithmillsThe Powder Flow Tester evaluates powder flow properties in industrial processing equipment rapidly and efficiently [40,41] Flow Function, Wall Friction, Bulk Density and Time Consolidation Test with Flow Function, Arching diameter, Rathole Dimension, Hopper Half Angle, etc be determined and calculated with the help of simple function in A concise summary of powder processing methodologies for 2022年10月19日 The iron ore processing industry produces usable concentrations of ironbearing material by removing nonferrous rock (gangue) from lowgrade ore In the United States, predominant iron ore is taconite which is a hard, banded, lowgrade ore Ninetynine percent of the crude iron ore produced in the United States is taconiteIron Ore Processing, General Springer

.jpg)

(PDF) Overview of Mineral Processing Methods ResearchGate

2015年8月3日 The first process that most of the ores or minerals undergo after they leave any mine, is mineral processing or mineral/ ore dressing It is a process of ore preparation, milling, and ore dressing 2012年1月1日 In this study, considering different operational parameters for stirred media mill, change in specific energy was compared to the change in Rx values, ie the cumulative weight of the material Dry Fine Grinding of Calcite Powder by Stirred Mill2017年8月24日 The end product of mineral processing is an ore concentrate ( Fig 62) that is then put through a metallurgical process Pyrometallurgy, hydrometallurgy, or other chemical methods are used to refine the concentrate for extraction of metals in the purest form In a size reduction circuit that uses pebble mills, large rocks (80–120 mm) are Mineral Processing SpringerLinkPhase one: raw material crushing Calcite blocks will be crushed to 15mm50mm by crusher Phase two: grinding Crushed calcite material will be sent to the storage hopper by the elevator, and then the feeder will send the material to the main mill for grinding Phase three: classifying Ground material will be classified, coarse powder will fall back to the main mill to be ground Calcite Grinding Mill Calcite Powder Processing Solution

Metallurgical Test Work: Gold Processing Options, Physical Ore

2016年1月1日 For the past 100 years, the key element in the processing of gold ore has been the cyanidation processOver the years, steady improvements have occurred in equipment design; milling has evolved from stamp mills, through tube mills and ball mills to the large semiautogenous grinding (SAG) and fully autogenous grinding (FAG) circuits in modern gold 2018年1月19日 The Ban Houayxai is a structurally controlled epithermal goldsilver deposit hosted within an early Permian volcanosedimentary sequence of the Trong Son Fold belt in the south western extremity of the Phu Bia Contract Area (Manaka et al 2014)The deposit is located on a steep narrow northsouth oriented ridge that protrudes into the Nam Ngum 2 Reservoir, a Predicting Mill Ore Feed Variability Using Integrated2024年7月10日 l Ball Mill/Vertical Roller Mill: The crushed calcite is then ground into fine powder using grinding mills Ball mills or vertical roller mills are typically used in this process l Grading and Screening: The ground material is passed through sieves and classifiers to obtain uniform particle size This step ensures the powder is of the desired Calcite Powder Manufacturing Process Vertical Roller Grinding Mill 2020年4月6日 In combination, dynamic, shear and bulk powder properties deliver a comprehensive, multifaceted profile that can help processors understand and address issues relating to process and product performance Instrumentation that delivers these capabilities therefore has much to offer powder processing industries References:Powder characterization for effective powder processing

3 Incredible Flows to Win Calcite Processing (Without Failing)

2023年4月26日 Calcite grinding process Calcite belongs to the type of ore that is easy to grind Calcite grinding powder generally requires the fineness of the finished product to be small 1 Process flow of calcite grinding Grinding: The crushed calcite (≤30mm) is lifted to the silo by the elevator and sent to the grinding chamber of the mill for 2019年8月29日 Sensor‐based ore sorting can be used as a separation process for coarser grain sizes before the application of fine comminution and separation technologies and is applicable for a large variety (PDF) Sensor‐Based Ore Sorting Technology in Mining2023年10月27日 An efficient titanium ore processing plant An effective titanium ore processing plant mainly includes a comminuting unit (crushing and grinding), a beneficiation unit, and auxiliary equipment The most commonly used production equipment is crushers (jaw crushers, cone crushers), ball mills, spiral chutes, magnetic separators, flotation cells How to Process Titanium Ore (A Stepbystep Guide)2019年8月16日 Mining, mineral processing and metal extraction are undergoing a profound transformation as a result of two revolutions in the making—one, advances in digital technologies and the other, availability of electricity from renewable energy sources at affordable prices The demand for new metals and materials has also arisen concurrently This necessitates Future of Mining, Mineral Processing and Metal Extraction

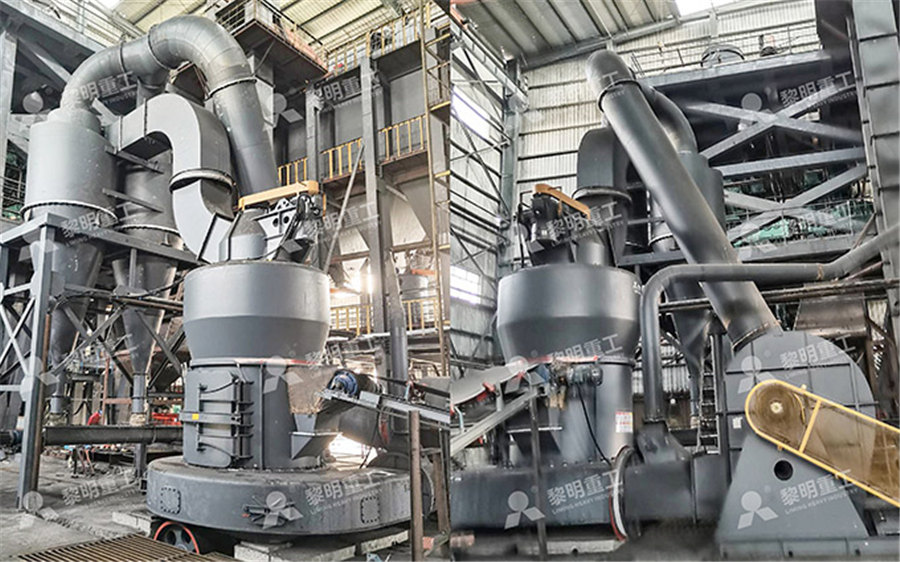

Advancements in ore powder production process

2024年10月13日 The initial step in ore powder production is the reduction of ore size, which is accomplished by crushers Jaw crushers, cone crushers, and impact crushers are commonly used to break down the ore into manageable pieces 2 Grinding Mills Grinding mills are central to the powder production process The following types of mills are widely 2019年8月28日 The object of the study was apatitenepheline ore of the Khibiny deposits group (Russia) and phosphate ore of the AbuTartur deposit (Egypt) For the development of beneficiation schemes and modes, complex studies were Mineralogical and Technological Aspects of 2020年5月1日 The main aim of this study is to improve the processing capacity of the largescale ball mill Taking a Φ549 × 883 m ball mill as the research object, the reason for the low processing capacity of the ball mill was explored via process mineralogy, physicochemical analysis, workshop process investigation, and the power consumption methodEnhancing the capacity of largescale ball mill through process 2022年10月20日 Iron ore handling, which may account for 20–50% of the total delivered cost of raw materials, covers the processes of transportation, storage, feeding, and washing of the ore en route to or during its various stages of treatment in the mill Since the physical state of iron ores in situ may range from friable, or even sandy materials, to monolithic deposits with hardness of Iron Ore Processing, General SpringerLink

82: Mining and Ore Processing Geosciences LibreTexts

Media Attributions; Metal deposits are mined in a variety of different ways depending on their depth, shape, size and grade Relatively large deposits that are quite close to surface and somewhat regular in shape are mined using openpit mine methods (Figure 815 in Section 81)Creating a giant hole in the ground is generally cheaper than making an underground 2018年1月18日 The process plant consists of a 26 ft 65 MW SAGBall mill circuit feeding a conventional carbon in leach (CIL) circuit Three ore types have been defined at Ban Houayxai based on the weathering profile—oxide, transitional and primary Average throughputs were assigned to these ore types, based on test work within the feasibility study and Predicting Mill Ore Feed Variability Using Integrated2019年9月24日 The Extended Drop Weight Test (ExDWT) improves understanding concerning sources of variation in ore competence through the value chain This technique measures and describes the variability in ore Simulating the Impact of Ore Competence Variability on Process 2021年8月5日 Recommendations for calcite industrial ultrafine powder grinder: Calcite can be ground into powder by industrial milling equipment, and calcite powder has a wide range of uses Common calcite powder has 3000 mesh, 2500 mesh, 2000 mesh, 1000 mesh, 1500 mesh, 1250 mesh, 800 mesh, and so on They are applicable to different fieldsCalcite Industrial Ultrafine Powder Grinder SBM Mill

A concise summary of powder processing methodologies for

2023年6月1日 The Powder Flow Tester evaluates powder flow properties in industrial processing equipment rapidly and efficiently [40, 41] Flow Function, Wall Friction, Bulk Density and Time Consolidation Test with Flow Function, Arching diameter, Rathole Dimension, Hopper Half Angle, etc be determined and calculated with the help of simple function in PDF On Jul 11, 2018, Sandra Lúcia de Moraes and others published Iron Ore Pelletizing Process: An Overview Find, read and cite all the research you need on ResearchGate(PDF) Iron Ore Pelletizing Process: An Overview ResearchGate