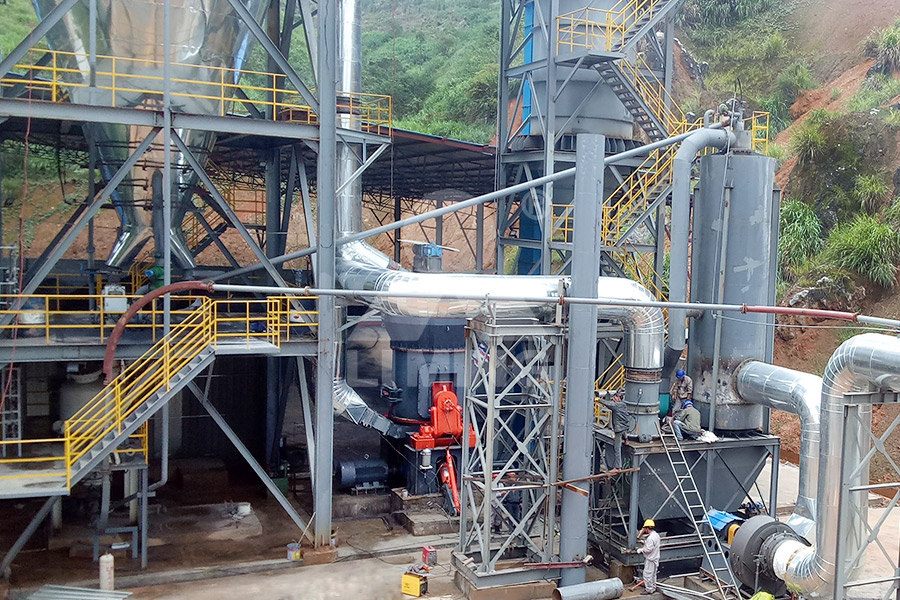

Large Egyptian carbonate calcium carbonate mill Raymond mill

GCC VS PCC and Calcium Carbonate Grinding Mills

2024年11月25日 PCC is synthetically made, pure, and ideal for highperformance applications in industries like pharmaceuticals, cosmetics, and premium paper 1 Ground Calcium Carbonate At the meeting, CLIRIK highlighted two ultrafine Raymond mills that are widely acclaimed in the field of calcium carbonate powder processing: HGM ring roller micro powder grinding Ultra Fine Raymond Mill Is The Future Of Calcium Carbonate 2024年7月10日 At present, heavy calcium carbonate with d97≥5μm is mainly produced by dry method, and the equipment includes improved Raymond mill (suspension roller mill or Heavy calcium carbonate grinding, surface modification Abstract: The investigation of surface modification of Egyptian calcium carbonate via polymers was achieved with simultaneous ultrafine grinding Attrition mill and planetary mill were used Influence of polymers on the grinding and rheology of

.jpg)

Typical processes and equipment for ultrafine

2023年10月10日 Calcium carbonate dry ultrafine grinding equipment mainly includes Raymond mill, vertical mill, ball mill, jet mill, stirring mill, vibration mill and various mechanical impact mills Raymond mill: used in large quantities to 2024年11月21日 The Raymond mill, also called Raymond roller mill, combines grinding, classifying, and if necessary, drying, in one machine to produce precisely sized powders to meet exact production specifications It is an Raymond Mill epicpowder2024年10月31日 Calcium carbonate is a kind of inorganic compound optimization (CaCO ₃) In this field, we can provide a detailed scheme for Calcium carbonate processing with years’ of Calcium carbonate mzenithmillsCalcium carbonate powder is limestone and calcite powder after grinding with grinding mills According to the different production methods of calcium carbonate, calcium carbonate powder can be divided into heavy calcium Calcium Carbonate Grinding Powder Production

.jpg)

How to choose a suitable calcium carbonate

2024年9月14日 Before choosing a grinding mill, you must know how to produce calcium carbonate There are currently two main methods: dry grinding and wet grinding Dry grinding is mainly for primary grinding It is for making powders 2022年7月26日 The processing capacity of the 600mesh calcium carbonate grinding mill is generally between 150t/h, which is very suitable for largescale and largecapacity manufacturers to produce highend calcium carbonate What is a 600 mesh calcium carbonate grinding 2024年11月6日 The bulk material of calcium carbonate is crushed by the crusher to the feed fineness (15mm50mm) that can enter the mill The crushed calcium carbonate small pieces of material are sent to the silo through the elevator, and then sent to the grinding chamber of the mill by the vibrating feeder for quantitative grindingCalcium carbonate millGrinding mill machine, mineral mill, raymond Calcium Carbonate powder can be generally divided into coarse powder processing (03MM), fine powder processing (20 mesh400 mesh), and ultrafine powder deep processing (400 mesh1250 mesh) and micro powder Calcium Carbonate grinding processing,

How to Choose a Calcium Carbonate Grinding Mill DASWELL

2022年8月13日 The selection of calcium carbonate grinding mill will affect the quality of the final ground calcium carbonate powder Choose a suitable one! For common grinding equipment, the energy consumption of ball mill and wet grinding mill is relatively large; the energy consumption of Raymond mill, micro powder roller mill and vertical mill is Calcium carbonate ultrafine grinding mill is a kind of high efficiency milling equipment, mainly used to process nonmetallic ores The equipment is independently developed and produced by SBM, sold directly by the factory, without middlemen, and is extremely costeffective It is a piece of ideal grinding equipment for processing 1503000 mesh Calcium Carbonate Ultrafine Grinding Mill2023年6月15日 Calcium carbonate in other industries before the application, generally need to be made into powder, the production process is large lump raw materials after crushing jaw crusher, under the action of vibrating screen machine on the finished product classification, after the belt conveyor will be sifted after the material uniform and continuous Calcium Carbonate Raymond Mill Production LineCalcium carbonate ultrafine vertical mill, integrating powder grinding, grading, conveying, secondary powder selection, and finished product packaging +17 [ protected] It can be used for largescale ultrafine dry powder processing of nonmetallic minerals such as calcite, marble, limestone, dolomite, barite, talc, kaolin, Calcium Carbonate Ultrafine Vertical Mill SBM Ultrafine

Calcium Carbonate Mill Powder Making Machine Sunco

2022年9月11日 The powder output size of Calcium Carbonate Mill (Raymond Mill)can be adjusted continuously according to the customers' demand Calcium Carbonate Mill Features: 01 Vertical structure of strong systematic characteristic, occupies small area From crushing of calcium carbonate to grinding and packing is an independent production systemProduct Calcium Carbonate Powder Processing Machine Raymond Mill Capacity:0545 t/h Feeding size:020 mm Output Size:2002500 mesh Clirikcalcium carbonate powder processing machine Raymond mill,Raymond roller mill is suitable for processing various nonflammable and nonexplosive mineral materials with Moh’s hardness less than 93 and humidity less than 6%, Calcium Carbonate Powder Processing Machine Raymond MillWhen the water contained in the material of the heavy calcium carbonate Raymond mill is relatively large, the material is easy to adhere in the equipment, and it is easy to block during the conveying process of the material, causing the capacity of the Raymond machine to decrease Relative to the milled material moisture is small, then the heavy calcium carbonate Raymond What is the output of Raymond Mill?2024年7月11日 Heavy calcium carbonate (heavy calcium) is obtained by directly pulverizing natural limestone, calcite, etc by a mechanical method (Raymond mill or the like) Light calcium carbonate (light calcium) is obtained by calcining calcium carbonate grinding mill, calcium

Calcium carbonate waste from an integrated pulp and paper mill

2008年2月1日 Calcium carbonate is used in large amounts in the pulp and paper industry as a paper filler When it is manufactured, the calcium carbonate waste is purged from the processGrinding Ring: The grinding ring is the main component that provides the necessary compression and shearing force for grindingIt rotates and provides the surface against which the rollers press the material Grinding Rollers: These are cylindrical rollers that apply the grinding pressure to the material against the grinding ringThey roll on the ring and crush the material into fine particlesRing Mill For Ultrafine Grinding Calcium Carbonate2024年10月31日 Calcium carbonate is a kind of inorganic compound optimization (CaCO ₃) CaCO ₃) In this field, we can provide a detailed scheme for Calcium carbonate processing with years’ of experience Raymond Mill Output Size: 80400mesh Capacity: 350TPH but attract a large number of customers from India, Bangladesh, South Korea, Japan Calcium carbonate mzenithmills2022年12月20日 Calcium carbonate ball mill Calcium carbonate ball mill Ball mill is mainly used for grinding materials in such production industries as cement, silicate product, new building materials, chemical engineering, nonferrous and black metal, mineral processing, glass and ceramic, etc When the large calcium carbonate is fed into ball mill, it will Calcium carbonate ball mill CM Mining Machinery

How Much Is The Calcium Carbonate Raymond Mill 1520

Calcium carbonate is prepared from calcite, marble, limestone, chalk, shells, etc through crushing, grinding and other processes It has the advantages of stable chemical properties, impact resistance, easy processing, nontoxic and harmless, and low cost It can be widely used in PE, ceramics, coatings, papermaking, medicine, microfiber leather, PVC, highend fillers, It solves the leakage phenomenon when grinding the calcium carbonate, improves the grinding efficiency, eliminates the impact on the main shaft, prolonging the service life of the roller shaft, greatly improves the precision and efficiency of selecting powder, reduces the transmission between the mill and classifier and eliminates the resonance phenomenonCalcium Carbonate Grinding Mill zenithmills2023年12月30日 A new approach of Egyptian calcium carbonate utilization as ingredients of toothpaste manufacture prevent decay by strengthening enamel, found naturally in many everyday things including foodA NEW APPROACH OF EGYPTIAN CALCIUM CARBONATE 2021年7月20日 CLIRIK YGM series Raymond mill for calcium carbonate powder making CLIRIK YGM series Raymond mill: The fineness of the product is generally between 325600 mesh If finer powder is produced, neither the equipment's bearing capacity nor the economy is allowed CLIRIK HGM series ring roller mill (characterized by large pulverization ratio and Calcium carbonate grinding millCLIRIK Machinery

.jpg)

The Egyptian Carbonate Company for Mining

2017年2月22日 Established in 1986, The Egyptian Carbonate Company for mining is one of the most reliable and trusted names in producing high quality calcium carbonate in Egypt We are using the latest Grinding and packaging technology 2020年12月24日 The common processing equipment of ground calcium carbonate produced by largescale dry process includes Raymond mill, Vertical mill, Ring roller mill and Ball mill Due to the different crushing Calcium Carbonate Ultrafine Powder Grinding2024年11月7日 Calcium carbonate is an inorganic compound, the main component of limestone and calcite It is divided into two categories: heavy calcium carbonate and precipitated calcium carbonate It is the upgraded mill of Raymond mill This mill has similar working principle outside surface with Raymond mill, but it has many more advantages, such as Grinding mill for Calcium carbonate2024年4月3日 Calcium Carbonate Middle East for mining industries applications Our Plant Our milling line is now in full production 3000 tons per month, was installed at May 2011, The mill utilizes Alpine Hosakawa milling Calcium Carbonate Misr Elhegaz

Calcium Carbonate Ball Mill Plant DASWELL

2024年9月14日 The calcium carbonate ball mill plant has the lowest energy consumption and the best particle size distribution, which is most suitable for market demand The scale of the heavy calcium ball mill production line we can design can be as small as 10,000 tons/year and as large as 500,000 tons/year Multiple product particle sizes can also be 2023年8月28日 Shanghai Clirik Machinery Co,Ltd is the professional Calcium Carbonate Grinding Mill,Calcium Carbonate Grinding Machine,Calcium Carbonate Processing Plant manufacturer, devoted to the calcium carbonate powder grinding more than 10 years,If you are interested in calcium carbonate grinder machine, we are welcoming to your visitingCalcium Carbonate Grinding Mill,Calcium Carbonate 2024年7月10日 At present, heavy calcium carbonate with d97≥5μm is mainly produced by dry method, and the equipment includes improved Raymond mill (suspension roller mill or pendulum mill), roller mill (including pressure roller mill/vertical mill, ring roller mill, etc) and ball mill, etcHeavy calcium carbonate grinding, surface modification 2023年6月20日 Uganda Calcium Carbonate HGM Series Ultrafine Grinding Mill Mill Model:HGM 125L Materiel:Calcium Carbonate This project intends to use mine waste materials to produce 325 tons of calcium carbonate powder for the production of putty powder and 3251250 tons of ultrafine powder to open up new business in AfricaUganda Calcium Carbonate Grinding Production Line Raymond mill

.jpg)

Limestone Dolomite Milling Machine Calcium Carbonate

3 天之前 YGM high pressure Raymond grinding mill is improved on the basis of R series Raymond mill Through high pressure spring pressure, increasing the grinding roller centrifugal force on the material grinding pressure , YGM raymond mill is especially suitable for processing Mohs hardness level 7, humidity below 6% of all kinds of nonflammable and explosive The calcium carbonate grinding system usually contains one of the Ball Mill, LM series Vertical Shaft Mill, Raymond Mill, Trapezium Mill, Coarse Powder Mill, Ultrafine Mill, etc for different usage, When the large calcium carbonate is fed into ball mill, it will be ground and the grain size can is between 0074mm and 04mm, in normal, this wet grinding mill for calcium carbonate plant2024年6月7日 Raymond Mill; Roller Mill; Table Roller Mill; Ultrafine Air Classifier Menu Toggle There is a large movable gap between the grinding roller installed on the grinding roller bracket and the pin shaft the tire’s airtight rubber mainly uses light calcium carbonate Read More » Differences in uses and properties between heavy calcium Ring Roller Mill Ultrafine calcium carbonate production 2022年7月26日 The processing capacity of the 600mesh calcium carbonate grinding mill is generally between 150t/h, which is very suitable for largescale and largecapacity manufacturers to produce highend calcium carbonate What is a 600 mesh calcium carbonate grinding

Calcium carbonate millGrinding mill machine, mineral mill, raymond

2024年11月6日 The bulk material of calcium carbonate is crushed by the crusher to the feed fineness (15mm50mm) that can enter the mill The crushed calcium carbonate small pieces of material are sent to the silo through the elevator, and then sent to the grinding chamber of the mill by the vibrating feeder for quantitative grindingCalcium Carbonate powder can be generally divided into coarse powder processing (03MM), fine powder processing (20 mesh400 mesh), and ultrafine powder deep processing (400 mesh1250 mesh) and micro powder Calcium Carbonate grinding processing, 2022年8月13日 The selection of calcium carbonate grinding mill will affect the quality of the final ground calcium carbonate powder Choose a suitable one! For common grinding equipment, the energy consumption of ball mill and wet grinding mill is relatively large; the energy consumption of Raymond mill, micro powder roller mill and vertical mill is How to Choose a Calcium Carbonate Grinding Mill DASWELLCalcium carbonate ultrafine grinding mill is a kind of high efficiency milling equipment, mainly used to process nonmetallic ores The equipment is independently developed and produced by SBM, sold directly by the factory, without middlemen, and is extremely costeffective It is a piece of ideal grinding equipment for processing 1503000 mesh Calcium Carbonate Ultrafine Grinding Mill

.jpg)

Calcium Carbonate Raymond Mill Production Line

2023年6月15日 Calcium carbonate in other industries before the application, generally need to be made into powder, the production process is large lump raw materials after crushing jaw crusher, under the action of vibrating screen machine on the finished product classification, after the belt conveyor will be sifted after the material uniform and continuous Calcium carbonate ultrafine vertical mill, integrating powder grinding, grading, conveying, secondary powder selection, and finished product packaging +17 [ protected] It can be used for largescale ultrafine dry powder processing of nonmetallic minerals such as calcite, marble, limestone, dolomite, barite, talc, kaolin, Calcium Carbonate Ultrafine Vertical Mill SBM Ultrafine 2022年9月11日 The powder output size of Calcium Carbonate Mill (Raymond Mill)can be adjusted continuously according to the customers' demand Calcium Carbonate Mill Features: 01 Vertical structure of strong systematic characteristic, occupies small area From crushing of calcium carbonate to grinding and packing is an independent production systemCalcium Carbonate Mill Powder Making Machine Sunco Product Calcium Carbonate Powder Processing Machine Raymond Mill Capacity:0545 t/h Feeding size:020 mm Output Size:2002500 mesh Clirikcalcium carbonate powder processing machine Raymond mill,Raymond roller mill is suitable for processing various nonflammable and nonexplosive mineral materials with Moh’s hardness less than 93 and humidity less than 6%, Calcium Carbonate Powder Processing Machine Raymond Mill

What is the output of Raymond Mill?

When the water contained in the material of the heavy calcium carbonate Raymond mill is relatively large, the material is easy to adhere in the equipment, and it is easy to block during the conveying process of the material, causing the capacity of the Raymond machine to decrease Relative to the milled material moisture is small, then the heavy calcium carbonate Raymond