Ball mill grinding gypsum

.jpg)

An experimental study on the ultrafine grinding of gypsum

2015年12月1日 In response, in this study, we have systematically investigated how certain grinding parameters (ie, mill speed, ball filling ratio, ball size distribution, powder filling ratio,2020年5月1日 Nowadays, ball mills are used widely in cement plants to grind clinker and gypsum to produce cement In this work, the energy and exergy analyses of a cement ball mill Energy and exergy analyses for a cement ball mill of a new 2022年1月11日 In this study, PBG was ballmilled to obtain phosphorus building gypsum with good performance, which can meet the requirements of the Chinese standards for firstclass Effect of Ball Milling Time on the Performance of 2016年4月1日 The paper is aimed to investigate the influence of operating parameters on dry fine grinding of calcite in a laboratory scale conventional ball mill Within the context, the An experimental study on the ultrafine grinding of gypsum

Enhancing the recovery of gypsum in limestonebased wet

2017年7月1日 Furthermore, Wang et al (2005) highlighted the systems commonly adopted for the grinding of limestone such as long drum or tube mill and the Hardings ball mill Generally, The Emax is an entirely new ball mill designed for high energy grinding The maximum speed of 2000 rpm, so far unrivaled in a ball mill, and the innovative jar design produce highly effective THE REVOLUTION IN ULTRAFINE GRINDING RETSCH2022年1月11日 In this study, PBG was ballmilled to obtain phosphorus building gypsum with good performance, which can meet the requirements of the Chinese standards for firstclass building gypsum(PDF) Effect of Ball Milling Time on the 2016年12月19日 One option is direct calcining in a Pfeifer vertical roller mill of the type MPSGC (Fig 2) In this process, the gypsum is dried and ground to the required fineness of the plaster Grinding and calcining of gypsum with Pfeiffer grinding

Predictive Controller Design for a Cement Ball

The clinker, along with additives viz gypsum, slag, and/fly ash, called feed minerals, are introduced into the horizontally placed ball mill, which consists of steel balls of different sizes The impact of these balls with feed materials 2024年11月25日 Ball Mill machine changes the intrinsic grinding mill structureIts body and ground plank are an integral whole So when fixing, it can be lowered on a plane surface once only Use double tiered roller axletree with centripetal spherical surface as the support of the host axletree can reduce energy cost by 30%Ball Mill clirikchinaVertical roller mill grinding table Ball mill hood cover Vertical roller mill rocker arm Ball mill pinion Vertical roller mill grinding roller Ball mill Liner Vertical roller mill grinding roller shaft Ball mill grinding media Vertical roller mill grinding roller wheel hub Rotary kiln shell Vertical roller mill grinding roller tyre Ball Mill Rotary Kiln Vertical Roller Mill Manufacturer Tongli Working principle Fed into the mill through one or both bearing trunnions, the material is ground by impact and friction from the balls The ground product is discharged from the mill through discharge slots provided in the mill tube, Ball mills for various applications Gebr Pfeiffer

Highquality Ball Mill with Low price for Kinds of Materials

2024年11月23日 Ball mill: Uses cast grinding steel balls and forged grinding steel balls as the grinding media Rod mill: Uses grinding rods and grinding cylpebs as the grinding media Ceramic ball mill: Uses ceramic balls as the grinding media 4 By lengthtodiameter ratio of the drum Ball mill: A typical ball mill has a drum length that is equal to or 15 2022年4月24日 Mohamed Abd Ellatif owns a gypsum mine He hopes that we can provide him with a 35tph ball mill to grind the gypsum to 100 meshes After checking various project information, our engineers designed drawings and customized a ball mill for him He said: "I have never seen such a responsible manufacturerBall Mill/Grinding Mill/Factory PriceCoarse natural gypsum or mixtures of such gypsum with FGD gypsum are ground, dried, partially calcined, and classified in the Pfeiffer vertical roller mill To be noted that up to 20% of recycling material may be added if required Product fineness can be Gypsum mill for all requirements Gebr PfeifferSafe and reliable feeding and delivery of new grinding balls to the mill is a key concern for many mine sites Manual handling is a hazardous task and should be avoided where possible to reduce the risk of injury to personnel Bulk Handling Technologies can assist with the design and supply of a custom ball charging system, incorporating a ball Ball Mills and Ball Charging Bulk Handling Technologies

Gypsum dehydration potential and mean residence time of a

The gypsum dehydration that is important for the cement properties is ensured in ball mills because of their long residence times and high grinding chamber temperatures However, there is little knowledge available for SMMs about the extent of gypsum dehydration, which means that the dehydration potential must be investigated systematically The performance and the result of sample preparation are also determined by the choice of the grinding jar and its ball charge The EasyFit range of jars has been specially designed for extreme working conditions such as longterm trials, even at maximum speed of 800 rpm, wet grinding, high mechanical loads and maximum speeds as well as for mechanical alloyingPlanetary Ball Mill PM 100 RETSCH highest finenessTypically the Clirik gypsum powder ball mill will grind friable or crystalline materials down to the 0075 04/089 mm average particle size range Particles larger than 10 microns are generally hardtofracture polymers such as toner compounds or hard waxes, and some organic materials, but if a larger size is wanted, many products can be Gypsum Powder Ball Mill Gypsum Grinding Mill,Gypsum Grinding 2016年12月19日 in a Pfeiffer vertical roller mill of the type MPSGC (Fig 2) In this process, the gypsum is dried and ground to the required fineness of the plaster in the mill Thanks to the relatively high temperature level in the gypsum calcining mill, the gypsum is simultaneously calcined When gypsum is calcined in an atmosphere satGrinding and calcining of gypsum with Pfeiffer grinding

.jpg)

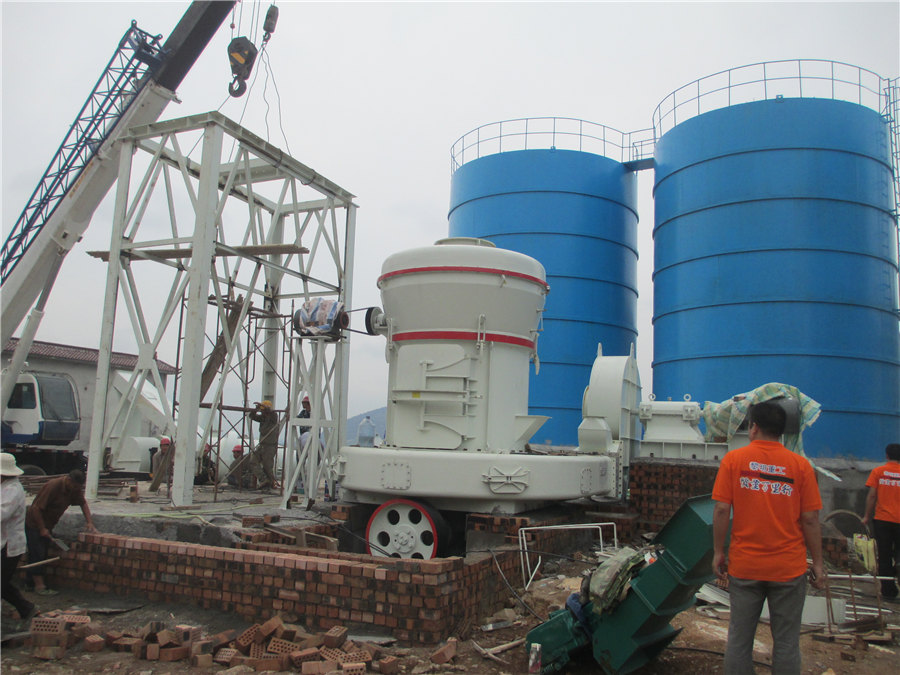

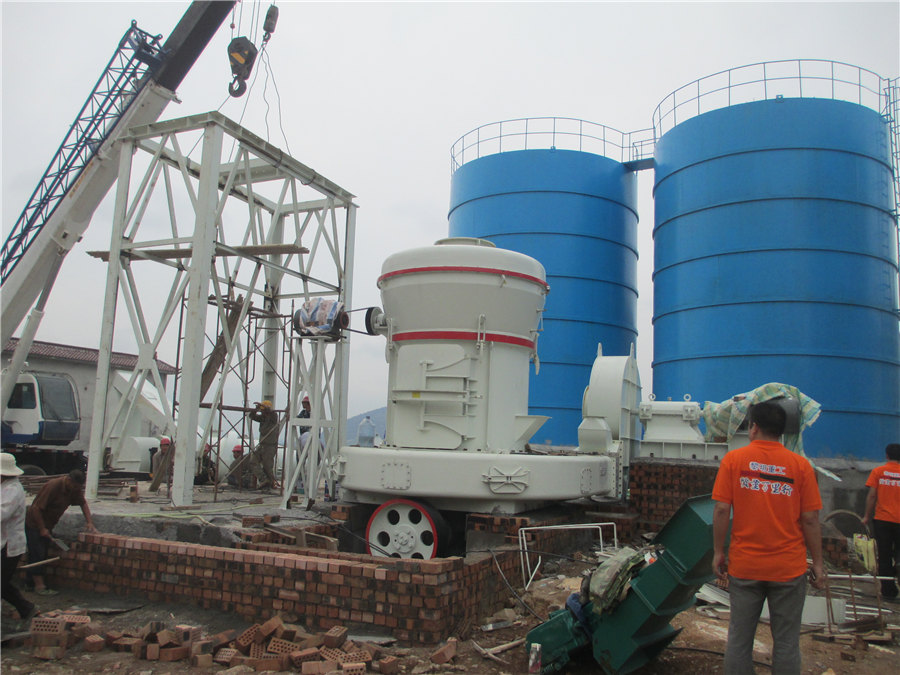

Single Cylinder Dryer Manufacturer, Three

AVP GROUP LIMITED (AVP for short) was founded in 2005, with its head office in Hongkong Shanghai VOSTOSUN Industrial Co, Ltd (VOSTOSUN for short) was established in 2006, as one of the subsidiary companies of AVP, 2024年7月31日 The production of cement, an essential material in civil engineering, requires a substantial energy input, with a significant portion of this energy consumed during the grinding stage This study addresses the gap in Effect of Grinding Conditions on Clinker 2011年7月1日 Furthermore, Tangsathitkulchai [7] investigated the effect of slurry concentration and powder filling on mill power for a small laboratory ball mill, with a constant ball load and rotational speed of the mill The outcome of tests was that grinding at about U = 1 gave the maximum in net mill power This paper will present some results on the Influence of interstitial filling on breakage kinetics of gypsum 2011年7月1日 Semantic Scholar extracted view of "Influence of interstitial filling on breakage kinetics of gypsum in ball mill" by Vedat Deniz An experimental study on the ultrafine grinding of gypsum ore in a dry ball mill Bilge Öksüzoğlu M Influence of interstitial filling on breakage kinetics of gypsum

Gypsum Powder Ultrafine Grinding Mill sbmmill

The gypsum powder ultrafine grinding mill can grind gypsum ore into gypsum powder, which is widely used in industry, construction, medicine, and other fields +17 [ protected] the output is twice that of ball mills, and the system energy consumption is 1 Ball Mill; 2 Product Parameter; 3 Product Overview; 4 Working Principle; 5 Ball Mill Advantage; 6 Other Products Offered 61 CLUM Series Ultrafine Vertical Powder Grinding Mill↗; 62 HGM Series Micro Powder Grinding Mill↗; 63Ball Mill Gypsum Grinding Mill,Gypsum Grinding Machine,Gypsum The Emax is an entirely new type of ball mill for high energy milling faster and finer grinding extremely fine particles in a short time Learn more ceramics, chemical products, clay minerals, coal, coke, concrete, fibres, glass, gypsum, iron ore, kaolin, limestone, metal oxides, minerals, ores, paper, pigments, plant materials, polymers Emax High Energy Ball Mill RETSCH2021年4月27日 Cement ball mills typically have two grinding chambers The first chamber is filled with larger diameter grinding media andlined with lifting liners The first chamber coarsegrinds the feed Clinker, Gypsum and other desired additives are fed to the ball mill in specific proportions based on the quality requirement Feed material is ground OPTIMIZATION OF CEMENT GRINDING OPERATION IN

.jpg)

Ball mill PPT Free Download SlideShare

2019年5月24日 The document summarizes the ball mill, which is a grinder used to grind and blend materials It discusses the basic parts of a ball mill including the hollow cylinder and balls abrasive andAll types of hard ,abrasive and brittle materials are grindedbrittle materials are grinded by itby it Gypsum grindingGypsum grinding • fig: BAll The grinding principle and the high efficiency classifier ensure the reduction of electric energy consumption by up to 40% as compared with conventional ball mills Optimum utilization of process heatCoal mill, gypsum mill, clay mill, etc Pfeiffer China Gypsum Grinder Mill wholesale Select 2024 high quality Gypsum Grinder Mill products in best price from certified Chinese Rice Mill manufacturers, Steel Mill suppliers, wholesalers and factory on MadeinChina Grinder Ball Mill Gypsum Powder Making Machine Marble Powder Production Line US$ 767726880 / Set 1 Set (MOQ) Henan Gypsum Grinder Mill MadeinChina2021年4月19日 Even though not practical mixtures such as C 100 G 0 were evaluated in this work, this was purely from a mathematical point of view in order to obtain a better sampling of the independent variables (ie the mixture composition) using a simplexcentroid design Resistance to Grinding A total of 700 ml of each blend were introduced in a 030 m cast iron drum (BICO Resistance to Grinding and Cement Paste Performance of

a) Cement ball mill view, b) Cement mill sketch

Nowadays, ball mills are widely used in cement plants to grind clinker and gypsum to produce cement The research focuses on the mill speed as well as air classifier speed effect on the two 2024年2月27日 High chromium casting ball has good hardness and is a highquality wearresistant material, which has been widely used in cement dry ball mills, but the toughness of high chromium casting ball is poor, and it is easy to break in the ball mill with a diameter greater than 3 meters, and the price is highHow To Choose Steel Balls For Ball Mill? Grinding Balls2023年4月23日 A comparison of the grinding media is given together with the knowledge gaps that still need to be bridged to improve the quality and performance of grinding media used in ball mills(PDF) Grinding Media in Ball MillsA Review ResearchGate2024年10月13日 1 Ball Mills: Ball mills are a traditional choice for gypsum powder grinding These mills use steel balls to crush and grind the gypsum ore The rotation of the mill cylinder causes the balls to fall back into the cylinder, onto the material to be ground, thus reducing it to powder 2 Raymond Mills:Gypsum powder processing: The role of grinding mills

Gypsum Powder Grinding Mill Price in Pakistan CM

2024年3月12日 Types of Gypsum Powder Grinding mill There are two main types of gypsum powder grinding mill: ball mill and Raymond mill Ball mill are the most common type of gypsum powder grinding mill They use a rotating drum filled with steel balls to grind the gypsum powder Ball mill are available in a variety of sizes and capacitiesLab Ball Grinding Mill Ball Mill Machine Grinder Copper Ore Cement Gypsum Coal Limestone Grinding Ball Mill Factory Price FOB Price: US $5,50010,000 / Piece Min Order: 1 Piece Contact Now Video Raymond Roller Grinding European Mill Mtw175 Automatic Limestone/Cacium Powder Grinding Machine Crusher; Grinding Mill; Rotary Dryer Manufacturer, Cone 2011年7月1日 An experimental study on the ultrafine grinding of gypsum ore in a dry ball mill 2016, Powder Technology Show abstract Gypsum is a crystalline form of hydrated calcium sulfate (CaSO 4 2H 2 0) generally used in cements and plasters in the construction industry, though also in paints, fertilizers, medicines, papers, and textilesInfluence of interstitial filling on breakage kinetics of gypsum 2024年11月25日 Ball Mill machine changes the intrinsic grinding mill structureIts body and ground plank are an integral whole So when fixing, it can be lowered on a plane surface once only Use double tiered roller axletree with centripetal spherical surface as the support of the host axletree can reduce energy cost by 30%Ball Mill clirikchina

Ball Mill Rotary Kiln Vertical Roller Mill Manufacturer Tongli

Vertical roller mill grinding table Ball mill hood cover Vertical roller mill rocker arm Ball mill pinion Vertical roller mill grinding roller Ball mill Liner Vertical roller mill grinding roller shaft Ball mill grinding media Vertical roller mill grinding roller wheel hub Rotary kiln shell Vertical roller mill grinding roller tyre Working principle Fed into the mill through one or both bearing trunnions, the material is ground by impact and friction from the balls The ground product is discharged from the mill through discharge slots provided in the mill tube, Ball mills for various applications Gebr Pfeiffer2024年11月23日 Ball mill: Uses cast grinding steel balls and forged grinding steel balls as the grinding media Rod mill: Uses grinding rods and grinding cylpebs as the grinding media Ceramic ball mill: Uses ceramic balls as the grinding media 4 By lengthtodiameter ratio of the drum Ball mill: A typical ball mill has a drum length that is equal to or 15 Highquality Ball Mill with Low price for Kinds of Materials2022年4月24日 Mohamed Abd Ellatif owns a gypsum mine He hopes that we can provide him with a 35tph ball mill to grind the gypsum to 100 meshes After checking various project information, our engineers designed drawings and customized a ball mill for him He said: "I have never seen such a responsible manufacturerBall Mill/Grinding Mill/Factory Price

Gypsum mill for all requirements Gebr Pfeiffer

Coarse natural gypsum or mixtures of such gypsum with FGD gypsum are ground, dried, partially calcined, and classified in the Pfeiffer vertical roller mill To be noted that up to 20% of recycling material may be added if required Product fineness can be Safe and reliable feeding and delivery of new grinding balls to the mill is a key concern for many mine sites Manual handling is a hazardous task and should be avoided where possible to reduce the risk of injury to personnel Bulk Handling Technologies can assist with the design and supply of a custom ball charging system, incorporating a ball Ball Mills and Ball Charging Bulk Handling TechnologiesThe gypsum dehydration that is important for the cement properties is ensured in ball mills because of their long residence times and high grinding chamber temperatures However, there is little knowledge available for SMMs about the extent of gypsum dehydration, which means that the dehydration potential must be investigated systematically Gypsum dehydration potential and mean residence time of a The performance and the result of sample preparation are also determined by the choice of the grinding jar and its ball charge The EasyFit range of jars has been specially designed for extreme working conditions such as longterm trials, even at maximum speed of 800 rpm, wet grinding, high mechanical loads and maximum speeds as well as for mechanical alloyingPlanetary Ball Mill PM 100 RETSCH highest fineness

.jpg)

Gypsum Powder Ball Mill Gypsum Grinding Mill,Gypsum Grinding

Typically the Clirik gypsum powder ball mill will grind friable or crystalline materials down to the 0075 04/089 mm average particle size range Particles larger than 10 microns are generally hardtofracture polymers such as toner compounds or hard waxes, and some organic materials, but if a larger size is wanted, many products can be