Electrical part of micro powder mill

.jpg)

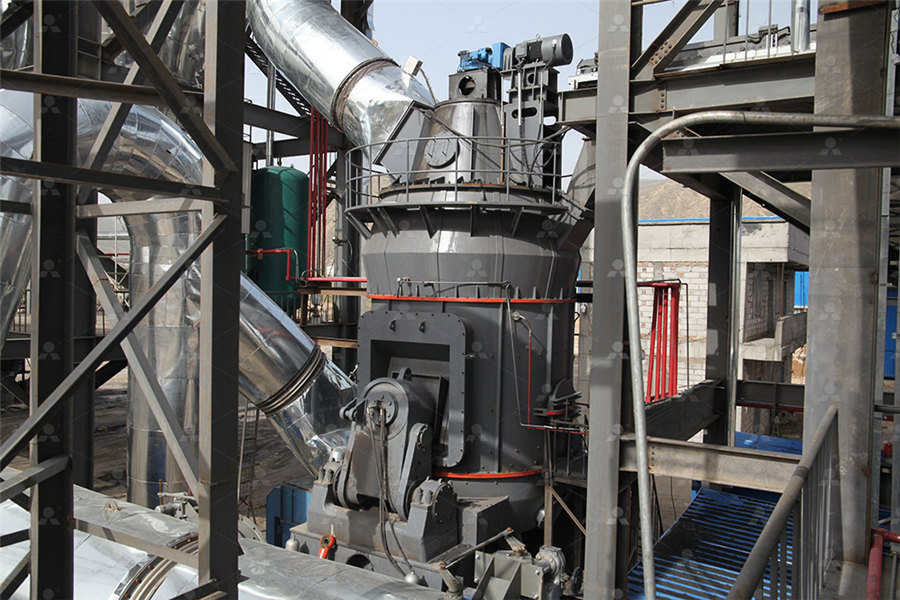

Threering Micro Powder Mill crusherinc

2010年7月15日 The JOYAL Threering Micro Powder Mill(ultrafine mill) is for superfine grinding materials with hardness less than 6 in Moh’s scale and humidity less than 62022年3月22日 Micro pulverizer machine manufactured by Mill Powder Technology is made up of three parts: main machine, auxiliary machine and electric control box The micro pulverizer machine has the properties of wind Micro Pulverizer Machine Mill Powder 2022年2月21日 HGM series micro powder mill is a processing equipment for fine powder and super fine powder It’s mainly used to grind nonflammable, nonexplosive nonmental Micro Powder Mill kefidchinaMicro Powder Grinding Mill is mainly formed by mill body, blower fan, ultrafine analyzer, finished product cyclone container, bag deduster, and air pipe The elevator, storage bin, electric control cabinet, powder feeder, and crusher are Micro Powder Grinding Mill

.jpg)

Micro Powder Grinding Mill,Micro Powder Mill

2022年8月31日 Working Principle of micro powder grinding mill: The main bearing and each dial are driven by electromotor of main machine through reducer, and numbers of rollers, which are rolling in the ring, are driven by dial Threering Micro Powder Mill >> EMail:joyal@crusherinc >> Http://joyalcrusher Features 1 Highefficiency and low consumption With the same endproducts fineness and Micro Powder Mill Shanghai Joyal Machinery Co, Ltd PDF 2023年10月11日 pared with jet mill, mixing grinder and ball mill of same finished product size and motor power, MW MicroPowder Mill has double capacity and saves 30% energy 2The lubricating device is installed outside MW Series Micro Powder Mill SMMVIK 2021年8月20日 Upper distributor is on the turn table, at the top of impeller Ring is installed at the inner of main machine body, aside the rollers Lower distributor is installed under the Rollers Current relay plays an important part in control Micro Powder Grinding Mill Clirik

Micro Powder Mill Kefid

2022年4月14日 Micro Powder Grinding Mill is a new type of mill for making super fine powder through more than 20 times of test and improvement The fineness can reach to 0006mm; 2022年4月14日 The whole set HGM Micro Powder Grinding Mill consists of (see sketch 1) hammer crusher, bucket elevator, storage hopper, vibrating feeder, main unit, inverter Micro Powder Mill kefidThe three ring medium speed micro powder mill can grind the material to an ultrafine particle size of more than 3000 mesh through fine processing of the material It is a common equipment for processing ultrafine powder in the market air Three ring medium speed micro powder mill2022年3月22日 Micro pulverizer machine manufactured by Mill Powder Technology is made up of three parts: main machine, auxiliary machine and electric control box +86 La máquina micropulverizadora Micro Pulverizer Machine Mill Powder

Air Classifying Mill hmicronpowder

2021年7月11日 MIKRO ACM® AIR CLASSIFYING MILL The Mikro ACM® Air Classifying Mill is an air swept mechanical impact mill with a dynamic air classifier designed to grind an extensive range of materials down to a D97 of 20 microns The Mikro ACM® Air Classifying Mill is available in a range of sizes and can be supplied for laboratory use or large 2023年10月11日 MW Series Micro Powder Mill is equipment designed for customers who need to make ultrafine powder This machine is equipped with efficient pulse dust collector and muffler, which can reduce dust and noise,The fineness can reach to 0pared with jet mill, It is economiccost, highcapacity, and the spare parts just need to exchange once a year, The MW Series Micro Powder Mill SMMVIK Machinery stonevik2021年8月19日 Electric discharge machining (EDM) is widely used to fabricate complex 3D geometries with a high aspect ratio in electrically conductive hard materials EDMmilling (EDMM) is an advancement of EDM which can cut complex features at the microlevel with high accuracy and precision This study reports an overview of EDMM in micro and macrodomain with Electric discharge milling: a stateoftheart review2010年7月15日 Threering Micro Powder Mill >> EMail:joyal@crusherinc >> Http://crusherinc Features 1 Highefficiency and low consumption With the same endproducts fineness and motor power, its output is over 1 time of that of Jet Mill, Mix Mill, and Ball Mill 2 Easydamaged parts with longer working lifeThreering Micro Powder Mill crusherinc

Dolomite Micro Powder Grinding Mill

Dolomite micro powder grinding mill is a new type mining equipment for make micro powders with ring rollers It is a kind of fine powder and ultrafine powder processing equipment They generally have simple construction and fewer moving parts, which reduces the risk of mechanical failure and makes maintenance tasks simpler 62015年9月21日 Flake silver powder with controllable particle size and specific surface area was prepared using planetary ball mill by varying milling parameters including milling time, revolution speed, and the weight ratio of balls to powder (BRP) Asprepared flake silver powder was characterized by laser particle analyzer, scanning electron microscope, Xray diffraction (XRD) Preparation of microsize flake silver powder by planetary ball mill 2013年10月30日 The document describes a threering micro powder mill manufactured by Shanghai Joyal Mining Machinery Co It consists of a main frame, reducer, classifier, blower, feeder and other components The mill can grind materials into a fine powder size of 3252500 meshes It has high efficiency and low energy consumptionMicro powdermill PDF Free Download SlideShare2023年6月9日 Micro Powder Grinding Mill is a new type of mill for making super fine powder through more than 20 times of test and improvement It is economiccost, highcapacity, and the spare parts just need to exchange once a year; The bag filter is added to protect the environment Output size : 3003000 mesh Production capacity : Up to 6000kg/Hour Micro Powder MillKefid Machinery

.jpg)

HGM Mill hiimac

2021年5月25日 Models: HGM80, HGM90, HGM100, HGM100A, HGM125 and HGM1680 Power: 1233444 kw Finished size: 325~3000 meshes, 547 micron HGM Micro Powder Grinding Mill is the new type mining equipment for making micro powders, fine powders,which is widely applied in the industries of metallurgy, mining, chemistry, cement, construction, refractory 2021年11月2日 Electrical explosion of aluminum wires has been shown to be a versatile method for the preparation of bimodal nano/micro powders The energy input into the wire has been found to determine the Preparation of Nano/Micro Bimodal Aluminum Powder by Electrical Our main products include ultrafine vertical roller mill, ultrafine grinding mill, stone powder production equipment, Welcome to consult +17 [ protected] Focus on the field of micro powder grinding CLUM Series SBM Ultrafine Powder Technology Industrial Micro Powder Grinding Mill – Grinding mill,grinding machine Micro Powder Grinding Mill Micro Powder Grinding Mill is a new type of mill for making super fine powder through more than 20 times of test and improvement The Micro Powder Grinding Machine Crusher Mills

What is Powder Grinding Mill? JXSC Machine

2021年11月27日 Grinding Mill Parts; Slurry Pumps Parts; Hydrocyclone Parts; Ore Project EPC bucket elevator, electromagnetic vibrating feeder, electric control cabinet, etc Users can choose flexibly according to site conditions pendulum roller mill, highpressure suspension grinding mills, highpressure micropowder mills, straightthrough 2024年8月26日 The micro powder grinding mill is capable of achieving particle sizes as fine as 1 micron or even smaller, making it ideal for applications that require ultrafine powders This mill is a gamechanger for industries that rely on precise The versatile and efficient micro powder grinding mill2014年2月27日 Threering Micro Powder Mill >> EMail:joyal@crusherinc >> Http://joyalcrusher Features 1 Highefficiency and low consumption With the same endproducts fineness and motor power, its output is over 1 time of that of Jet Mill, Mix Mill, and Ball Mill 2 Easydamaged parts with longer working lifeThreering Micro Powder Mill joyalcrusher2021年2月23日 When the ratio of sphere particle to flake silver powder is 1:1, the electrical resistivity of microsilver paste cured at 200 °C for 45 min in air is about (331 ± 073) × 10⁻⁵ Ω cm, the (PDF) Tuning the Electrical Resistivity of Conductive Silver

.jpg)

Micro Powder Grinding Mill Clirik

2021年8月20日 Wear Parts Of Micro Powder Grinding Mill Upper distributor Upper distributor is on the turn table, at the top of impeller Turn table Turn table is in the center of upper machine body Rollers Rollers are installed under the upper distributor, shaftcentered and near the ring Ring Ring is installed at the inner of main machine body, aside MW Micro Powder Mill (Medium speed microgrinding mill, absorbing advanced Swedish grinding technology, is good at superfine powder processing Low loss and high fineness: tear and wear parts use highquality wearresistant materials, the serve life is more than a year, final fineness up to D97 le; 5mu;m at one time 3MW Micro Powder Mill, micro powder mill, micro powder mill price, micro 2024年8月25日 For nano/micro powder mixing into dielectric liquid, also causes an undesirable effect that reduces the capacitance effect Cylindrical parts are widely used in pressing or punching methods, and with complex profile parts, most of them have to be handworked Ahmed, GI, et al: Elucidating powdermixed electric discharge machining Effect of SiC Powder in PMEDM Process on Electrode Wear First before the micro powder mill start running,you should inspection each part good mechanical and electrical equipment, check the connecting bolts are loose; whether all lubrication points lubrication is normal, if normal and reliable transmission, guards intact, electrical instruments are sensitive, good contact brushless motor Wait;Micro powder mill specifications Operating Instructions

.jpg)

Micro Powder Mill Shanghai Joyal Machinery Co, Ltd

Threering Micro Powder Mill >> EMail:joyal@crusherinc >> Http://joyalcrusher Features 1 //joyalcrusher The Model Number of All the Bearings and Name and Quantity of the Quickwear Parts For the mill and wearing parts, you can refer to these two tables in order that the customer can select them conveniently Table 2010年12月22日 One of the biggest challenges for mechanical micro/nano milling is the design and fabrication of high precision and high efficiency micro milling tools Commercially available micro milling tools are either too expensive (around several hundred US dollars) or simply made from downsizing of macro milling tools, which is sometimes not appropriate for the specific Design and development of PCD micro straight edge end mills for micro 2023年10月25日 The micro powder mill is mainly composed of the main machine, a blower, an ultrafine analyzer, a cyclone powder collector, a bagtype dust collector, and a connecting pipe According to the needs of users, it can be equipped with some auxiliary equipment, such as the bucket elevator, storage silo, electric control cabinet, powder feeder Sinogomine Industrial Technology Co,LtdMicro Powder Mill FRITSCH Planetary Ball Mills – highperformance allrounder in routine laboratory work The Planetary Micro Mill PULVERISETTE 7 premium line with 2 grinding stations is designed for a broad range of applications and ideally suited for lossfree grinding down to a final fineness of 100 nm of hard, mediumhard and brittle materials Depending on the desired final fineness, the Planetary Micro Mill PULVERISETTE 7 premium line /

Tuning the electrical resistivity of conductive silver paste

2021年4月27日 As an important interconnection material in electronics, conductive silver paste has attracted much research interest in chip packaging and printed circuit board due to its predominant properties like high conductivity and flexible interconnection In this paper, the silver nanoparticles, the silver sphere particles, and flake silver powders are fabricated by various 2024年9月27日 Hosokawa Micron Powder Systems designs and manufactures size reduction systems and powder processing solutions for the chemical, mineral, pharmaceutical, cosmetic, food and plastic industries Hosokawa Micron Powder Systems specializes in coarse to ultrafine grinding, classification, mixing, drying, containment, compaction and analytical Home Hosokawa Micron Powder SystemsOverview Micro Powder Grinding Mill is widely used in making fine powder or micro powder, and the raw materials should be noninflammable and nonexplosive under the Moh’s hardness less than 6 grade such as limestone, calcite, dolomite, kaolin, bentonite, talc, illite, pyrophillite, barite, meerschaum, fluorite, potash ore, etc The lifetimeMicro Powder Grinding Mill CM Mining Machinery2022年4月14日 Compared with jet mill, agitation mill and ball mill, If the fineness and motor power is the same as each other, its production capacity is twice than others; 2 Longer lifetime of spare parts The roller and ring are made of special material, which improve the grinding efficiency a lot For same materialMicro Powder Mill kefid

.jpg)

Three ring medium speed micro powder mill

The three ring medium speed micro powder mill can grind the material to an ultrafine particle size of more than 3000 mesh through fine processing of the material It is a common equipment for processing ultrafine powder in the market air 2022年3月22日 Micro pulverizer machine manufactured by Mill Powder Technology is made up of three parts: main machine, auxiliary machine and electric control box +86 La máquina micropulverizadora Micro Pulverizer Machine Mill Powder 2021年7月11日 MIKRO ACM® AIR CLASSIFYING MILL The Mikro ACM® Air Classifying Mill is an air swept mechanical impact mill with a dynamic air classifier designed to grind an extensive range of materials down to a D97 of 20 microns The Mikro ACM® Air Classifying Mill is available in a range of sizes and can be supplied for laboratory use or large Air Classifying Mill hmicronpowder2023年10月11日 MW Series Micro Powder Mill is equipment designed for customers who need to make ultrafine powder This machine is equipped with efficient pulse dust collector and muffler, which can reduce dust and noise,The fineness can reach to 0pared with jet mill, It is economiccost, highcapacity, and the spare parts just need to exchange once a year, The MW Series Micro Powder Mill SMMVIK Machinery stonevik

Electric discharge milling: a stateoftheart review

2021年8月19日 Electric discharge machining (EDM) is widely used to fabricate complex 3D geometries with a high aspect ratio in electrically conductive hard materials EDMmilling (EDMM) is an advancement of EDM which can cut complex features at the microlevel with high accuracy and precision This study reports an overview of EDMM in micro and macrodomain with 2010年7月15日 Threering Micro Powder Mill >> EMail:joyal@crusherinc >> Http://crusherinc Features 1 Highefficiency and low consumption With the same endproducts fineness and motor power, its output is over 1 time of that of Jet Mill, Mix Mill, and Ball Mill 2 Easydamaged parts with longer working lifeThreering Micro Powder Mill crusherincDolomite micro powder grinding mill is a new type mining equipment for make micro powders with ring rollers It is a kind of fine powder and ultrafine powder processing equipment They generally have simple construction and fewer moving parts, which reduces the risk of mechanical failure and makes maintenance tasks simpler 6Dolomite Micro Powder Grinding Mill2015年9月21日 Flake silver powder with controllable particle size and specific surface area was prepared using planetary ball mill by varying milling parameters including milling time, revolution speed, and the weight ratio of balls to powder (BRP) Asprepared flake silver powder was characterized by laser particle analyzer, scanning electron microscope, Xray diffraction (XRD) Preparation of microsize flake silver powder by planetary ball mill

Micro powdermill PDF Free Download SlideShare

2013年10月30日 The document describes a threering micro powder mill manufactured by Shanghai Joyal Mining Machinery Co It consists of a main frame, reducer, classifier, blower, feeder and other components The mill can grind materials into a fine powder size of 3252500 meshes It has high efficiency and low energy consumption2023年6月9日 Micro Powder Grinding Mill is a new type of mill for making super fine powder through more than 20 times of test and improvement It is economiccost, highcapacity, and the spare parts just need to exchange once a year; The bag filter is added to protect the environment Output size : 3003000 mesh Production capacity : Up to 6000kg/Hour Micro Powder MillKefid Machinery