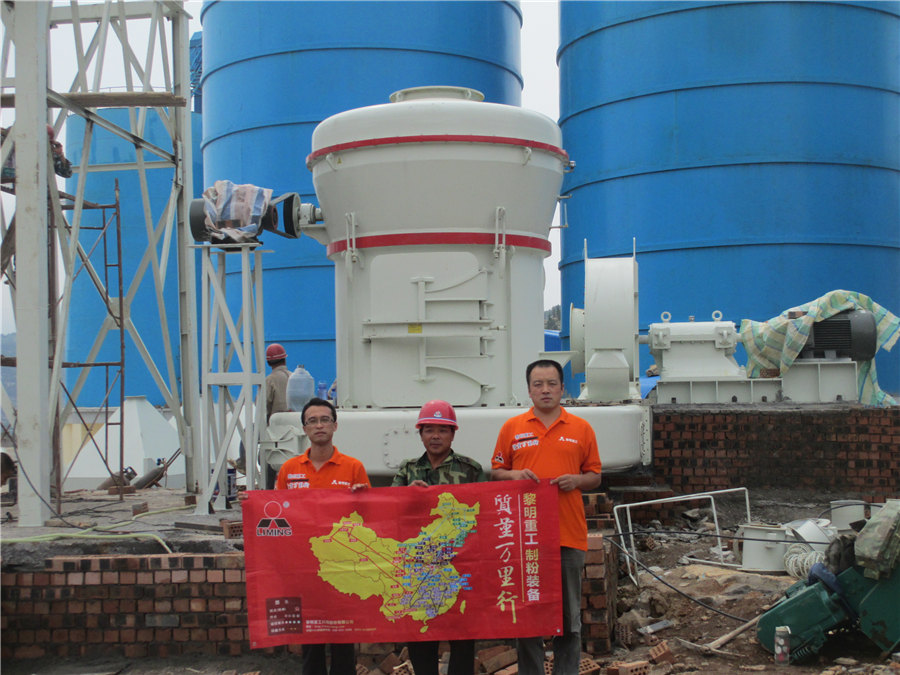

Machinery and equipment for grinding magnesium sulfate and heavy calcium

.jpg)

Magnesium Sulfate Heavy Calcium Powder Grinding Machine

Today, we’re going to dive deep into the fascinating realm of magnesium sulfate heavy calcium powder grinding machine This powerful piece of machinery is revolutionizing various industries by effortlessly crushing and grinding minerals like never beforeAsh calcium machine ultrafine grinding mill Ash calcium mac GuiLin HangDa Mining Machinery Products Made In China, China Manufacturer Applications:Kaolin, lithopone, carbon black, Ash calcium machine ultrafine grinding mill GuiLin HangDa 2023年4月28日 Lightburned magnesia grinding equipment – HGM superfine ring roller mill HGM ultrafine grinding machine is an industrial grinding equipment independently developed Lightburned magnesia powder ultrafine grinding machine2024年7月10日 Common surface modification equipment for heavy calcium carbonate includes SLG continuous powder surface modifier, HEM highefficiency hybrid modifier, highspeed Heavy calcium carbonate grinding, surface modification

.jpg)

The ultrafine grinding mill for processing heavy calcium

An ultrafine grinding mill is a specialized piece of equipment designed to process these minerals into ultrafine powders Heavy calcium carbonate and calcite are valued for their high Ball mill grinding is one of the most traditional and widely used methods for ultrafine grinding of heavy calcium powder The working principle is to rotate the cylinder with the grinding body UltraFine grinding processing method and flow of heavy calcium Browse Metso's wide offering of reliable grinding mills: AG mills, SAG mills, ball and pebble mills, and stirred mills to fit your needs Our pioneering innovations in horizontal grinding mills Grinding mills for mining and minerals processing MetsoChemical grinding relies on precise particle size reduction to achieve consistent yield and minimize undesirable fines MPE is the leading grinding equipment manufacturer for dry, Chemical Grinding Applications Modern Process Equipment

.jpg)

How to do the grinding of heavy calcium industry?

2022年2月21日 Heavy calcium carbonate is made of calcite, chalk, marble and other ores as raw materials, and is produced by mechanical pulverization It is a commonly used powdery inorganic filler with high chemical purity, high 2023年2月15日 Lime is made of limestone which needs to be calcinated with a temperature over 900℃ Limestone is a kind of sedimentary rock that is alkaline, and the main component is calcium carbonate, calcium magnesium Lime Production Process and Required EquipmentMagnesium Sulfate Standard, 29 mL, for Calcium Titration and Hardness Monitor, 10,000 mg/L as CaCO₃, for SP510Magnesium Sulfate Standard, 29 mL, for Calcium Titration and3 UltraFine Grinding Process of Heavy Calcium Powder The ultrafine grinding process of heavy calcium powder mainly includes the following steps: Crushing and Grinding The raw material is first crushed to a suitable size by a jaw crusher or impact crusher, and then enters the grinding equipment (such as ball mill, roller mill, or jet mill UltraFine grinding processing method and flow of heavy calcium

.jpg)

Cement SpringerLink

2021年3月3日 Cement is produced by a hightemperature (about 1500 °C) reaction in a rotary kiln of carefully proportioned and blended ratios of lime (CaO), silica (SiO 2), alumina (Al 2 O 3), and iron oxide (Fe 2 O 3)The production of cement is a chemical process requiring an accurate blend of the previously cited four key organic oxides and the limitation of several undesirable 2021年7月28日 2 Grinding stage: Small pieces of material that meet the conditions will evenly enter the grinding chamber of the dolomite grinding millThey enter the chamber through the feeding system quantitatively, and grind into powder in the mill cavity 3 Classification stage: the ground material will pass through the classifier and the system’s airflow for classificationDolomite Grinding Mill SBM Ultrafine Powder Technology2023年9月14日 While generic CNC machines can handle a wide range of materials, when it comes to magnesium, investing in specialized equipment can make a huge difference in safety Machines designed explicitly for magnesium come with features that reduce fire risks, such as integrated fire suppression systems and designs that minimize magnesium chip accumulationSafety First: Everything You Need to Know About Magnesium Highpurity crystallized nickel and cobalt sulfates (and chlorides) are typically used in the battery industry as a starting point for cathode active material preparation These nickel and cobalt sulfate crystals are dissolved to form a purified metal sulfate solution from which the cathode precursor manufacturing startsHydrometallurgical nickel and cobalt plants and processes

.jpg)

water treatment – removing hardness (calcium and magnesium)

And if amounts of reagent are precisely adjusted, the water’s alkalinity will be reduced to the theoretical solubility applicable to the CaCO 3 + Mg (OH) 2 system which ranges from 2 to 3°F under normal temperature and concentration conditions However, this limit Malk figure may be increased in practice when dissolved impurities are present (eg organic acids, ammonium, The calcium carbonate grinding production line is an efficient, stable, and reliable production line with wide application prospects By using advanced equipment and technology, this production line is able to produce highquality calcium carbonate powder to meet the needs of different industries At the same time, the production line also has the advantages of energy Calcium Carbonate Grinding Production Line TAYMACHINERY2014年1月20日 CALCIUM COMPOUNDS Gypsum very soft sulfate mineral composed of calcium sulfate, CaSO42H2O component of Portland cement used to prevent the flash settling of concrete added about 4 5% during the final Portland Cements, Calcium and Magnesium Taking into account the quality of the medium itself and the control of the particle size of the calcium carbonate after grinding and the current of the grinding machine, the amount of the medium is 1/2~3/5 of the grinding volume of the grinding machine, and the types of media used by different grinding units are different, according to For the grinding process, a unit can be Quality requirements and grinding process control of heavy calcium

.jpg)

Grinding calcium carbonate: techniques, challenges

High abrasion: Calcium carbonate is an abrasive mineral, which causes rapid wear to grinding equipment This requires careful selection of the materials of construction of the machines to prolong their life Granulometry control: 27 Sep 2023; Grinding equipment for calcium carbonate is essential in the process of producing fine and ultrafine calcium carbonate powder Calcium carbonate grinding equipment mainly includes ball mill, Raymond mill, vertical roller mill, and ultrafine millThese grinding equipment are widely used in various fields of mining, construction, metallurgy, chemical industry, and so ongrinding equipment for calcium carbonate process CM Mining Machinery2021年1月1日 The leaching behaviors of calcium and magnesium in the rare earth tailings leached with magnesium sulfate using deionized water, CaCl 2 solution and lime water were investigated Experimental data indicated that magnesium in the tailings was easy to be leached out since most of the magnesium was in the form of watersoluble phaseLeaching behaviors of calcium and magnesium in ion 2023年3月15日 ① HGM ultrafine grinding mill: 745 micron (2002500 mesh); D97=5 micron HGM series ultrafine mill has superior performance, stable quality, simple operation and convenient maintenance It can be adjusted arbitrarily to produce finished powder with fineness ranging from 325 mesh to 2500 mesh, which is suitable for grinding hundreds of materials with Serpentine crushing and grinding processing production line machinery

News Apply The Heavy Calcium Grinding Mill Machine To The

At present, the production methods of heavy calcium carbonate mainly include dry method and wet method The dry method generally produces heavy calcium with less than 2500 mesh If the heavy calcium with more than 2500 mesh is produced, wet grinding is mainly used, and dry grinding is the first step of wet grinding Wet grinding heavy calcium has the characteristics of 2 Advanced Grinding Technology Utilizing the latest in grinding technology, the mill employs a combination of impact and shearing forces to achieve the desired fineness 3 Customizable Grinding Media The choice of grinding media can be tailored to the specific material properties, ensuring optimal grinding efficiency and particle size The ultrafine grinding mill for processing heavy calcium 2020年11月13日 1 Quality requirements for heavy calcium carbonate slurry for papermaking The heavy calcium carbonate used in the wet end of the paper must meet the following requirements: high whiteness, high purity, stable particle size and distribution, low hydrochloric acid insoluble content and abrasion, slow settling performance, and the likeQuality requirements and grinding process control of heavy calcium 4Why do you need a Grinding and Granulating Machine? For manufacturing tablets, this step is of prime importance There are a variety of applications that require size reduction of granules, thus, grinding and granulation machines are important ways to get universal and reliable granulation of powders best fit for further process 5Next StepTop 11 Machineries for Manufacturing Pharmaceutical Tablets

Frontiers A Composite of Cubic CalciumMagnesium

2022年6月6日 1 Introduction Calcium sulfate (CS) bone cement has received extensive attention from researchers due to its nontoxic properties and high biocompatibility (Nilsson et al, 2013)At present, CS has been widely used as With more than 80 years of experience in wheat and corn processing, Prillwitz has most of the necessary machinery for the production of animal feed For flour and feed storage, Prillwitz manufactures a wide variety of silos (flexible Feed Processing Machinery Prillwitz USA2023年10月10日 Calcium carbonate dry ultrafine grinding equipment and process Calcium carbonate dry ultrafine grinding equipment mainly includes Raymond mill, vertical mill, ball mill, jet mill, stirring mill, vibration mill and Typical processes and equipment for ultrafine 2021年10月29日 Production of magnesium sulfate and other magnesiumcontaining compounds, mordants, desiccants, solvents, decolorants, and adsorbents, etc Light Industry: Purifier for the sugar industry, curing agent for paper, the accelerator for vulcanization process in the rubber industry, manmade fibers, plastics, cosmetics, and special glass raw materialsMagnesite Grinding Equipment Production Line

Calcium Carbonate Manufacturing Process and Equipment

2021年12月20日 The equipment used during the processing of calcium carbonate powder affects grain types and particle size distribution Prater Equipment for Calcium Carbonate Manufacturing Processes Prater Industries makes a number of machines wellsuited for breaking apart aggregates like limestone, chalk, or marble to make calcium carbonate2013年8月29日 calcium carbonate powder plant china to find beneficiation plant solution and various crusher spare grinding mill for calcium carbonate magnesium Grinder milling 2251200 purpose of calcium and magnesium powdercalcium magnesium powder crusher Mining Quarry PlantVarious conventional physicochemical methods have been used to remove heavy metals and sulfate from wastewater, including reverse osmosis, soil washing, coagulation–flocculation, ion exchange, adsorption, membrane technology, electrolysis, thermal extraction, cementation, direct solvent extraction, and precipitation of intermediates (Kikot et al 2009, 2010; Iakovleva et al Advances in heavy metal removal by sulfatereducing bacteriaMachined Magnesium Magnesium: European Directive 98/37/ EC – Mechanical Equipment – Machinery 156 Fire There is, in the UK, a statutory obligation specified under the “Magnesium (Grinding of Castings and Other Articles) Special Regulations, 1946”Machined Magnesium Advice Luxfer MEL Technologies

.jpg)

(PDF) Chemical Processing of Bauxite: Alumina and Silica Minerals

2022年1月23日 The Chapter covers the rational of sizing of principal equipment 2 and other calcium and magnesium compounds is an important aspect of the Bayer Figure 412 demonstrates that sulfate anions2023年3月30日 Calcium and magnesium ions content can be reduced to less than 100 ppm, and high purity manganese sulfate solution from which calcium and magnesium ions have been removed deeply can be obtainedExtraction Technology for Manganese Sulfate Solution Purification2022年2月21日 Heavy calcium carbonate is made of calcite, chalk, marble and other ores as raw materials, and is produced by mechanical pulverization It is a commonly used powdery inorganic filler with high chemical purity, high How to do the grinding of heavy calcium industry?2023年2月15日 Lime is made of limestone which needs to be calcinated with a temperature over 900℃ Limestone is a kind of sedimentary rock that is alkaline, and the main component is calcium carbonate, calcium magnesium Lime Production Process and Required Equipment

.jpg)

Magnesium Sulfate Standard, 29 mL, for Calcium Titration and

Magnesium Sulfate Standard, 29 mL, for Calcium Titration and Hardness Monitor, 10,000 mg/L as CaCO₃, for SP5103 UltraFine Grinding Process of Heavy Calcium Powder The ultrafine grinding process of heavy calcium powder mainly includes the following steps: Crushing and Grinding The raw material is first crushed to a suitable size by a jaw crusher or impact crusher, and then enters the grinding equipment (such as ball mill, roller mill, or jet mill UltraFine grinding processing method and flow of heavy calcium 2021年3月3日 Cement is produced by a hightemperature (about 1500 °C) reaction in a rotary kiln of carefully proportioned and blended ratios of lime (CaO), silica (SiO 2), alumina (Al 2 O 3), and iron oxide (Fe 2 O 3)The production of cement is a chemical process requiring an accurate blend of the previously cited four key organic oxides and the limitation of several undesirable Cement SpringerLink2021年7月28日 2 Grinding stage: Small pieces of material that meet the conditions will evenly enter the grinding chamber of the dolomite grinding millThey enter the chamber through the feeding system quantitatively, and grind into powder in the mill cavity 3 Classification stage: the ground material will pass through the classifier and the system’s airflow for classificationDolomite Grinding Mill SBM Ultrafine Powder Technology

Safety First: Everything You Need to Know About Magnesium

2023年9月14日 While generic CNC machines can handle a wide range of materials, when it comes to magnesium, investing in specialized equipment can make a huge difference in safety Machines designed explicitly for magnesium come with features that reduce fire risks, such as integrated fire suppression systems and designs that minimize magnesium chip accumulationHighpurity crystallized nickel and cobalt sulfates (and chlorides) are typically used in the battery industry as a starting point for cathode active material preparation These nickel and cobalt sulfate crystals are dissolved to form a purified metal sulfate solution from which the cathode precursor manufacturing startsHydrometallurgical nickel and cobalt plants and processesAnd if amounts of reagent are precisely adjusted, the water’s alkalinity will be reduced to the theoretical solubility applicable to the CaCO 3 + Mg (OH) 2 system which ranges from 2 to 3°F under normal temperature and concentration conditions However, this limit Malk figure may be increased in practice when dissolved impurities are present (eg organic acids, ammonium, water treatment – removing hardness (calcium and magnesium)The calcium carbonate grinding production line is an efficient, stable, and reliable production line with wide application prospects By using advanced equipment and technology, this production line is able to produce highquality calcium carbonate powder to meet the needs of different industries At the same time, the production line also has the advantages of energy Calcium Carbonate Grinding Production Line TAYMACHINERY