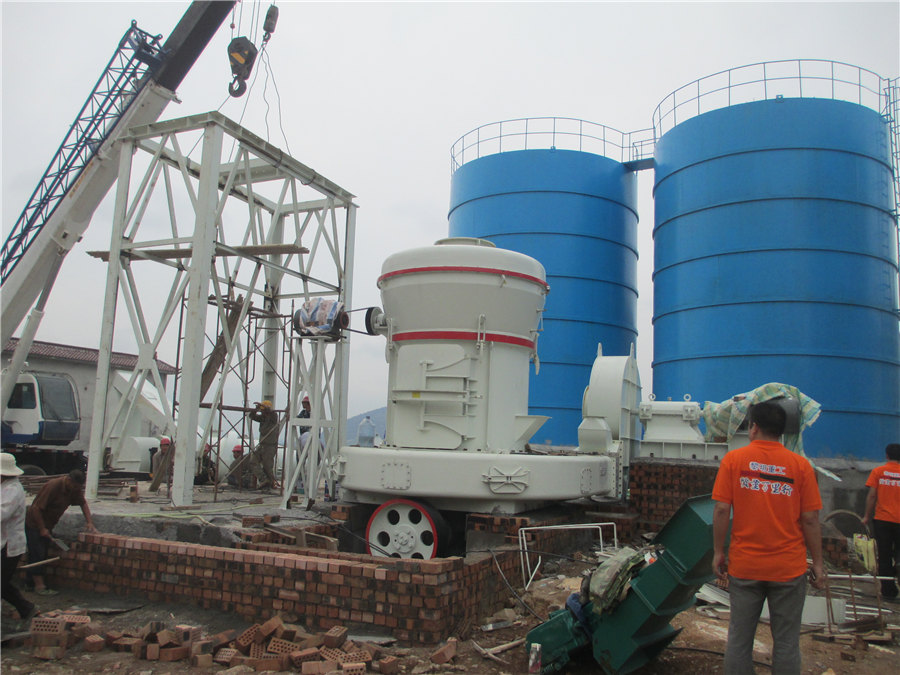

Large lime calcium carbonate material grinding production line

.jpg)

China FTM® Active Lime Production Line Fote

Active lime is made of limestone, dolomites, chalk, shells and other raw materials with high content of calcium carbonate, which is formed by the 900~1100℃ calcination It's widely used in civil engineering because of its features of wide CHAENG can undertake the 2001500t/d active lime production line EPC, including the the reach report, civil engineering, designing, equipment, installation and debugging "turnkey” service active lime production line CHAENGThe Lime Kiln production line equipment that Zhongke can provide: Rotary Kiln, Lime Kiln, Rotary dryer, Ball Mills , Cyclone Dust Collector etc Activated limestone is mainly made of lime, white active lime production lineHenan Zhongke EngineeringThe calcium carbonate grinding production line is an efficient, stable, and reliable production line with wide application prospects By using advanced equipment and technology, this production line is able to produce highquality calcium carbonate powder to meet the needs of different industries At the same time, the production line also has the advantages of energy Calcium Carbonate Grinding Production Line TAYMACHINERY

Calcium Carbonate Grinding Production Line TAYMACHINERY

The calcium carbonate grinding production line is an efficient, stable, and reliable production line with wide application prospects By using advanced equipment and technology, this production line is able to produce highquality calcium carbonate powder to meet the needs of different industries At the same time, the production line also has the advantages of energy Various calcium carbonate powder production capacity available According to customer’s needs, Daswell can offer you tailored solution with different calcium carbonate production capacity A calcium carbonate production line can produce finished ground calcium carbonate powder in different particle sizes for different applicationsCustomize Suitable Calcium Carbonate Plant DASWELL2024年3月26日 Calcium carbonate is an important industrial raw material with a wide range of applications With the development of economy, the demand for calcium carbonate will continue to grow Therefore, the establishment of a calcium carbonate ultrafine grinding production line has broad market prospectsHow to set up a calcium carbonate ultrafine grinding production line?The bulk material of calcium carbonate is crushed by the crusher to the incoming fineness (15mm50mm) which can enter the mill Second stage: milling The crushed calcium carbonate small material is sent to the silo through the hoist, and then uniformly and quantitatively fed into the mill grinding chamber through the vibrating feeder for grindingcalcium carbonate grinding mill, calcium carbonate machine, calcium

What equipment does the calcium carbonate powder production line

2021年7月22日 The production process of calcium carbonate can be roughly divided into two links: crushing and grinding Calcium carbonate crushing process: 1 Large pieces of calcium carbonate are evenly fed into a broken (jaw crusher) by a vibrating feeder through the silo for coarse crushing2021年12月20日 The Importance of Calcium Carbonate Calcium carbonate (CaCO3) comprises more than 4% of the earth’s crust and is found worldwide Its most common natural forms are chalk, limestone, and marble (produced by the sedimentation of small fossilized shellfish, snails, and coral over millions of years)Calcium Carbonate Manufacturing Process and Equipment2022年5月5日 Calcium carbonate grinding mill is an efficient industrial ultrafine powder mill It can grind calcium carbonate into fine and superfine powder(1503000mesh) SBM is China’s famous calcium carbonate grinding mill manufacturer Its selfdeveloped HGM series ultrafine grinding mills and CLUM series ultrafine vertical roller mills are the most Calcium Carbonate Grinding Mill Powder Modify SBM 2023年11月21日 A ground calcium carbonate production line typically involves several stages, including mining, crushing, grinding, and classification What Is Ground Calcium Carbonate? Ground calcium carbonate (GCC) is a type of calcium carbonate that is obtained by mechanically grinding and crushing natural calcite, limestone, chalk, marble , or other sourcesGround Calcium Carbonate Production Line

.jpg)

Calcium Carbonate Powder Production Line – Powder Equipment

A calcium carbonate production line can produce finished ground calcium carbonate powder in different particle sizes for different applications Both dry grinding and wet grinding are available A grinder or grinding mill is the core equipment for a calcium carbonate grinding plant, which can largely determine the fineness of the end productCHAENG can undertake the 2001500t/d active lime production line EPC, including the the reach report, civil engineering, designing, Materials: Calcium carbonate, limestone, barite, heavy calcium carbonate, etc Large capacity The single active lime production line CHAENGProduct: Lime Production Plant Capacity: 50 – 1200 TPD FUEL: Coal Gas, Natural Gas, and Pulverized Coal Application: Active Lime Production Line/ Quicklime Production Line/ Hydrated Lime Production Line Main Equipment for Lime Production Line: Rotary Lime Kiln / Vertical Lime Kiln, Raymond Mill, Jaw Crusher, Bucket Elevator, Separator, Dust Collector, etcLime Production Line for HighOutput Lime Production PlantUltrafine Calcium Carbonate Production Linecalcium carbonate ultrafine powder as raw is output from the raw material bin and fed to the CRLM1200X Superfine Vertical Roller Mill through the belt feeder for grinding The ground material enters the collector and the finished product has a particle size of Hydrated Lime Production LineGuangxi Artificial Granite Ultrafine Calcium Carbonate Production Line

Calcium Carbonate Grinding Production Line TAYMACHINERY

The calcium carbonate grinding production line is an efficient, stable, and reliable production line with wide application prospects By using advanced equipment and technology, this production line is able to produce highquality calcium carbonate powder to meet the needs of different industries At the same time, the production line also has the advantages of energy 2023年12月8日 Limestone Properties The main component of limestone is calcium carbonate (CaCO3), with a Mohs hardness of 3 After limestone is mined from limestone, it is crushed to form limestone particles, that is, stone and sand, or further ground to form limestone powder, which is widely used in industries such as building materials, highways, metallurgy, and Limestone crushing technology and equipment SBM Ultrafine The process flow of the sulfuric acid method lithium carbonate vertical roller mill production line is as follows: ① The spodumene or lepidolite ore is transformed and roasted, and after cooling, it is transported to the vertical roller mill for fine grinding to achieve a certain concentrate particle ②The ground powder is mixed with concentrated sulfuric acid with a certain acidtoore Process Flow Of Lithium Carbonate Vertical Roller Mill Production Line2024年9月14日 Also, calcium carbonate is a common filler in paints, plastics, and rubber It improves their texture and performance while cutting production costs Calcium carbonate powder, from a production view, comes from grinding limestone, marble, and calcite The calcium carbonate production line has several key partsHow to choose a suitable calcium carbonate grinding mill?

Active Lime Production Line

Active lime is made from minerals with high calcium carbonate content, such as limestone, dolomite, and chalk, which are calcined at 10001100°CThe calcium carbonate grinding production line is an efficient, stable, and reliable production line with wide application prospects By using advanced equipment and technology, this production line is able to produce highquality calcium carbonate powder to meet the needs of different industries At the same time, the production line also has the advantages of energy Calcium Carbonate Grinding Production Line TAYMACHINERYIt is widely used in calcium carbonate (calcite, marble, lime stone, chalk), quartz, zircon, paillite, barite, kaoline, dolomite, magnesite, alumina, super fine cement, slag, steel slag, etc According to different materials and application industries, Technical parameters of ball mill grinding and classifying production line Ball Mill and Air Classifier Production Line ALPA PowderThere are many varied uses for calcium carbonate: As raw material for the construction material industry (manufacture of cement and quick lime or limestone for building and calcium carbonate is used in the paper industry as a filler Calcium Carbonate NETZSCH Grinding Dispersing

.jpg)

Minerals Line

Minerals Line Trading is pleased to introduce ourselves as one of the leading producer and exporter of high grade Minerals, Talc Powder (Various Grades) and Lumps, Lime Stone, Super Whiting, Natural Calcium Carbonate, China Clay, In terms of production process, calcium carbonate powder is mainly obtained by grinding limestone, marble, calcite and other raw materials The calcium carbonate production line is mainly composed of crushers, screw conveyors, How to Choose a Calcium Carbonate Grinding Mill2019年12月9日 Precipitated calcium carbonate production process: first burn the limestone and other raw material sections to generate lime (the main component is calcium oxide) and carbon dioxide, then add water to digest the lime to produce lime milk (main component is calcium hydroxide), and then pass the carbon dioxide carbonized lime milk Calcium carbonate Precipitated calcium carbonate manufacturing process2024年6月7日 Calcium carbonate (calcite, marble, lime stone, chalk), quartz, zircon, paillite, barite, kaoline, dolomite, magnesite, alumina, super fine cement, slag, steel slag Calcium carbonate (CaCO3), which occurs primarily in the form of the minerals calcite and aragonite, is one of the most prevalent compounds on EarthBall Mill Calcium carbonate dry grinding high quality equipment

Calcium Carbonate Ultrafine Vertical Mill SBM Ultrafine

CLUM series calcium carbonate ultrafine vertical mill, a new type of ultrafine grinding equipment integrating powder grinding, grading, conveying, secondary powder selection, and finished product packaging, focusing on the largescale production field of nonmetallic mineral ultrafine powder processingCalcium carbonate ultrafine grinding mill is a kind of high efficiency milling equipment, mainly used to process nonmetallic ores +17 [ protected]Calcium Carbonate Ultrafine Grinding MillScrew conveyor: suitable for conveying finegrained and powdery materials, such as activated lime powder Advantages of Hongji active lime production line High output: It is suitable for largescale activated lime production lines A lime rotary kiln with a daily output of 2,200 tons has been put into productionActive Lime Production Line Hongji Mining Machinery2021年9月13日 The limestone ultrafine mill machine is a highly efficient industrial grinding mill It can grind limestone into a fine powder (1503000 mesh), and the fineness can be adjusted freely In addition, it can also grind 100+ kinds of nonmetallic minerals with Mohs hardness less than 6, such as calcium carbonate, talc, calcite, carbon black, dolomite, mica, etcLimestone Ultrafine Mill Machine SBM Ultrafine Powder

Calcium Carbonate Production Line MadeinChina

China Calcium Carbonate Production Line wholesale Materials: Calcium Carbonate 1 / 6 Favorites Complete Set White Limestone Calcium Carbonate Grinding Mill Production Line/Raymond Mil US$ 90009444 / Set 1 Set (MOQ) Shanghai DingBo Heavy Industry Machinery Co, LtdThe calcium carbonate grinding production line is an efficient, stable, and reliable production line with wide application prospects By using advanced equipment and technology, this production line is able to produce highquality calcium carbonate powder to meet the needs of different industries At the same time, the production line also has the advantages of energy Calcium Carbonate Grinding Production Line TAYMACHINERYThe calcium carbonate grinding production line is an efficient, stable, and reliable production line with wide application prospects By using advanced equipment and technology, this production line is able to produce highquality calcium carbonate powder to meet the needs of different industries At the same time, the production line also has the advantages of energy Calcium Carbonate Grinding Production Line TAYMACHINERYVarious calcium carbonate powder production capacity available According to customer’s needs, Daswell can offer you tailored solution with different calcium carbonate production capacity A calcium carbonate production line can produce finished ground calcium carbonate powder in different particle sizes for different applicationsCustomize Suitable Calcium Carbonate Plant DASWELL

How to set up a calcium carbonate ultrafine grinding production line?

2024年3月26日 Calcium carbonate is an important industrial raw material with a wide range of applications With the development of economy, the demand for calcium carbonate will continue to grow Therefore, the establishment of a calcium carbonate ultrafine grinding production line has broad market prospectsThe bulk material of calcium carbonate is crushed by the crusher to the incoming fineness (15mm50mm) which can enter the mill Second stage: milling The crushed calcium carbonate small material is sent to the silo through the hoist, and then uniformly and quantitatively fed into the mill grinding chamber through the vibrating feeder for grindingcalcium carbonate grinding mill, calcium carbonate machine, calcium 2021年7月22日 The production process of calcium carbonate can be roughly divided into two links: crushing and grinding Calcium carbonate crushing process: 1 Large pieces of calcium carbonate are evenly fed into a broken (jaw crusher) by a vibrating feeder through the silo for coarse crushingWhat equipment does the calcium carbonate powder production line 2021年12月20日 The Importance of Calcium Carbonate Calcium carbonate (CaCO3) comprises more than 4% of the earth’s crust and is found worldwide Its most common natural forms are chalk, limestone, and marble (produced by the sedimentation of small fossilized shellfish, snails, and coral over millions of years)Calcium Carbonate Manufacturing Process and Equipment

Calcium Carbonate Grinding Mill Powder Modify SBM

2022年5月5日 Calcium carbonate grinding mill is an efficient industrial ultrafine powder mill It can grind calcium carbonate into fine and superfine powder(1503000mesh) SBM is China’s famous calcium carbonate grinding mill manufacturer Its selfdeveloped HGM series ultrafine grinding mills and CLUM series ultrafine vertical roller mills are the most 2023年11月21日 A ground calcium carbonate production line typically involves several stages, including mining, crushing, grinding, and classification What Is Ground Calcium Carbonate? Ground calcium carbonate (GCC) is a type of calcium carbonate that is obtained by mechanically grinding and crushing natural calcite, limestone, chalk, marble , or other sourcesGround Calcium Carbonate Production LineA calcium carbonate production line can produce finished ground calcium carbonate powder in different particle sizes for different applications Both dry grinding and wet grinding are available A grinder or grinding mill is the core equipment for a calcium carbonate grinding plant, which can largely determine the fineness of the end productCalcium Carbonate Powder Production Line – Powder Equipment