Limestone grinding retarder

Resistance to Grinding and Cement Paste Performance of Blends

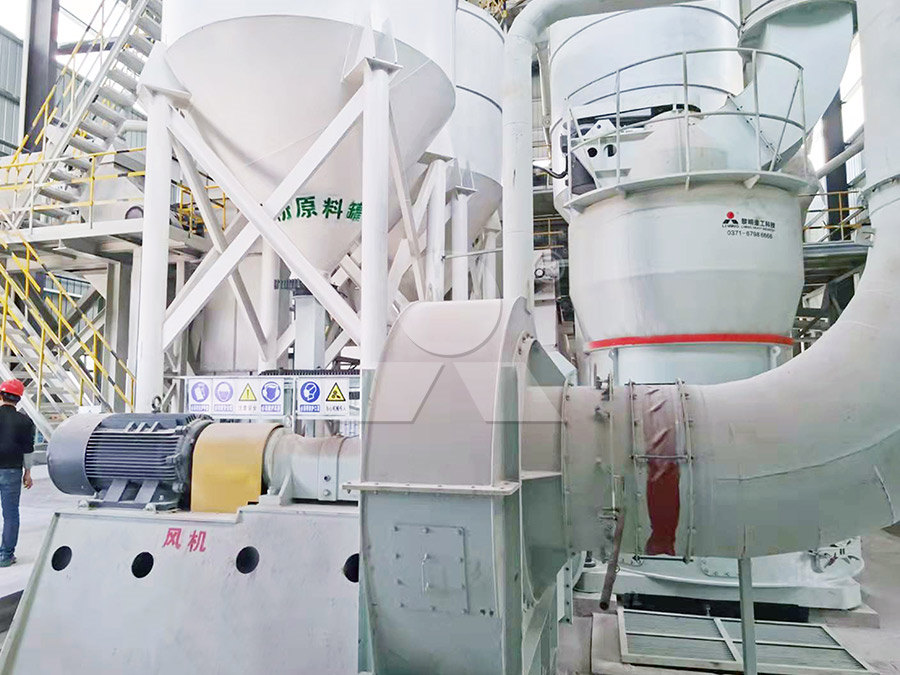

Figure 2 shows the XRD diffractograms and Table 1 the summary of the XRF analysis for the three raw materials studied The spectrum for limestone shows a strong single peak induced by the presence of calcite (CaCO3) characteristic of this material XRF analysis (Table S1) for this material confirms the presence of calcium 展开2018年8月30日 Incorporating superfluous fine limestone powder or coarse limestone powder increases the porosity of cementbased materials due to dilution effect The chemical effect of A review on use of limestone powder in cementbased materials The grinding aid facilitates size reduction so that the mill has to apply less grinding power without hurting any of the properties of the resulting cement The present research work aimed to EFFECT OF GRINDING AIDS ON CEMENT PROPERTIES AND Introduction A Limestone Grinding Mill Plant is a facility designed to process limestone into fine powder for various applications Limestone is a sedimentary rock primarily composed of calcium carbonate (CaCO₃) and is widely used in industries such Limestone Grinding Mill Plant TAYMACHINERY

Cement Clinker Calcination in Cement Production

Raw Materials Crushing, Storing and Grinding Clinker calcination is the most crucial part of the whole process of cement manufacturing At this stage, ground raw materials will be sent into the cement kiln and be heated at a high 2024年1月29日 As limestone powder has numerous applications across various industries, selecting the appropriate limestone grinding machine is essential The choice depends on several factors Firstly, it's important to clarify your processing requirements, including the desired fineness of the powder, production capacity, and quality standardsHow to choose limestone grinding mill? SANDMINE2000年11月1日 Cement plants are being built on or close to a limestone quarry, so that the practice of limestone grinding with clinker is obviously cheap Limestone dust, which is produced in quarrying operations, Limestone as a retarder and filler in limestone blended cement CeramSilik, 39 (1995), pp 1519 View in Scopus Google Scholar [4]Limestonefilled pozzolanic cement ScienceDirect2023年10月19日 Clinker is a critical component in the production of cement and forms the intermediate product during the cement manufacturing process It can be best described as a nodular material, usually grayish in color, which is produced by sintering limestone and aluminosilicate materials such as clay at high temperatures in a cement kilnClinker Grinding Techniques in Cement Manufacturing JM

Limestone Quarrying and Processing: A LifeCycle Inventory

Limestone is often produced with a natural surface, but finishes can be applied In such cases, often a polished or honed finishing is given to limestone products, but a variety of other finishes are also common Polishing and honing are manually and/or mechanically accomplished through the 2024年1月18日 Limestone has been widely used in human civilization history due to its wide distribution and easy lime, and carbide and is an essential flux limestone in the metallurgical industry Highquality limestone, after ultrafine grinding, is widely used in the production of paper, rubber, paint, coatings, pharmaceuticals, cosmetics How to choose a limestone grinding mill SANDMINEHOME > APPLICATIONS > MINERALS > LIMESTONE GRINDING Limestone Grinding The main application for limestone is as hydrated lime (calcium hydroxide) for mortar or plaster preparation On a smaller scale, lime is additionally used as a fertilizer, for wastewater treatment or as an additive in the food industry (for example as a neutralizing agent or acidityLIMESTONE GRINDING Bauermeister Size Reduction Equipment2021年2月1日 In this study mortars have been produced using ordinary Portland cement (CEM I – 325) and limestone cement with 15% limestone addition (CEM II/ALL – 325)(PDF) Optimization of Gypsum Composition Against Setting Time

.jpg)

Limestone Grinding Mill That You Need To Know Mortar Plant

2023年9月19日 Limestone grinding mill Material: Limestone Finished product particle size: 01730044mm Processing capacity: 8176t/shift Applicable materials: calcium carbonate crushing processing, gypsum powder processing, power plant desulfurization, nonmetallic ore pulverizing, coal powder preparation, etc Main limestone grinding machines Vertical roller Grinding requires a thorough understanding of limestone's natural properties and is a job for professionally trained technicians We offer services to both private and commercial clients with our broad client base ranging from small houses to large shopping complexesLIMESTONE GRINDING STONE RESTORATION2023年2月15日 Besides, limestone (80% to 90%, mass fraction, the same below), clay (10% to 15%), and iron ore powder (1% to 2%) are also applied in the cement manufacturing process To control the setting rate, after the Gypsum Is Essential and Necessary to Cement Fote 2020年9月10日 For limestone particles coarser than cement, there was a decrease in particle packing and specific surface area This reduced the ability of the paste to resist shear, thus explaining the reduced yield stress When fine limestone powder (07 and 03 µm) was used as replacement and OPC, there was increase in yield stress and plastic viscosityA study on fresh properties of limestone calcined clay blended

.jpg)

Limestone Mills Williams Crusher

Williams Direct Injection Roller Mills are used as limestone grinding machines and can grind to very exact particle sizes that are required for efficient SO2 removal These limestone mills are designed to operate at 3 to 4 PSI (02 to 03 bar) and 250°F (120°C) to inject the limestone directly into the Circulating Fluidized Bed (CFB), thus eliminating costly material handling, Limestone ultrafine grinding mill can process fine limestone powder, fineness: 1503000 mesh adjustable It has stable operation, good performance +17 [ protected] language >Shibang Industry Technology Group, Shanghai Ultrafine Powder Tech Co, Ltd Home; About Us; ProductsLimestone Ultrafine Grinding Mill2022年7月9日 Limestonegypsum Wet Desulfurization Wastewater Shanshan Zhang, WU Qiaoling, JIN Yinjia Study on desulfurized gypsum used as cement retarder Jianmei Zhou* School of Chemistry and Chemical Engineering, and use it for standby after grinding The desulfurized gypsum is heat treated at 50℃, 80℃ and 110℃ respectivelySVXPXVHGDVFHPHQW Limestonegypsum Wet Desulfurization 2023年3月1日 Concrete has ruled the construction sector for more than one century with the production rate rising from 15 billion tons in 2000 to over 3 billion tons in 2012 and over 6 billion tons in 2022 [1, 2]The consumption of concrete is estimated to amount to over 18 billion tons annually by 2050 [3]As the most important component of concrete, cement has established its Recent progress and technical challenges in using calcium

.jpg)

Limestone Grinding Mill MadeinChina

The Limestone Grinding Mill is a premium choice in the Mining Mill categoryTo ensure a supplier's authenticity in China, conduct thorough research, check for certifications, and request client references Visiting the production facility and observing the manufacturing process firsthand can also provide valuable insightsGypsum is one of the additive raw materials added to the clinker grinding process that regulate the binding time of cement or commonly known as a retarderEffect of gypsum on the setting time ResearchGate2013年1月1日 In their experiment, they obtained the fillers by grinding limestone, dolomite, and basalt gravel to the fineness of 1150–1300, 3700–3980, T Mohamed, Limestone as a retarder and filler in limestone blended cement Ceramics—Silikaty 39(1), 15–19 (1995) Google ScholarLimestone SpringerLink2023年5月15日 A limestone grinding mill is a machine that grinds and powderizes limestone It is very useful in the manufacture of cement, glass, steel and other industrial products that require finely ground limestone Limestone What is Limestone Grinding Mill SBM Mill Crusher

EnergyModel and Life CycleModel for Grinding

2022年5月22日 Fine and ultrafine grinding of limestone are frequently used in the pharmaceutical, chemical, construction, food, and cosmetic industries, however, research investigations have not yet been published on the it functions as an accelerator or a retarder When added at 002 % to Portland cement, TEA accelerates the setting process, but at 025 %, it mildly retards it grinding aids on the fine grinding of limestone, quartz and Portland cement clinker, Powder Technol, 67, 3, EFFECT OF GRINDING AIDS ON CEMENT PROPERTIES AND GRINDING 2022年4月20日 Or further grinding to form limestone powder, which is widely used in building materials, highways, metallurgy, chemical industry and other industries +17 [ protected] language >Shibang Industry Technology Group, Shanghai Ultrafine Powder Tech Co, Ltd Home; About Us;Limestone crushing and grinding production line SBM Ultrafine When grinding, it has a grinding effect on clinker and other mixed materials, make the cement with much more fine particles and a significantly larger specific surface Due to these two factors, when used as a retarder, the performance of natural gypsum is somewhat inferior to desulfurized gypsum Use desulfurization gypsum as cement retarderDesulfurization gypsum uses and properties take it as cement retarder

.jpg)

Overview of cement grinding: fundamentals, additives, technologies

2017年5月19日 Grinding is an essential operation in cement production given that it permits to obtain fine powder which reacts quickly with water, sets in few hours and hardens over a period of weeks i) During grinding, a small quantity, about 3 to 4 percent, of gypsum is added The gypsum controls the initial setting time of cement If gypsum is not added, the cement would set as soon as water is added The gypsum acts as a retarder and it delays the setting action of cementCement Manufacturing Process Civil Engineering Blog2021年9月13日 The limestone ultrafine mill machine is a highly efficient industrial grinding mill It can grind limestone into a fine powder (1503000 mesh), and the fineness can be adjusted freely In addition, it can also grind 100+ kinds of nonmetallic minerals with Mohs hardness less than 6, such as calcium carbonate, talc, calcite, carbon black, dolomite, mica, etcLimestone Ultrafine Mill Machine SBM Ultrafine Powder In this investigation, four blended cement pastes were made from Portland cement and limestone by using the suitable water of consistency of each paste The influence of limestone replacement was studied through the determination of nonevaporable water content, free lime content, total porosity, compressive strength and pH value for each blended cement paste The blended Limestone as a retarder and filler in limestone blended cement

Use of Limestone Powder (LSP) in Concrete in GCC Region

2016年11月25日 Limestone powder (LSP) is a fine material results from grinding the limestone rocks Limestones are sedimentary rocks primarily of calcium carbonate Sign in to view more contentIntroduction A Limestone Grinding Mill Plant is a facility designed to process limestone into fine powder for various applications Limestone is a sedimentary rock primarily composed of calcium carbonate (CaCO₃) and is widely used in industries such Limestone Grinding Mill Plant TAYMACHINERYRaw Materials Crushing, Storing and Grinding Clinker calcination is the most crucial part of the whole process of cement manufacturing At this stage, ground raw materials will be sent into the cement kiln and be heated at a high Cement Clinker Calcination in Cement Production 2024年1月29日 As limestone powder has numerous applications across various industries, selecting the appropriate limestone grinding machine is essential The choice depends on several factors Firstly, it's important to clarify your processing requirements, including the desired fineness of the powder, production capacity, and quality standardsHow to choose limestone grinding mill? SANDMINE

.jpg)

Limestonefilled pozzolanic cement ScienceDirect

2000年11月1日 Cement plants are being built on or close to a limestone quarry, so that the practice of limestone grinding with clinker is obviously cheap Limestone dust, which is produced in quarrying operations, Limestone as a retarder and filler in limestone blended cement CeramSilik, 39 (1995), pp 1519 View in Scopus Google Scholar [4]2023年10月19日 Clinker is a critical component in the production of cement and forms the intermediate product during the cement manufacturing process It can be best described as a nodular material, usually grayish in color, which is produced by sintering limestone and aluminosilicate materials such as clay at high temperatures in a cement kilnClinker Grinding Techniques in Cement Manufacturing JM Limestone is often produced with a natural surface, but finishes can be applied In such cases, often a polished or honed finishing is given to limestone products, but a variety of other finishes are also common Polishing and honing are manually and/or mechanically accomplished through the Limestone Quarrying and Processing: A LifeCycle Inventory2024年1月18日 Limestone has been widely used in human civilization history due to its wide distribution and easy lime, and carbide and is an essential flux limestone in the metallurgical industry Highquality limestone, after ultrafine grinding, is widely used in the production of paper, rubber, paint, coatings, pharmaceuticals, cosmetics How to choose a limestone grinding mill SANDMINE

LIMESTONE GRINDING Bauermeister Size Reduction Equipment

HOME > APPLICATIONS > MINERALS > LIMESTONE GRINDING Limestone Grinding The main application for limestone is as hydrated lime (calcium hydroxide) for mortar or plaster preparation On a smaller scale, lime is additionally used as a fertilizer, for wastewater treatment or as an additive in the food industry (for example as a neutralizing agent or acidity2021年2月1日 In this study mortars have been produced using ordinary Portland cement (CEM I – 325) and limestone cement with 15% limestone addition (CEM II/ALL – 325)(PDF) Optimization of Gypsum Composition Against Setting Time 2023年9月19日 Limestone grinding mill Material: Limestone Finished product particle size: 01730044mm Processing capacity: 8176t/shift Applicable materials: calcium carbonate crushing processing, gypsum powder processing, power plant desulfurization, nonmetallic ore pulverizing, coal powder preparation, etc Main limestone grinding machines Vertical roller Limestone Grinding Mill That You Need To Know Mortar Plant