What is the board pressed after crushing cotton stalks called

PARTICLE BOARDS FROM COTTON STALK Introduction

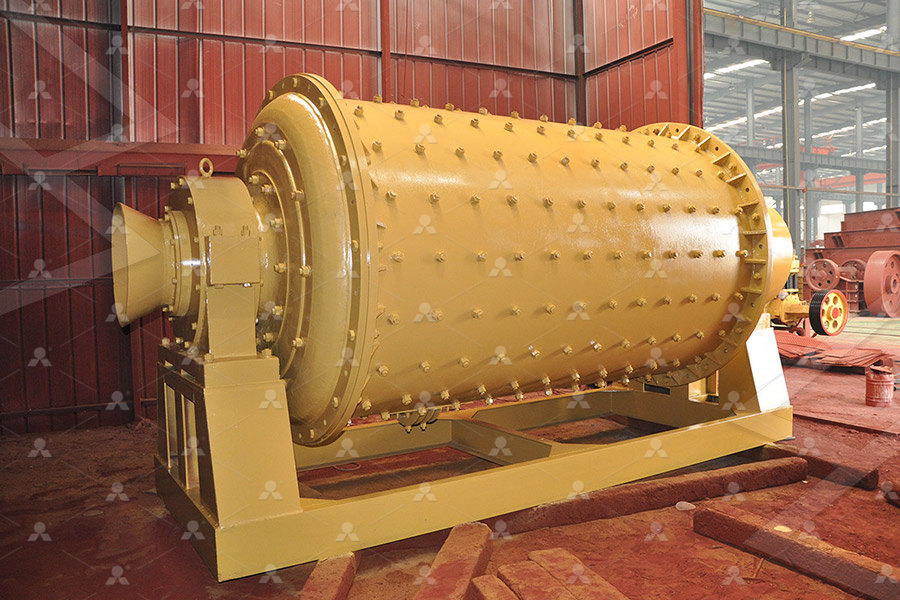

Pressing the mat between heated platens of a hydraulic press for specific time and pressure The board thus made is cooled to attain dimensional stability and then cut to the desired size2019年7月26日 Cotton stalk (CS) plant residue left in the field following harvest must be buried or burned to prevent it from serving as an overwintering site for insects such as the pink bollworm (PBW)(PDF) Bioenergy Recovery from Cotton Stalk2020年8月27日 Particleboards manufactured from four different opening particle sizes (6, 8, 10, and 20 mm) using an emulsifiable polymeric isocyanate adhesive (eMDI) were investigated (PDF) Homogenous Particleboard Made from Whole Cotton 2004年3月1日 In this study, water absorption, thickness swelling, bending strength, and internal bond properties of particleboards produced with cotton stalks at various resin addition levels (PDF) Some properties of particleboards made from cotton stalks

.jpg)

Bioenergy Recovery from Cotton Stalk IntechOpen

2019年1月16日 This chapter reviews potential energy generation from cotton stalks through combustion, hydrothermal carbonization, pyrolysis, fermentation, and anaerobic digestion Raw material of the particle board production line after chipping and sifting treatment will be conveyed into chip silo for transit storage Then the chip will be conveyed into flaker for flake Wood/reed/cotton stalks based particle board/Chipboard making 2007年9月10日 This plant is meant to demonstrate the utilization of cotton plant stalks mainly and other related biomass to prepare particle boards of 4’x3’ size in a three day light hydraulic Cotton Plant Stalk – An Alternate Raw material to Board Industry2022年10月7日 Kargarfard and Latibari developed the particle boards which met the standards of EN specifications using cotton stalks residues by giving 2 or 4% resin dosage gradients Technological Advancement in Harvesting of Cotton Stalks to

Some properties of particleboards made from cotton stalks

2004年1月23日 In order to obtain the aimed board thickness, the press can be operated at higher pressure and temperature in the production of cotton stalks particleboard As a result of In the open press, there is little information about fiberboards obtained from cotton stalks using the dry process The greatest problems in the processing of many species of annual plants A Technology for Production of Fiberboards Based on Cotton Stalks2022年10月7日 The cultivation of cotton produces about 2–3 tonne of residues per hectare after harvesting Uprooting and disposal of such a huge amount of cotton residues have become a serious problem In this review, different technologies developed for clearing standing cotton stalks from the field, performances of available technologies, limitations, and technological gap Technological Advancement in Harvesting of Cotton Stalks to 2007年9月10日 Cotton stalks were stored in different forms such as whole cotton stalks and chips Samples collected at different intervals were analysed for chemical composition to assess the deterioration if any in quality during storage The cotton stalks as is and in chipped form were kept in open and also inside the shedCotton Plant Stalk – An Alternate Raw material to Board Industry

.jpg)

Fibers from Cotton Stalks SpringerLink

2014年10月23日 In addition to the seed from which cotton fibers are harvested, cotton plants consist of stalks and leaves that are left as byproducts, equivalent to 3–5 times the weight of the cotton fiber produced Cotton stalks consist of an outer bark (20 % by weight of the stalk) and inner pith The outer bark is fibrous and could be utilized as a 2015年3月11日 The last post looked primarily at planting and harvesting cotton After creating all that fluffy white goodness, what comes The ginned fiber, now called lint, is pressed together and made into dense bales weighting about 500 pounds To determine the value of cotton, samples are taken from each bale and classed according to Cotton — What Happens After Harvest? Catbird Quilt StudioThe cage of loading machine will send the mat into multiopening hot press for pressing and the pressed raw board will be pushed into unloading machine by tray of loading car 25 Cooling and trimming section Raw board in the unloading machine will be sent to infeed roller conveyor by unloading conveyor, and then into star cooler for coolingWood/reed/cotton stalks based particle board/Chipboard SN The proposed system is based on the concept of cutting and crushing of cotton stalks The concept of cutting and crushing of cotton stalks after yielding of cotton is focused Present invention relates generally to Mechanical Engineering field and more particularly to Agricultural component The said invention focuses on the concept of DESIGN AND FABRICATION OF COTTON STALKS CUTTING AND CRUSHING

The Story of Cotton How Cotton is Ginned and Marketed

Today, nearly all cotton is stored in modules, which look like giant loaves of bread Modules allow the cotton to be stored without loosing yield or quality prior to ginning Specially designed trucks pick up modules of seed cotton from the field and move them to the gin Modern gins place modules in front of machines called module feeders2023年9月14日 Another method of producing bamboo fiber is by using a mechanical process called "retting" In this process, the cellulose pulp is mechanically pressed and combed to remove any impurities and create a smoother, more refined fiber Once the bamboo fiber is produced, it can be dyed and woven into various textiles and fabricsUnderstanding The Benefits Of Bamboo Fiber: A Sustainable And 2019年7月26日 The cultivation of cotton produces about 2–3 tonne of residues per hectare after harvesting Uprooting and disposal of such a huge amount of cotton residues have become a serious problem(PDF) Bioenergy Recovery from Cotton Stalk ResearchGateThey also found that crystallinity values (398, 403, 416, 427, 448, and 456%) were less than cellulose of flax, cotton, and kenaf fibers (70, 65, and 60%, respectively) AbdelHalim extracted cellulose from sugarcane bagasse by alkaline treatment with sodium hydroxide, followed by delignification/bleaching using sodium chlorite/hexamethylenetetramine solution [ 44 ]Sugarcane bagasse A source of cellulosic fiber for diverse

Cotton Seed Size – What is the “Fuzz” all About?

species in the cotton genus (Gossypium L), four have been domesticated from wild perennial plants to an annual crop (Brubaker et al, 1999; Lee and Fang, 2015; Wendel and Cronn, 2003) Gossypium hirsutum (also known as Upland cotton) is the most adapted, studied, and widely cultivated cotton species representing2023年6月19日 to simulate the cutting and crushing process for cotton stalks based on finite element simulations with ANSYS/LSDYNA In this study , the cutting and crushing mechanisms of cotton stalks are Simulation Research on Cotton Stalk Cutting and 2020年11月5日 After being separated inside the harvester, the resulting fiber, called seed cotton, is directed separately into a basket A cotton picker pulls cotton from the open bolls, which is pressed into 480pound bales The How is cotton harvested? – Texas Farm Bureau – 2023年8月19日 The good news for corn growers is there is now a better way to manage your remaining corn stalks after harvest It’s easier than baling and using stalks for animal bedding It’s healthier for your soil than tilling Plus, it produces impressive return on What Should I do with my Corn Stalks After Harvest?

What Is Ginning Cotton Knowing Fabric

2023年7月8日 Once the cotton is dry, it’s ready to be ginned The ginning process involves separating the cotton fibers from the seeds This is done using a machine called a gin, which uses a combination of saws and brushes to pull the cotton fibers away from the seeds After the cotton has been ginned, it’s ready to be baled and shipped to textile millsHowever, these crushed stalks can be saved and made into other items before they get thrown away What kind of residue is left after crushing sugar cane? Bagasse (/bəˈɡæs/ bəGAS) is the fibrous matter that remains after sugarcane or sorghum stalks are crushed to extract their juiceWhat is the leftover of sugarcane called? WiseAnswer2019年1月16日 Cotton stalk (CS) plant residue left in the field following harvest must be buried or burned to prevent it from serving as an overwintering site for insects such as the pink bollworm (PBW) This pest incurs economic costs and detrimental environmental effects However, CS contains lignin and carbohydrates, like cellulose and hemicelluloses, which can be converted Bioenergy Recovery from Cotton Stalk IntechOpen2011年2月21日 The cultivation of cotton produces about 2–3 tonne of residues per hectare after harvesting Uprooting and disposal of such a huge amount of cotton residues have become a serious problemThe performance of corn and cotton stalks for medium

制粉项目-2023.11.17.jpg)

Agriculture III and IV ICSE Class 10 Geography Notes

2021年4月19日 The cotton crop after harvesting goes through the following process1 The freshly picked cotton is pressed into large modules 2 The cotton gin mechanically separates the fibres from the seed and turns it into ginned cotton also called lint 3 This process of separation of cotton fibre from the cotton seed is called Ginning 42023年1月16日 The precious grain that fills their bulk tanks isn’t the only valuable part of the wheat plant The stalks left behind the combine have a variety of uses as well Those wheat stalks are commonly called straw; a term you’ve undoubtedly heard before Wheat straw is more than just bedding for animals, a common way many people see it usedWhat is wheat straw used for? Washington Wheat Foundation2013年6月1日 Selfbonding of airdried undebarked cotton stalks during hot pressing in a closely fitting mold was studied Advanced boardlike green nanocomposites from ground undebarked cotton stalks were (PDF) Advanced binderless boardlike green 2015年10月17日 This biomass left in the field after picking seed cotton is called cotton stalks (Sidhu, 2015) Globally more than 100 million tons of cotton stalk is produced annually (Reddy and Yang, 2009;Li et Engineering properties of cotton stalks (Gossypium

Particle Board vs MDF: What Is the Difference?

Particle board is slightly more fireresistant with a FlameSpread Rating (FSR) of 116178 MDF measures in at 167 Safety Both MDF and particle board are manufactured with formaldehydebased resins Formaldehyde is a known 2012年2月21日 The cleaning of the lint cotton After the preginning treatment, seed cotton is ready for seed extraction The cotton gin separates seeds and removes the “trash main purpose of ginning process is to separating the seed from the fibers in such a way that it protects the seed from crushing and cause minimum fiber fragmentationCotton Ginning Process: Objects, Types and Faults Textile Learner2021年3月4日 Tang et al [15] designed cotton stalks plucking harvester using the principle of the pushing and pulling action of the tooth knife Chen et al [16] using the principle of the tine disc clamping (PDF) Crop residue management in cotton ResearchGateand bale about 230,000 kilograms of cotton in one day THE GINNING PROCESS The seed cotton arrives at the gin in round bales or modules The first step in the ginning process is where the cotton is vacuumed into tubes that carry it to a dryer Cotton must be ginned with a moisture level of 5% The cotton is dried outCHAPTER 7

Cotton Harvesting Methods Learn How Cotton is Picked

2019年5月30日 Raw cotton fibers are delivered to a cotton processing facility for ginning after defoliation Ginning is the mechanical removal of seeds, leaves, twigs, and other 'trash' from raw cotton strands The end result is supersoft cotton fibers known as "white gold," which are then dried and pressed into bales (lint)2016年8月22日 First, winemakers decide whether or not to crush grapes “whole cluster,” wine speak for the stems intact In red and orange wines, stems add extra tannin and structure to developing winesThe Crush Is The First Step In Turning Grapes Into Wine2023年4月2日 In a global perspective, source materials such as straw from annual and perennial plants (eg, rape, rice, or rye, miscanthus, sisal), waste products from such plants after their industrial processing (flax, rape and hemp shives, bagasse, cotton stalks) as well as oil palms, rubber trees (Ficus elastica), bamboo, peanut shells as well as recycling paper [25,26,27] ParticleBased Materials SpringerLink2004年3月1日 In the case of harvest residues, particleboard panels were studied more than any other panel type (Table 7) Harvest residues from castor [158], cotton [124], eggplant [128], pepper [132], canola (PDF) Some properties of particleboards made from cotton stalks

.jpg)

Technological Advancement in Harvesting of Cotton Stalks to

2022年10月7日 The cultivation of cotton produces about 2–3 tonne of residues per hectare after harvesting Uprooting and disposal of such a huge amount of cotton residues have become a serious problem In this review, different technologies developed for clearing standing cotton stalks from the field, performances of available technologies, limitations, and technological gap 2007年9月10日 Cotton stalks were stored in different forms such as whole cotton stalks and chips Samples collected at different intervals were analysed for chemical composition to assess the deterioration if any in quality during storage The cotton stalks as is and in chipped form were kept in open and also inside the shedCotton Plant Stalk – An Alternate Raw material to Board Industry2014年10月23日 In addition to the seed from which cotton fibers are harvested, cotton plants consist of stalks and leaves that are left as byproducts, equivalent to 3–5 times the weight of the cotton fiber produced Cotton stalks consist of an outer bark (20 % by weight of the stalk) and inner pith The outer bark is fibrous and could be utilized as a Fibers from Cotton Stalks SpringerLink2015年3月11日 The last post looked primarily at planting and harvesting cotton After creating all that fluffy white goodness, what comes The ginned fiber, now called lint, is pressed together and made into dense bales weighting about 500 pounds To determine the value of cotton, samples are taken from each bale and classed according to Cotton — What Happens After Harvest? Catbird Quilt Studio

.jpg)

Wood/reed/cotton stalks based particle board/Chipboard

The cage of loading machine will send the mat into multiopening hot press for pressing and the pressed raw board will be pushed into unloading machine by tray of loading car 25 Cooling and trimming section Raw board in the unloading machine will be sent to infeed roller conveyor by unloading conveyor, and then into star cooler for coolingSN The proposed system is based on the concept of cutting and crushing of cotton stalks The concept of cutting and crushing of cotton stalks after yielding of cotton is focused Present invention relates generally to Mechanical Engineering field and more particularly to Agricultural component The said invention focuses on the concept of DESIGN AND FABRICATION OF COTTON STALKS CUTTING AND CRUSHING Today, nearly all cotton is stored in modules, which look like giant loaves of bread Modules allow the cotton to be stored without loosing yield or quality prior to ginning Specially designed trucks pick up modules of seed cotton from the field and move them to the gin Modern gins place modules in front of machines called module feedersThe Story of Cotton How Cotton is Ginned and Marketed2023年9月14日 Another method of producing bamboo fiber is by using a mechanical process called "retting" In this process, the cellulose pulp is mechanically pressed and combed to remove any impurities and create a smoother, more refined fiber Once the bamboo fiber is produced, it can be dyed and woven into various textiles and fabricsUnderstanding The Benefits Of Bamboo Fiber: A Sustainable And

(PDF) Bioenergy Recovery from Cotton Stalk ResearchGate

2019年7月26日 The cultivation of cotton produces about 2–3 tonne of residues per hectare after harvesting Uprooting and disposal of such a huge amount of cotton residues have become a serious problemThey also found that crystallinity values (398, 403, 416, 427, 448, and 456%) were less than cellulose of flax, cotton, and kenaf fibers (70, 65, and 60%, respectively) AbdelHalim extracted cellulose from sugarcane bagasse by alkaline treatment with sodium hydroxide, followed by delignification/bleaching using sodium chlorite/hexamethylenetetramine solution [ 44 ]Sugarcane bagasse A source of cellulosic fiber for diverse