Graphite manufacturing cold ling device report

.jpg)

A Shortened Process of Artificial Graphite Manufacturing for

3 天之前 Recently, due to the rapid increase in the demand for artificial graphite, there has been a strong need to improve the productivity of artificial graphite In this study, we propose a new 2021年1月28日 Reported data shows that carboncontaining composites could be manufactured using graphite powder, graphene, and carbon nanotubes by SLAlike 3D printing 10Novel hybrid method to additively manufacture denser This report provides a detailed literature review on the lifecycle inventory (LCI, or material and energy flows) for all four LIB anodes – natural and synthetic graphite, lithium, and silicon – LIB Anodes Final Document Argonne National LaboratoryGraphitization furnaces utilize heat generated by either electric current passing through the graphitizing material or induction heating Pyrolytic graphite is a form of graphite produced by GRAPHITE MANUFACTURING PROCESS IDCOnline

.jpg)

Manufacturing artificial graphite

Based on the properties deriving from the manufacturing methods and production stages, graphite (see box) may be used in various applications, such as: the manufacture of silicon, a critical This research work gives a detail description of designing a manufacturing process for expanded graphite based on the observation from patents and design a continuous production line for Design of manufacturing process and production line for 2021年12月22日 Understanding the formulation and manufacturing parameters that lead to higher energy density and longevity is critical to designing energydense graphite electrodes Formulation and manufacturing optimization of lithiumion raphite supply challenges: economic, security and climate consideration raw materials for the largescale deployment of lowcarbon technologies Graphite is a critical mineral for Graphite Supply chain challenges recommendations for a

Production techniques for graphite structures (left) isostatic

This study introduces two hybrid processes integrating an additive manufacturing technique with postprocessing treatments namely (i) Binder Jetting Printing (BJP) + Cold Isostatic Pressing2022年9月30日 Traditional methods of producing batterygrade graphite (high purity >99%) include processing naturally mined graphite or manufacturing synthetic graphite via the Prospective Life Cycle Assessment of Synthetic Graphite 2024年7月30日 It is still largely used for portable device batteries where battery lifetime requirement is less Tokai COBEX is a European company with more than 125 years of experience in the manufacturing of graphite products for a wide ‘New policies in Inner Mongolia may tighten synthetic graphite supply – report’, Mining Carbon footprint assessment of manufacturing of synthetic graphite 2020年10月29日 Natural graphite sheet (NGS) is compressible, porous, electrically and thermally conductive material that shows a potential to be used in fuel cells, flow batteries, electronics cooling systems Material properties and structure of natural graphite sheet

.jpg)

Graphite Market Size, Share, Forecast Industry

2024年11月11日 The global graphite market size is projected to grow from $780 billion in 2024 to $1335 billion by 2032, Request a Free sample to learn more about this report Graphite Market Growth Factors These are some of 2024年5月21日 Natural graphite: Supply constraints and geographic concentration The IEA report highlights that natural graphite, predominantly mined in China, faces substantial supply constraintsCurrently, China accounts for 80% of global production, but this share is expected to decrease to 70% by 2030 due to emerging producers in Mozambique, Madagascar, Canada, Natural and Synthetic Graphite in Battery ManufacturingThe Graphite Market is expected to reach USD 362 billion in 2024 and grow at a CAGR of 5% to reach USD 463 billion by 2029 Betterui New Materials Group Co Ltd, Shenzhen Xiangfenghua Technology Co Ltd, Shanghai Shanshan Technology Co Ltd, Syrah Resources Limited and Jiangxi Zichen Technology Co Ltd are the major companies operating in this marketGraphite Market Report Industry Trends, Size Forecast Analysisline for the manufacturing process The report covers two important part of the research, overall patent analysis and investigation on eight raw materials from different company From the patent analysis the design for manufacturing expanded graphite is completed withDesign of manufacturing process and production line for expanded graphite

GRAPHITE MANUFACTURING PROCESS IDCOnline

GRAPHITE MANUFACTURING PROCESS The process of synthetic graphite manufacturing consists of the following principal stages: Powder preparation Shape forming Baking Graphitization Pyrolytic graphite Powder preparation Raw materials for synthetic graphite fabrication (petroleum coke, pitch coke, carbon black, naturalWe report the synthesis of isotopicallylabeled graphite fi lms on nickel substrates by using coldwall chemical vapor deposition (CVD) During the synthesis, carbon from 12C and 13Cmethane was deposited on, and dissolved in, a nickel foil at high temperature, and a uniform graphite film was segregated from the nickelSynthesis of IsotopicallyLabeled Graphite Films by Cold2012年2月7日 Experimental XRD for coldcompressed graphite at two different pressures from Ref 7 and simulated XRD pattern for carbon (at 239 GPa) and graphite (at 137 GPa) The main characteristics of the proposed carbon are perfectly in agreement with the experimentally observed changesReuse PermissionsCrystal Structure of Cold Compressed Graphite Physical 2018年9月7日 Graphite formation in the solid state is both in ductile cast irons and in steels strongly promoted by high silicon contents above 3 wt% Si The matrix microstructure in austempered ductile iron can be further refined by secondary graphite if the austenitization, quench, and isothermal transformation into ausferrite are preceded by an austenitization at a Graphite Formation and Dissolution in Ductile Irons and Steels

.jpg)

StepbyStep: Exploring the Manufacturing Process of

2024年3月10日 Isostatic graphite is a kind of highperformance material obtained by a special process In the manufacturing process, the internal structure of the graphite material is refined and densified using isostatic Report Overview: IMARC Group’s report, titled “Graphite Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue,” provides a complete roadmap for setting up a graphite manufacturing plant It covers a comprehensive market overview to microlevel information such as unit operations Graphite Manufacturing Plant Report 2024: Setup CostThe Graphite Electrode Market is expected to reach 161 thousand kilotons in 2024 and grow at a CAGR of 355% to reach 192 thousand kilotons by 2029 ZHONGZE GROUP, Resonac Holdings Corporation, Fangda Carbon New Graphite Electrode Market Size Mordor Intelligence2023年12月13日 The compacted parts (”green compacts”) are heat treated (baked) in a baking furnace at 18402200°F(10001200ºC) in the absence of air The baking process, which is called carbonization, results in thermal decomposition (pyrolysis) of the binder into elementary carbon and volatile componentsGraphite manufacturing process SubsTech

Graphite Imerys

Graphite has a wide variety of properties and uses Prized for its electrical conductivity, thermal conductivity, softness, chemical inertness, heat resistance and lubricity, its applications range from high performance lithiumion batteries, alkaline batteries, conductive polymers, refractories or graphiterich solid lubricating film on the worn surface When the Cucoated graphite content exceeded 10 wt%, the dominant wear mechanism changed to mild abrasive wear, in contrast to the oxidative wear of the pure copper coating Keywords aluminum alloy antiwear coating copper–graphite coating lowpressure cold spraying solid lubricationLowPressure Cold Spraying of Copper–Graphite Solid Lubricating XRD Graphite Manufacturing CO,LTD 335 followers on LinkedIn Graphite Materials, Graphite Machining XRD Graphite was established in 2011 Since then has grown considerably and built up a XRD Graphite Manufacturing CO,LTD LinkedIn[13] [14] [15] Manufacturing 1 metric ton of graphite (in terms of graphite electrodes) consumes over 40 × 10 4 MJ of energy, with over 10 metric tons of CO 2 eq emissions 16,17 In short Bulk graphite: Materials and manufacturing process

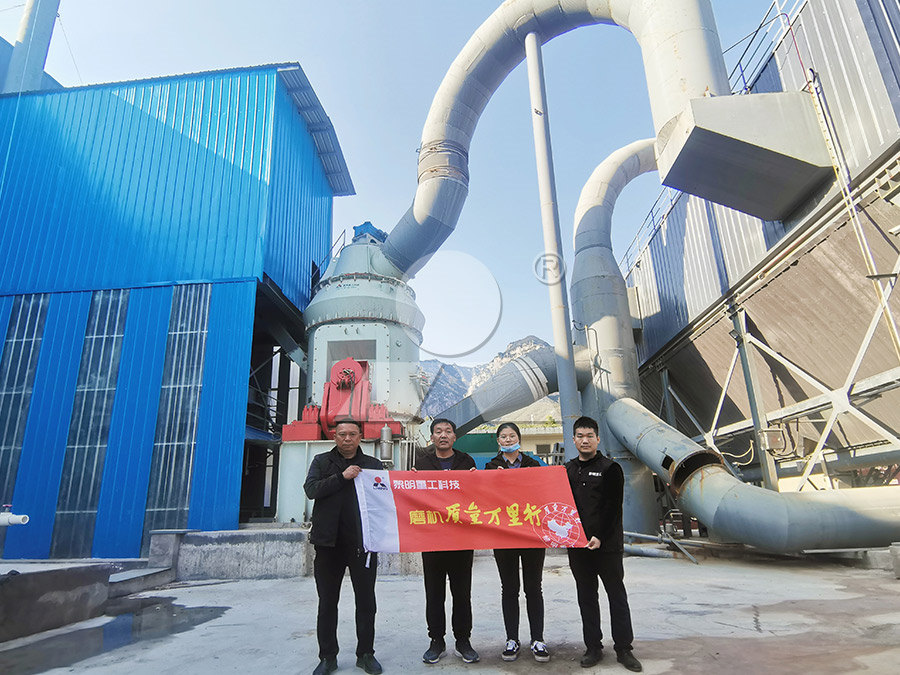

CFB石灰石脱硫剂制备——磨机公众号12.8 推送案例(8)53.jpg)

Reproducible graphene synthesis by oxygenfree chemical vapour

2024年5月29日 Chemical vapour deposition (CVD) synthesis of graphene on copper has been broadly adopted since the first demonstration of this process1 However, widespread use of CVDgrown graphene for basic THERMAL STRAPS THERMALLY CONDUCTIVE VIBRATION ISOLATION Thermal Straps, sometimes referred to as "Flexible Thermal Links," "Thermal Braids," or "Heat Straps," are passive heat transfer devices consisting of two or more end fittings ("terminals" or "lugs"), and a flexible conductive material connecting themThey transfer heat between two or more locations THERMAL STRAPS Techapps2009年11月1日 We report the synthesis of isotopicallylabeled graphite films on nickel substrates by using coldwall chemical vapor deposition (CVD) During the synthesis, carbon from 12C and 13Cmethane was (PDF) Synthesis of IsotopicallyLabeled Graphite The synthetic graphite manufacturing process includes numerous steps namely powder preparation, shape forming, Cold isostatic pressing is the powder compaction method conducted at room temperature and involving applying Graphite manufacturing process GAB Neumann

Design and manufacture of graphite components for 21st century

2022年1月1日 An objective of this research was to focus on highlighting the CS development in the US by ASTM International and ASME International and examine graphite component designer and manufacturer responsibilities to fulfil the requirements in the CS, which, in turn, may satisfy US licensing requirements set by NRC2024年4月9日 IMARC Goup’s report titled “Graphite Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue” provides a Graphite Manufacturing Plant Report 2024: Industry Trends2021年6月8日 Graphite One Inc has defined America’s largest highquality graphite deposit – Graphite Creek, situated on the Seward Peninsula about 60 kilometers north of Nome: A potential longlife source of supply for the second link in Graphite One’s advanced graphite materials supply chain—the company’s advanced material manufacturing plantHome Graphite OneThe invention discloses a method for manufacturing cold isostatic pressing formed graphite, which comprises the following: a step of primary roasting, which is to raise a temperature below 300 DEG C in three days at a speed of 50 DEG C per shift, keep the temperature when the temperature reaches 300 DEG C, raise the temperature from 300 DEG C to 600 DEG C in five CNA Method for manufacturing cold isostatic

Ultralow energy processing of graphite: a fasttrack journey

2022年12月1日 The current graphite manufacturing processes, apart from consuming a large amount of energy, they result in the emission of toxic gases due to the pyrolysis of the precursors Graphite layers are bonded together by vdW force [6] 2023年11月1日 Although the advantages of porous material aerostatic bearings are undisputed, orifice type aerostatic bearings are more widely adopted in commercial solutions, arguably because the orifice technology was developed earlier [7]Orifice type bearings are highly sensitive to orifice size and geometry which makes them expensive to manufacture and highly sensible Manufacturing and static performance of porous aerostatic 2019年4月25日 It is a challenge to obtain metalsolid lubricant composite coatings with good tribological performance by cold spraying due to the poor interfacial bonding between solid lubricants and metal matrix along with uncompacted microstructure of the resulted composite coatingsHere, we report the preparation of graphite reinforced copper based composite Microstructure and improved tribological performance of graphite2015年12月17日 Large area shows conditions used for bulk precursors such as graphite and glasslike carbon in, eg, Refs [112,173,497], while conditions below 1500 K were used in Ref [697] to transform carbon A review on the structure of coldcompressed graphite phase

Carbon footprint assessment of manufacturing of synthetic graphite

2024年7月30日 It is still largely used for portable device batteries where battery lifetime requirement is less Tokai COBEX is a European company with more than 125 years of experience in the manufacturing of graphite products for a wide ‘New policies in Inner Mongolia may tighten synthetic graphite supply – report’, Mining 2020年10月29日 Natural graphite sheet (NGS) is compressible, porous, electrically and thermally conductive material that shows a potential to be used in fuel cells, flow batteries, electronics cooling systems Material properties and structure of natural graphite sheet2024年11月11日 The global graphite market size is projected to grow from $780 billion in 2024 to $1335 billion by 2032, Request a Free sample to learn more about this report Graphite Market Growth Factors These are some of Graphite Market Size, Share, Forecast Industry 2024年5月21日 Natural graphite: Supply constraints and geographic concentration The IEA report highlights that natural graphite, predominantly mined in China, faces substantial supply constraintsCurrently, China accounts for 80% of global production, but this share is expected to decrease to 70% by 2030 due to emerging producers in Mozambique, Madagascar, Canada, Natural and Synthetic Graphite in Battery Manufacturing

.jpg)

Graphite Market Report Industry Trends, Size Forecast Analysis

The Graphite Market is expected to reach USD 362 billion in 2024 and grow at a CAGR of 5% to reach USD 463 billion by 2029 Betterui New Materials Group Co Ltd, Shenzhen Xiangfenghua Technology Co Ltd, Shanghai Shanshan Technology Co Ltd, Syrah Resources Limited and Jiangxi Zichen Technology Co Ltd are the major companies operating in this marketline for the manufacturing process The report covers two important part of the research, overall patent analysis and investigation on eight raw materials from different company From the patent analysis the design for manufacturing expanded graphite is completed withDesign of manufacturing process and production line for expanded graphiteGRAPHITE MANUFACTURING PROCESS The process of synthetic graphite manufacturing consists of the following principal stages: Powder preparation Shape forming Baking Graphitization Pyrolytic graphite Powder preparation Raw materials for synthetic graphite fabrication (petroleum coke, pitch coke, carbon black, naturalGRAPHITE MANUFACTURING PROCESS IDCOnlineWe report the synthesis of isotopicallylabeled graphite fi lms on nickel substrates by using coldwall chemical vapor deposition (CVD) During the synthesis, carbon from 12C and 13Cmethane was deposited on, and dissolved in, a nickel foil at high temperature, and a uniform graphite film was segregated from the nickelSynthesis of IsotopicallyLabeled Graphite Films by Cold

Crystal Structure of Cold Compressed Graphite Physical

2012年2月7日 Experimental XRD for coldcompressed graphite at two different pressures from Ref 7 and simulated XRD pattern for carbon (at 239 GPa) and graphite (at 137 GPa) The main characteristics of the proposed carbon are perfectly in agreement with the experimentally observed changesReuse Permissions2018年9月7日 Graphite formation in the solid state is both in ductile cast irons and in steels strongly promoted by high silicon contents above 3 wt% Si The matrix microstructure in austempered ductile iron can be further refined by secondary graphite if the austenitization, quench, and isothermal transformation into ausferrite are preceded by an austenitization at a Graphite Formation and Dissolution in Ductile Irons and Steels