Coal preparation workshop crusher

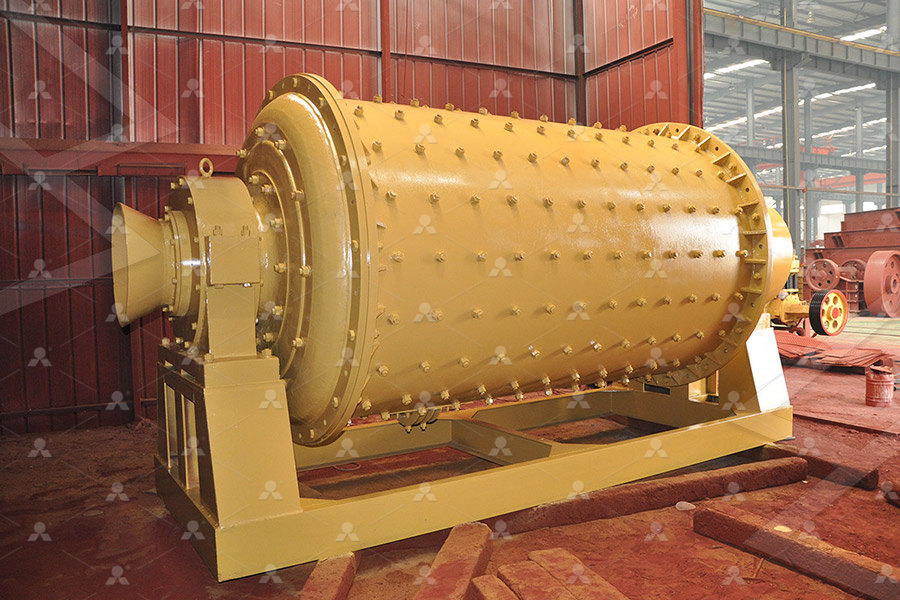

CFB石灰石脱硫剂制备64.jpg)

Enhancing Coal Preparation with Crushers and Sizers Equipment

Crushers, such as jaw crushers and impact crushers, are fundamental in the coal preparation process They reduce the size of the coal ore, making it easier to handle and process 2023年10月8日 To ensure that coal is not affected by overcrushing while achieving the required particle size and output requirements, FTM Machinery will help you choose the optimal coal crusher machine 1 Jaw crusher The jaw 6 Types of Coal Crusher: Which Is Best for Crushing My Our lab coke coal testing equipment include crushers, grinders, splitters mixers are used for sample prepping, particle sizing or hardness determinationsCoal Testing Equipment Gilson Co2015年7月1日 Rather than lockedcircuit crushing and grinding operations used for mineral processing, coal preparation plants often employ a single stage of lowenergy breakage Many A review of stateoftheart processing operations in coal

.jpg)

Coal Mining and Processing Methods The National

Runofmine coal must be crushed to an acceptable top size for treatment in the preparation plant Typical crushing and breaking devices are feeder breakers, rotary breakers, hammer mills, and roll crushers2019年10月23日 In introducing ramming technology, equipment in the coal preparation and coke sorting shops must be constructed or reconstructed With ramming, the moisture content of the Innovations in Coal Preparation and Coke SortingSTATUS OF COAL PREPARATION TECHNOLOGY IN CHINA Most of ROM coal produced is routed through CPP Fraction exported is fully washed CP industry enjoying greatest boom in STATUS OF COAL PREPARATION TECHNOLOGY IN CHINAcoal belt conveyor enters the main workshop or the coal storage silo, and its structural arrangement mainly in cludes the belt entrance layer connected with the coal conResearch on Structural Design of Coal Crusher House in Thermal Power

(PDF) Research on Structural Design of Coal Crusher

2020年7月24日 PDF This paper takes the specific characteristics of pulverized coal room in thermal power plant as the starting point,firstly, this paper analyzes Find, read and cite all the research Workshop; News News Xinjia News Rendering of coal preparation plant Coal preparation technology 2ZKX3673 Clean Coal Dewatering Screen Number of views: 1000 2PG70150 Series Tooth Roll Crusher Number of views: 1000 Keywords: TLLA Series of Vertical Scraper Discharge Centrifuge Number of views:Modular and intelligent coal preparation equipmentCoal preparation plant is a coal processing plant that include a series of processes: raw Raw coal is transported to crushing workshop by belt conveyor First, +50mm materials and extra large gangue enter the crusher and are crushed to – 50mm,Coal Preparation Plant Coal Preparation Process Coal WashingAfter coal is mined, it needs to be transported to and conveyed through a processing plant to prepare it for shipment and sale McLanahan’s line of Feeders can move coal from one aspect of the processing plant to another They feed material at a rate that matches the capacity of a crusher or conveyor beltCoal McLanahan

New Acland Coal Secondary Crusher Replacement)

ENAP’s scope was awarded a project to undertake the site installation of new McLanahan Secondary Crusher for Plant Two at the New Acland Coal Mine This scope also included the workshop fabrication of new chutes and structural modifications to suit the upgraded crusher There was one week of preparation work to complete site inductions andIntegrated Sample Preparation System Supplier, Hammer Crusher, Jaw Crusher Manufacturers/ Suppliers Jiangxi Guangming Intelligent Technology Co, Ltd Sign In Join Free For Most of our products have gained the unit recommendation of China Coal Department and Coal Science College Our General Manager, Integrated Sample Preparation System Manufacturer, Hammer Crusher注意:可根据客户需求提供不同的电压 供401xl破碎机使用的打孔型筛板Coal Crusher China Mainland/简体中文 Preiser ScientificCoal stockpile Coal stacker Coal reclaimer Coal needs to be stored at various stages of the preparation process, and conveyed around the CPP facilities Coal handling is part of the larger field of bulk material handling, and is a complex and vital part of the CPP Stockpiles provide surge capacity to various parts of the CPP ROM coal is delivered with large variations in Coal preparation plant Wikipedia

Hard coal preparation in a single stage crushing circuit for

The article concerned the problem of coal preparation for gasification purposes The main aim was to design the coal crushing circuit, which would produce the material within the particle size range between 05 and 5 mm The onestage crushing circuit crushing circuit reduces the overall coal size of the ROM coal so that it can be handled and processed with ease This coal is conveyed from the ROM silo to the coal preparation plant to wash, separate and stockpile the coal in grades to transport it to the market The primary crusher blocked on oversize material and suffered a breakdown thatCase Study PragmaWET COAL FEEDER PRIMARY AIR CRUSHER DRYER BYPASS DAMPER Figure 4 Ball Tube Mill Pulverizing System 8 Operate at system primary air temperatures below those historically used as normal The trend is toward classifier outlet temperatures of 125 OF away from 150 Fire and Explosion Prevention in Coal Pulverizing Systems2015年12月13日 A Review on Steam Coal –Sampling Preparation AIJRSTEM15806pdf improper mixing of constituents, due granulometr y HGI (in blended coals), feed rate and crusher typeA Review on Steam CoalSampling Preparation

Full article: A review of intelligent coal gangue separation

2023年11月6日 In Fig 1, the mined raw coal is transported by tram to the screening workshop, where the screened product is then placed in a fine ore binThe product on the screen is crushed by a jaw crusher to a qualified particle size and then deposited in a buffer ore bin The raw coal is then conveyed to the ore feeder through the bucket feeder and through the conveyor beltWe specialise in the design, manufacture, supply and installation of analytical and sampling preparation equipment, in particular for the coal mining industry Australian Designed Manufactured Our Australian designed and manufactured machines are also used by other industries that require equipment that will crush, grind, analyse, pulverize, size, hammer, Wallerby Mining Products Custom Made Mining Products2021年5月28日 KB Bradford drum crusher designed at th e KOMAG Institute of Mining Technology, presented in Figure 1, is the Polish equivalent of this type of equipment Figure 1 Drum crusher KB 3200 × 6000 (view and section) [20] Drum crusher s main component is a drum with a horizontal axis of rotation RotaSelective Crushing of RunofMine as an Important Part of the Hard Coal 2024年6月24日 Coal crushing machines are essential equipment in the coal preparation process, reducing raw coal into smaller particles suitable for further processing, transportation, and utilization The selection of an appropriate coal crushing machine depends on various factors, including the size of the raw coal, the required product size, the desired productionCoal crushing machine type and features

Study on Corrosion Wear and Protection of Coal Preparation

2023年1月12日 Due to the advantages of dense medium coal preparation, it has a wide range of applications and can be applied to the separation of different coal qualities Compared with other coal preparation methods, it has high separation accuracy for coal with large slime content or difficult to separate coal (2) Moving screen jig2015年7月1日 Coal preparation can be a costly portion of the raw material production chain, given the large throughput requirements and the variety of technologies needed to create a suitable product As a result, coal preparation requires carefully engineered processing plants which employ lowcost solid–solid and solid–liquid separation processesA review of stateoftheart processing operations in coal preparation (1) Crushing: The large pieces of coal are sent to the jaw crusher by the vibrating feeder for rough crushing, and the conveyor transports the coarsely crushed materials to the impact crusherThe impact crusher is suitable for medium or fine crushing to further dissociate clean coal (2) Screening: Thevibrating screen screens out three kinds of materials with different particle Coal Washing Process Plant JXSC MachineryTo do this, the entire upper part of the crusher had to be dismantled in advance, which was timeconsuming and costly The crusher segment design from thyssenkrupp Polysius now makes it easy to replace the crusher segments Crushing Technologies thyssenkrupp Polysius

Coal Sample Preparation Procedures Overview

2018年7月2日 The coal samples processed by roller crusher will not be excessively crushed or overheated The sample size is controlled by adjusting the clearance of the rolls XDSP300 is a kind of roller crusher produced by Our lab coke coal testing equipment include crushers, grinders, splitters mixers are used for sample prepping, particle sizing or Mixing Wheels are required in ASTM D2013 for laboratory preparation of certain coal samples Mixing wheels rotate samples of dry, granular materials to produce homogeneous test specimens This larger Coal Testing Equipment Gilson Co2020年3月21日 Size Grading of Coals for Sampling 031 Original Standard : 5 Size Groups Revised Standard : 3 Size Groups Name Nominal Size Run of Mine Coal 23 to 0 cm Coal Large 15 to 5 cm Coal small 5 to 0 cm Clause 032 Division of coal on ash content basis Earlier two groups Ash content 10% Since most Indian coal are >10% ,hence not necessary Coal quality sampling ; preparation as per indian standard2021年2月28日 Lowrank coal, accounting for 45% of the global coal reserves, is easier to use in terms of realizing ignition and stable combustion due to its relatively high levels of volatile contentPreparation schemes of crushed coal for combustion in fluidized

Application of 2PGL Hightenacity Double Roll Crusher in Xinghua Coal

Apricot Xinghua Washery Preparation of the workshop process of transformation, with 2PGL400 × 750 hightenacity double roll crusher replacing two jaw crushers, resolved into the washing transfinite granularity, and introduce 2PGL400 × 750 hightenacity double roll crusher working principle, structure, main characteristics and technical indicators, after the installation of cost 63 Preparation Plants and Crusher Buildings 631 Building Construction 632 Fire Protection 6321 Portable Extinguishers 6322 Fixed Fire Protection Systems 6323 Standpipe and Hose Systems 63231* Class III standpipe systems shall be provided in all coal preparation plants and crusher buildings in accordance with NFPA 14NFPA 120, Standard for Fire Prevention and Control in Coal Mines areas to realize the concept of green coal preparations [2] In general, the raw coal is transported to the rolltype crusher to crush coal and gangue to 100 mm after underground mining Then, spiral size screen machines are applied to screen out materials below 50 mm, limiting the granularity of material within the range 50–100 mmExtraction of Coal and Gangue Geometric Features with important step to take before analysing coal is sample preparation with laboratory crushers and mills to obtain a representative sample For more inhomogeneous coal samples, such as brown coal, the sample preparation step becomes even more important in ensuring reproducible analysis results The fineness of the sample canSample preparation for coal analysis Romquest

Efficient Jaw Crusher Sample Divider for Coal Analysis insmart

Jaw Crusher with inbuilt Sample Divider is a unique combination of crushing with inbuilt sample division system for reliable and reproducible particle size reduction quantity reduction Representative sample drawal in the range of 2% to 25% Provided with 3 variants to accept a wide variety of materials with top size ranging from 150 mm to 65 mm and provide final coal belt conveyor enters the main workshop or the coal storage silo, and its structural arrangement mainly in cludes the belt entrance layer connected with the coal conResearch on Structural Design of Coal Crusher House in Thermal Power 2020年7月24日 PDF This paper takes the specific characteristics of pulverized coal room in thermal power plant as the starting point,firstly, this paper analyzes Find, read and cite all the research (PDF) Research on Structural Design of Coal Crusher Workshop; News News Xinjia News Rendering of coal preparation plant Coal preparation technology 2ZKX3673 Clean Coal Dewatering Screen Number of views: 1000 2PG70150 Series Tooth Roll Crusher Number of views: 1000 Keywords: TLLA Series of Vertical Scraper Discharge Centrifuge Number of views:Modular and intelligent coal preparation equipment

Coal Preparation Plant Coal Preparation Process Coal Washing

Coal preparation plant is a coal processing plant that include a series of processes: raw Raw coal is transported to crushing workshop by belt conveyor First, +50mm materials and extra large gangue enter the crusher and are crushed to – 50mm,After coal is mined, it needs to be transported to and conveyed through a processing plant to prepare it for shipment and sale McLanahan’s line of Feeders can move coal from one aspect of the processing plant to another They feed material at a rate that matches the capacity of a crusher or conveyor beltCoal McLanahanENAP’s scope was awarded a project to undertake the site installation of new McLanahan Secondary Crusher for Plant Two at the New Acland Coal Mine This scope also included the workshop fabrication of new chutes and structural modifications to suit the upgraded crusher There was one week of preparation work to complete site inductions andNew Acland Coal Secondary Crusher Replacement)Integrated Sample Preparation System Supplier, Hammer Crusher, Jaw Crusher Manufacturers/ Suppliers Jiangxi Guangming Intelligent Technology Co, Ltd Sign In Join Free For Most of our products have gained the unit recommendation of China Coal Department and Coal Science College Our General Manager, Integrated Sample Preparation System Manufacturer, Hammer Crusher

.jpg)

Coal Crusher China Mainland/简体中文 Preiser Scientific

注意:可根据客户需求提供不同的电压 供401xl破碎机使用的打孔型筛板Coal stockpile Coal stacker Coal reclaimer Coal needs to be stored at various stages of the preparation process, and conveyed around the CPP facilities Coal handling is part of the larger field of bulk material handling, and is a complex and vital part of the CPP Stockpiles provide surge capacity to various parts of the CPP ROM coal is delivered with large variations in Coal preparation plant WikipediaThe article concerned the problem of coal preparation for gasification purposes The main aim was to design the coal crushing circuit, which would produce the material within the particle size range between 05 and 5 mm The onestage crushing circuit Hard coal preparation in a single stage crushing circuit for