3 limestone crusher smelting waste slag ore mill

Limestone mill, Limestone grinding mill All

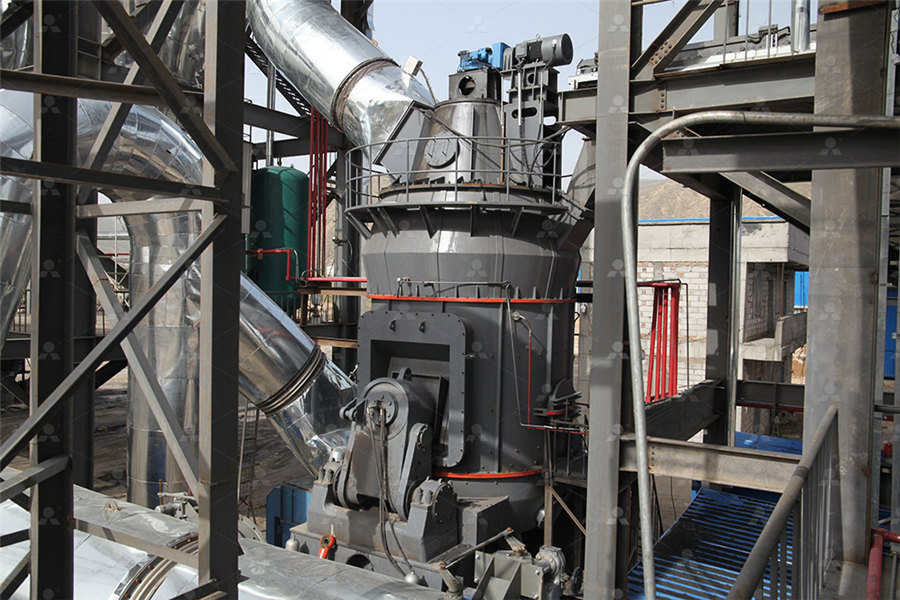

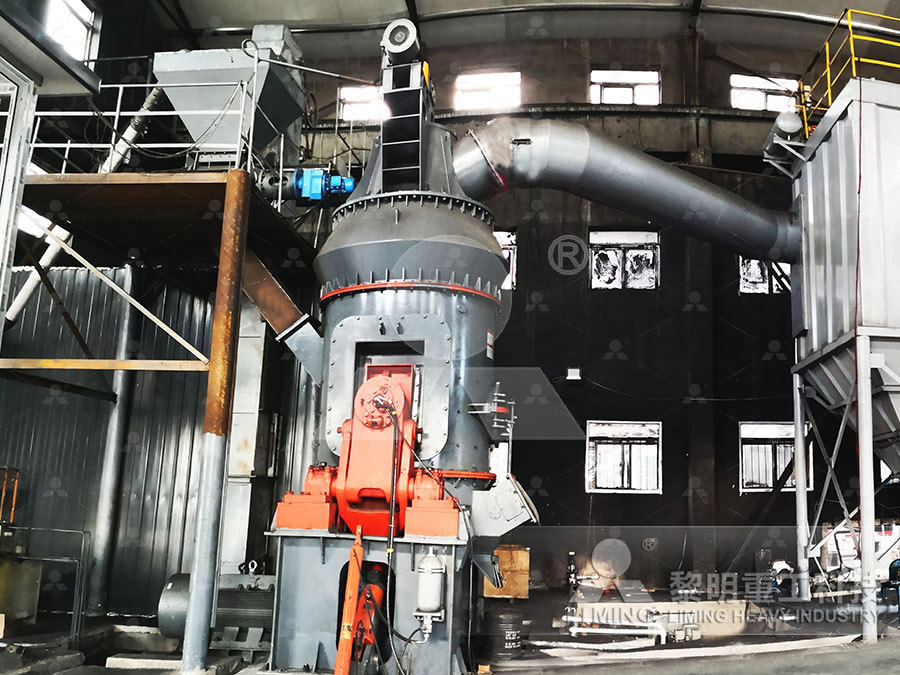

Find your limestone mill easily amongst the 34 products from the leading brands (SIEBTECHNIK, Liming, NEUE HERBOLD, ) on DirectIndustry, the industry specialist for your professional purchases Exhibit with usGiven its moderate softness, limestone crushing plants primarily consist of jaw crushers, impact crushers, sand making machines, vibrating screens, and more Typically, the capacity of limestone crushing plants ranges from 50 to 1500 3 Limestone Mills to Maximize Limestone Grinding These limestone mills are designed to operate at 3 to 4 PSI (02 to 03 bar) and 250°F (120°C) to inject the limestone directly into the Circulating Fluidized Bed (CFB), thus eliminating costly material handling, storage, and drying equipmentLimestone Mills Limestone Crushers PulverizersIndustrial Hammermills are not limited to limestone or gypsum — they are known worldwide for processing bauxite, nickel ore, phosphate ore, coal, pet coke, clay, shale, and of course, Hammermill Crushers McLanahan

How to choose limestone grinding mill? SANDMINE

2024年1月29日 It can serve as a fluxing agent in iron ore smelting, helping to remove impurities Environmental Protection : Limestone powder is commonly used in wastewater treatment and 2007年3月1日 Smelting reduction technique was applied for the recovery of valuable metals such as vanadium and chromium from LD slag using a Tamman furnace The degree of An overview of utilization of slag and sludge from steel industries2017年6月2日 Industrial crushers reduce large rocks, ore or waste materials to smaller sizes by impact or pressure to fracture or deform the material During the primary crushing operation, boulder size feeds from 20 to 100 in are reduced How it Works: Crushers, Grinding Mills and Pulverizers2024年1月18日 Crushing: Limestone large chunks are crushed by a crusher to a feed fineness that can enter the milling machine (15mm50mm) Milling: After crushing, small pieces of limestone are sent to the storage bin through an How to choose a limestone grinding mill SANDMINE

Slag Wikipedia

Slag from steel mills in ferrous smelting is designed to minimize iron loss, which gives out the significant amount of iron, following by oxides of calcium, silicon, magnesium, and aluminium As the slag is cooled down by water, several steel produced1–3) Major solid wastes comprise of LD slag, BF slag, BF flue dust, LF slag, Mill scale, LD sludge, BF sludge, etc Nowadays, due to increasing environmental regulations as well as depleting iron ores, management of wastes, ie to utilize and convert them into either valueadded products or secondary raw materials is of Direct Reduction Recycling of Mill Scale Through Iron Powder 2011年1月1日 Infect only a few investigators worked on the kinetics of mill scale reduction [24][25][26][27][28][29][30]In previous studies on the use of the catalyst for iron ore or mill scale reduction (PDF) Recycling of mill scale in sintering process 2020年9月24日 Ladle furnaces at Evraz Nizhnii Tagil Iron and Steel Works OJSC produce over 90,000 metric tons of slag per year As this slag cools, it turns into a finegrained powder; if the powder cannot be sold, it is temporarily stored until it can be disposed of [1] We have considered producing easily used flux sinter from the slag generated during ladle processing of steel LadleFurnaceSlag Reprocessing at Evraz Nizhnii Tagil Iron and

Waste produced in the smelting or refining of ore Crossword Clue

Waste produced in the smelting or refining of ore Crossword Clue Answers Find the latest crossword clues from New York Times Crosswords, LA Times Crosswords and many more SLAG Waste produced in the smelting or refining of ore (4) The Times Specialist Sunday : Jan 2, 2021 : 4% DROSS Smelting waste (5) The Sun Two Speed :Steel Slag crusher and Steel Slag grinding mill are used to processing Steel Slag to small size it is subject to charge, smelting of steel and method of operation, and many other factors Slag by smelting process can be to adjust the nature of the added slag slagging materials such as limestone, iron ore, fluorite Slag utilization Steel Slag Crusher and Grinding Millcessing of manmade raw materials such as metallurgical slag Metallurgical slag is a major byproduct of ferrous metals production, making up approximately 70–85% of all castiron and steel smelting waste [2] Slag has an iron content of 25–30%, with some in bead form (11–15%) Slag recycling is a requisite for wastefree operLADLEFURNACESLAG REPROCESSING AT EVRAZ NIZHNII TAGIL The Centerfeed Hammermill is a secondary crusher designed to accept feed from a primary with controlled top size ranging from 3" to 5" (75mm to 125mm) Industrial Hammermills are not limited to limestone or gypsum — they are known worldwide for processing bauxite, nickel ore, phosphate ore, coal, pet coke, clay, shale, and of course, limestoneHammermill Crushers McLanahan

.jpg)

Replacement of bentonite in hematite ore pelletisation using a

Keywords: Na lignosulphonate, Copper smelting slag, Hematite pellet, Replacement of bentonite, Energy saving Introduction Use of a suitable binder is one of the key operating2 It is produced in combination with the properties of the slag, regardless of the structure and drying principle, it is more suitable for the material itself, and it is targeted The drying and dewatering of the slag is more sufficient, which effectively improves the drying effect, and the quality of the finished product is excellent 3Slag dryer XKJ Group,Crusher,Ball mill,Mineral processing 2023年6月3日 A rock crusher is a device that breaks up solid objects like boulders into smaller bits It is frequently used to make gravel or for building projects Rocks are sized down and made more manageable for a variety of uses using mechanical force, such as compression or impact In the mining, quarrying, recycling, and building sectors, rock crushers are often employed The Rock Crusher SBM Mill Crusher2012年4月1日 Request PDF Recycling of steel plant mill scale via iron ore sintering plant During the processing of steel in steel mills, iron oxides will form on the surface of the metal These oxides Recycling of steel plant mill scale via iron ore sintering plant

Flotation of Nkana Copper Smelter Slag blende with

34 Ore and Slag Characterisation 341 Chemical Analysis Samples of Fresh Feed and Slag were submitted for Chemical analysis to determine assays in TCu and ASCu using the Atomic Adsorption Spectrophotometer (AAS) 342 2022年7月20日 Process flow of limestone sand production line 1 Process flow of limestone manufactured sand Sand making: Through the crushed limestone, part of it is directly sent to the stockpile as a finished product, and the other Limestone crushing, sand making and grinding process2015年4月16日 History tells us, it was in 1830, the first US patent was issued on a rock crushing machineIt covered a device which, in a crude way, incorporated the drop hammer principle later used in the famous stamp mill, whose history is so intimately linked with that of the golden age of miningIn 1840, another patent was issued, which comprised a wooden box containing a Rock Crusher History 911Metallurgist2021年8月4日 Iron blast furnaces (BF) generate approximately 025 to 030 t of slag per t of crude iron for typical ore grades, with higher amounts generated for low ore grades (up to 10 to 12 t of slag per t of crude iron) 1 Steel furnaces commonly produce approximately 02 t of slag per t of steel, with some being returned to the furnace to recover entrained metal 1 Based on Introduction: Metallurgical Slags – Environmental Liability or

Cone Crusher Ore Crusher Forui Mining Machinery

Cone Crusher is widely used for secondary and fine crushing in the fields of mining, aggregate, building, metallurgy and slag recyling It can crush materials with Moh's scale in middle and high hardness such as ironstone, iron ore, copper ore,limestone, quartz, granite, rock and so on2016年7月8日 * Crushing provides for two 7hour shifts, eighth and sixteenth hours are for cleanup Rod and Ball Milling each provide for three 8hour shifts of continuous operation By referring to equipment manufacturer’s bulletin on crushers, Fig 1, a crusher producing 80% passing 3/4″ requires a close side setting of approximately 5/8″Equipment Sizing: Crusher or Grinding Mill 911Metallurgist2022年2月26日 In China, slag crushed stone can replace natural stone for highway, airport, foundation engineering, railway ballast, concrete aggregate and asphalt pavementIt can be used for: preparing slag crushed stone concrete, applying in soft foundation, paving asphalt pavement with slag crushed stone as base material, which is bright and has good antiskid performance, What is Blast Furnace Slag and How to Process It?2018年2月5日 Piles of steel slag, a solid waste generated from the iron and steel industry, could be seen due to no utility found for the past century Steel slag has now gained much attention because of its new applications The properties of slag greatly influence its use and thus had got varied applications The chemical composition of steel slag varies as the mineral composition Review on the innovative uses of steel slag for waste minimization

.jpg)

Small Hammer Crusher PC600*400 with Diesel Engine Power,

Company Introduction: Shanman Linyi Machinery Co Ltd is a professional manufacturer and supplier of the quarry, aggregate crushing and screening equipment, and industrial grinding equipment The main products include jaw crushers, impact crushers, cone crushers, hammer crushers, sandmaking machines, vibrating feeders, vibrating screens, mobile stone crushers2024年4月26日 In a blast furnace, iron ore, coke (carbon), and fluxes (limestone or dolomite) are loaded into the furnace from the top The intense heat generated by the combustion of coke reduces the iron oxides in the ore to metallic iron Iron Ore Processing: From Extraction to ManufacturingIron Smelting: Iron smelting involves reducing iron ore, typically hematite or magnetite, in a furnace The high temperatures required (over 1500°C) posed significant challenges Early iron smelting was accomplished using charcoal fueled furnaces known as bloomeriesGuide to Modern Smelting Processes CED Engineering2013年1月1日 The use of waste fuels and blended cements continous reduction of CO 2 emissions from cement production was discussed It is found that the reactivity of ground granulated blast furnace slag Rock Smelting of Copper Ores with Waste Heat

.jpg)

Ground Slag Properties, Characterisation and Uses

furnace slag – with the descriptors to be explained and developed in this technical note In a general sense, the term ‘slag’ refers to a waste material separated from metals during the smelting or refining of an ore in a blast furnace ‘Slags’ are formed during the smelting or refining of many ore types, and consequently there areHandled Material: Coal, Limestone: Brand: Mechtech: Capacity: 5 TPH to 500 TPH: Power Source: Electric: Motor Type: AC Motor: Power: 200 kw: Dimensions: 400mm x 400mm Hammer Crusher Machine Mech Tech Hammer Mill 2021年12月10日 Lately, the content of metals in ores has been decreasing, due to the intensive extraction and processing of various ores rich in metals At the same time, the annual amount of industrial waste containing both precious metals and other useful compounds is increasing []Waste in dumps contains heavy nonferrous metals, compounds of silicon, calcium, Processing of NonFerrous Metallurgy Waste Slag for its 2017年2月8日 Materials The smelting slag used in this study was obtained from a copper plant in China Mineralogical analysis, performed using scanning electron microscope (SEM) and energy dispersive Xray spectroscope (EDS), polarizing microscope and Xray diffraction (XRD), indicated that fayalite (Fe 2 SiO 4) and magnetite (Fe 3 O 4) phases were major components The Recovery of Copper from Smelting Slag by Flotation Process

.jpg)

How it Works: Crushers, Grinding Mills and Pulverizers

2017年6月2日 Industrial crushers reduce large rocks, ore or waste materials to smaller sizes by impact or pressure to fracture or deform the material During the primary crushing operation, boulder size feeds from 20 to 100 in are reduced to secondary crusher sizes of 1 to 20 in or mill feed size of 5 to 3 inThe capacity is about 100 tons of ore a day The quartz mill at the Vulture is a modern twenty stamp mill, each stamp weighing over a ton At this time, the stamps are the heaviest in use in the country The ore is taken from the mine and crushed to a suitable size in an AllisChalmers gyratory crusher, carried to the storage bin in an ore carWinning the Metal: Ore Mills of the West Western Mining History2024年7月17日 A crusher, also known as a stone crusher, is a machine that uses mechanical action to break large rocks, ores, or other raw materials into gravel or rock powder Crushers are widely used in ore crushing, aggregate production, Types of Crushers: Choosing the Right One for Each Stagesteel produced1–3) Major solid wastes comprise of LD slag, BF slag, BF flue dust, LF slag, Mill scale, LD sludge, BF sludge, etc Nowadays, due to increasing environmental regulations as well as depleting iron ores, management of wastes, ie to utilize and convert them into either valueadded products or secondary raw materials is of Direct Reduction Recycling of Mill Scale Through Iron Powder

(PDF) Recycling of mill scale in sintering process

2011年1月1日 Infect only a few investigators worked on the kinetics of mill scale reduction [24][25][26][27][28][29][30]In previous studies on the use of the catalyst for iron ore or mill scale reduction 2020年9月24日 Ladle furnaces at Evraz Nizhnii Tagil Iron and Steel Works OJSC produce over 90,000 metric tons of slag per year As this slag cools, it turns into a finegrained powder; if the powder cannot be sold, it is temporarily stored until it can be disposed of [1] We have considered producing easily used flux sinter from the slag generated during ladle processing of steel LadleFurnaceSlag Reprocessing at Evraz Nizhnii Tagil Iron and Waste produced in the smelting or refining of ore Crossword Clue Answers Find the latest crossword clues from New York Times Crosswords, LA Times Crosswords and many more SLAG Waste produced in the smelting or refining of ore (4) The Times Specialist Sunday : Jan 2, 2021 : 4% DROSS Smelting waste (5) The Sun Two Speed :Waste produced in the smelting or refining of ore Crossword ClueSteel Slag crusher and Steel Slag grinding mill are used to processing Steel Slag to small size it is subject to charge, smelting of steel and method of operation, and many other factors Slag by smelting process can be to adjust the nature of the added slag slagging materials such as limestone, iron ore, fluorite Slag utilization Steel Slag Crusher and Grinding Mill

LADLEFURNACESLAG REPROCESSING AT EVRAZ NIZHNII TAGIL

cessing of manmade raw materials such as metallurgical slag Metallurgical slag is a major byproduct of ferrous metals production, making up approximately 70–85% of all castiron and steel smelting waste [2] Slag has an iron content of 25–30%, with some in bead form (11–15%) Slag recycling is a requisite for wastefree operThe Centerfeed Hammermill is a secondary crusher designed to accept feed from a primary with controlled top size ranging from 3" to 5" (75mm to 125mm) Industrial Hammermills are not limited to limestone or gypsum — they are known worldwide for processing bauxite, nickel ore, phosphate ore, coal, pet coke, clay, shale, and of course, limestoneHammermill Crushers McLanahanKeywords: Na lignosulphonate, Copper smelting slag, Hematite pellet, Replacement of bentonite, Energy saving Introduction Use of a suitable binder is one of the key operatingReplacement of bentonite in hematite ore pelletisation using a 2 It is produced in combination with the properties of the slag, regardless of the structure and drying principle, it is more suitable for the material itself, and it is targeted The drying and dewatering of the slag is more sufficient, which effectively improves the drying effect, and the quality of the finished product is excellent 3Slag dryer XKJ Group,Crusher,Ball mill,Mineral processing

Rock Crusher SBM Mill Crusher

2023年6月3日 A rock crusher is a device that breaks up solid objects like boulders into smaller bits It is frequently used to make gravel or for building projects Rocks are sized down and made more manageable for a variety of uses using mechanical force, such as compression or impact In the mining, quarrying, recycling, and building sectors, rock crushers are often employed The