300 cubic meters of coal gangue sand powder vertical mill

.jpg)

Sand powder vertical millGrinding mill machine, mineral mill,

LM sand powder vertical mill is a kind of ultrafine sand making and powder grinding equipment, which is mainly suitable for the prefabricated sand powder process before the crushing of Process introduction GRMC coal vertical mill produced by CHAENG adopts a special structure design and production technology, and the quality is up to the leading level in China It is the COAL VERTICAL MILL Xinxiang Great Wall Machinery Co, Ltdthis dissertation was to investigate the effect of coal feedstock property variation on the vertical spindle coal pulverising mill’s performance to facilitate optimal plant performance Plant design Performance optimisation of vertical spindle coal pulverisers2024年7月12日 Incorporating calcined CG powder and limestone powder to replace 30–50 % of the cement in cementitious materials generally satisfies and exceeds the performance criteria Review Highcapacity utilization of coal gangue as supplementary

.jpg)

Study on the Reactivity Activation of Coal Gangue for

2023年9月21日 In this study, the research aim is to enhance the activity index of activated coal gangue and study its activation mechanism The activation process of coal gangue was optimized through orthogonal tests, and the Back Vertical Coal Mill (VCM) is equipment for grinding and pulverizing coal into micron size Rotary kilns then use the powders as fuel burners The VCM has a housing section equipped with a lining The layout of the coal mill with a rotary classifier2021年9月28日 The coal gangue powder of more than 300 mesh was placed into a hemispherical crucible with a loading amount of 1 kg each time Then, the surface of the powder in the crucible was flattened and placed into a microwave oven (ORW10S3T, 2450 MHz, 380 V) The coal gangue powder was set to 133 kw and irradiated for 25–30 minMechanism on Activation of Coal Gangue Admixture2023年8月31日 From cement to fine casting sand, coal gangue has huge potential So vertical mills can better meet powder production requirements (fineness, largescale production, environmental protection, and dry for 12 hours Preheating at 300°C for 30 minutes to remove surface moistureHow to Recycle and Process Coal Gangue: 7 Effective Ways

Mechanical Properties of Reactive Powder Concrete with Coal Gangue

2022年2月28日 Coal gangue (CG) represents a huge amount of industrial solid waste in China, and usually is used as a coarse aggregate to produce lowstrength coalganguebased concrete In this paper, in order to prove the possibility to obtain a higherstrength concrete with a higher CG utilization rate, reactive powder concrete (RPC) with coal gangue as a sand replacement at 2020年4月14日 22 Experiment The chemical composition measured by Bruker S8 TIGER XRF analysis; the mineralogical composition measured via Bruker D8 ADVANCE XRD analysis; thermal analysis conducted with Mettler Toledo analyzer in a temperature range of 30–1000 °C at a heating rate of 10 °C/min and N 2 or O 2 atmosphere Mortar strength test: prismatic mortar Identification and Activation of Coal Gangue and Performance 2021年9月1日 Coal gangue was collected from Ordos mining area, China The mineral phase was characterized by XRD (Fig 1 (a))Kaolinite (Al 2 O 3 2SiO 2 2H 2 O) and quartz (SiO 2) were the main crystalline minerals in raw coal gangueThe chemical composition is listed in Table 1The mineral composition of raw coal gangue is given in Table 2Results show that the raw Performance of microwaveactivated coal gangue powder as 2024年9月7日 Coal gangue is a complex industrial solid waste mixed with organic compounds, inorganic compounds and minerals (Fabiańska et al 2013)Its major chemical compositions are SiO 2, Al 2 O 3 and Fe 2 O 3, with traces of CaO, P 2 O 5, MgO and MnO 2The chemical composition of coal gangue from various sources and its comparison with soil reference Opportunities, challenges and modification methods of coal gangue

Fabrication and characterization of selfignition coal gangue

2016年5月5日 Coal gangue (CG) accounting for approximately 10% of coal production is the commercial worthless rock that surrounds, or is closely mixed with coal Coal mining which contain some inorganic minerals and organic matter results in substantial ecological and environmental problems, including cropland occupation, pollution of groundwater resources, The coal vertical mill, also referred to as the vertical roller coal mill, is an advanced equipment developed by our company It combines modern technology with our extensive experience in powder manufacturing This coal pulverizer efficiently integrates coal grinding and drying, providing highperformance and energysaving featuresHighEfficiency Vertical Coal Mill Enhancing Coal Pulverization2021年9月28日 could activate coal gangue, and the composite activation effect was the best e fineness of the coal gangue powder was more than 300 mesh, according to the optimal compounding methodMechanism on Activation of Coal Gangue Vertical roller mills are mainly engaged in three major fields of slag, coal powder, and nonmetallic ore Divided into: vertical roller mill, vertical slag mill, vertical coal mill, and ultrafine vertical millvertical roller mill, vertical coal mill, vertical slag mill, superfine

Mechanical and environmental performance of structural concrete

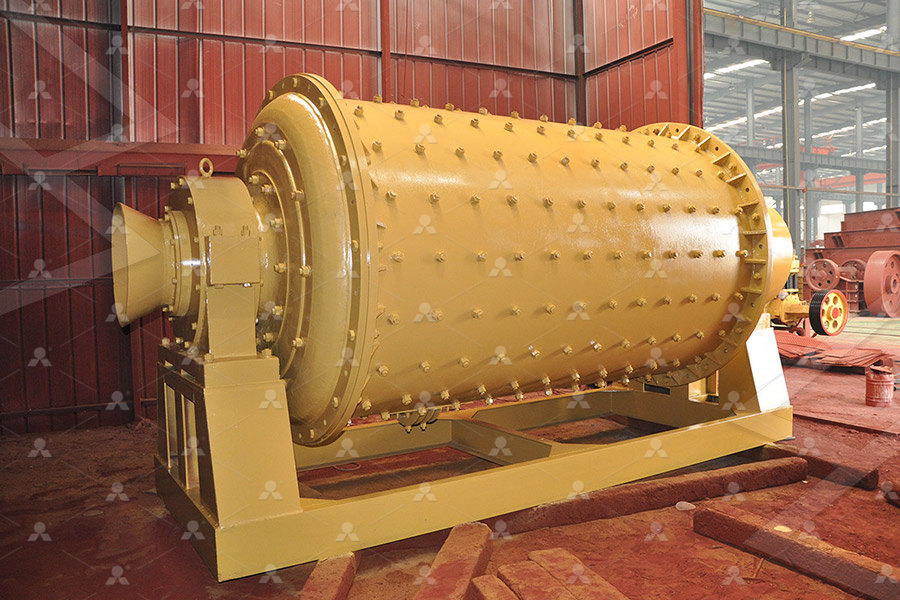

2024年5月1日 The coal gangue was collected from Fuxin, northeast of China The large particles of coal gangue were crushed and sieved into gangue fine aggregate, according to GB/T 146842022 [48]The cumulative screening percentage and physical properties of natural and gangue fine aggregate are listed in Table 1 and Table 2 respectively The macroscopic and A vertical roller mill, also known as a vertical grinding mill or vertical mill, is a comprehensive grinding equipment integrating crushing, drying, grinding, grading, and conveying Vertical grinding mills can be widely used in electric power, metallurgy, construction, chemical industry, and other industries to make powder, especially for materials such as cement clinker, coal Energysaving and Efficient Vertical Roller Mill Fote Machinery2023年8月9日 Coal gangue is a kind of solid waste A highductility cementcalcined coalganguepowdercompositebased rapid repair material (HDRRM) was prepared by partially replacing cement with calcined coal gangue powder (CCGP) for achieving high ductility and rapid hardening and conforming to the strength requirements of pavement layers First, the physical Preparation of HighDuctility CementCalcined CoalGanguePowder The ball mill is a traditional coal pulverizer machine, which has been widely used since it was invented In the cement plant, the new dry process cement manufacturing requires the moisture content of coal powder to be 05% ~ 15%, while that of raw coal is 15% ~ 40%Coal Mill in Cement Plant Vertical Roller Mill AirSwept Ball Mill

Vertical Coal Mill for Coal Grinding in Cement Plant Power Plant

Vertical coal grinding mill integrates crushing, drying, grinding, powder selection and conveying; It has simple system and compact structure Vertical coal mill covers an floor area about 50% of the coal ball mill with the same specification; Coal vertical mills can work in openair environments, greatly reducing the cost of investment The design of the vertical coal mill system is simple 2022年1月26日 Thus, the use of coal gangue (CG) and coal gasification slag (CGS) as SCMs in concrete attracted more researcher’s attention This paper investigated the mechanical strength, porosity, and Durability of Concrete With Coal Gasification Slag and Coal Gangue Powder2022年2月28日 Mechanical Properties of Reactive Powder Concrete with Coal Gangue as Sand Replacement February 2022; Materials 15(5):1807; DOI:103390 TYE300 universal testing machine with a loading rate Mechanical Properties of Reactive Powder Concrete with Coal Gangue 2022年1月25日 Multicriteria comparative analysis of the pressure drop on coal gangue flyash slurry at different parts along an Lshaped pipelineMulticriteria comparative analysis of the pressure drop on coal gangue

.jpg)

Activation Mechanism of Coal Gangue and Its Impact

2022年9月15日 Coal gangue is one of the industrial solid wastes that may harm the human body through the ecosystem for a long time Using coal gangue in geopolymer preparation can effectively reduce cement output and meet the 2023年7月1日 The diffusion coefficient for chloride ions and the diffusion decay coefficient for chloride ions are essential variables for a service life evaluation of concrete structuresInfluence of Activated Coal Gangue Powder on Compressive 2020年12月7日 The coal gangue powder was calcined in a muff furnac e at a ground by a small ball mill and calcined in a muffle furnace at 700 °C fo r 2 h Coal Gangue Slag Sand Coal Gangue Gravel 28 d Study of Mechanical Properties and Durability of Alkali 2020年5月6日 Airvoid characteristics test for coal gangue aggregate concrete (CGAC), (a) Rapid air concrete airvoid analyzer; (b) Treated surface of CGAC before air structural testingFrost Resistance of Coal Gangue Aggregate Concrete Modified by Steel

(PDF) Activation Mechanism of Coal Gangue and Its Impact on

2022年9月15日 PDF Coal gangue is one of the industrial solid wastes that may harm the human body through the ecosystem for a long time Using coal gangue in Find, read and cite all the research you need 2023年2月1日 Zhang et al 137 pretreated and ground coal gangue, soaked coal gangue powder in HNO 3 solution for 48 h at room temperature, washed it to neutral pH, and then soaked it inFabrication and application of porous materials made from coal gangue Lack and quality decrease of supplementary cementing materials (SCMs) such as fly ash and granulated blastfurnace slag is increasingly prominent in China Thus, the use of coal gangue (CG) and coal gasification slag (CGS) as SCMs in concrete attracted more researcher’s attention This paper investigated the mechanical strength, porosity, and durability of CGand CGS Durability of Concrete With Coal Gasification Slag and Coal Gangue Powder2023年9月3日 A highductility cementcalcined coalganguepowdercompositebased rapid repair material (HDRRM) was a sand–cement ratio of 03, The specimens were cured for 6 h, and their cubic Preparation of HighDuctility CementCalcined CoalGanguePowder

.jpg)

Utilization of Coal Gangue Aggregate for Railway Roadbed

2020年6月4日 As a massive solid waste, the high valueadded utilization of coal gangue has received more and more attention in China This study focuses on the utilization of coal gangue aggregate in railway engineering for coal transportation passage Coal gangue aggregate was employed as highgrade railway subgrade filler andprepared concrete for roadbed drainage 2022年9月30日 Coal gangue (CG) is a type of industrial solid waste produced by the process of coal excavation and separation 1,2,3Generally, one ton of CG is discarded for every 10 tons of produced coal 4,5 Preparation of coal gangue ceramsite highstrength concrete and 2023年9月21日 In this study, the research aim is to enhance the activity index of activated coal gangue and study its activation mechanism The activation process of coal gangue was optimized through orthogonal tests, and the Back Study on the Reactivity Activation of Coal Gangue for Vertical Coal Mill (VCM) is equipment for grinding and pulverizing coal into micron size Rotary kilns then use the powders as fuel burners The VCM has a housing section equipped with a lining The layout of the coal mill with a rotary classifier

.jpg)

Mechanism on Activation of Coal Gangue Admixture

2021年9月28日 The coal gangue powder of more than 300 mesh was placed into a hemispherical crucible with a loading amount of 1 kg each time Then, the surface of the powder in the crucible was flattened and placed into a microwave oven (ORW10S3T, 2450 MHz, 380 V) The coal gangue powder was set to 133 kw and irradiated for 25–30 min2023年8月31日 From cement to fine casting sand, coal gangue has huge potential So vertical mills can better meet powder production requirements (fineness, largescale production, environmental protection, and dry for 12 hours Preheating at 300°C for 30 minutes to remove surface moistureHow to Recycle and Process Coal Gangue: 7 Effective Ways2022年2月28日 Coal gangue (CG) represents a huge amount of industrial solid waste in China, and usually is used as a coarse aggregate to produce lowstrength coalganguebased concrete In this paper, in order to prove the possibility to obtain a higherstrength concrete with a higher CG utilization rate, reactive powder concrete (RPC) with coal gangue as a sand replacement at Mechanical Properties of Reactive Powder Concrete with Coal Gangue 2020年4月14日 22 Experiment The chemical composition measured by Bruker S8 TIGER XRF analysis; the mineralogical composition measured via Bruker D8 ADVANCE XRD analysis; thermal analysis conducted with Mettler Toledo analyzer in a temperature range of 30–1000 °C at a heating rate of 10 °C/min and N 2 or O 2 atmosphere Mortar strength test: prismatic mortar Identification and Activation of Coal Gangue and Performance

.jpg)

Performance of microwaveactivated coal gangue powder as

2021年9月1日 Coal gangue was collected from Ordos mining area, China The mineral phase was characterized by XRD (Fig 1 (a))Kaolinite (Al 2 O 3 2SiO 2 2H 2 O) and quartz (SiO 2) were the main crystalline minerals in raw coal gangueThe chemical composition is listed in Table 1The mineral composition of raw coal gangue is given in Table 2Results show that the raw 2024年9月7日 Coal gangue is a complex industrial solid waste mixed with organic compounds, inorganic compounds and minerals (Fabiańska et al 2013)Its major chemical compositions are SiO 2, Al 2 O 3 and Fe 2 O 3, with traces of CaO, P 2 O 5, MgO and MnO 2The chemical composition of coal gangue from various sources and its comparison with soil reference Opportunities, challenges and modification methods of coal gangue 2016年5月5日 Coal gangue (CG) accounting for approximately 10% of coal production is the commercial worthless rock that surrounds, or is closely mixed with coal Coal mining which contain some inorganic minerals and organic matter results in substantial ecological and environmental problems, including cropland occupation, pollution of groundwater resources, Fabrication and characterization of selfignition coal gangue The coal vertical mill, also referred to as the vertical roller coal mill, is an advanced equipment developed by our company It combines modern technology with our extensive experience in powder manufacturing This coal pulverizer efficiently integrates coal grinding and drying, providing highperformance and energysaving featuresHighEfficiency Vertical Coal Mill Enhancing Coal Pulverization