Is the ore grinding machine powerful

Energy Use of Fine Grinding in Mineral Processing

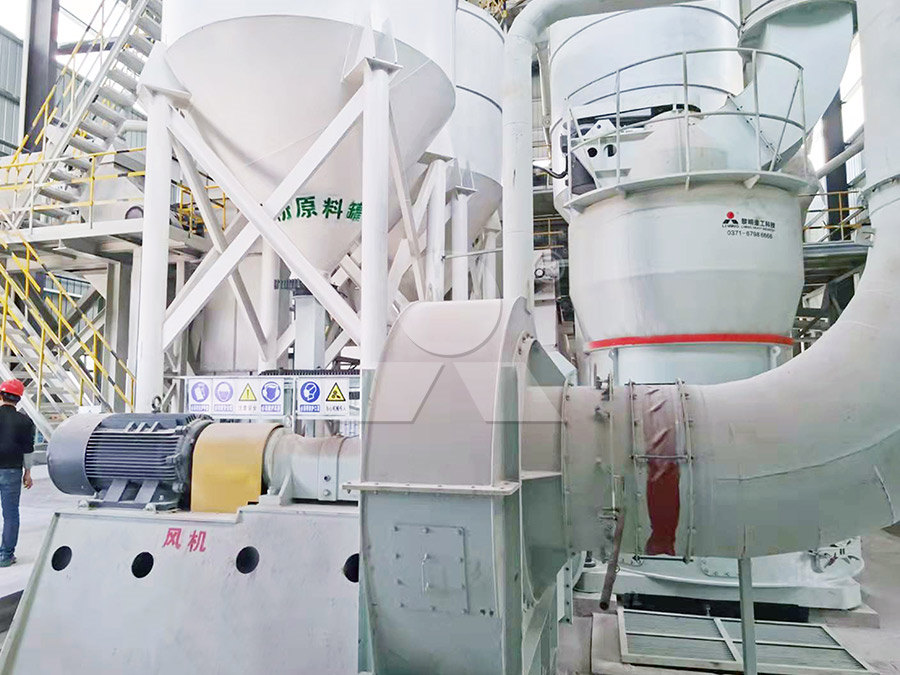

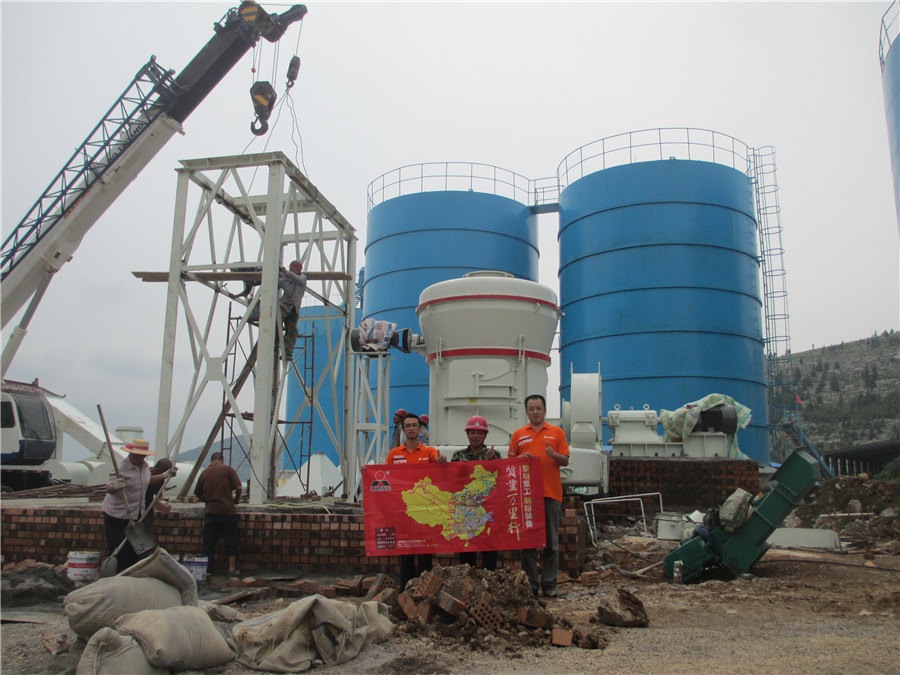

Fine grinding is usually performed in highintensity stirred mills; several manufacturers of these stirred mills exist Two frequently used stirred mills include the Isamill, produced by 展开2018年1月1日 Grinding is an essential technology used for finishing operations of many precision components, especially such made of hard and brittle materials This work presents Energy efficiency of stateoftheart grinding processes2021年8月31日 Grinding efficiency refers to the amount of ore processed for every 1kWh of electricity consumed It has the following representation methods: Grinding products (tons) of a specified level (often less than 200 mesh) are Grinding Efficiency Henan Forui Machinery How to estimate the power required for a grinding mill ? What is the work index ? What is the power required to mill an ore ?Grinding power : step by step calculation PowderProcess

.jpg)

Grinding Mill an overview ScienceDirect Topics

All ores have an economic optimum particle size which maximizes the difference between net smelter return (NSR) and grinding costs (Chapter 1): too coarse a grind and the inadequate 2023年9月1日 Based on the machine learning method, this study analyzed the full process parameters (ie, ball mill power, fresh ore feed rate, hydrocyclone feed pump power, Analyzing process parameters for industrial grinding circuit based 2023年7月20日 Ore grinding is a process to further reduce and disperse the ore particle size In the mineral processing industry, ore grinding is the particle size preparation before the Ore Grinding SpringerLinkCrushing and grinding are preparatory operations of enrichment and are intended for ore grains separation (opening) of various minerals, contained in the mineral in the form of closely Reengineering of the ore preparation production process in the

Breaking down energy consumption in industrial

2017年1月17日 Grinding mills are infamous for their extremely low energy efficiency It is generally accepted that the energy required to produce new mineral surfaces is less than 1% of the electricity2024年7月17日 Early 19th Century: The Industrial Revolution spurred the development of mechanized grinding machines 1873: Brown Sharpe introduced the world’s first universal grinding machine Early 20th Century: What is Grinding? Understanding the Basics and What is a Grinding Machine? A grinding machine, often shortened to grinder, is one of the power tools or machine tools used for grinding, it is a type of machining using an abrasive wheel as the cutting tool Each grain of abrasive on the wheel’s surface cuts a small chip from the workpiece via shear deformationWhat Is Grinding Machine? Definition, and Types The Why the Grinding Machinery has been Used Across Industries as a Powerful Tool The powerful grinding machine tools provide a high surface finish and production of accurate dimension products It is a production machine tool Grinding Machine Surface Grinder Machine, Indian

Grinding Machines SpringerLink

2015年1月1日 As grinding machines belong to the class of machines for the material removal with geometrically nondefined cutting edges, those machines can be classified in correlation to the classification of the different process technologies with geometrically nondefined cutting edges as it is given in DIN 8589, parts 11, 12, and 13 (DIN 858911 2003; DIN 858912 2003; 2020年5月19日 Grinding machines produce flat, cylindrical, and other surfaces by means of highspeed rotating abrasive wheels A grinding machine or grinder is an industrial power tool that uses an abrasive wheel for cutting There are various grinding machine types, each with a different purposeMarket Prospects What Is A Grinding Machine? How Should The 2023年10月10日 Ball Mills: Suitable for dry or wet grinding, these machines use balls to crush and grind the ore Rod Mills: Utilize rods instead of balls for grinding, often used for coarser ore Grinding Efficiency: The efficiency of the grinding process is crucial for maximizing the recovery of valuable titanium minerals In the titanium ore processing Titanium Ore Crushing and Grinding Machine Liming Heavy RETSCH grinding mills for reliable size reduction tasks with a high degree of grindability for exact and fine results newest technology Learn more Retsch GmbH The impact force can be delivered by moving hammers, balls, or discs within a grinding machine As the material is subjected to these highenergy impacts, Grinding Mills for reliable size reduction tasks RETSCH

.jpg)

Hand Grinding Machine Parts And Functions AD SERVICE

Hand Grinding Machine Parts Hand Grinding Machine Parts And Functions – Hand grinding machine is a machine used for leveling and cutting workpieces It has important parts in the form of a series of electrical components interconnected with each other From these parts of the grinding machine, produce a rotation of the motion energyHere’s a look at some of the most common types of precision grinding machines from Maximum AdvantageCarolinas 1 Surface Grinders: A surface grinder consists of an abrasive wheel, a chuck (a workpiece holding device), and a rotary table 2 Cylindrical Grinders: A cylindrical grinder is used for shaping the outside of a workpiece 3What Is Grinding Machine? Definition, and Types MechdailyThe Grinding Laws and Machines Grinding is an essential process in the mining industry, and it involves breaking down large pieces of ore into smaller fragments The grinding laws are fundamental principles that guide the design and operation of grinding machines These laws include Kick's law, Bond's law, and Rittinger's lawUnderstanding the SAG Mill in Copper Ore Mining Process2024年4月18日 One of the key advantages of an electric grinder machine is its power Unlike manual grinding tools, an electric grinder machine is equipped with a powerful motor that can provide constant and consistent power This means that you can work faster and achieve better results in less timeRevolutionize Your Grinding Experience: The Ultimate Guide To

What is a Grinding Machine? – Detailed Information

Definition of Grinding Machine A grinder (grinding machine) is a machine tool that uses a grinding tool to grind the surface of a workpiece Most of the grinding machines use highspeed rotating grinding wheels for grinding, and a few use 2024年8月20日 The 7 Best Angle Grinders for Cutting Tile, Grinding Grout, and Polishing Metal Trust us, this versatile power tool is a gamechanger By Tony Carrick Published: Aug 20, 2024 5:41 PM EDTThe 7 Best Angle Grinders in 2024 Angle Grinders 2022年11月2日 So much so that we’ve wondered whether any rotary tool—especially cordless models—can outperform the corded Dremel in what it does best: grinding, sanding, removing burrs, drilling tiny The Corded Dremel Tool Is Still Best 4 Best Rotary Tools 年11月1日 A third type of grinding machine is a surface grinding machine Surface grinding machines are unique because they feature an adjustable head The head on a surface grinding machine can be lowered down to the workpiece Once lowered, the head can then rotate back and forth under the machine’s grinding wheelExploring the Different Types of Grinding Machines

The 10 Best Angle Grinders Best of Machinery

2022年5月1日 Smaller angle grinders are most favored by home hobbyists and the DIY crowd Models that use a 45inch disc are relatively lightweight and can get into small spaces Even with their small size, they are powerful enough to tackle most of the projects you have in mind, including grinding, sanding, and sharpening2021年4月16日 Grinding hand tools A die grinder is a highspeed rotary tool that is typically powered by compressed air The tool has a smalldiameter abrasive bit that rotates to get the job done Check out Choosing the Right Air Die Grinder for more information and some recommended models Angle grinders are also abrasive hand tools Unlike die grinders, Intro to Grinding Methods, Machines and ToolsThe grinding machine G400 is a light, powerful, compact and versatile grinder, suitable for rapidly carrying out the main process of taping and grinding of ferrules and typical manufactured items for boilers as: back gaugingfor welding root removal; polishing of Grinding machine G400 for back gouging Grinding disc 400 2024年1月23日 Initial Investment: Grinding machines, especially those used for precision applications, are costly Highend machines with advanced features like CNC systems are even more expensive Basic Grinding Machines: Entrylevel grinding machines, suitable for smallscale operations or less complex tasks, typically range from $5,000 to $20,000What is Grinding: Definition, Process, Types Specifications

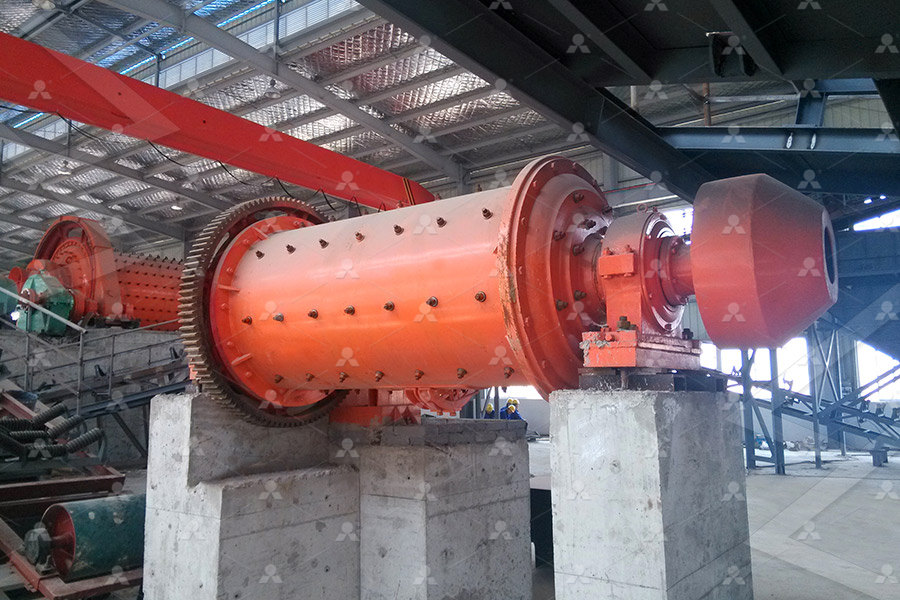

Ball Mill Is The Key To Grinding Lithium Ore JXSC Machinery

6 天之前 Additionally, the ball mill’s versatility allows parameters such as speed, feed rate and material composition to be adjusted, making it adaptable to different types of lithium ore This flexibility is essential to optimize the grinding process for each specific ore type, thereby increasing cost efficiency and resource sustainability2024年9月25日 Still, if you’re looking for a powerful angle grinder with up to 6inch discs, the ProFactor is a top contender Get the Bosch angle grinder at Amazon , Lowe’s , or Zoro Best 7To 9InchThe Best Angle Grinders, According to Our Testing2023年4月27日 The grinding software is becoming more powerful and, at the same time, also becoming more userfriendly A multispindle universal grinding machine can machine the entire workpiece, eliminating an additional The advantages of a universal cylindrical grinding 2022年2月16日 A 5axis grinding machine is a cutter grinder commonly used to shape and sharpen milling cutters and other tool bits 5axis tool grinders can perform a broad range of grinding operations, including surface grinding, Grinding Machine Types How it works Phillips

Grinder Machine – Working, Types, Applications, Pros Cons

2023年5月5日 A grinding machine consists of the following parts: 1 Base – The base of the grinding machine supports the other parts of the machine It is made of cast iron and rests on a flat foundation 2 Column – The column is a vertical structure that supports the grinding wheel and the grinding head It is made of cast iron and has a dovetail slide on which the grinding 2023年7月20日 Moist grinding, a special grinding method, is used to prepare pellets for smelting According to the grinding medium features, ore grinding is mainly classified into ball grinding process, rod grinding process, and autogenous grinding process Ore grinding process falls into opencircuit and closedcircuit grinding The grinding products of the Ore Grinding SpringerLinkThis article speaks about different types of grinding machines, parts, and their working A workshop can have a single grinding machine or multiple grinding machines based on the surface finish requirements of the workpiece This is normally the last operation performed on an item to achieve high precision Our Videos Refer YouTubeGrinding Machine: Definition, Types, Parts, Working Operations2018年1月1日 Coolant application is critically important in grinding, preventing workpiece damage and increasing the quality of manufactured components However, delivery of grinding fluids is difficult to Energy efficiency of stateoftheart grinding processes

.jpg)

The Advantages of Surface Grinding Machines: A Comprehensive

2023年9月1日 How Surface Grinding Machines Work Surface grinding machines operate by rotating an abrasive wheel on a horizontal spindle that is mounted on a reciprocating table The workpiece is held on the table and moves back and forth under the grinding wheel, while the wheel itself remains stationary The grinding wheel is typically made of bonded A grinding machine, often shortened to grinder, is any of various power tools or machine tools used for grinding It is a type of material removal using an abrasive wheel as the cutting tool [1] Each grain of abrasive on the wheel's surface cuts a Grinding machine Wikipedia2022年11月28日 Grinding is a type of finishing process in mechanical processing, with less machining and high precision It is widely used in the machinery manufacturing industry The heattreated and quenched carbon tool steel and carburized and quenched steel parts often have a large number of regularly arranged grinding cracks on the surface that is basically What is Grinding Process How It Works Different Types of Grinding2024年7月17日 Early 19th Century: The Industrial Revolution spurred the development of mechanized grinding machines 1873: Brown Sharpe introduced the world’s first universal grinding machine Early 20th Century: What is Grinding? Understanding the Basics and

What Is Grinding Machine? Definition, and Types The

What is a Grinding Machine? A grinding machine, often shortened to grinder, is one of the power tools or machine tools used for grinding, it is a type of machining using an abrasive wheel as the cutting tool Each grain of abrasive on the wheel’s surface cuts a small chip from the workpiece via shear deformationWhy the Grinding Machinery has been Used Across Industries as a Powerful Tool The powerful grinding machine tools provide a high surface finish and production of accurate dimension products It is a production machine tool Grinding Machine Surface Grinder Machine, Indian 2015年1月1日 As grinding machines belong to the class of machines for the material removal with geometrically nondefined cutting edges, those machines can be classified in correlation to the classification of the different process technologies with geometrically nondefined cutting edges as it is given in DIN 8589, parts 11, 12, and 13 (DIN 858911 2003; DIN 858912 2003; Grinding Machines SpringerLink2020年5月19日 Grinding machines produce flat, cylindrical, and other surfaces by means of highspeed rotating abrasive wheels A grinding machine or grinder is an industrial power tool that uses an abrasive wheel for cutting There are various grinding machine types, each with a different purposeMarket Prospects What Is A Grinding Machine? How Should The

Titanium Ore Crushing and Grinding Machine Liming Heavy

2023年10月10日 Ball Mills: Suitable for dry or wet grinding, these machines use balls to crush and grind the ore Rod Mills: Utilize rods instead of balls for grinding, often used for coarser ore Grinding Efficiency: The efficiency of the grinding process is crucial for maximizing the recovery of valuable titanium minerals In the titanium ore processing RETSCH grinding mills for reliable size reduction tasks with a high degree of grindability for exact and fine results newest technology Learn more Retsch GmbH The impact force can be delivered by moving hammers, balls, or discs within a grinding machine As the material is subjected to these highenergy impacts, Grinding Mills for reliable size reduction tasks RETSCHHand Grinding Machine Parts Hand Grinding Machine Parts And Functions – Hand grinding machine is a machine used for leveling and cutting workpieces It has important parts in the form of a series of electrical components interconnected with each other From these parts of the grinding machine, produce a rotation of the motion energyHand Grinding Machine Parts And Functions AD SERVICEHere’s a look at some of the most common types of precision grinding machines from Maximum AdvantageCarolinas 1 Surface Grinders: A surface grinder consists of an abrasive wheel, a chuck (a workpiece holding device), and a rotary table 2 Cylindrical Grinders: A cylindrical grinder is used for shaping the outside of a workpiece 3What Is Grinding Machine? Definition, and Types Mechdaily

Understanding the SAG Mill in Copper Ore Mining Process

The Grinding Laws and Machines Grinding is an essential process in the mining industry, and it involves breaking down large pieces of ore into smaller fragments The grinding laws are fundamental principles that guide the design and operation of grinding machines These laws include Kick's law, Bond's law, and Rittinger's law