Can spodumene ore powder grinding be done by crushing slag

Lithium deportment by size of a calcined spodumene ore

2022年10月31日 This work investigates the energy efficiency of different grinding circuits used for upgrading the lithium content in the finer fraction of the calcined spodumene ore2023年1月1日 This paper focuses on the research progress of extracting lithium from spodumene, lepidolite, petalite, and zinnwaldite by acid, alkali, salt roasting, and chlorination Lithium extraction from hard rock lithium ores (spodumene, 2023年12月27日 In step 1, to convert spodumene into lithium sulfate (Li 2 SO 4), the raw ore is crushed and separated both mechanically and via floatation Next, the concentrate undergoes energy and chemically intensive hot acid Hard Rock Spodumene Lithium Processing Saltworks Flotation is used to generate a high grade spodumene concentrate (7585% spodumene) suitable for lithium extraction Minimize the cost of roasting Lithium can be extracted from spodumene Hard Rock Lithium Processing SGS

.jpg)

Aspects of Spodumene Lithium Extraction Techniques

2024年9月30日 Of these, only extraction from spodumene has established a reliable industrial production of Li salts The current approaches for cracking of the naturally occurring, stable α spodumene structure into a more open 2022年7月7日 Processing spodumene for lithium is challenging as it requires a high temperature transformation of the natural αmonoclinic form to βtetragonal form, usually followed by acid Novel extraction route of lithium from αspodumene by dry 2023年6月25日 In this study, a novel lithium extraction method was proposed for α spodumene by combining activated roasting and sulfuric acid leaching First, the thermodynamics of the An effective method for directly extracting lithium from α 2019年5月29日 This process starts with the crushing of spodumene ore The cause behind the grinding of the spodumene is an acceleration of the heat transfer between the surrounding Spodumene: The Lithium Market, Resources and Processes

.jpg)

Recovery of lithium from spodumenebearing pegmatites: A

2023年2月1日 In general, the spodumenebearing pegmatite rock is subjected to crushing for the preparation of feed to dense media separators The sink fraction, free from coarse gangue 2016年3月31日 The results reveal that the presence of slag powder enhances the system modulus evidently, while maintaining the normal strength level of PLA Therefore, the slag Recycling of spodumene slag: preparation of green polymer 2020年8月12日 The sulfuric acid method initially requires subjecting natural spodumene to hightemperature calcination, transforming it from αspodumene to βspodumene [59,60] Following crushing and grinding Lithium Extraction from Spodumene by the Traditional Sulfuric 2023年8月22日 Grinding is usually used to increase the specific surface area of steel slag to improve its activity However, due to the large amount of hardtogrind minerals in steel slag, a large amount of energy is wasted in the grinding process Therefore, the current investigation aims to remove the hardtogrind minerals in steel slag as much as possible to explore the The Effect of Removing HardtoGrind Minerals from Steel Slag on

.jpg)

Crushing and Grinding Calculations by Bond PDF

This document presents equations for calculating particle size reduction in crushing and grinding processes It begins with an overview of the three main theories of comminution: Rittinger's theory which states work input is The dryprocess steel slag production process does not need to consume precious water resources After the steel slag is crushed, rod milled, and magnetically separated, the slag steel can be selfgrinding to obtain grade A and B scrap steel The iron content of the slag powder can reach more than 55%Steel slag recycling crushing and grinding production line2023年2月1日 The present scenario has urged the necessity to beneficiate and extract lithium from the available resources judiciously Pegmatites constitute the second major economic resource of lithium, after brines, accounting for about 25% of global production [14]The lithiumbearing minerals, hosted by the pegmatite rocks, include spodumene, lepidolite, petalite, Recovery of lithium from spodumenebearing pegmatites: A 2023年5月15日 Steel slag is the main solid waste generated in the steelmaking process, accounting for 15 to 20% of crude steel output [1]China's crude steel output in 2021 was 1035 billion tons [2], more than half of the global crude steel output (19505 billion tons) [3], and the steel slag output exceeded 120 million tonsIn contrast, the comprehensive utilization rate of Comprehensive utilization of steel slag: A review ScienceDirect

.jpg)

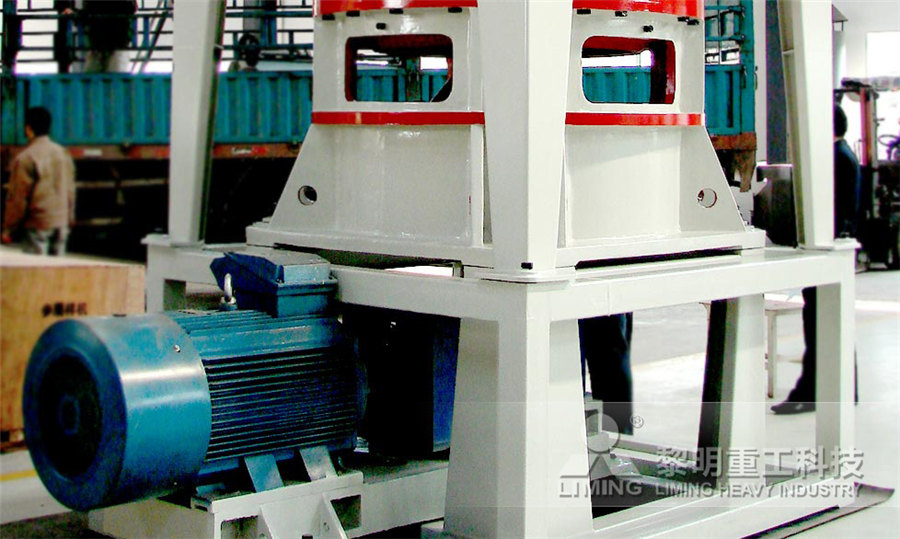

Powder Grinding Mills Engineered by FTM Fote Machinery

Applicable materials: Coal, cement raw material, clinker, slag, quicklime powder, steel slag, manganese ore, etc Famous for its large output and high fineness The output is 2–420 t/h and the fineness is up to 2,500 mesh With its drying system, it can 2024年9月30日 Li removal from spodumene can be separated into two groups: Li removal from αspodumene without pretreatment and Li removal from leachable βspodumene after αspodumene breakdown to βspodumene The excessive expenses of these traditional processes in terms of equipment, energy, chemicals, and environmental issues necessitate the Aspects of Spodumene Lithium Extraction Techniques MDPIcrushing of generally moist ore, and subsequent wet grinding and classification However, especially case when the subsequent beneficiation process involves dry processing, such as dryCase Study of Dry HPGR Grinding and Classification in Ore 2022年4月21日 Calcination of spodumene is used to convert αspodumene to more reactive βspodumene, has been shown to greatly impact the physical characteristics of some of the components in the oreLithium deportment by size of a calcined spodumene ore

What is Blast Furnace Slag and How to Process It?

2022年2月26日 Blast furnace slag can be processed into the following materials by various processes In China, blast furnace slag is usually processed into water slag, slag gravel, expanded slag and slag beadsWater slag is the process of 2023年6月25日 In addition, most investigations have focused on βspodumene instead of αspodumene, whereas the extra energy consumption is caused inevitably by hightemperature crystal transformation (αphase to βphase)Thus, some researchers directly choose αspodumene as the object of studyXing et al [33] successfully achieved the extraction of An effective method for directly extracting lithium from αspodumene 2003年4月1日 When the molten slag is rapidly cooled with water, or cooled with powerful water jets, it turns into a fine, granular, almost fully noncrystalline, glassy form known as granulated slag (GBFS)(PDF) Utilisation of LD slag — An overview2016年10月28日 The grinding efficiency of steel slag was obviously increased and the particle characteristics were improved after using grinding aids (GA), especially the particle proportions of 332 Mm were (PDF) Comparison of Grinding Characteristics of Converter Steel Slag

Progress of Five Spodumene Beneficiation Methods

6 天之前 When the temperature is too high, the mica present in the ore will sinter; when the temperature is too low, the transformation of spodumene from α to β is incomplete ②The ore cannot contain a large amount of minerals that are easy to melt during roasting or other minerals with thermal cracking properties, otherwise the purpose of separating spodumene will not be 2023年12月27日 In step 1, to convert spodumene into lithium sulfate (Li 2 SO 4), the raw ore is crushed and separated both mechanically and via floatationNext, the concentrate undergoes energy and chemically intensive hot acidroasting This process (as shown in Figure 1 below) sees concentrated spodumene powder roasted at 1050°C, cooled, mixed with sulfuric acid, Hard Rock Spodumene Lithium Processing Saltworks TechnologiesStedman impact crushers, mills, and grinders are used in nearly every mineral, ore, and mining applicationWhether you are processing iron ore, coal, rock, salt, wood chips, or clay – to name a few – we have your solution to size reduction with our mineral crushing machines industrial ore slag crushersIndustrial Ore, Mineral, Slag Crusher Mineral Crushing 2012年1月1日 "Spodumene mineral is a source of lithium for lithium ion batteries Thus, the production of a spodumene concentrate with an approximate grade of 6% Li2O is targeted Traditionally, spodumene is concentrated by froth flotation using fatty acid as the collector Amine collector can also be used to float mica ahead of spodumene as required or feldspar from the An Overview of Spodumene Beneficiation OneMine

What is a Slag Crusher Machine and How Does it Work?

2023年3月2日 Discover the benefits, types, and applications of Slag Crusher Machines in the steel industry Learn how these machines work, the types of slag they can crush, and the maintenance required for optimal performance Maximize the benefits of steel recycling and contribute to a more sustainable future with this comprehensive guide2022年5月12日 In industrial production, slag plays an important role Some major factories refine and process slag into slag cement, slag micro powder, slag powder, slag Portland cement, and slag wool Blast furnace slag can also be used as raw materials for cast stone, glassceramic, fertilizer, enamel, ceramics, etc (1) GlassceramicSlag grinding mill micro powder production line SBM Ultrafine Powder Although simulations of grinding circuits are very important in mineral processing industries, this is beyond the scope of this work Materials and methods Ore preparations Spodumene ore samples (− 15 mm) were obtained from the Bald Hill Mine Eastern Goldfields, Western Australia Table 1 shows the mineralogy of the sample determined using XRDLithium deportment by size of a calcined spodumene ore2018年1月15日 Request PDF Assessment of a spodumene ore by advanced analytical and mass spectrometry techniques to determine its amenability to processing for the extraction of lithium A combination of Assessment of a spodumene ore by advanced analytical and mass

Steel Slag an overview ScienceDirect Topics

Steel slag can also be produced by smelting iron ore in a basic oxygen furnace According to methods for cooling molten steel Crushing value (%) 120: 129: Water absorption (%) 118: 070: Specific physical excitation, which stimulates the hydration activity by physically grinding steel slag into finer powder (Liu et al, 2016), (ii) 2017年3月4日 Ball mills are used for wet grinding iron ore, g old/copper ore, nickel ore and other ores, as wel l as lime/limestone for flue gas desulphurisat ion systems, coal and other raw materials Rod mill :SIZE REDUCTION BY GRINDING METHODS ResearchGate2016年2月29日 The mixture of heat, fluxes, carbon and lead assure an appropriate reducing environment When the smelting process is complete, the charge is poured into a mold Once the slag is cool, this can be separate from lead and precious metals by using a hammer or any device than can break the slagGold Smelting Refining Process 911MetallurgistWhen crushed and sized properly, slag can be sold and used as valuable material in many different ways, for example, as aggregates However, since slag usually contains uncrushable objects, it is typically considered a challenging feed material for conventional jaw crushers Uncrushable objects in feedSlag crushing Metso

.jpg)

Comparing Leaching Efficiency of Novel Deep Eutectic Solvent

2024年10月8日 This study gives a comparison of leaching efficiency for lithium extraction from spodumene mineral with hydrochloric acid, aqua regia, nitric acid, sulfuric acid, and a novel eutectic solvent Operational conditions under investigation are solid–liquid ratio temperature, stirring speed, and particle size The reagents and products are characterized by field 2018年8月19日 Spodumene is one of the many lithium rich minerals , but is the most common and the most studied among all A process of lithium extraction from spodumene ore has been patented as early as the middle of the twentieth century This has led it to be the leader in the commercial mining of lithium rich minerals industryRevisiting the Traditional Process of Spodumene Conversion 2020年7月1日 The slag grinding system is the core of the slag powder control system, which con sists of batching station, conveyor belt, vertical mill, hot gas generator , dust collector and product warehouseAnalysis and multiobjective optimization of slag powder 2017年3月4日 Despite its significant contribution, this growth has implications for dust emissions, especially during the processes of crushing and grinding mineral ore Dust has the potential to degrade air SIZE REDUCTION BY CRUSHING METHODS ResearchGate

.jpg)

Lithium Extraction from Spodumene by the Traditional Sulfuric

2020年8月12日 The sulfuric acid method initially requires subjecting natural spodumene to hightemperature calcination, transforming it from αspodumene to βspodumene [59,60] Following crushing and grinding 2023年8月22日 Grinding is usually used to increase the specific surface area of steel slag to improve its activity However, due to the large amount of hardtogrind minerals in steel slag, a large amount of energy is wasted in the grinding process Therefore, the current investigation aims to remove the hardtogrind minerals in steel slag as much as possible to explore the The Effect of Removing HardtoGrind Minerals from Steel Slag on This document presents equations for calculating particle size reduction in crushing and grinding processes It begins with an overview of the three main theories of comminution: Rittinger's theory which states work input is Crushing and Grinding Calculations by Bond PDFThe dryprocess steel slag production process does not need to consume precious water resources After the steel slag is crushed, rod milled, and magnetically separated, the slag steel can be selfgrinding to obtain grade A and B scrap steel The iron content of the slag powder can reach more than 55%Steel slag recycling crushing and grinding production line

Recovery of lithium from spodumenebearing pegmatites: A

2023年2月1日 The present scenario has urged the necessity to beneficiate and extract lithium from the available resources judiciously Pegmatites constitute the second major economic resource of lithium, after brines, accounting for about 25% of global production [14]The lithiumbearing minerals, hosted by the pegmatite rocks, include spodumene, lepidolite, petalite, 2023年5月15日 Steel slag is the main solid waste generated in the steelmaking process, accounting for 15 to 20% of crude steel output [1]China's crude steel output in 2021 was 1035 billion tons [2], more than half of the global crude steel output (19505 billion tons) [3], and the steel slag output exceeded 120 million tonsIn contrast, the comprehensive utilization rate of Comprehensive utilization of steel slag: A review ScienceDirectApplicable materials: Coal, cement raw material, clinker, slag, quicklime powder, steel slag, manganese ore, etc Famous for its large output and high fineness The output is 2–420 t/h and the fineness is up to 2,500 mesh With its drying system, it can Powder Grinding Mills Engineered by FTM Fote Machinery2024年9月30日 Li removal from spodumene can be separated into two groups: Li removal from αspodumene without pretreatment and Li removal from leachable βspodumene after αspodumene breakdown to βspodumene The excessive expenses of these traditional processes in terms of equipment, energy, chemicals, and environmental issues necessitate the Aspects of Spodumene Lithium Extraction Techniques MDPI

Case Study of Dry HPGR Grinding and Classification in Ore

crushing of generally moist ore, and subsequent wet grinding and classification However, especially case when the subsequent beneficiation process involves dry processing, such as dry2022年4月21日 Calcination of spodumene is used to convert αspodumene to more reactive βspodumene, has been shown to greatly impact the physical characteristics of some of the components in the oreLithium deportment by size of a calcined spodumene ore