15TPH semi calcium carbonate grinding and crushing station

15TPH Heavy calcium carbonate production line HNM

Heavy calcium carbonate (heavy calcium carbonate) is produced by directly crushing natural limestone, calcite, etc using mechanical methods (grinding equipment such as Raymond mill) 2024年11月26日 The calcium carbonate grinding production line provides an efficient, environmentally friendly, and stable solution for the production of calcium carbonate powder, Calcium Carbonate Grinding Production Line TAYMACHINERYA large calcium carbonate enterprise in ChongQing province has ordered a HC1700 grinding mill for calcium carbonate plant from our factory, the final particle size is 250 mesh D90, and with Calcium Carbonate Grinding Machine HC1700 Mill, 15TPH 2024年4月7日 Heavy calcium carbonate (heavy calcium) is obtained by directly pulverizing natural limestone, calcite, etc by a mechanical method (Raymond mill or the like) Light Calcium Carbonate Grinding Line HengYang Machinery

Grinding HNM Machinery

When used for coarse and medium crushing of soft rock, the PFW series impact crusher represents today's advanced crushing technology and technology, with large moment of inertia 2024年7月10日 Heavy calcium carbonate is a calcium carbonate powder material produced by mechanical crushing using calcite, chalk, marble and other minerals as raw materials It has Heavy calcium carbonate grinding, surface modification China Calcium Carbonate Crusher wholesale Select 2024 high quality Calcium Carbonate Crusher products in best price from certified Chinese Crusher Machinery manufacturers, Calcium Carbonate Crusher MadeinChinaMetso is introducing two unique, cost efficient and modular mining crushing stations: FIT™ stations and Foresight™ stations FIT™ stations are focused on speed and flexibility for quick installation Meanwhile the Foresight™ stations Mining crushing stations Metso

CALCIUM CARBONATE (GCC) Hosokawa Alpine

2020年6月23日 PERFECT TOP CUT LIMITATION OF COATED AND UNCOATED GCC THROUGH INTEGRATED HIGH PERFORMANCE CLASSIFIER Pure filler or highquality 2024年9月13日 Before choosing a grinding mill, you need to understand how calcium carbonate is produced At present, there are two main methods, dry grinding method and wet grinding method The dry grinding method is mainly How to Choose a Calcium Carbonate Grinding 2024年7月10日 Heavy calcium carbonate is a calcium carbonate powder material produced by mechanical crushing using calcite, chalk, marble and other minerals as raw materials It has the characteristics of wide raw material sources, high whiteness, low oil absorption value, good applicability and low price Heavy calcium carbonate grinding technology and Heavy calcium carbonate grinding, surface modification 2022年4月20日 The main component of limestone is calcium carbonate (CaCO 3) with a Mohs hardness of 3 After limestone is mined from limestone rock, it is crushed to form limestone particles, namely stone and sand The particle Limestone crushing and grinding production line

How to Choose a Calcium Carbonate Grinding

2024年9月13日 The choice of grinding mill machine is related to the quality of the final ground calcium carbonate powder, so how to choose the right calcium carbonate grinding equipment has also become a concern for many 2024年11月7日 The calcium carbonate grinding production line is an efficient, stable, and reliable production line with wide application prospects By using advanced equipment and technology, this production line is able to produce highquality calcium carbonate powder to meet the needs of different industries At the same time, the production line also has the advantages Calcium Carbonate Grinding Production Line TAYMACHINERY2023年12月7日 For synthetic calcium carbonate, the process typically involves calcining limestone or other calciumrich materials Calcination is a process of heating the material to a high temperature, which converts the calcium carbonate into calcium oxideWhat is the steps in the Calcium Carbonate Manufacturing 2024年2月20日 Calcium carbonate (CaCO3) is the calcium salt of carbonic acid which at room temperature appears as a white solid and is created by the reaction H 2 CO 3 + Ca(OH) 2 = CaCO 3 + H 2 O; it is the main component of marble When heated or placed in contact with acid substances, it behaves like other carbonates, decomposing and releasing carbon dioxideMachines for crushing, grinding and handling Calcium Carbonate

Mining crushing stations Metso

Mining Crushing Stations combines legacy and expertise to bring unique, costefficient and modular solutions Calcium Carbonate Starch Silica sand Our Foresight™ offering includes an MP Series™ cone crusher station and a semimobile primary gyratory (SMPG) station27 Sep 2023; Grinding equipment for calcium carbonate is essential in the process of producing fine and ultrafine calcium carbonate powder Calcium carbonate grinding equipment mainly includes ball mill, Raymond mill, vertical roller mill, and ultrafine millThese grinding equipment are widely used in various fields of mining, construction, metallurgy, chemical industry, and so ongrinding equipment for calcium carbonate process CM 2023年9月19日 CALCIUM CARBONATE MILLING PROCESS Heavy calcium carbonate (heavy calcium) is made by directly crushing natural limestone, calcite, etc, by mechanical methods (Raymond mill or ultrafine vertical grinding mill and other grinding equipment) Its production methods include dry method and wet method, and all domestic products are produced by dry Calcium carbonate milling process SBM Ultrafine Powder 2019年12月9日 The grinding process includes coarse crushing of precipitated calcium carbonate During the grinding stage, the fine stones from the raw material warehouse are placed in a precipitated calcium powder mill for grinding, and the powder is sent to a superclassified machine Fineness can be adjusted between 2002000 mesh Calcium Carbonate Precipitated calcium carbonate manufacturing process

Exploring Different Grinding Mills for Calcium Carbonate

2023年9月28日 The material is fed into the grinding chamber between the grinding roller and the grinding ring, and the grinding roller applies pressure to the material, resulting in grinding and pulverizing of the calcium carbonate particlesThey are commonly used in the production of calcium carbonate powders with a fineness ranging from 80 mesh to 600 meshCLUM series calcium carbonate ultrafine vertical mill, a new type of ultrafine grinding equipment integrating powder grinding, grading, conveying, secondary powder selection, and finished product packaging, focusing on the largescale Calcium Carbonate Ultrafine Vertical Mill SBM 2024年9月13日 Calcium carbonate air classifier is used for further cut of calcium carbonate powder After being ground in calcium carbonate grinding mill, the calcium carbonate powder will be transferred into air classifier In there, the air flow inside will carry the lighter powder upward and get further cut, while the coarse ones will fall down due to Customize Suitable Calcium Carbonate Plant DASWELL2021年12月20日 The Importance of Calcium Carbonate Calcium carbonate (CaCO3) comprises more than 4% of the earth’s crust and is found worldwide Its most common natural forms are chalk, limestone, and marble (produced by the sedimentation of small fossilized shellfish, snails, and coral over millions of years)Calcium Carbonate Manufacturing Process and Equipment

.jpg)

CALCIUM CARBONATE POWDER

2023年9月25日 um carbonate powder, the processing technology of ground calcium carbonate should also comprehensively consider the process route and equipment selection according to the product positioning Generally speaking, the design of grinding equipment is based on different principles: impact, extrusion, friction, shear and combination of various CLUM Calcium Carbonate Ultrafine Vertical Roller Mill is the specialized ultrafine grinding equipment for nonmetallic ores It suits for grinding nonflammable, nonexplosive brittle materials with Moh’s hardness below 6 such as limestone, calcite, marble, talc, barite, brucite, wollastonite, pyrophyllite, dolomite, kaolin, lime, saponite, etcCLUM calcium carbonate ultrafine vertical roller millIn a bid to enhance their production capabilities and expand their product offerings, this customer has invested in 3 sets of HGM125 micro powder grinding millsThese mills are specifically used to produce ultrafine calcium carbonate and coal powder, achieving a fineness of 600 meshThe final product, which expands upon mixing with water, is utilized as an expansion agent in various Calcium Carbonate and Coal Powder Production Line In China2024年11月26日 In addition to kaolin and talc, calcium carbonate is used in the paper industry as a filler and coating pigment in the production of paper Since calcium carbonate is rhombohedral even when very finely ground, it is primarily used in papers with the highest degree of whiteness and good printabilityCalcium Carbonate NETZSCH Grinding Dispersing

Limestone crushing technology and equipment SBM

2023年12月8日 Limestone Properties The main component of limestone is calcium carbonate (CaCO3), with a Mohs hardness of 3 After limestone is mined from limestone, it is crushed to form limestone particles, that is, stone and sand, or further ground to form limestone powder, which is widely used in industries such as building materials, highways, metallurgy, and 2 天之前 Calcium Carbonate and Mineral CrushingGrinding Roller Mill, Find Details and Price about Crusher Pulverizer from Calcium Carbonate and Mineral CrushingGrinding Roller Mill Fujian Longyi Powder Equipment Manufacturing Co, LtdCalcium Carbonate and Mineral CrushingGrinding Roller Mill2024年3月26日 Therefore, the establishment of a calcium carbonate ultrafine grinding production line has broad market prospects The following are some suggestions for +17 [ protected] Crushing: Crush raw How to set up a calcium carbonate ultrafine 2024年11月7日 Crushing and grinding: The crushed limestone is then ground into a fine powder using a variety of grinding mills, such as ball mills, roller mills, or jet mills This process helps to increase the surface area of the calcium carbonate, making it easier to extract and purify Calcium carbonate grinding mills are an important part of the Calcium Carbonate Manufacturing Process and Grinding Mills

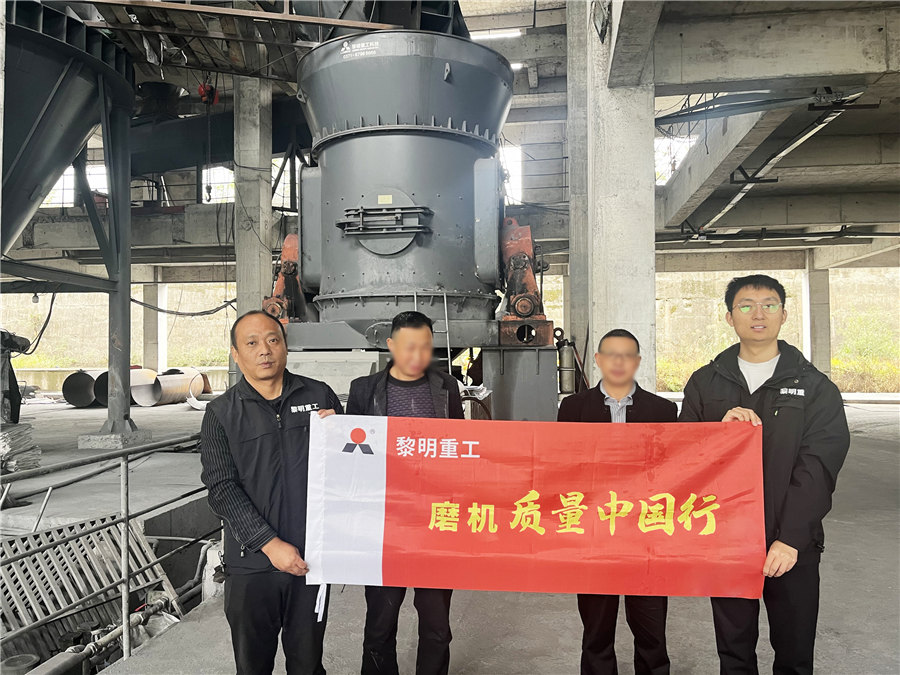

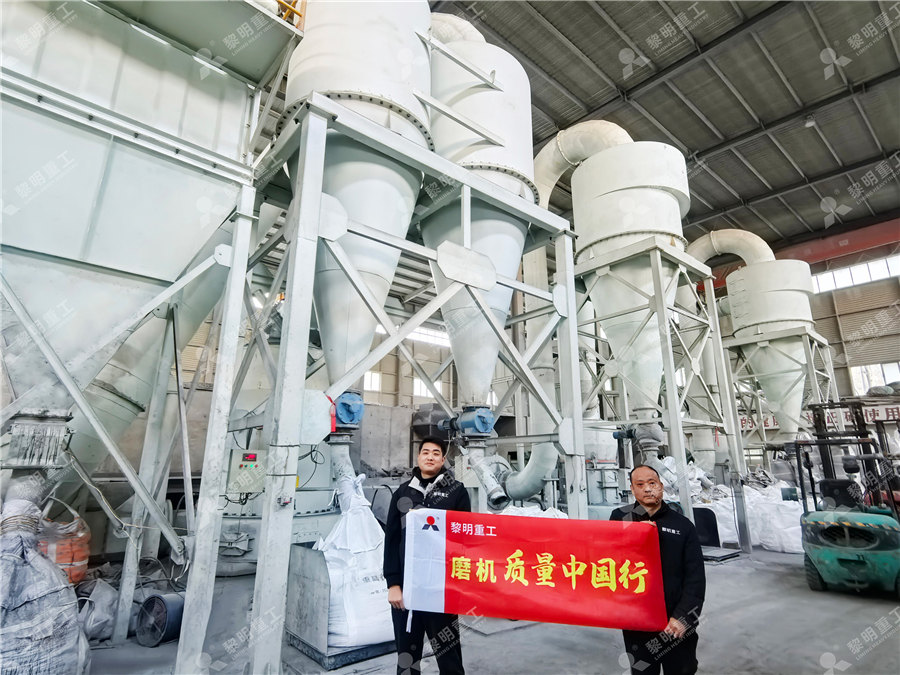

China Hubei heavy calcium carbonate HGM100P ultrafine grinding

2023年11月13日 China Hubei heavy calcium carbonate HGM100P ultrafine grinding mill production line 13/11/2023 admin After selection, it enters the secondary hammer crusher again for further fine crushing The ore finally enters the bottom vertical elevator, which lifts the material to the top of the silo and then transports it to the feed buffer bin of 2024年1月25日 This station also will reduce plant footprint due to the use of multiple pieces of equipment in a compact design and eliminates the need for other equipment downstream Applications include secondary or tertiary crushing, or can be used for direct feeding to a high pressure grinding roll (HPGR) or a SAG mill Fully connected solutionCombining legacy and expertise Mining Crushing 2024年6月7日 The nonmetallic mineral grinding ring roller mill pulverizes nonmetallic minerals into fine powder It is designed and developed based on many years of research and experience in grinding mill production and falls back into the crushing area for crushing the tire’s airtight rubber mainly uses light calcium carbonate Read More Ring Roller Mill Ultrafine calcium carbonate production Heavy calcium carbonate, referred to as heavy calcium, is made from ground natural carbonate minerals such as calcite, marble, and limestone 15TPH Heavy calcium carbonate production line Get More Meet Our Specialist Meet Our Specialist When used for coarse and medium crushing of soft rock, the PFW series impact crusher represents today Grinding HNM Machinery

.jpg)

Ring Mill For Ultrafine Grinding Calcium Carbonate

Grinding Ring: The grinding ring is the main component that provides the necessary compression and shearing force for grindingIt rotates and provides the surface against which the rollers press the material Grinding Rollers: These are cylindrical rollers that apply the grinding pressure to the material against the grinding ringThey roll on the ring and crush the material into fine particles2023年11月21日 A ground calcium carbonate production line typically involves several stages, including mining, crushing, grinding, and classification What Is Ground Calcium Carbonate? Ground calcium carbonate (GCC) is a type of calcium carbonate that is obtained by mechanically grinding and crushing natural calcite, limestone, chalk, marble, or other sourcesIt is one of the Ground Calcium Carbonate Production Line clirikchina2024年6月14日 GCC VS PCC and Calcium Carbonate Grinding Mills ; CLUM Series Mill: EcoFriendly and EnergySaving, Leading UltraFine Powder Production to New Height ; Efficient Grinding Of Calcium Carbonate Calcium Oxide: HGM125 Ultrafine Grinding Mill in Liaoning Ground Calcium Carbonate Production Plant In Sichuan6 天之前 The mobile crushing station, mounted on wheels or tracks, can do mobile crushing or portable crushing between sites to form an efficient crushing and screening plant It can be used for coarse, medium, fine crushing or sand making of hard rocks and minerals on any harsh site, with an output range of 10 to 650 tons/hourA Catalog of All Mobile Crushing Station Fote Machinery

Heavy calcium carbonate grinding, surface modification

2024年7月10日 Heavy calcium carbonate is a calcium carbonate powder material produced by mechanical crushing using calcite, chalk, marble and other minerals as raw materials It has the characteristics of wide raw material sources, high whiteness, low oil absorption value, good applicability and low price Heavy calcium carbonate grinding technology and 2022年4月20日 The main component of limestone is calcium carbonate (CaCO 3) with a Mohs hardness of 3 After limestone is mined from limestone rock, it is crushed to form limestone particles, namely stone and sand The particle Limestone crushing and grinding production line 2024年9月13日 The choice of grinding mill machine is related to the quality of the final ground calcium carbonate powder, so how to choose the right calcium carbonate grinding equipment has also become a concern for many How to Choose a Calcium Carbonate Grinding 2024年11月7日 The calcium carbonate grinding production line is an efficient, stable, and reliable production line with wide application prospects By using advanced equipment and technology, this production line is able to produce highquality calcium carbonate powder to meet the needs of different industries At the same time, the production line also has the advantages Calcium Carbonate Grinding Production Line TAYMACHINERY

.jpg)

What is the steps in the Calcium Carbonate Manufacturing

2023年12月7日 For synthetic calcium carbonate, the process typically involves calcining limestone or other calciumrich materials Calcination is a process of heating the material to a high temperature, which converts the calcium carbonate into calcium oxide2024年2月20日 Calcium carbonate (CaCO3) is the calcium salt of carbonic acid which at room temperature appears as a white solid and is created by the reaction H 2 CO 3 + Ca(OH) 2 = CaCO 3 + H 2 O; it is the main component of marble When heated or placed in contact with acid substances, it behaves like other carbonates, decomposing and releasing carbon dioxideMachines for crushing, grinding and handling Calcium CarbonateMining Crushing Stations combines legacy and expertise to bring unique, costefficient and modular solutions Calcium Carbonate Starch Silica sand Our Foresight™ offering includes an MP Series™ cone crusher station and a semimobile primary gyratory (SMPG) stationMining crushing stations Metso27 Sep 2023; Grinding equipment for calcium carbonate is essential in the process of producing fine and ultrafine calcium carbonate powder Calcium carbonate grinding equipment mainly includes ball mill, Raymond mill, vertical roller mill, and ultrafine millThese grinding equipment are widely used in various fields of mining, construction, metallurgy, chemical industry, and so ongrinding equipment for calcium carbonate process CM

Calcium carbonate milling process SBM Ultrafine Powder

2023年9月19日 CALCIUM CARBONATE MILLING PROCESS Heavy calcium carbonate (heavy calcium) is made by directly crushing natural limestone, calcite, etc, by mechanical methods (Raymond mill or ultrafine vertical grinding mill and other grinding equipment) Its production methods include dry method and wet method, and all domestic products are produced by dry 2019年12月9日 The grinding process includes coarse crushing of precipitated calcium carbonate During the grinding stage, the fine stones from the raw material warehouse are placed in a precipitated calcium powder mill for grinding, and the powder is sent to a superclassified machine Fineness can be adjusted between 2002000 mesh Calcium Carbonate Precipitated calcium carbonate manufacturing process