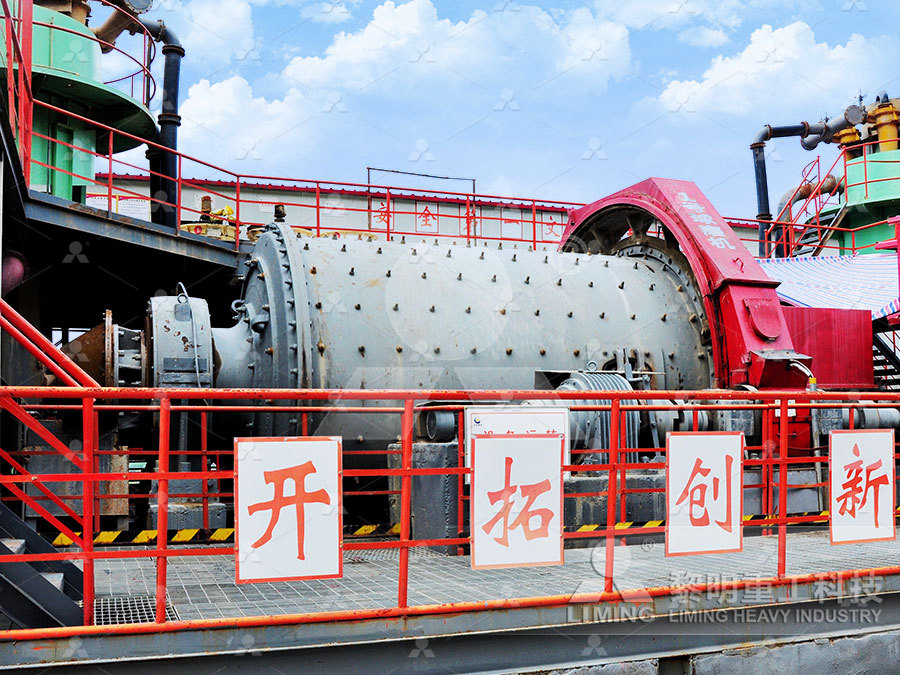

Ore mill produces limestone

.jpg)

Limestone – Its Processing and Application in Iron and IspatGuru

2017年7月7日 The first process takes place at limestone mines where the mined ore undergo crushing and screening for the separation of the different size fractions of the ore In the iron 2015年8月10日 One of the most common fluxing materials for iron ore pellet production is limestone, which is mainly calcium oxide (CaO) In this study, the effect of adding limestone on Effect of adding limestone on the metallurgical properties of iron 2013年5月8日 Dry hydrated lime is generally produced from high calcium quicklime and contains 72 % to 74 % calcium oxide with 23 % to 24 % chemically combined water Limestone Limestone and Dolomite and their Use in Iron and Steel PlantThe blast furnace uses coke, iron ore and limestone to produce pig iron Coal traditionally has been a key part of the cokemaking process The coal is crushed and ground into a powder Steel Production American Iron and Steel Institute

.jpg)

Understanding the Steel Making Process: A Flow Diagram

2024年3月20日 The steel making process involves several key stages: preparation of raw materials such as iron ore, coke, and limestone; smelting and reduction to produce molten 2017年10月10日 Iron is made by reacting iron ore (iron oxide and impurities), coke (a reductant) and limestone (CaCO 3) in a blast furnace Iron ores with lower iron content such as taconite Ironmaking 101 – From Ore to Iron with Blast Furnaces2024年3月13日 As a fluxing agent, limestone is added to the blast furnace during iron and steel production to remove impurities and facilitate the formation of slag This slag, a byproduct of Limestone—A Review with Special Reference to the Iron and Steel 2024年4月26日 Iron ore, a naturally occurring mineral composed primarily of iron oxides, is mined and processed to extract iron for various industrial applications This article provides a Iron Ore Processing: From Extraction to Manufacturing

.jpg)

(PDF) Iron Ore Sintering: Process ResearchGate

2017年2月16日 The present paper reviews the sintering process that the mixture follows, once granulated, when is loaded onto the sinter strand There, the sinter mixture is partially melted 2021年7月15日 The current trend of limestone mining in the Indian mineral industry harnesses emerging technologies to redefine and reinvent solutions that suit production optimization and Modern Technological Applications for Limestone Mining2024年1月18日 Milling: After crushing, small pieces of limestone are sent to the storage bin through an elevator and then evenly and quantitatively fed into the milling chamber of the mill by a vibrating feeder For fine powder processing, How to choose a limestone grinding mill SANDMINEThis produces more magnetite (Fe2O3FeO) along with slag Table 3 Mix proportion of raw material Mill scale, % % 0 10 20 30 40 Iron ore fines Mill scale Bentonite Limestone Corex sludge B2 Carbon 941 00 07 36 16 050 100 Recycling of steel plant mill scale via iron ore sintering

.jpg)

Types of Crushers: Choosing the Right One for Each

2024年7月17日 They can crush low to medium hardness materials such as limestone and coal, as well as materials with moisture content below 15%, suitable for both dry and wet crushing Hammer crushers have a reduction 2021年9月13日 The limestone ultrafine mill machine is a highly efficient industrial grinding mill It can grind limestone into a fine powder (1503000 mesh), and the fineness can be adjusted freely In addition, it can also grind 100+ kinds of nonmetallic minerals with Mohs hardness less than 6, such as calcium carbonate, talc, calcite, carbon black, dolomite, mica, etcLimestone Ultrafine Mill Machine SBM Ultrafine Powder A Limestone Grinding Mill Plant is a facility designed to process limestone into fine powder for various applications Limestone is a sedimentary rock primarily composed of calcium carbonate (CaCO₃) and is widely used in industries such as construction, agriculture, and manufacturingLimestone Grinding Mill Plant TAYMACHINERY2022年4月20日 Limestone crushing process Limestone or limestone are rich in resources, and the grade of raw ore can generally meet the requirements of various industrial sectors Therefore, it is generally only necessary to carry out simple ore washing and does not need to adopt a complex beneficiation process for purificationLimestone crushing and grinding production line SBM Ultrafine

Blast Furnace Process Steel Museum

1 Charge (solid iron ore, coke, and limestone) is constantly dumped into the top of the furnace 2 A blast of hot air is blown into the furnace from the bottom 3 Coke is the fuel that supplies additional heat, increasing the temperature of the charge 42023年12月8日 After limestone is mined from limestone, it is crushed to form limestone particles, and the raw ore grade can generally meet the requirements of various industrial sectors Clum ultrafine vertical mill Fineness: 1503000mesh Yield: 120t/h see More >> GET IN TOUCH Tel: +86 Limestone crushing technology and equipment SBM Ultrafine Project Name: Ultrafine Vertical Limestone Powder Production Line Finished fineness: 1500 mesh Finished product use: The main filler in rubber industry, plastic industry, paper industry, paint industry, coating and feed industry Optional equipment: Limestone ultrafine vertical mill, Crusher, Bucket Elevator, Vibrating Feeder Project Benefits 1 Highquality particle shapeChina Henan limestone ultrafine vertical mill production line2023年10月25日 Highergrade iron ore is more desirable because it requires less processing to produce steel The price of iron ore is also influenced by its quality, with highergrade ore commanding a premium price Iron ore is transported from the mine to the steel mill through a supply chain that includes mining, processing, and transportationIron Ore Supply Chain: From Mining to Steel Production

.jpg)

Limestone Mills Williams Crusher

Hammer Mills Williams manufactures a large variety of hammer mills and hammer crushers wellsuited to handle limestone crushing applications As the manufacturer holding the very first hammer mill patent to utilize midair impact furnaces This ore is poor in iron and has high silica and phosphorous contents In an expansion plant two larger (BFs) having 1033m3 useful volume each were added in order to produce 15 million tons of liquid steel /year Bahariya iron ore was discovered and used in the form of selffluxing sinter as BF feed This ore isEffect of Partial Replacement of Iron Ore by Mill Scale on the 2022年9月1日 VRM has been widely researched in processing of cement (Ito et al, 1997, Jorgensen, 2005, Wang et al, 2009, Ghalandari et al, 2021)), coal (Tontu 2020), iron ore (Reichert et al 2015), zinc ore (van Drunick et al 2010), copper ore (Viljoen et al, 2001, Altun et al, 2015), gold (Erkan et al 2012; Altun et al 2017), nickel ore (Viljoen et al 2001), etc, and it Towards waterless operations from mine to mill ScienceDirect2017年7月7日 Limestone is also a very important industrial mineral Its chemical properties make it a valuable mineral for a wide range of industrial/manufacturing uses Limestone is also one of the vital raw materials used in production of iron and steel Limestone, by definition, is a rock that contains at least 50 % of CaCO3 in the form of calcite by weightLimestone – Its Processing and Application in Iron and

Limestone Grinding Mill Solution Adjustable Powder Fineness

The different finenesses of lime grinding powder are suitable for different industriesAGICO’s raymond limestone grinding mill and limestone ball mill can grind powder with fineness of 80400 mesh, if you want even finer powder, you can choose the vertical If you want finer powder, you can choose the vertical limestone grinding mill, which can grind the powder fineness above Ore grinding is one of the key stages in the mining process It's where the ore is reduced to a fine powder, which can then be used in other stages of the extraction process Grinding performance is a critical parameter for this stage, as it affects both the speed and quality of the final product The parts of a ball millFactors affecting ores grinding performance in ball mills2023年12月15日 The iron ore used in this study included three Australian ores and two Brazilian ores The fuel was coke, and the fluxes included limestone, dolomite, and WM from a paper mill in Shandong Province, China The compositions and loss on ignition (LOI) of these raw materials are shown in Table 1A new disposal method for white mud: Replacing limestone in iron ore Limestone Raymond mill 80600 mesh Discharge fineness: 80600 mesh Feed size: 35 mm Output: 0435 t/h Materials: various nonflammable and explosive materials with Mohs hardness less than 93 and humidity less than 6%Limestone Raymond mill 80600 mesh SBM Ultrafine Powder

Recycling of steel plant mill scale via iron ore ResearchGate

2009年8月1日 Mill scale is an iron oxide waste generated during steelmaking, casting and rolling Total generation of mill scale at JSWSL is around 150 t/day and contains 60–70%FeO and 30–35%Fe2O32017年12月21日 (a) Acidic iron ore pellet without mill scale (b) Acidic iron ore pellet with 15% mill scale Figure 6 Effect of mill scale on apparent porosity in acidic pellet(PDF) Mill scale as a potential additive to improve the quality 2024年3月13日 Limestone, Fluorite, and Calcium carbide are the materials used as flux in steel making It is combined with other materials such as iron ore and coke in a blast furnace to produce molten iron This molten iron is then further processed to obtain steel 3Limestone—A Review with Special Reference to the Iron and Steel 2011年1月1日 Infect only a few investigators worked on the kinetics of mill scale reduction [24][25][26][27][28][29][30]In previous studies on the use of the catalyst for iron ore or mill scale reduction (PDF) Recycling of mill scale in sintering process

(PDF) Influence of Pellet Basicity (CaO/SiO2) on Iron

2011年1月18日 The pellet containing dolomitic limestone (Ba 03 C 11 B 07 ) presented a tumble index of 209% Umadevi et al 15 mentioned that pellets with higher basicity generally exhibit better tumble 2023年8月27日 Limestone has played an essential role in Centre County steel makers began integrating blast furnaces with their mills and sourcing higher quality ore from the Lake Superior region A blast furnace at a Pittsburgh mill might produce 1,000 tons of pig iron in a day—more than a small regional furnace could produce in a week Limestone Centre County Encyclopedia of History Culture2020年1月8日 Australia produces 19 useful minerals in significant amounts, from over 350 operating mines From these minerals, useful materials such as metals can be extracted Australia is one of the world's leading producers of bauxite (aluminium ore), iron ore, lithium, gold, lead, diamond, rare earth elements, uranium, and zincAustralian mineral facts Geoscience Australia2013年10月31日 Produces Limestone Ebony Iron Cloth JewelryBoosted with Limestone Rock Ebony Tree Iron Ore Wool Gemstone Paper Mill Coffee Roaster Wiremill Porcelain Manufactory Tar Kiln: Size 2x3 3x3 3x3 4x4 3x5: Produces Paper Coffee Iron Ore Gemstone Limestone Rock WoolUnrefined Needs Fertilizer Coke Rubber Textiles Whale Oil:[Guide] Goods Buildings Tech Tree Requirements

.jpg)

8 Types of Gold Ore Properties and Ways to Process

2023年6月12日 The most valuable ores of gold are quartz gold ore, silver gold ore, copper gold ore, gold sulfide ore, etc 1 Grind bulk silverrich gold ore to a finer size by using a ball mill 2 Leach the flotation tailings and then the resulting product is evaporated to recover the mercury and produce gold sponge residue2020年9月15日 What kind of mill can be used to grind limestone powder? HCMilling(Guilin Hongcheng) provides limestone Raymond mill equipment, including Raymond mill, vertical roller mill, ultrafine mill, superfine vertical grinding mill, etc These mills are highend environmental protection ore mills developed by HCM Its grinding fineness is between 3252500 mesh, and Project Cases:325 Mesh Limestone Raymond Mill Production Line 2017年7月26日 Soft ore Work Index 13 = 100,000/90,000 = 11 kwh/t Hard ore Work Index 16 = 100,000/65,000 = 154 kwh/t For the purposes of this example, we will hypothesize that the the crushing index of the hard ore with the increased energy input of 154 kw/t reduces the ball mill feed size to 6,500 micrometersHow Ball Mill Ore Feed Size Affects Tonnage CapacityMaterials: Raymond mill grinds minerals like gypsum and limestone, while ball mill processes metal ores and cement clinker b Output: Raymond mill produces less than ball mill but uses less power c Dust pollution: Raymond mill has cleaner dust control, whereas ball mill is larger, harder to manage, and causes more dust pollution dHighefficient Raymond Mill Fote Machinery

How to choose a limestone grinding mill SANDMINE

2024年1月18日 Milling: After crushing, small pieces of limestone are sent to the storage bin through an elevator and then evenly and quantitatively fed into the milling chamber of the mill by a vibrating feeder For fine powder processing, This produces more magnetite (Fe2O3FeO) along with slag Table 3 Mix proportion of raw material Mill scale, % % 0 10 20 30 40 Iron ore fines Mill scale Bentonite Limestone Corex sludge B2 Carbon 941 00 07 36 16 050 100 Recycling of steel plant mill scale via iron ore sintering 2024年7月17日 They can crush low to medium hardness materials such as limestone and coal, as well as materials with moisture content below 15%, suitable for both dry and wet crushing Hammer crushers have a reduction Types of Crushers: Choosing the Right One for Each 2021年9月13日 The limestone ultrafine mill machine is a highly efficient industrial grinding mill It can grind limestone into a fine powder (1503000 mesh), and the fineness can be adjusted freely In addition, it can also grind 100+ kinds of nonmetallic minerals with Mohs hardness less than 6, such as calcium carbonate, talc, calcite, carbon black, dolomite, mica, etcLimestone Ultrafine Mill Machine SBM Ultrafine Powder

Limestone Grinding Mill Plant TAYMACHINERY

A Limestone Grinding Mill Plant is a facility designed to process limestone into fine powder for various applications Limestone is a sedimentary rock primarily composed of calcium carbonate (CaCO₃) and is widely used in industries such as construction, agriculture, and manufacturing2022年4月20日 Limestone crushing process Limestone or limestone are rich in resources, and the grade of raw ore can generally meet the requirements of various industrial sectors Therefore, it is generally only necessary to carry out simple ore washing and does not need to adopt a complex beneficiation process for purificationLimestone crushing and grinding production line SBM Ultrafine 1 Charge (solid iron ore, coke, and limestone) is constantly dumped into the top of the furnace 2 A blast of hot air is blown into the furnace from the bottom 3 Coke is the fuel that supplies additional heat, increasing the temperature of the charge 4Blast Furnace Process Steel Museum2023年12月8日 After limestone is mined from limestone, it is crushed to form limestone particles, and the raw ore grade can generally meet the requirements of various industrial sectors Clum ultrafine vertical mill Fineness: 1503000mesh Yield: 120t/h see More >> GET IN TOUCH Tel: +86 Limestone crushing technology and equipment SBM Ultrafine

.jpg)

China Henan limestone ultrafine vertical mill production line

Project Name: Ultrafine Vertical Limestone Powder Production Line Finished fineness: 1500 mesh Finished product use: The main filler in rubber industry, plastic industry, paper industry, paint industry, coating and feed industry Optional equipment: Limestone ultrafine vertical mill, Crusher, Bucket Elevator, Vibrating Feeder Project Benefits 1 Highquality particle shape2023年10月25日 Highergrade iron ore is more desirable because it requires less processing to produce steel The price of iron ore is also influenced by its quality, with highergrade ore commanding a premium price Iron ore is transported from the mine to the steel mill through a supply chain that includes mining, processing, and transportationIron Ore Supply Chain: From Mining to Steel Production