HOME→How much is a tire cracking carbon black milling production line processing equipment How much is a tire cracking carbon black milling production line processing equipment How much is a tire cracking carbon black milling production line processing equipment

How much is a tire cracking carbon black milling production line processing equipment How much is a tire cracking carbon black milling production line processing equipment How much is a tire cracking carbon black milling production line processing equipment

.jpg)

Tire pyrolysis carbon black deep processing grinding

2023年4月7日 Carbon black deep processing grinding equipment For further processing of the coarse carbon black from tire pyrolysis, we can use the HGM series ultrafine ring roller mill and CLUM series vertical roller mill Discover a toptier waste tire cracking carbon black deep processing line for all your carbon black needs Highquality equipment for efficient productionWaste Tire Cracking Carbon Black Deep Processing Line2023年9月19日 ClirikProfessional waste tire carbon black production equipment The Clirik HGM80 model production line is a small milling production line with a total length of only 15 HGM80 Ultra Fine Grinding Mill Used in Waste Tire Powder 2T/H Tire Pyrolysis Carbon Black Project Equipment: MW1080 Material: carbon black after tire pyrolysis Capacity: 152t/h Output size: D99 400600 mesh Location: Atlanta, USA Using 2T/H Tire Pyrolysis Carbon Black ProjectLIMING HEAVY

.jpg)

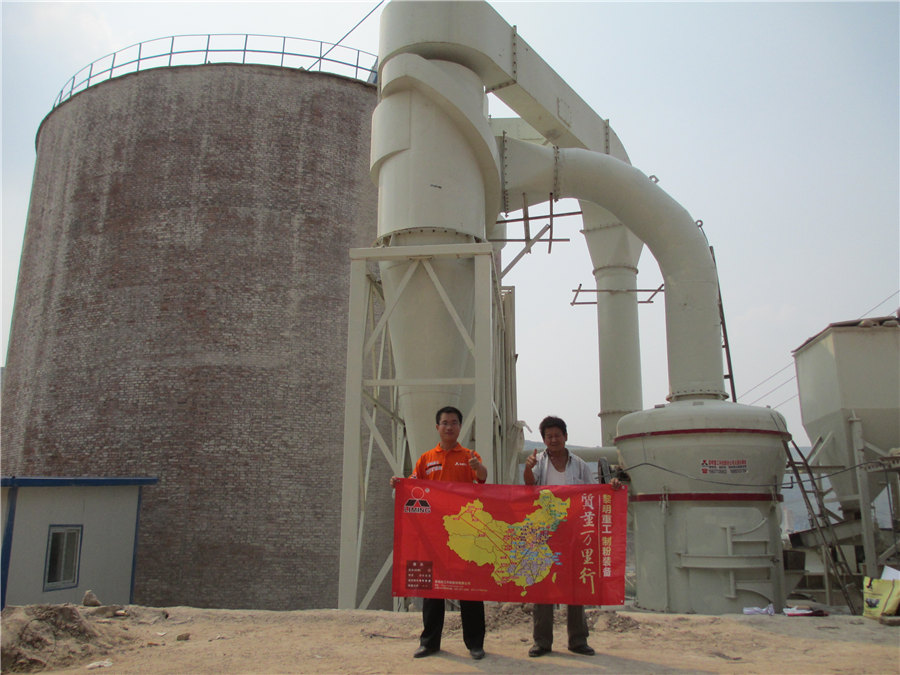

Tire cracking and fine grinding production line equipment

2023年4月25日 The ultrafine ring roller mill can be used in the 3060 tons per day tire cracking and fine grinding production line After processing by the grinding equipment, it can produce 2022年3月9日 Pyrolysis enables the recovery of both energy and material from endoflife tires, yielding valuable gas, liquid, and solid fractions The latter, known as recovered carbon black (rCB), has been extensively researched in the last Production and Upgrading of Recovered Carbon Black 2022年3月9日 Pyrolysis enables the recovery of both energy and material from endoflife tires, yielding valuable gas, liquid, and solid fractions The latter, known as recovered carbon black (rCB), has(PDF) Production and Upgrading of Recovered Carbon 2024年11月26日 Notch Consulting’s forecast for carbon black demand in 2029 is estimated at 187 million tons (following the increasing tire production) Using the same intensity rate, GHG emission associated with the Carbon Black Sustainable Carbon Black produced from endoflife

.jpg)

Lifecyclebased reconfiguration of sustainable carbon black

2024年2月25日 This study proposed an integrated process of waste tire pyrolysis and carbon black production (IntTech) which can help to establish a closedloop process between rubber 2024年11月20日 Project Overview: The comprehensive treatment scale of waste tires is 100,000 tons/year, and a complete set of carbon black deep processing production lines with a Complete production line for waste tire pyrolysis carbon black 2024年1月30日 By mixing carbon black with rubber, you can increase the wear resistance, durability, and strength of your tires Carbon black content in tires The amount of carbon black varies depending on tire type and use Typically, the carbon black content in an average passenger car tire is about 20% to 30%How Much Carbon Black Will Be In Tires? Dery2022年7月18日 The production of carbon black, a crucial industrial material with diverse applications ranging from rubber reinforcement to ink pigmentation, plays a pivotal role in various manufacturing sectors(PDF) Production of Carbon Black ResearchGate

Efficient Carbon Black Milling Equipment Pulva

As the leading supplier of industrial carbon black milling equipment, we provide customers worldwide with the products they need to process nearly gritfree carbon black At Pulva Corporation, our range of PulvaSizer ™ carbon black 2024年4月15日 Production Process The production of carbon black from tires involves the following steps: Tire Shredding: Waste tires are shredded into smaller pieces to facilitate the pyrolysis process and increase surface area for efficient heat transfer Pyrolysis: The shredded tires are subjected to high temperatures in a reactor, typically ranging from 400°C to 800°C, in Understanding Carbon Black from Tires: Production, Properties, These processes produce nearly all of the world's carbon blacks, with the furnace black process being the most common The furnace black process uses heavy aromatic oils as feedstock The production furnace uses a closed reactor to atomize the feedstock oil under carefully controlled conditions (primarily temperature and pressure)How is it Produced? ICBA2023年6月10日 You’re not alone! Tire cracking is more common than you might think, and it can raise a lot of questions, especially when it comes to the safety and performance of your vehicle Tire Cracking Tire cracking is a common occurrence as tires age and are exposed the sun’s UV rays, harsh weather, and even ozone in the airTire Cracking (FAQ) TireGrades

.jpg)

What is Carbon Black and How is it Made? Prater

Processing Carbon Black The prime piece of equipment used for processing carbon black is the reactor in which it’s fired, with adjustments to conditions producing different grades Temperatures, flow rates, time in the reactor, and reactor design all affect the physical characteristics of the end product2024年11月11日 The US carbon black market size was worth USD 348 billion in 2022 and is projected to record a CAGR of 42% during the forecast period Carbon black is an almost pure form of carbon which is produced in the form of colloidal particles by partial combustion or thermal decomposition of hydrocarbonsUS Carbon Black Market Size, Share Growth Report [2030]2022年11月1日 Thus, the char yield obtained in fast pyrolysis is usually slightly higher than the carbon black content of original tire rubber, ie in the 25 to 35% range However, the opposite effect can be observed under slow pyrolysis conditions with a higher extent of secondary reactions, higher char yields, and carbon black adulterationTire pyrolysis char: Processes, properties, upgrading and 2023年9月19日 ClirikProfessional waste tire carbon black production equipment The Clirik HGM80 model production line is a small milling production line with a total length of only 15 meters, HGM80 ultrafine grinding mill production line: Processing materials: carbon black: Finished product particle size: 200600 mesh:HGM80 Ultra Fine Grinding Mill Used in Waste Tire Powder Processing

Tire Shredding Equipment Rubber Recycling

ECO Green Leads in Global Tire Recycling Equipment Eco Green Equipment is the global leader in costeffective turnkey tire recycling systems Our systems deliver optimum production performance and profitability at the industry’s most A tire is a complex combination of components made from numerous ingredients But how do we get from the rubber tree to the road? Tire production is a multistep process Let’s follow a Continental tire through all five essential stages of Tire production Continental Tires2020年9月25日 Radiation from the plasma torch, as well as heat convection from the plasma gas, provides enough energy for the pyrolysis of hydrocarbons Temperature is the important parameter in cracking reactions [38]After the conversion of hydrocarbons into carbon black and hydrogen, a waste heat recovery system takes advantage of the heat of the products to Carbon black and hydrogen production process analysis2021年10月19日 Recovered Carbon Black is a carbonaceous nanomaterial, it is a new category of Carbon Black, containing various commercial Carbon Black grades (between 80 and 90 wt%) and inorganic substances (between 10 and 20 wt%), often referred to Upgrading Recovered Carbon Black from endoflife tires

Carbon black market demand to reach 17 million tons per year

2022年2月24日 The global production of and demand for carbon black are increasing The region Asia Pacific is a forerunner in this area: It accounts for more than 64% of the global carbon black production volume With a demand of approx 48 million tons, China is the largest consumer of carbon black2024年1月1日 Pyrolysis is a clean and lowcarbon thermochemical technology for waste tire management, which converts waste tires to highvalue alternative fuels (gas and liquid oil), carbon black, limonene, and monocyclic aromatic hydrocarbons [3, 4]Carbon black is an essential fine chemical product and primarily utilized as a reinforcing ingredient for tire manufacture [5]Carbon black production characteristics and mechanisms from Looking for topoftheline waste tire cracking carbon black equipment? Trust Weifang Jinghua for highquality solutions and exceptional service : jinghuapowder@163; Phone: +86(WhatsApp/Wechat) Home; Waste Tire Cracking Waste Tire Cracking Carbon Black Equipmentautomotive industry in North America In Europe, the demand for carbon black is estimated at ~27M tons, representing ~$3b and 15% of the overall demand Recovered carbon black serves as a sustainable alternative to virgin carbon black and has the potential to replace 1020% of virgin carbon black (due to its inferior quality), equivalent to 250Emerton White Paper Recovered Carbon Black 2024

.jpg)

Recommended Mixing Equipment for Carbon Black Dispersions

Application Summary Used in paints, inks, coatings, adhesives, sealants, plastics, electronics and specialty products, carbon black dispersions are typically prepared using high shear mixing or milling equipment to effectively break down agglomeratesAs a reinforcing filler, pigment, conductive agent and UV stabilizer, carbon black must ideally be dispersed uniformly as 2024年11月11日 Carbon black is likewise an exceptional coloring agent as a black pigment and is extensively used for printing inks, resin coloring, paints, and toners Furthermore, carbon black is utilized in numerous different applications as an electric conductive agent, consisting of antistatic films, fibers, and floppy disksCarbon Black Market Trends Fortune Business Insights2024年1月11日 Pyrolysis is a promising way to reuse of waste tires However, the carbon black generated in the process is often contaminated with various pyrolysis products This study aims to recycle lowquality recycled carbon Recycling of LowQuality Carbon Black Produced by Carbon Black Applications for Attritors Carbon black has a history dating back to ancient China, India and Egypt Although it’s one of the oldest manufactured materials, it’s still found in numerous products today Carbon black is used both for its coloring capabilities and for its physical properties It is used to color a wide rangeCarbon Black Milling Union Process

The Role Of Carbon Black In The Tire Industry Dery

2024年8月20日 Each grade of carbon black is selected based on its performance characteristics, such as reinforcement capability, abrasion resistance, and processability Benefits of Carbon Black in Tire Manufacturing 2022年3月9日 The tire industry is no exception to this, with a global production of more than 15 billion tires per year raising environmental concerns about their endoflife recycling or disposal(PDF) Production and Upgrading of Recovered Carbon Black Replacement tire segment has been leading the tire industry as stable to weak automotive output hindered Original Equipment (OE) tire demand Imports of Carbon black from Asia and Europe remained weak as freight charges rose persistently during the first quarter after observing some stability in later stage of December 2021 Asia PacificCarbon Black Prices, News, Monitor, Analysis Demand2018年6月8日 The team spends most of its time gathering VOC (voice of customers), looking at current product performance, analyzing benchmarking data, reviewing customers’ feedback and press testing data They crunch the data and create a comprehensive requirement for a new tire line or a specific tireTire Technology: The Science Engineering Behind Making a Tire

.jpg)

Carbon black recycled from car tires Phys

2021年7月1日 Around three kilograms of carbon black—also known as industrial soot—are found in a standard car tireHere's the problem: To produce one ton of carbon black, we need approximately 15 tons of Recovered Carbon Black (rCB):A sustainable alternative to traditional carbon black, rCB is produced by recycling carbon black from used rubber products It reduces waste and carbon emissions while offering performance comparable to virgin carbon black Our equipment is tailored to handle rCB's specific properties and processing needsBest Carbon Black Processing Plant Rieco Enquire NowCarbon black is a fine, soft powder created when crude oil or natural gas is burned with a limited amount of oxygen, causing incomplete combustion and creating a large amount of fine soot So much carbon black is required for manufacturing tires that rail cars transport it and huge silos store the carbon black at the tire factory until it is How tire is made material, history, used, processing, parts Carbon Black Market Size Trends The global carbon black market size was valued at USD 2235 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 48% from 2024 to 2030 Rising product usage in the production of plastics is anticipated to drive growth Moreover, the rising usage of these plastics in electrical and electronic components Carbon Black Market Size, Share And Growth Report, 2030

.jpg)

How Much Carbon Black Will Be In Tires? Dery

2024年1月30日 By mixing carbon black with rubber, you can increase the wear resistance, durability, and strength of your tires Carbon black content in tires The amount of carbon black varies depending on tire type and use Typically, the carbon black content in an average passenger car tire is about 20% to 30%2022年7月18日 The production of carbon black, a crucial industrial material with diverse applications ranging from rubber reinforcement to ink pigmentation, plays a pivotal role in various manufacturing sectors(PDF) Production of Carbon Black ResearchGateAs the leading supplier of industrial carbon black milling equipment, we provide customers worldwide with the products they need to process nearly gritfree carbon black At Pulva Corporation, our range of PulvaSizer ™ carbon black Efficient Carbon Black Milling Equipment Pulva2024年4月15日 Production Process The production of carbon black from tires involves the following steps: Tire Shredding: Waste tires are shredded into smaller pieces to facilitate the pyrolysis process and increase surface area for efficient heat transfer Pyrolysis: The shredded tires are subjected to high temperatures in a reactor, typically ranging from 400°C to 800°C, in Understanding Carbon Black from Tires: Production, Properties,

.jpg)

How is it Produced? ICBA

These processes produce nearly all of the world's carbon blacks, with the furnace black process being the most common The furnace black process uses heavy aromatic oils as feedstock The production furnace uses a closed reactor to atomize the feedstock oil under carefully controlled conditions (primarily temperature and pressure)2023年6月10日 You’re not alone! Tire cracking is more common than you might think, and it can raise a lot of questions, especially when it comes to the safety and performance of your vehicle Tire Cracking Tire cracking is a common occurrence as tires age and are exposed the sun’s UV rays, harsh weather, and even ozone in the airTire Cracking (FAQ) TireGradesProcessing Carbon Black The prime piece of equipment used for processing carbon black is the reactor in which it’s fired, with adjustments to conditions producing different grades Temperatures, flow rates, time in the reactor, and reactor design all affect the physical characteristics of the end productWhat is Carbon Black and How is it Made? Prater2024年11月11日 The US carbon black market size was worth USD 348 billion in 2022 and is projected to record a CAGR of 42% during the forecast period Carbon black is an almost pure form of carbon which is produced in the form of colloidal particles by partial combustion or thermal decomposition of hydrocarbonsUS Carbon Black Market Size, Share Growth Report [2030]

.jpg)

Tire pyrolysis char: Processes, properties, upgrading and

2022年11月1日 Thus, the char yield obtained in fast pyrolysis is usually slightly higher than the carbon black content of original tire rubber, ie in the 25 to 35% range However, the opposite effect can be observed under slow pyrolysis conditions with a higher extent of secondary reactions, higher char yields, and carbon black adulteration2023年9月19日 ClirikProfessional waste tire carbon black production equipment The Clirik HGM80 model production line is a small milling production line with a total length of only 15 meters, HGM80 ultrafine grinding mill production line: Processing materials: carbon black: Finished product particle size: 200600 mesh:HGM80 Ultra Fine Grinding Mill Used in Waste Tire Powder Processing