Limestone processing production line

Limestone Quarrying and Processing: A LifeCycle Inventory

Process flow diagram for limestone processing operations Processing commences with transportation of the (raw) stone from the quarry to the processing facility, as depicted by Figure 22023年2月15日 The whole lime production line includes: mining, crushing, screening and calcinating First, limestone is quarried from mines with the help of big machines and blasting In this stage, limestone with big blocks which are Lime Production Process and Required Equipment2024年1月23日 To transform limestone into various raw materials, a series of processing steps are required Today, we will focus on the limestone crushing and screening process: Initially, the raw limestone blocks are uniformly conveyed to a jaw crusher through a vibrating feederLimestone crushing and screening production line introductionThe limestone grinding production line is a production process for the fine processing of limestone raw materials The limestone grinding production line grinds limestone into powders of different fineness through crushing, grinding, classification, and other processes to meet the needs of different fields This production line covers the complete process from raw material processing Limestone Grinding Mill Plant TAYMACHINERY

.jpg)

How Lime is Made

Limestone is a naturally occurring and abundant sedimentary rock consisting of high levels of calcium and/or magnesium carbonate and/or dolomite (calcium and magnesium carbonate), along with minerals Lime production begins by extracting limestone from quarries and mines Sizing Limestone enters a primary crusher to break the rockLimestone The main component of limestone is calcium carbonate (CaCO3) Lime and limestone are applied in a lot of building materials It is also an important raw material in many industries Limestone can be directly processed into aggregated rock and calcined into quicklime Lime are divided into two kinds: quicklime and slaked limelimestone grinding mill, limestone grinding machine, limestone The limestone production line designed by Luoyang Dahua perfectly matches the machine character, fully shows its efficacy This production line has the features of large production capacity, stable operation, uniform granularity, less dust, and the produced particles with good shape ♦ 1 Coarse CrushingLimestone Processing Luoyang DahuaLimestone Crushing Production Line The limestone crushing production line mainly consists of a vibrating feeder, jaw crusher, impact crusher, vibrating screen, belt conveyor, centralized electronic control, and other equipment To meet the different processing needs of customers, it can be equipped with a cone crusher, dust collector Equipment, etcLimestone Crushing Equipment and Production Line

Lime Production Process and Required Equipment

2023年2月15日 The industrial production line of lime The whole lime production line includes: mining, crushing, screening and calcinating Mining highquality limestone First, limestone is quarried from mines with the help of big machines and blasting In this stage, limestone with big blocks which are not suitable for putting in a kilnii table of contents 1 introduction 1 2 limestone quarrying and processing operations 2 21 limestone 2 22 limestone quarrying operations 2 23 limestone processing operations 3 3 lci methodology 5 31 lci data collection 5 32 quality of lci data set 5 331 limestone quarry operations 5 332 limestone processing operations 6 4 lci results 7Limestone Quarrying and Processing: A LifeCycle InventoryAdditionally, since the mid1980s, we’ve developed extensive experience in Circulating Fluidized Bed (CFB) technology and our limestone mills have proven themselves as an essential part of CFB systems The limestone crushers and mills are effective for directinjection of dry sorbent lime or limestone during the CFB processLimestone Mills Williams Crusher2024年1月11日 Equipment Configuration Of Limestone SandMaking Plant The equipment for the limestone sand production line mainly includes a vibrating feeder, jaw crusher, sand making machine, circular vibrating screen, sand washing machine, etc The vibrating feeder is responsible for evenly and quantitatively delivering raw materials to the stone crusherLimestone Crushing And SandMaking Plant Eastman Rock

.jpg)

Limestone Crushing Plant Indonesia 12200T/H

Limestone crushing plant Indonesia is a special stone processing production line for crushing limestone, and other minerals with similar hardness It can crush limestone into various sizes of stones that meet special production The limestone grinding production line is a production process for the fine processing of limestone raw materials The limestone grinding production line grinds limestone into powders of different fineness through crushing, grinding, classification, and other processes to meet the needs of different fields This production line covers the complete process from raw material processing Limestone Grinding Mill Plant TAYMACHINERYLimestone crushing production line is a type of production line used to process limestone into crushed stone and sand Secondary crusher: If the screened material is not fine enough, it may be sent to a secondary crusher for further processingLimestone crushing production line NEWS SMMVIK MachineryWe can supply you with a single piece of equipment or a complete pelletizing line When utilized in this way, pin mixers can yield increased production; the majority of the required moisture can be added during the preconditioning step, Limestone Processing, Pelletized (Pelletised) Limestone Pelletized (Pelletised) Limestone Processing Equipment FEECO International Inc

.jpg)

Production European Lime Association

Lime is made from indigenous limestone or chalk rock, one of the most abundant materials in the Earth’s crust Limestone and chalk are both sedimentary rocks and are chemically known as calcium carbonate When crushed or ground, they are widely used as aggregates and building products As a raw material, calcium carbonate can also be processed []The limestone grinding production line is a production process for the fine processing of limestone raw materials The limestone grinding production line grinds limestone into powders of different fineness through crushing, grinding, classification, and other processes to meet the needs of different fields This production line covers the complete process from raw material processing Limestone Grinding Mill Plant TAYMACHINERY2022年4月20日 After limestone is mined from limestone rock, Limestone crushing and grinding production line 20/04/2022 admin Limestone Properties The processing of limestone is mainly to crush, classify and produce quicklime, slaked lime, precipitated calcium carbonate, Limestone crushing and grinding production line SBM Ultrafine 2024年9月13日 Today, let us follow the footsteps of the miners and unveil the mystery of the limestone production line Limestone, a common mineral, is widely used in building materials, chemicals, Transportation and processing The crushed limestone is transported to the processing area by belt conveyorA Day of a Miner: Exploring a Limestone Production Line

Lime Production Line Active Lime Production Line Cement Plant

SOLUTION2: Lime Production Line With Vertical Kiln The vertical lime kiln is suitable for smallcapacity active lime production lines, lowcost, safe and environmentally friendly The vertical lime kiln uses the principle that the material’s own weight descends and the hot gas rises for heat exchange to burn lime We supply twin shaft lime kiln, double beam lime kiln, annular lime kiln If you need a plan for turn limestone into granules in a small scale, which is about 15 t/h Disc granulation line is an ideal choice for you For one thing, it can fully meet your requirement to prepare 15 tons of limestone pellets per hourLimestone Pellets Granulating Production LineRecently, a mine owner from Sudan contacted the Nile for a list of the configuration of a limestone crushing production line with a capacity of 600 tons per hour After understanding the customer’s needs, our technicians 600 t/h limestone crushed stone production lineProject Name: Ultrafine Vertical Limestone Powder Production Line Finished fineness: 1500 mesh Finished product use: The main filler in rubber industry, plastic industry, paper industry, paint industry, coating and feed industry Optional equipment: Limestone ultrafine vertical mill, Crusher, Bucket Elevator, Vibrating Feeder Project Benefits 1 Highquality particle shapeChina Henan limestone ultrafine vertical mill production line

.jpg)

Limestone ultrafine grinding production line customer site

2023年12月6日 Recently, the HGM100 ultrafine mill production line of a customer in Binzhou, Shandong, China has been installed and officially put into production The production line mainly produces limestone powder of more than 800 mesh The customer said:”The operation is very stable, the grade of the finished product is quite high, and the actual Learn more about our proven wet processing solutions for limestone processing +44 28 8676 7900 Language Applications Sand Aggregates Our Sand Concrete Production Turnkey washing plant processing 6mm crushed limestone with high fines content and producing aggregates and manufactured sandsLimestone Processing Limestone Wash Plant CDE CDEThe latest limestoneprocessing equipment is present at Kilkenny Limestone, from fast texturing options to a semiautomated tile cutting line Our advanced ITsystem allows for full traceability throughout the quarry and factory production process, which means each customerorder can be traced back to a certain layer in each quarry EquipmentKilkenny Limestone® production process Brachotprocesses in the production of lime are: (1) quarrying raw limestone; (2) preparing limestone for the kilns by crushing and sizing; (3) calcining limestone; (4) processing the lime further by hydrating; and (5) miscellaneous transfer, storage, and handling operations A generalized material flow diagram for a lime1117 Lime Manufacturing US EPA

.jpg)

Tutorial:Production line Official Satisfactory Wiki

This article describes the basics of setting up production lines, how to read the UI of buildings (such as input and output item rates), and how to calculate building ratios For more information on planning a production line, see Tutorial:Production line design tips A simple production line involves Miner → Smelter → Constructor → Storage Container The example shows the 2022年7月20日 Process flow of limestone sand production line 1 Process flow of limestone manufactured sand Sand making: Through the crushed limestone, part of it is directly sent to the stockpile as a finished product, and the other part is crushed and made sand by the sand making machine Screening: The vibrating screen is also responsible for distinguishing the finished Limestone crushing, sand making and grinding process2 Limestone Quarrying and Processing Operations 21 Limestone Limestone is a sedimentary rock composed primarily of calcium carbonate with the occasional presence of magnesium Most limestone is biochemical in origin meaning the calcium carbonate in the stone originated from shelled oceanic creatures Limestone can also be chemical in originA LifeCycle Inventory of Limestone Dimension Stone Quarrying 2024年1月23日 To transform limestone into various raw materials, a series of processing steps are required Today, we will focus on the limestone crushing and screening process: Initially, the raw limestone blocks are uniformly conveyed to a jaw crusher through a vibrating feederLimestone crushing and screening production line introduction

Limestone Grinding Mill Plant TAYMACHINERY

The limestone grinding production line is a production process for the fine processing of limestone raw materials The limestone grinding production line grinds limestone into powders of different fineness through crushing, grinding, classification, and other processes to meet the needs of different fields This production line covers the complete process from raw material processing Limestone is a naturally occurring and abundant sedimentary rock consisting of high levels of calcium and/or magnesium carbonate and/or dolomite (calcium and magnesium carbonate), along with minerals Lime production begins by extracting limestone from quarries and mines Sizing Limestone enters a primary crusher to break the rockHow Lime is MadeLimestone The main component of limestone is calcium carbonate (CaCO3) Lime and limestone are applied in a lot of building materials It is also an important raw material in many industries Limestone can be directly processed into aggregated rock and calcined into quicklime Lime are divided into two kinds: quicklime and slaked limelimestone grinding mill, limestone grinding machine, limestone The limestone production line designed by Luoyang Dahua perfectly matches the machine character, fully shows its efficacy This production line has the features of large production capacity, stable operation, uniform granularity, less dust, and the produced particles with good shape ♦ 1 Coarse CrushingLimestone Processing Luoyang Dahua

Limestone Crushing Equipment and Production Line

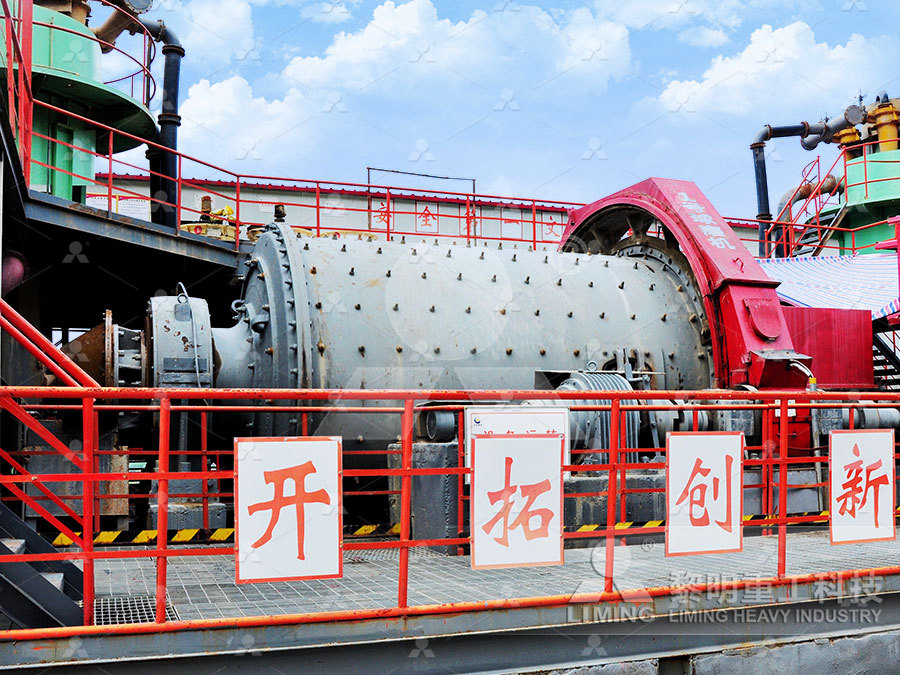

Limestone Crushing Production Line The limestone crushing production line mainly consists of a vibrating feeder, jaw crusher, impact crusher, vibrating screen, belt conveyor, centralized electronic control, and other equipment To meet the different processing needs of customers, it can be equipped with a cone crusher, dust collector Equipment, etc2023年2月15日 The industrial production line of lime The whole lime production line includes: mining, crushing, screening and calcinating Mining highquality limestone First, limestone is quarried from mines with the help of big machines and blasting In this stage, limestone with big blocks which are not suitable for putting in a kilnLime Production Process and Required Equipmentii table of contents 1 introduction 1 2 limestone quarrying and processing operations 2 21 limestone 2 22 limestone quarrying operations 2 23 limestone processing operations 3 3 lci methodology 5 31 lci data collection 5 32 quality of lci data set 5 331 limestone quarry operations 5 332 limestone processing operations 6 4 lci results 7Limestone Quarrying and Processing: A LifeCycle InventoryAdditionally, since the mid1980s, we’ve developed extensive experience in Circulating Fluidized Bed (CFB) technology and our limestone mills have proven themselves as an essential part of CFB systems The limestone crushers and mills are effective for directinjection of dry sorbent lime or limestone during the CFB processLimestone Mills Williams Crusher

Limestone Crushing And SandMaking Plant Eastman Rock

2024年1月11日 Equipment Configuration Of Limestone SandMaking Plant The equipment for the limestone sand production line mainly includes a vibrating feeder, jaw crusher, sand making machine, circular vibrating screen, sand washing machine, etc The vibrating feeder is responsible for evenly and quantitatively delivering raw materials to the stone crusher