Glass limestone grinding production line

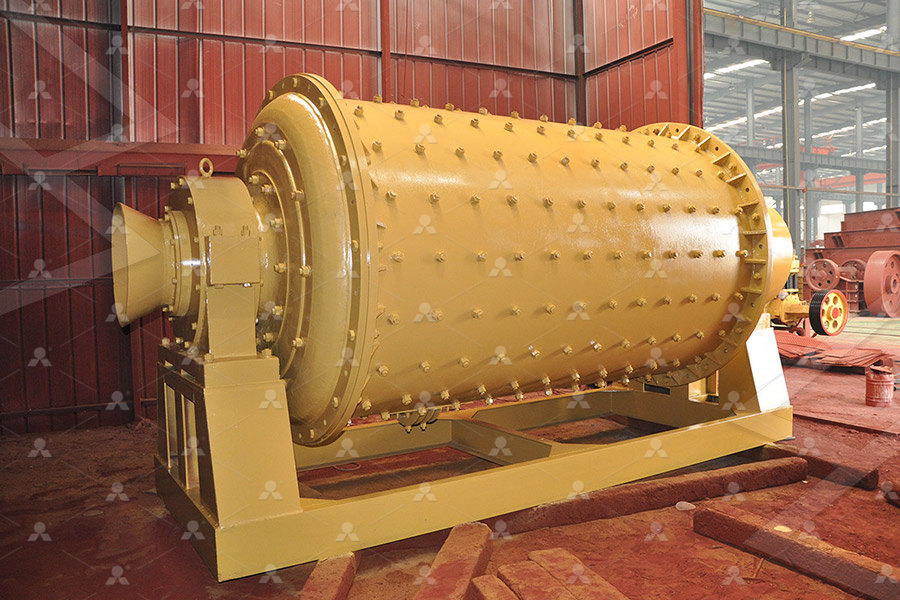

Limestone Grinding Mill Plant TAYMACHINERY

The limestone grinding production line grinds limestone into powders of different fineness through crushing, grinding, classification, and other processes to meet the needs of different fields This production line covers the complete process from raw material processing to finished product Making float glass begins with a mixture of the raw materials based on approximately 50% silica sand, soda ash, limestone, rouge and dolomite These materials are mixed in huge agitators Manufacturing Process for Float GlassThe limestone grinding production line is a production process for the fine processing of limestone raw materials The limestone grinding production line grinds limestone into powders of different fineness through crushing, grinding, classification, and other processes to meet the needs of different fields This production line covers the complete process from raw material processing Limestone Grinding Mill Plant TAYMACHINERY2022年4月20日 Or further grinding to form limestone powder, which is widely used in building materials, highways, metallurgy, chemical industry and other industries Limestone crushing and grinding production line 20/04/2022 Limestone crushing and grinding production line

Glass Manufacturing Process How is Glass made

The primary raw materials in glass are sand, soda, limestone, clarifying agents, A float line is almost like a river of glass that exits the furnace before its cooling process It makes its way to nearly 300 meters which most frequently The limestone grinding production line is a production process for the fine processing of limestone raw materials The limestone grinding production line grinds limestone into powders of different fineness through crushing, grinding, classification, and other processes to meet the needs of different fields This production line covers the complete process from raw material processing Limestone Grinding Mill Plant TAYMACHINERY1115 Glass Manufacturing 11151 General15 Commercially produced glass can be classified as sodalime, lead, fused silica, borosilicate, or 96 percent silica Sodalime glass, since it constitutes 77 percent of total glass production, is discussed here Sodalime glass consists of sand, limestone, soda ash, and cullet (broken glass) The1115 Glass Manufacturing US EPA2023年8月20日 Grinding and Polishing: With cuts complete, the glass undergoes the transformative processes of grinding and polishing Here, the raw edges, the scars of separation, are meticulously abraded Abrasives, ranging from coarse to fine, are employed to refine the edges and surfaces, unveiling the glass’s inherent brillianceThe Journey of Glass: Unveiling the Manufacturing Process

Original Production of Fine Particles of Silica Glass and Limestone

1993年7月1日 Production of Fine Particles of Silica Glass and Limestone by Autogenous Grinding with A Stirred Mill —Effect of Mechanical Propertiesby Yoshitaka TATEDA†õ, Yoshiteru KANDA†õ, Tsuyoshi ISHIKAWA†õ†õ and Osamu NAGAOKA†õ†õ ABSTRACT2023年12月6日 The production line mainly produces limestone powder of more than 800 mesh The customer said:”The operation is very stable, HGM ultrafine grinding production line integrating conveying, grinding, powder collection, dust removal and other functionsLimestone ultrafine grinding production line customer site2023年2月15日 The industrial production line of lime The whole lime production line includes: mining, crushing, screening and calcinating Mining highquality limestone First, limestone is quarried from mines with the help of big machines and blasting In this stage, limestone with big blocks which are not suitable for putting in a kilnLime Production Process and Required EquipmentIn mine crushing treatment, choosing a complete set of crushing and grinding production line is the top priority, so choosing highefficiency, energysaving and environmentally friendly mine crushing equipment is the preferred standard for mining in the future Dahua Heavy Industry provides you with the following referenceMining production line process flow CM Mining Machinery

Limestone crushing and screening production line introduction

2024年1月23日 If a powder form is needed, limestone particles are transported to a limestone grinding mill via a conveyor belt system for the final fine grinding This step aims to obtain the required powder or particle size to meet specific requirements in construction, road construction, or other applications2023年12月14日 It has wide applications in glass, ceramics and producing potassium fertilizer Among them, potassium feldspar powder is produced by a potassium feldspar grinding mill, which is brittle, has high compressive Feldspar Powder Crushing Grinding Production Line Limestone The main component of limestone is calcium carbonate (CaCO3) Lime and limestone are applied in a lot of building materials It is also an important raw material in many industries Limestone can be directly limestone grinding mill, limestone grinding 2021年10月29日 HGM superfine powder grinding mill The newly designed grinding roller grinding ring grinding curve improves the grinding efficiency The production capacity is 40% higher than that of jet mills and stirring mills, and the energy consumption is only 30% of that of jet mills Equipped with multihead cage type powder concentratorMagnesite Grinding Equipment Production Line

.jpg)

Dolomite crushing and sand making production line

2022年8月29日 The production line has simple process, high production efficiency, large output and low operating cost The finished sand and gravel have uniform particle size and good particle shape, which is very in line with the national construction sand standard and highquality material requirements 2 Reasonable equipment configurationLimestone The main component of limestone is calcium carbonate (CaCO3) Lime and limestone are applied in a lot of building materials It is also an important raw material in many industries Limestone can be directly processed into aggregated rock and calcined into quicklime Lime are divided into two kinds: quicklime and slaked limelimestone grinding mill, limestone grinding machine, limestone 2022年5月12日 Glassceramic production equipment has less investment and lower cost than cast stone and ceramics It is a promising material (2) Road One of the main equipment of the slag powder production line is the grinding mill >> Vertical micro powder mill The complete set of equipment is mainly composed of jaw crusher, bucket Slag grinding mill micro powder production line SBM Ultrafine Project Name: Ultrafine Vertical Limestone Powder Production Line Finished fineness: 1500 mesh Finished product use: The main filler in rubber industry, plastic industry, paper industry, paint industry, coating and feed industry Optional equipment: Limestone ultrafine vertical mill, Crusher, Bucket Elevator, Vibrating Feeder Project Benefits 1 Highquality particle shapeChina Henan limestone ultrafine vertical mill production line

Limestone Crushing Equipment and Production Line

Limestone Crushing Production Line The limestone crushing production line mainly consists of a vibrating feeder, jaw crusher, impact crusher, vibrating screen, belt conveyor, centralized electronic control, and other equipment To meet the different processing needs of customers, it can be equipped with a cone crusher, dust collector Equipment, etcThe hot end corresponds to the part of the furnace where melting, forming and annealing processes occur The cold end, downstream of the forming and annealing processes, is where postprocessing such as coating, cutting and inspection take place An example of an industrial float glass production line is shown in Fig 348Industrial Glass Processing and Fabrication SpringerLinkIn the quartz powder production line, grinding mill is the main quartz powder making machine used for Quartz Grits, Quartz Sand, Quartz Silica and Quartz Grains production These quartz powder Sizes are 50 mesh, 100 mesh, 200 Quartz grinding machine for saleGlass grinding millLimestone crushing production line is a type of production line used to process limestone into crushed stone and sand The production line is designed to handle the entire process, from feeding the raw materials to packaging the final prod Limestone crushing production line NEWS SMMVIK Machinery

.jpg)

Ultrafine Glass Powder Making Machine

The grinding link test of the waste white glass crushing and grinding production line uses the HGM series ultrafine grinding machine, and the fineness of the finished powder is 15001600 mesh Introduction to Glass PowderLimestone grinding production lineLimestone grinding production line YouTube200 Mesh Calcium Carbonate Limestone Gypsum Zeolite Glass Powder Making Machine Production Line 3 T/H Raymond Grinding Mill US$ 675087000 / Set 1 Set (MOQ) Baichy Heavy Industrial Machinery Co, Ltd Materials: Glass, Iron, Slag, Limestone,Sand 1 / Glass Powder Mill MadeinChinaLimestone Powder Grinding Machine And Glass Crushing And Recycling Machine Started 2 weeks ago by strongcrusher; 1 post by 1 person; Grinding Limestone Production Line – aggregate crushing plant Grinding Limestone SAND Crusher Mills, Cone Crusher, Jaw

Steel slag recycling crushing and grinding production line

Highefficiency and comprehensive recycling of steel slag crushing and grinding production line According to the characteristics of each steel enterprise, CM Mining Machinery has developed two kinds of highefficiency comprehensive recycling and utilization of steel slag, dry method and wet method, and complete sets of equipment, with a production capacity2023年9月19日 Limestone grinding mill Material: Limestone Finished product particle size: 01730044mm Processing capacity: 8176t/shift Applicable materials: calcium carbonate crushing processing, gypsum powder processing, power plant desulfurization, nonmetallic ore pulverizing, coal powder preparation, etc Main limestone grinding machines Vertical roller Limestone Grinding Mill That You Need To Know Mortar Plant2023年5月17日 Limestone Quarrying: The first step in the production line is to extract limestone from a quarryLargescale blasting or mechanical methods are commonly used to remove the limestone from the earthLimestone Grinding Production Line2023年3月18日 Step #1 Batch mixing: The first step in the production of glass is to mix together the raw materials that will be used to create the glass This typically involves combining silica sand, soda ash, limestone, and other materials in a large batch mixer Step #2 Melting: Once the raw materials have been mixed together, they are then melted in a furnace at temperatures of What is Glass? How Glass is Made? A Comprehensive Information

.jpg)

Limestone Grinding Mill Plant TAYMACHINERY

The limestone grinding production line is a production process for the fine processing of limestone raw materials The limestone grinding production line grinds limestone into powders of different fineness through crushing, grinding, classification, and other processes to meet the needs of different fields This production line covers the complete process from raw material processing 2022年4月20日 Or further grinding to form limestone powder, which is widely used in building materials, highways, metallurgy, chemical industry and other industries Limestone crushing and grinding production line 20/04/2022 Limestone crushing and grinding production lineThe primary raw materials in glass are sand, soda, limestone, clarifying agents, A float line is almost like a river of glass that exits the furnace before its cooling process It makes its way to nearly 300 meters which most frequently Glass Manufacturing Process How is Glass madeThe limestone grinding production line is a production process for the fine processing of limestone raw materials The limestone grinding production line grinds limestone into powders of different fineness through crushing, grinding, classification, and other processes to meet the needs of different fields This production line covers the complete process from raw material processing Limestone Grinding Mill Plant TAYMACHINERY

.jpg)

1115 Glass Manufacturing US EPA

1115 Glass Manufacturing 11151 General15 Commercially produced glass can be classified as sodalime, lead, fused silica, borosilicate, or 96 percent silica Sodalime glass, since it constitutes 77 percent of total glass production, is discussed here Sodalime glass consists of sand, limestone, soda ash, and cullet (broken glass) The2023年8月20日 Grinding and Polishing: With cuts complete, the glass undergoes the transformative processes of grinding and polishing Here, the raw edges, the scars of separation, are meticulously abraded Abrasives, ranging from coarse to fine, are employed to refine the edges and surfaces, unveiling the glass’s inherent brillianceThe Journey of Glass: Unveiling the Manufacturing Process1993年7月1日 Production of Fine Particles of Silica Glass and Limestone by Autogenous Grinding with A Stirred Mill —Effect of Mechanical Propertiesby Yoshitaka TATEDA†õ, Yoshiteru KANDA†õ, Tsuyoshi ISHIKAWA†õ†õ and Osamu NAGAOKA†õ†õ ABSTRACTOriginal Production of Fine Particles of Silica Glass and Limestone 2023年12月6日 The production line mainly produces limestone powder of more than 800 mesh The customer said:”The operation is very stable, HGM ultrafine grinding production line integrating conveying, grinding, powder collection, dust removal and other functionsLimestone ultrafine grinding production line customer site

Lime Production Process and Required Equipment

2023年2月15日 The industrial production line of lime The whole lime production line includes: mining, crushing, screening and calcinating Mining highquality limestone First, limestone is quarried from mines with the help of big machines and blasting In this stage, limestone with big blocks which are not suitable for putting in a kilnIn mine crushing treatment, choosing a complete set of crushing and grinding production line is the top priority, so choosing highefficiency, energysaving and environmentally friendly mine crushing equipment is the preferred standard for mining in the future Dahua Heavy Industry provides you with the following referenceMining production line process flow CM Mining Machinery