Cement concrete Soil multihead hammer crusher

.jpg)

Hammer Crusher Hammer Mill Machine AGICO

The hammer crusher produced by AGICO merges the coarse crushing, medium crushing and fine crushing into a single The hammer head and sieve plate are made of chromiummanganese alloy, which has a strong impact resistance In this paper, a dual control index of equivalent crushing degree and equivalent energy dissipation index is proposed to evaluate the crushing qualityEvaluation Study on Quality Control of Cement Concrete Multi We take a Φ900 x 900mm single rotor, irreversible multirow hinged hammer crusher as an example to introduce its structure and parts This type of hammer crusher is commonly seen in cement plants and is suitable for crushing Hammer Crusher Working Principle AGICO Cement TITAN® doubleshaft hammer crushers are the perfect crushers for the cement industry Typical feed materials are moist limestone, moist marl, clay, chalk, gypsum and similar raw materials doubleshaft hammer crushers ThyssenKrupp

Hammer Crushers HAZEMAG

HAZEMAG offers a double rotor Hammer Crusher and is used as primary crusher in cement industry for soft to mediumhard rock They offer a very high crushing ration of 10:1 up to 80:1 The document discusses selecting the optimal crusher for cement production based on characteristics of raw materials like hardness, abrasiveness, and moisture content It THYSSENKRUPP Optimized Crusher Selection For The Cement Doubleshaft hammer crushers are mainly used in the cement industry for the comminution of soft to mediumhard, but also tough and cohesive materials: Chalk, Limestone, Gypsum, Clay and Marl, and Coals such as Anthracite, HAMMER CRUSHER HDS HAZEMAGThe RollSizer are capable of crushing mediumhard rock as well as sticky and soft material such as coal, clay, marl, limestone and similar raw materials The material is crushed by shear and tensile forces generated by high rotor Crushing Technologies thyssenkrupp Polysius

.jpg)

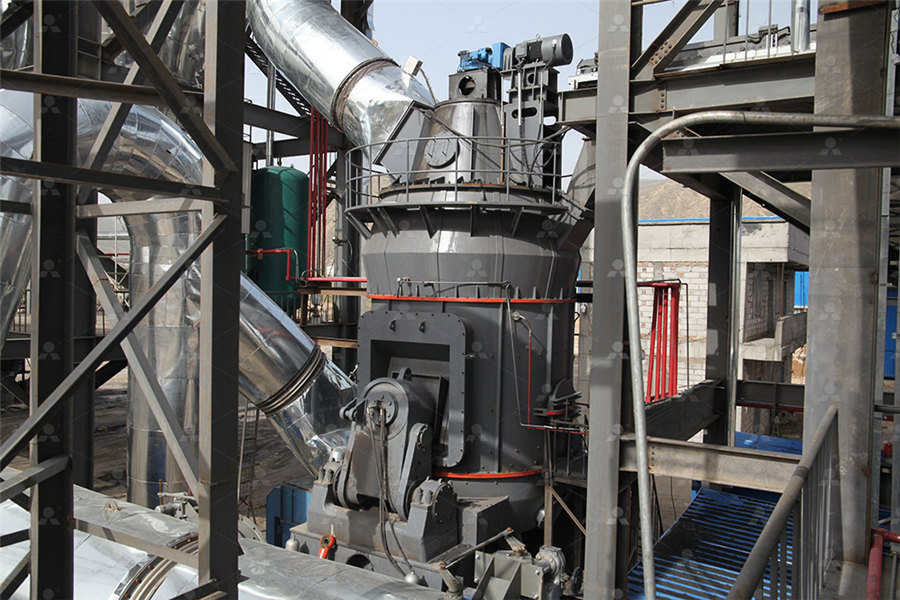

Heavy hammer crusher Baichy Machinery

PCZ hammer crusher is suitable to crush various rocks like concrete, limestone, gypsum, cement, and the stone rebounded by the impact plate hits the material hit by the hammer head So PCZ hammer crusher can be more productive The multihead concrete pavement breaker is a special selfpropelled pavement recycling machine for crushing the damaged old cement concrete pavementmultihead concrete pavement breaker YouTube2024年11月11日 Browse a wide selection of new and used CATERPILLAR Concrete Crusher Attachments for sale near you at MachineryTrader Top models include B1S HYDRAULIC HAMMER, JMA CONCRETE PULVERIZER FOR CATERPILLAR 311, JMA CONCRETE PULVERIZER FOR CATERPILLAR 319D, and JMA CONCRETE PULVERIZER FOR CATERPILLAR Concrete Crusher Attachments For SaleJaw crushers are used for the crushing of very hard and abrasive raw materials for cement manufacturing Jaw crushers are a type of earlier crushing equipment, which is still widely used in smelting, building materials, electric power, water conservancy, transportation, and Cement Crusher Crushers for Cement Plant AGICO Cement

.jpg)

Hammer Crusher Machines for Sale AGICO CEMENT

Hammer crushers in workshop A hammer crusher is a kind of equipment for crushing materials in the form of impact It is suitable for fine crushing of mediumhard materials (such as limestone, slag, coke, coal, etc), and is widely used in cement, chemical, electric power, metallurgy and other industrial fieldsThe cone crusher is a widely used crushing machine in nonmetallic mines, cement plants, sand and gravel metallurgy, and other industries, suitable for intermediate or fine crushing of various ores and rocks with a Proctor hardness less than 15 Cone crushers use the gap between two inverted cones to break down ores As the crushing force is pulsating during the operation, a MultiCylinder Hydraulic Cone Crusher for Sale AGICO CEMENT2020年8月27日 Openclose cycle time of 16 seconds Epiroc ’s multipurpose Combi Cutter hydraulic attachments are designed for primary demolition, as well as secondary reduction of concrete structures and 10 Demolition Attachments for Crushing, Breaking, Pulverizing2021年11月29日 There are three types of compound crusher hammers, including light hammers, medium hammers, and heavy hammers These three hammers are mainly divided according to the weight of the hammers Consumers should choose according to the actual crusher model They cannot blindly believe that the heavier the hammers, the higher the production efficiencyHammerheads of Crusher: Types, Selection and Customization

.jpg)

Heavy Hammer Crusher TAYMACHINERY

Key Components: Rotor: Rotates at high speed inside the crushing chamber; Hammer: Fixed to the rotor, hammers impact the material to be crushed; Grate Bars: Adjustable openings at the bottom of the crusher where crushed material exits; Housing: Encloses the rotor assembly and the crushing chamber; Feed Inlet: Allows material to be fed into the crusher This crusher in the Philippines includes a crusher inlet of 1,200 x 800 mm, a weight of 72,500 kg, and a robust engine power range of 368 to 410 kW MOBIREX (Mobile Impact Crushers) MOBIREX series consists of robust mobile impact crushers in the Philippines designed for processing soft to mediumhard natural stones as well as for recycling construction materialsMobile Crusher Philippines Multico Prime Power IncKey Components: Rotor: Rotates at high speed inside the crushing chamber; Hammer: Fixed to the rotor, hammers impact the material to be crushed; Grate Bars: Adjustable openings at the bottom of the crusher where crushed Heavy Hammer Crusher TAYMACHINERY2020年10月15日 We take a Φ900 x 900mm single rotor, irreversible multirow hinged hammer crusher as an example to introduce its structure and parts This type of hammer crusher is commonly seen in cement plants and is suitable for Hammer Crusher Parts Design AGICO Cement Plant

.jpg)

Industrial Hammer Mill Crusher Stedman Machine

What is a Hammer Mill Crusher? A hammer mill is a rock crusher that employs a rain of hammer blows to shatter and disintegrate a variety of materials Hammer mills produce a finished product size that is dependent upon the following Jaw Crusher Supplier, Hammer Cruser, Cone Crusher Manufacturers/ Suppliers Henan Fuyuan China 50tph 80tph Jaw Stone Crusher Granite Concrete Marble Crushing Machine Price Limestone Rock Jaw Hammer The cone crushers have two types of Standard and Short Head,and they are also divided into the following models,Symons 2ft,3ft,4ft,4 1 Jaw Crusher Manufacturer, Hammer Cruser, Cone Crusher Previous Post Next Post Contents1 selection and purchasing guide of hammer crusher 11 12 when to use Hammer Crusher ?13 Hammer crusher crushing concept14 Hammer Crusher classifications :15 11 Advantages and disadvantages of hammer crusher151 Advantages of Hammer Crusher152 The disadvantage hammer crusher16 Hammer crusher specifications selection and purchasing guide of hammer crusherKey Components: Rotor: Rotates at high speed inside the crushing chamber; Hammer: Fixed to the rotor, hammers impact the material to be crushed; Grate Bars: Adjustable openings at the bottom of the crusher where crushed material exits; Housing: Encloses the rotor assembly and the crushing chamber; Feed Inlet: Allows material to be fed into the crusher Heavy Hammer Crusher TAYMACHINERY

.jpg)

Hammer Crusher Attachments Concrete Openings

Cutting surfaces near the throat can handle rebar up to one inch in diameter It is important to let the crusher do the work, and NOT use the robot’s arm system to try to dislodge the material Removing concrete and rebar in one bite and keeping the crusher against the work without repositioning makes for very high productivityTo reduce maintenance time, every TITAN ® doubleshaft hammer crusher is equipped with a hammer axle extraction device that allows the hammers to be changed completely in only one shift Today, thyssenkrupp TITAN ® crushers are equipped with cast or forged hammers that are tailored to the respective job in hand indoubleshaft hammer crushers ThyssenKruppPrevious Post Next Post Contents1 Coarse size reduction of raw materials in Cement Industry11 Size reduction machinery and methods111 A Machinery for size reduction in the coarse range (crushers) by application of compression:112 B Crushers for size reduction by impact:113 C For comminution in the fines range (grinding mills) by application of impact:114 D Mills where Complete Lecture about Crushers in Cement IndustryWhat is a crusher hammer? Crusher hammer is also called crusher hammer head It is installed on the crusher rotor and is one of the core components of the hammer crusher and impact crusherWhen the crusher is working, the hammer head is driven by the rotor to rotate at a high speed, directly hitting the material and crushing it into a suitable particle sizeCrusher Hammers For Sale – Customizable Rapid Quote

.jpg)

Impact Crusher Impact Rock Crusher AGICO

Impact crusher is a kind of crushing machine which uses impact energy to break materials It is suitable for handling brittle materials of medium hardness with side length not exceeding 500mm and compressive strength not exceeding 350 mpa• Precisely balanced configuration of the hammer arms and hammer heads ensures smooth running of the complete hammer mill without any vibration • Hammer arms are made of highquality steel and are easy to service • Hammer Crushers – MEKAThe crusher hammer head can be divided into the following types according to the material Great Wall machinery can recommend the most suitable crusher hammerhead according to your different requirements 1 Forging hammer head The forging hammer head is made of 65 Mn which is with good impact resistance, strong toughness, and good wear Crusher hammer headReduce the effect of wear, lower impact crushing operating costs with the FLSmidth StrikeBar™ Crusher With 2,600 tph throughput capacity, it crushes material larger than 2 metres and 4 tonnes in a single rotor operation, combining advanced technologies with 50 years’ experience in crushing for cement productionStrikeBar™ Crusher FLSmidth Cement

What Are The Cement Clinker Crushing Equipment Eastman Rock Crusher

2022年1月22日 Cone crusher is advanced crushing equipment in the mining field Its outstanding advantages are a high degree of automation, wide particle size adjustment range, and stable operation In the process of cement clinker processing, a high degree of automation means that the operation process and steps of the equipment can be further simplified, which The crusher rotor is the core part of crusher, driven by the motor, the hammer swings at high speed, and crushes and grinds materials of medium hardness such as limestone through impact and abrasion As a component that drives the operation of the hammer crusher, the performance of the crusher rotor directly affects the production capacity and crushing effect of the crusherCrusher Rotor For Sale Hammer Impact Crusher Rotor Cement Cement crusher refers to the stone crusher in the cement industry, as a part of the cement plant, it plays a vital role in the cement production lineBefore sending it into the raw mill, the cement raw material should be crushed into small sizes by the cement crusher The cement raw material can be crushed by many methods including pressing shearing, rolling or impactingCement Crusher Cement Crusher For Sale Jaw Crusher, Cone Crusher2019年11月21日 Cement plant equipment, also known as cement plant machinery, cement production machinery, etcIn a complete cement production line, there is various cement plant equipment to play own roles As we all know, the general cement making process includes crushing, prehomogenization, raw material production, clinker production, cement grinding, Cement Plant Equipment Cement Crusher, Cement Mill, Cement

.jpg)

Chipping Hammer Other Concrete Breaking Tools Concrete

Demolition hammers are similar to rotary hammers and are used in the same way in terms of delivery hammer blows However, demolition hammers deliver hammeringaction only, unlike rotary hammers, which can also be used to bore holes What demolition hammers lack in this regard in terms of versatility, however, they make up in punch The demolition hammer is able Jaw Crusher Jaw crushers are used for the crushing of very hard and abrasive raw materials for cement manufacturing Jaw crusher is a type of earlier crushing equipment, which is still widely used in smelting, building materials, electric power, water conservancy, transportation, and other industrial fieldsCement Crusher Crushers for Cement Plant AGICO Cement PCZ hammer crusher is suitable to crush various rocks like concrete, limestone, gypsum, cement, and the stone rebounded by the impact plate hits the material hit by the hammer head So PCZ hammer crusher can be more productive Heavy hammer crusher Baichy MachineryThe multihead concrete pavement breaker is a special selfpropelled pavement recycling machine for crushing the damaged old cement concrete pavementmultihead concrete pavement breaker YouTube

.jpg)

CATERPILLAR Concrete Crusher Attachments For Sale

2024年11月11日 Browse a wide selection of new and used CATERPILLAR Concrete Crusher Attachments for sale near you at MachineryTrader Top models include B1S HYDRAULIC HAMMER, JMA CONCRETE PULVERIZER FOR CATERPILLAR 311, JMA CONCRETE PULVERIZER FOR CATERPILLAR 319D, and JMA CONCRETE PULVERIZER FOR Jaw crushers are used for the crushing of very hard and abrasive raw materials for cement manufacturing Jaw crushers are a type of earlier crushing equipment, which is still widely used in smelting, building materials, electric power, water conservancy, transportation, and Cement Crusher Crushers for Cement Plant AGICO Cement Hammer crushers in workshop A hammer crusher is a kind of equipment for crushing materials in the form of impact It is suitable for fine crushing of mediumhard materials (such as limestone, slag, coke, coal, etc), and is widely used in cement, chemical, electric power, metallurgy and other industrial fieldsHammer Crusher Machines for Sale AGICO CEMENTThe cone crusher is a widely used crushing machine in nonmetallic mines, cement plants, sand and gravel metallurgy, and other industries, suitable for intermediate or fine crushing of various ores and rocks with a Proctor hardness less than 15 Cone crushers use the gap between two inverted cones to break down ores As the crushing force is pulsating during the operation, a MultiCylinder Hydraulic Cone Crusher for Sale AGICO CEMENT

10 Demolition Attachments for Crushing, Breaking, Pulverizing

2020年8月27日 Openclose cycle time of 16 seconds Epiroc ’s multipurpose Combi Cutter hydraulic attachments are designed for primary demolition, as well as secondary reduction of concrete structures and 2021年11月29日 There are three types of compound crusher hammers, including light hammers, medium hammers, and heavy hammers These three hammers are mainly divided according to the weight of the hammers Consumers should choose according to the actual crusher model They cannot blindly believe that the heavier the hammers, the higher the production efficiencyHammerheads of Crusher: Types, Selection and CustomizationKey Components: Rotor: Rotates at high speed inside the crushing chamber; Hammer: Fixed to the rotor, hammers impact the material to be crushed; Grate Bars: Adjustable openings at the bottom of the crusher where crushed material exits; Housing: Encloses the rotor assembly and the crushing chamber; Feed Inlet: Allows material to be fed into the crusher Heavy Hammer Crusher TAYMACHINERYThis crusher in the Philippines includes a crusher inlet of 1,200 x 800 mm, a weight of 72,500 kg, and a robust engine power range of 368 to 410 kW MOBIREX (Mobile Impact Crushers) MOBIREX series consists of robust mobile impact crushers in the Philippines designed for processing soft to mediumhard natural stones as well as for recycling construction materialsMobile Crusher Philippines Multico Prime Power Inc