Difference between dry grinding and wet grinding of mineral powder

.jpg)

Dry Grinding VS Wet Grinding 911Metallurgist

2017年5月25日 A slight difference of condition between the two cases, however, is that with dry milling the fluid (air) fills the whole of the mill shell not occupied by the balls, whereas with wet milling the liquid occupies only a part of the mill 2019年9月1日 Dry grinding consumes higher energy and produces wider particle size distributions compared with wet grinding It significantly decreases the rate of media A comparative study on the effects of dry and wet grinding on Understanding the core differences between these techniques is crucial: Presence of Liquid: The most apparent difference is the use of liquid in the wet method Heat Generation: Dry method can produce more heat Particle Size: Differences Between Wet and Dry grinding: Why Dry grinding limits water content to below 4%, while wet grinding suspends raw materials in a liquid carrier stream with added dispersants Wet grinding proves advantageous in food Difference between Wet Grinding and Dry Grinding

The Difference Between Wet Grinding and Dry Grinding

2024年8月2日 Understanding the differences between wet grinding and dry grinding helps in optimizing processing material Apart from this, it also helps to achieve desired results Wet Grinding uses liquid to cut heat and friction2019年8月11日 Dry grinding can have lower media wear, produce more agglomerates and rugged mineral surfaces and mechanically activate the said surfaces while wet grinding is A comparative study on the effects of dry and wet grinding on 1988年9月1日 In general, advantages for wet grinding compared with dry grinding are: (i) Power consumption per unit mass is lower (ii) Capacity of the mill increases (iii) No dust is A fundamental study of dry and wet grinding from the viewpoint Explore the differences between dry and wet grinding in the powder industry, delving into advantages, disadvantages, and their impact on ultrafine powder production Choose the Difference between Wet Grinding and Dry Grinding allwingrinding

.jpg)

A comparative study on the effects of dry and wet grinding on

2019年8月31日 Dry grinding consumes higher energy and produces wider particle size distributions compared with wet grinding It significantly decreases the rate of media Different milling conditions, such as wet or dry, and use of different grinding media have a great impact on the flotation performance of sulphide minerals In the present study, the effects of A comparative study on the effects of dry and wet grinding on 2024年8月2日 Dry Grinding It may produce a rough surface finish at high temperatures and a lack of lubrication As a result, it will lead you towards surface imperfections Choosing between wet and dry grinding depends on the The Difference Between Wet Grinding and Dry 2023年2月15日 Difference between wet and dry grinding 1 Difference in (ball mill) structure Dry grinding A dry ball mill is equipped with a cylindrical rotating device and two bins, which can rotate by gears The discharge port is straight What Are the Differences between Dry and Wet

A comparative study on the effects of dry and wet grinding on mineral

2019年9月1日 Besides of different grinding environments (dry or wet), the type of grinding media (such as stainless and mild steel) can also affect the surface properties of particles subject to flotation separation [11] During grinding of sulfides, 2024年9月23日 Applicable Conditions Dry grinding, due to the design of the cylinder, sometimes forms a dead end, in the dead end of the part of the material is not ball milling; but wet grinding and dry grinding compared to also have a weakness, that is, wet grinding powder to dry to remove moisture or other liquid media, so it will increase the energy consumption and cost; Dry or Wet Grinding Ball Mill for Quartz Sand JXSC Mineral2022年2月28日 The particular rate of breakage ratio between dry and wet grinding varies from 11 to 20 for various minerals In the case of gold concentrates containing hematite, dry grinding can greatly enhance the gold leaching rate in the thiosulfate system Gold leaching can reach from 35% (wet grinding) to 85% (dry grinding) in 8 h (Fig 18)Grinding SpringerLinkand the traditional dry grinding method was used as a reference The effect of wet grinding on the activation of IOTs was evaluated through ion leaching from an alkaline solution and the reactivity index Additionally, a detailed comparison between Drygrinding Iron Ore Tail ings (DIOTs) and Wetgrinding Iron Ore Tailings (WIOTs) was madeDifferent Effects of Wet and Dry Grinding on the Activation of

.jpg)

Influence of dry and wet grinding conditions on fineness and

2011年1月31日 Therefore, the reasonable grinding conditions according to the properties of different ores is the key to obtain good grinding results Dry or wet grinding, steel ball size or shape, feed particle 2019年8月11日 Request PDF A comparative study on the effects of dry and wet grinding on mineral flotation separationA review Water scarcity dictates to limit the use of water in ore processing plants A comparative study on the effects of dry and wet grinding on mineral Dry grinding refers to the moisture content not exceeding 4% during the grinding, while wet grinding is to get the raw material suspended in the carrier liquid flow for grinding appropriately with dispersants and other additives to help When the moisture content exceeds 50%, the dust problem can be overcome in wet grinding But wet grinding The difference between dry grinding and wet grinding2023年9月15日 Dry grinding machine: A dry grinding machine uses no liquid element and relies on particleonparticle contact to reduce the size of the materials Wet grinding machine: On the other hand, a wet grinding machine uses a liquid, such as water or solvent, as a lubricant and cooling agent to disperse the particles in a slurryDry Grinding Vs Wet Ball Mill Grinding Economy Ball Mill

.jpg)

Different Effects of Wet and Dry Grinding on the Activation of

and the traditional dry grinding method was used as a reference The effect of wet grinding on the activation of IOTs was evaluated through ion leaching from an alkaline solution and the reactivity index Additionally, a detailed comparison between Drygrinding Iron Ore Tail ings (DIOTs) and Wetgrinding Iron Ore Tailings (WIOTs) was made2020年1月1日 Also, since the feed material is in slurry form, moisture removal required prior to dry grinding and dry grinding causes the reagglomeration of fine powders [36–38], hence wet grinding method is employed in the present study for Wet and dry grinding of coal in a laboratoryscale ball mill: Particle 2016年11月7日 Thus, material between about 1in and 2in size may be reduced to about 6 mesh for feeding to the ball mills Rod mills are, however, being used in closed circuit with a classifier to produce a product of less than Grinding Mills Common Types 911Metallurgist2022年12月11日 Different milling conditions, such as wet or dry, and use of different grinding media have a great impact on the flotation performance of sulphide minerals In the present study, the effects of wet and dry grinding and the use of different grinding media, such as mild steel (MS) and stainless steel (SS), were investigated on a Cusulphide ore The samples were ground as Effects of Different Grinding Media and Milling Conditions on the

Difference between Wet Grinding and Dry Grinding allwingrinding

Explore the differences between dry and wet grinding in the powder industry, delving into advantages, disadvantages, and their impact on ultrafine powder production Choose the optimal grinding method based on your product's characteristics and economic considerationsIt has been known that slurry rheology significantly influences the grindability of industrial minerals in wet ultrafine grinding This which represents the potential difference between the S Kingman, G Brown, A new method for determining the optimum dispersant concentration in aqueous grinding, Powder Technology 123 (PDF) Slurry rheology in wet ultrafine grinding of industrial minerals 2020年1月1日 Coal has an important role in electricity generation worldwide According to data from the World Coal Association, coalfueled power plants currently provide 37% of the global electricity [1]In 2017, China's coalfired power generation accounted for 645% of the total power generation [2]Nearly 176 billion tons coal produced in China is used for generating electricity Wet and dry grinding of coal in a laboratoryscale ball mill: 2019年11月1日 The mineral processing plants are using the wet grinding, while dry grinding is widely used at typical thermal power stations and a boiler plant [15], [16], [17] In this study, our attention was focused on the effect of wet and dry grinding conditions on the breakage ratesDifferences in dry and wet grinding with a high solid

.jpg)

Kinetics of fine wet grinding of zeolite in a steel ball mill in

As seen from Fig 10, the maximum values in the dry and wet grinding of zeolite were reached at approximately 035 of fractional ball filling The effect of fractional interstitial filling of the void spaces of the ball bed by powder (U) on the dry and wet grinding of zeolite is shown in Fig 112019年8月31日 (DOI: 101016/JJMRT201907053) Water scarcity dictates to limit the use of water in ore processing plants particularly in arid regions Since wet grinding is the most common method for particle size reduction and mineral liberation, there is a lack of understanding about the effects of dry grinding on downstream separation processes such as flotation This A comparative study on the effects of dry and wet grinding on mineral 2015年4月9日 The process can be wet or dry but generally it is carried out wet Maximum rod length is about 6 to 7 meters, otherwise there is a risk of the rods bowing The drum diameter is limited to 06 or 07 times the length of the mill Grinding Mills and Their Types IspatGuruEFFECT OF PARTICLE SIZE DISTRIBUTION ON GRINDING KINETICS IN DRY AND WET BALL MILLING OPERATIONS Figure 4 Variation of breakage distribution parameters with grinding time for Set1 data on wet EFFECT OF PARTICLE SIZE DISTRIBUTION ON GRINDING KINETICS IN DRY

Difference between Wet Grinding and Dry Grinding allwingrinding

Explore the differences between dry and wet grinding in the powder industry, delving into advantages, disadvantages, and their impact on ultrafine powder production Choose the optimal grinding method based on your product's characteristics and economic considerationsThe peak at around 441 cm –1 became sharp and began to split after dry and wet grinding Moreover, with increasing grinding time, there was a decreased shift in frequency of the SiO band at around 975 cm –1 in both the dry and wet processes Some slight differences were observed between the dry and wet grinding techniquesArticle Different Effects of Wet and Dry Grinding on the 2023年1月5日 In the present study, the effects of wet and dry grinding and the use of different grinding media, such as mild steel (MS) and stainless steel (SS), were investigated on a Cusulphide oreEffects of Different Grinding Media and Milling Conditions on the There are interactions between different minerals from the same ore, minerals and grinding media, and the electrochemical conditions present in the system Grinding in steel rod and ball mills is aWET AND DRY GRINDING METHODS EFFECT ON THE

.jpg)

Wet and dry grinding of coal in a laboratoryscale ball mill: Particle

2019年10月1日 Dry grinding is more difficult than wet grinding: the energy of wet grinding is 20% less than dry [14], is due in part to the fact that the smallest particles of material stick to the surface of 2017年12月1日 Unlike in many other scientific works, the impacts of grinding aids were analyzed on different levels simultaneously: Grinding success and agglomerate size distributions were evaluated by wet and Impact of grinding aids on dry grinding performance, bulk properties Additionally, a detailed comparison between Drygrinding Iron Ore Tailings (DIOTs) and Wetgrinding Iron Ore Tailings (WIOTs) was made This comparison was based on particle characteristics, crystal structures, chemical structure, and surface properties The results showed that the particle size of IOTs reduced rapidly during wet grindingJRM Different Effects of Wet and Dry Grinding on the Article Effects of Different Grinding Media and Milling Conditions on the Flotation Performance of a Copper‐Pyrite Ore N Metin Can 1,* and Çağrı Başaran 2 Department of Mining Engineering, Hacettepe University, Beytepe, Ankara 06800, Turkey Konutkent Mah, 2944 Sk, No 10, Ankara 06810, Turkey * Correspondence: 1 2 Abstract: Different milling Effects of Different Grinding Media and Milling Conditions on the

The Difference Between Wet Grinding and Dry

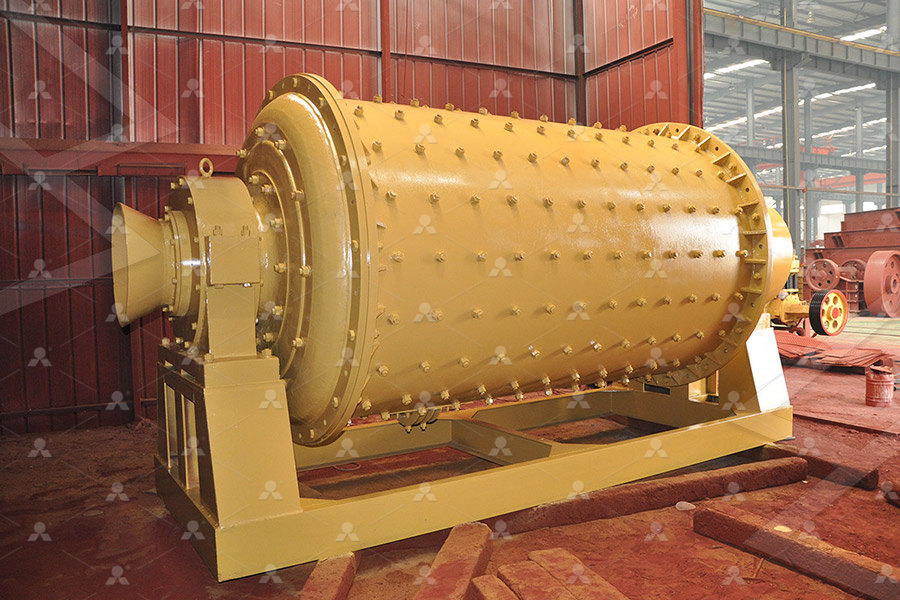

2024年8月2日 Dry Grinding It may produce a rough surface finish at high temperatures and a lack of lubrication As a result, it will lead you towards surface imperfections Choosing between wet and dry grinding depends on the 2023年2月15日 Difference between wet and dry grinding 1 Difference in (ball mill) structure Dry grinding A dry ball mill is equipped with a cylindrical rotating device and two bins, which can rotate by gears The discharge port is straight What Are the Differences between Dry and Wet 2019年9月1日 Besides of different grinding environments (dry or wet), the type of grinding media (such as stainless and mild steel) can also affect the surface properties of particles subject to flotation separation [11] During grinding of sulfides, A comparative study on the effects of dry and wet grinding on mineral 2024年9月23日 Applicable Conditions Dry grinding, due to the design of the cylinder, sometimes forms a dead end, in the dead end of the part of the material is not ball milling; but wet grinding and dry grinding compared to also have a weakness, that is, wet grinding powder to dry to remove moisture or other liquid media, so it will increase the energy consumption and cost; Dry or Wet Grinding Ball Mill for Quartz Sand JXSC Mineral

Grinding SpringerLink

2022年2月28日 The particular rate of breakage ratio between dry and wet grinding varies from 11 to 20 for various minerals In the case of gold concentrates containing hematite, dry grinding can greatly enhance the gold leaching rate in the thiosulfate system Gold leaching can reach from 35% (wet grinding) to 85% (dry grinding) in 8 h (Fig 18)and the traditional dry grinding method was used as a reference The effect of wet grinding on the activation of IOTs was evaluated through ion leaching from an alkaline solution and the reactivity index Additionally, a detailed comparison between Drygrinding Iron Ore Tail ings (DIOTs) and Wetgrinding Iron Ore Tailings (WIOTs) was madeDifferent Effects of Wet and Dry Grinding on the Activation of 2011年1月31日 Therefore, the reasonable grinding conditions according to the properties of different ores is the key to obtain good grinding results Dry or wet grinding, steel ball size or shape, feed particle Influence of dry and wet grinding conditions on fineness and 2019年8月11日 Request PDF A comparative study on the effects of dry and wet grinding on mineral flotation separationA review Water scarcity dictates to limit the use of water in ore processing plants A comparative study on the effects of dry and wet grinding on mineral

.jpg)

The difference between dry grinding and wet grinding

Dry grinding refers to the moisture content not exceeding 4% during the grinding, while wet grinding is to get the raw material suspended in the carrier liquid flow for grinding appropriately with dispersants and other additives to help When the moisture content exceeds 50%, the dust problem can be overcome in wet grinding But wet grinding 2023年9月15日 Dry grinding machine: A dry grinding machine uses no liquid element and relies on particleonparticle contact to reduce the size of the materials Wet grinding machine: On the other hand, a wet grinding machine uses a liquid, such as water or solvent, as a lubricant and cooling agent to disperse the particles in a slurryDry Grinding Vs Wet Ball Mill Grinding Economy Ball Mill