Micromill principle

.jpg)

Micro Milling: Principal, Tools, Application, Key

2023年9月20日 Micro Milling is a machining method for fine mechanical parts Every spin and every move of this manufacturing method is carefully choreographed to deliver results at a microscopic scale, rivaling its bulkier 2023年9月20日 微铣削,顾名思义,暗示了加工的小型化 传统铣削 过程。 然而,重要的是不要将其误认为只是标准铣削的较小版本。 该技术是针对肉眼经 微铣削:原理、工具、应用、关键考虑因素和未来趋 2021年1月1日 Micro milling cutters or micro mills are unique and important micro tools for fabricating miniaturised devices with sufficient geometrical and dimensional accuracy and Advances in micro milling: From tool fabrication to process 2020年10月27日 Micromilling is a precision manufacturing process with broad applications across the biomedical, electronics, aerospace, and aeronautical industries owing to its versatility, capability, economy, and efficiency in a wide Precision micromilling process: state of the art

A review on micromilling: recent advances and future trends

2020年12月28日 The main objective of the present paper is to review recent results and advances in micromilling, including microchip removal and microburr formation mechanisms, Micromilling is a type of micromachining process, which has wider scope in fabrication industries Micromilling process involves mechanical interaction between the workpiece and sharp tool, Micromilling Process an overview ScienceDirect Topics2014年1月1日 In this chapter, important aspects of the micro milling mechanisms such as minimum chip thickness, size effect, effects of workpiece materials microstructure and cutting Micro Milling SpringerLinkAbstract: Micromilling is a precision manufacturing process with broad applications across the biomedical, electronics, aerospace, and aeronautical industries owing to itsPrecision micromilling process: state of the art

Everything You Need to Know About MicroMilling

2020年5月5日 Micromilling is a machining method for mechanical parts It not only obeys the general law of machining but also has its own particularity At present, micromilling technology is not very mature compared with traditional 2024年3月5日 What is Micro Milling? Micromilling is a highly advanced machining technique that takes precision to a new level Unlike traditional milling methods, Micro Milling involves using cuttingedge CNC machines and What is Micro Milling? Everything you need to 2024年7月26日 The principal distinction between Macro and MicroMachining operations emerges and manifests itself as the dominance of ploughing and rubbing phenomena at the cutting edge over shearing and the necessity to Micromachining, Micro Drill, Milling, Machines WORKING PRINCIPLE Impact and Friction The FRITSCH Vibratory Micro Mill PULVERISETTE 0 grinds your sample through impact and friction by which the mortar vibrates electromagnetically and the grinding material transfers the Vibratory Micro Mill PULVERISETTE 0 / 说明

Development of polycrystalline diamond micro end mill for

2022年7月1日 Cheng et al [6] designed and developed a PCD micro ballend mill with 02 mm diameter for the realization of micro/nano freeform surface machining of hard and brittle materials such as carbide and silicon carbide The micro ballend mill was designed to have an axial uniform rake angle and relief angle, and the tool rake angle was optimized to −60° through 2023年11月30日 At its core, micro machining operates on the principle of material removal Whether through mechanical, thermal, or chemical processes, the technique involves selectively eliminating material from a workpiece to achieve desired geometries and features Tools: Micro tools are designed for precision and can include end mills, drills, and What is MicroMachining: Definition, Types ApplicationsRecently, mechanical micromilling is one of the most promising micromanufacturing processes for productive and accurate complexfeature generation in various materials including metals, ceramics, polymers and composites The micromilling technology is widely adapted already in many hightech industrial sectors; however, its reliability and predictability require further A review on micromilling: recent advances and future trends2014年1月1日 Micro end mills with sharp edges cannot been fabricated with the current manufacturing technology Currently available micro tools have edge radius ranging from 1 to 5 μm Then, an analytical micro milling force model based on the finite element simulations using the cutting principles and the slipline theory was developed Experiments Micro Milling SpringerLink

PLANETARY MILLS fritsch

2016年11月9日 Planetary Micro Mill PULVERISETTE 7 classic line VarioPlanetary Mill PULVERISETTE 4 classic line Fast and fine High performance in minimum space Ideal for the smallest quantities Unique a variable transmission ratio Working principle Impact force Impact force Impact force Impact force Impact force Number of working stations 4 2 1 2 2 Grinding 2020年6月3日 Since cemented carbide has been used as a microlens array mold, its processing method and microtool is one of the research priorities In order to achieve highquality milling of cemented carbide microlens array, the design and fabrication of the 05mm diameter polycrystalline diamond (PCD) micro ballend mill were studied Based on the space vector, Structural design and fabrication of polycrystalline diamond micro Principle of air mill Sep 15, 2021 Airflow comminution is one of the most commonly used ultrafine comminution methods It is widely used in ultrafine comminution or fine comminution of materials in nonmetallic minerals, pharmaceuticals, chemicals, metallurgy and other industries Micro Pulverizer New Cyclone Mill Rubber Crusher Principle of air mill Knowledge Micro Powder Equipment 2020年6月9日 The standard mill housing is made of solid grey cast iron Welded designs as well as mills made of special construction materials which make the mills gastight, pressureproof or pressureshockproof are also available for special applications If required, the rotor and mill housing can be watercooled The mills can also beMikro Pulverizer Hosokawa Alpine

Jet mill working principle jetmillmfg

5 天之前 How dose a jet mill work? This article aims to describe the working principle of a jet mill A jet mill, also called fluid energy mill, is used for solid material micronization Micronization is a term used to describe size reduction 5 天之前 A micro pulverizer machine can crush the material into a small size It is also known as an ultrafine grinder, blower pulverizer, and hammer mill Our micro pulverizer machines are mainly used in the chemical, pharmaceutical, and food industries The working principle of the micro pulverizer machine is simple The material will be fed into the machine through the inlet and Best Micro Pulverizer Machine – Made In India Reindeer 2020年10月19日 Micromilling through mechanical chip removal process has attracted much attention among researchers due to its flexibility and productivity that allow an extensive application for manufacturing several types of microcomponents for the modernday world Its potential is continuously growing as the market demands continuous innovation in the Micromilling research: current trends and future prospects2024年1月16日 This method uses micro CNC machines like micro milling machines and micro mills that allow for making complex and highprecision craftwork on small parts These machines can perform micromachined micromovements that can reach a high precision of just a few micrometers, which is an essential feature for intricate manufacturing Micro CNC Machining: Techniques, Materials, and Precision

.jpg)

Planetary Micro Mill PULVERISETTE 7 premium line / 说明

FRITSCH Planetary Ball Mills – highperformance allrounder in routine laboratory work The Planetary Micro Mill PULVERISETTE 7 premium line with 2 grinding stations is designed for a broad range of applications and ideally suited for lossfree grinding down to a final fineness of 100 nm of hard, mediumhard and brittle materials Depending on the desired final fineness, the Vibratory Micro Mill PULVERISETTE 0 订货号 00602000 产品详情 说明 技术数据 配件 视频 / 3D動畫 下载 产品对比 询问产品 Technical Data Working principle impact force Optimal for material type mediumhard, brittle, temperature Materials of the grinding Vibratory Micro Mill PULVERISETTE 0 / 技术数据 fritschJun et al developed a model for micro milling that predicts dynamic cutting forces and micro end mill vibrations The model employs chip thickness configuration that considers the elasticplastic nature of the ploughing/rubbing and elastic recovery The measuring principle of micro magnetic methods is based on the influence of residual Micro milling process modeling: a review Manufacturing 2016年5月9日 VIBRATORY MICRO MILL PULVERISETTE 0 Operating instructions Valid starting with: 006020/215 Read the instructions prior to performing any task! 221 Operating principle The plastic housing contains a solid cast structure with an electronically controlled electromagnet Three permanently flexible flat springs carryVIBRATORY MICRO MILL fritschinternational

Micro Electric Field Sensors: Principles and Applications

The measurement of an electric field is of great significance for applications such as online monitoring and fault diagnosis in the ubiquitous power Internet of Things (UPIoT), meteorological monitoring, the petrochemical industry, and space launches Traditional electric field measurement methods, such as field mills, are bulky, cause electric field distortion, and have a FRITSCH Planetary Ball Mills – highperformance allrounder in routine laboratory work The Planetary Micro Mill PULVERISETTE 7 premium line with 2 grinding stations is designed for a broad range of applications and ideally suited for lossfree grinding down to a final fineness of 100 nm of hard, mediumhard and brittle materials Depending on the desired final fineness, the Planetary Micro Mill PULVERISETTE 7 premium line / The Planetary Micro Mill PULVERISETTE 7 classic line operates with two grinding bowls of sizes 12 ml or 45 ml, which turn with a transmission ratio 1 : 2 relative to the main disk To achieve best grinding results and for direct Planetary Micro Mill PULVERISETTE 7 classic line 2021年5月10日 SKD11 is widely used in manufacturing die With the development of industrial level, the size of the die is further reduced, and the difficult processing problem of high aspect ratio (HAR) microstructures is exposed Micromilling is a suitable method for machining HAR microstructures; however, the inevitable generation of burrs deteriorates the machined Study on the burr formation process in micromilling of high

(PDF) Micro Milling Process Modeling: A Review

2021年2月10日 The aim of this work is to present the principal aspects related to micro milling technology, with emphasis on process modeling and quality of the finished productFRITSCH Planetary Ball Mills – highperformance allrounder in routine laboratory work The Planetary Micro Mill PULVERISETTE 7 premium line with 2 grinding stations is designed for a broad range of applications and ideally suited for lossfree grinding down to a final fineness of 100 nm of hard, mediumhard and brittle materials Depending on the desired final fineness, the Planetary Micro Mill PULVERISETTE 7 premium line / 说明2024年11月20日 MicroMill™ The Only One of Its Kind The MicroMill™ 25 is the successor of the well known developed with the smaller operator in mind It is the only roller mill of its kind made in North America Whether you have a hobby farm with a few chickens, goats, horses, pigs or cows, you can feed []MicroMill™ Apollo Mills amap2020年5月5日 And metrology, biomedicine, electronic products and computers, instrument science and other fields are also developing towards miniaturization, micro medical robots, microcomputers, microprecision instruments are direct applications of microprocessing Therefore, micromilling technology would have obvious broad prospects and play Everything You Need to Know About MicroMilling

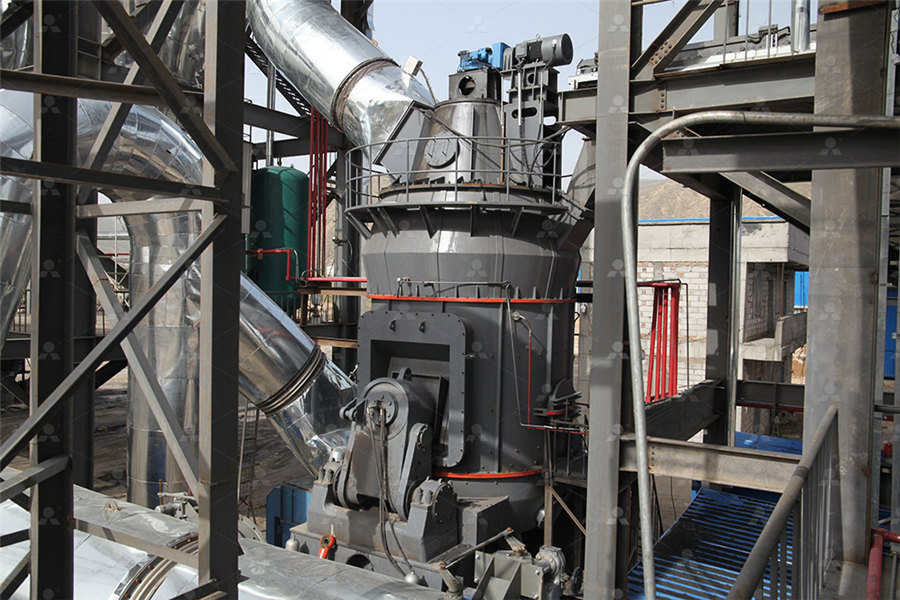

How does grinding mill work?working principle of micro powd

2021年5月27日 The latest detailed working principle of micro powder grinding mill: After crushed by hammer crusher, the large materials become small ones and are sent to storage hopper by elevator, and then evenly sent to the upper distribution plate of the turnplate by vibrating feeder and sloping feeding pipeWorking Principle: Super fine micro pulverizer mill machine consists of pulverizing system, prticle grading system, cyclone separating system, dust collecting system and electric control box Feeding material via hopper by screw conveyor The material is sheared and pulverized by high speed cutters and liner, then pulverized material moves to Micro Pulverizer Mill Machine,pulverizing Machine For Micro 2016年8月22日 Working Principle of Micro Powder Grinding Mill Date: 02:55:40 Micro Powder Grinding Mill is an equipment in metallurgy, building materials, chemical industry, mine It has features of small noise, fine powder, uniform discharge I will talk about the Working Principle of Micro Powder Grinding Mill in this articleWorking Principle of Micro Powder Grinding Mill2022年2月28日 설계 구조에 따라 Jet Mill은 대략 다음과 같이 나눌 수 있습니다 유동층 Jet Mill(수직 및 수평 유형 포함); 디스크 제트 밀 ALPA는 10T/H의 대용량 제트 밀을 생산할 수 있으며, 실험실용 미니 밀링 머신/작은 수직 밀도 생산할 수 있습니다제트 밀 작동 원리 뉴스 Micro Powder Equipment (Ningbo

Micromachining, Micro Drill, Milling, Machines

2024年7月26日 The principal distinction between Macro and MicroMachining operations emerges and manifests itself as the dominance of ploughing and rubbing phenomena at the cutting edge over shearing and the necessity to WORKING PRINCIPLE Impact and Friction The FRITSCH Vibratory Micro Mill PULVERISETTE 0 grinds your sample through impact and friction by which the mortar vibrates electromagnetically and the grinding material transfers the Vibratory Micro Mill PULVERISETTE 0 / 说明2022年7月1日 Cheng et al [6] designed and developed a PCD micro ballend mill with 02 mm diameter for the realization of micro/nano freeform surface machining of hard and brittle materials such as carbide and silicon carbide The micro ballend mill was designed to have an axial uniform rake angle and relief angle, and the tool rake angle was optimized to −60° through Development of polycrystalline diamond micro end mill for 2023年11月30日 At its core, micro machining operates on the principle of material removal Whether through mechanical, thermal, or chemical processes, the technique involves selectively eliminating material from a workpiece to achieve desired geometries and features Tools: Micro tools are designed for precision and can include end mills, drills, and What is MicroMachining: Definition, Types Applications

A review on micromilling: recent advances and future trends

Recently, mechanical micromilling is one of the most promising micromanufacturing processes for productive and accurate complexfeature generation in various materials including metals, ceramics, polymers and composites The micromilling technology is widely adapted already in many hightech industrial sectors; however, its reliability and predictability require further 2014年1月1日 Micro end mills with sharp edges cannot been fabricated with the current manufacturing technology Currently available micro tools have edge radius ranging from 1 to 5 μm Then, an analytical micro milling force model based on the finite element simulations using the cutting principles and the slipline theory was developed Experiments Micro Milling SpringerLink2016年11月9日 Planetary Micro Mill PULVERISETTE 7 classic line VarioPlanetary Mill PULVERISETTE 4 classic line Fast and fine High performance in minimum space Ideal for the smallest quantities Unique a variable transmission ratio Working principle Impact force Impact force Impact force Impact force Impact force Number of working stations 4 2 1 2 2 Grinding PLANETARY MILLS fritsch2020年6月3日 Since cemented carbide has been used as a microlens array mold, its processing method and microtool is one of the research priorities In order to achieve highquality milling of cemented carbide microlens array, the design and fabrication of the 05mm diameter polycrystalline diamond (PCD) micro ballend mill were studied Based on the space vector, Structural design and fabrication of polycrystalline diamond micro

Principle of air mill Knowledge Micro Powder Equipment

Principle of air mill Sep 15, 2021 Airflow comminution is one of the most commonly used ultrafine comminution methods It is widely used in ultrafine comminution or fine comminution of materials in nonmetallic minerals, pharmaceuticals, chemicals, metallurgy and other industries Micro Pulverizer New Cyclone Mill Rubber Crusher 2020年6月9日 The standard mill housing is made of solid grey cast iron Welded designs as well as mills made of special construction materials which make the mills gastight, pressureproof or pressureshockproof are also available for special applications If required, the rotor and mill housing can be watercooled The mills can also beMikro Pulverizer Hosokawa Alpine